Abstract

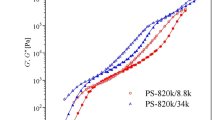

The linear viscoelastic behavior of three well-entangled linear monodisperse polystyrene melts and their blends is investigated. The monodisperse melts are blended in a 1:1 weight ratio to obtain three polystyrene bidisperse blends for which the linear viscoelastic behavior is also measured. Special attention is paid to controlling sample size and solvent content, and checking for consistency in the high-frequency regime. We also attempt to estimate uncertainty quantitatively. The experimental results agree well with the discrete slip-link model, a robust mesoscopic theory that has been successful in predicting the rheology of flexible entangled polymer liquids and gels. Using recently developed analytic expressions for the relaxation modulus, predictions of the monodisperse samples are made. The parameters for the model are obtained from the low-frequency crossover of one experiment. Using this parameter set without adjustment, predictions over the fully accessible experimental frequency range are obtained for the monodisperse samples and their blends with very good agreement.

Similar content being viewed by others

References

Andreev M, Schieber JD (2015) Accessible and quantitative entangled polymer rheology predictions, suitable for complex flow calculations. Macromolecules 48:1606–1613

Andreev M, Khaliullin RN, Steenbakkers RJA, Schieber JD (2013) Approximations of the discrete slip-link model and their effect on nonlinear rheology predictions. J Rheol 57:535–557

Andreev M, Feng H, Yang L, Schieber JD (2014) Universality and speedup in equilibrium and nonlinear rheology predictions of the fixed slip-link model. J Rheol 58:723–736

Archer LA et al. (2001) Linear and nonlinear rheology of bidisperse polymer blends. J Rheol (1978-present) 45:691–708

Auhl D, Ramirez J, Likhtman AE, Chambon P, Fernyhough C (2008) Linear and nonlinear shear flow behavior of monodisperse polyisoprene melts with a large range of molecular weights. J Rheol 52:801–835

Bach A, Almdal K, Rasmussen HK, Hassager O (2003) Elongational viscosity of narrow molar mass distribution polystyrene. Macromolecules 36:5174–5179

Baumgaertel M, Schausberger A, Winter H (1990) The relaxation of polymers with linear flexible chains of uniform length. Rheol Acta 29:400–408

Bernabei M, Moreno AJ, Zaccarelli E, Sciortino F, Colmenero J (2011) Chain dynamics in nonentangled polymer melts: a first-principle approach for the role of intramolecular barriers. Soft Matter 7:1364–1368

Das C, Inkson N J, Read DJ, Kelmanson MA, McLeish TC (2006) Computational linear rheology of general branch-on-branch polymers. J Rheol (1978-present) 50:207–234

Desai PS, Kang B-G, Katzarova M, Hall R, Huang Q, Lee S, Shivokhin M, Chang T, Venerus DC, Mays J et al (2016) Challenging tube and slip-link models: predicting the linear rheology of blends of wellcharacterized star and linear 1, 4-polybutadienes. Macromolecules 49:4964–4977

Doi M (1988) The theory of polymer dynamics, vol 73. Oxford University Press, Oxford

Edwards S (1967) The statistical mechanics of polymerized material. Proc Phys Soc 92:9

Feng H, Andreev M, Pilyugina E, Schieber JD (2016) Smoothed particle hydrodynamics simulation of viscoelastic flows with the slip-link model. Mol Syst Des Eng 1:99–108

Ferry JD (1980) Viscoelastic properties of polymers. Wiley, New York

Graham RS, Likhtman AE, McLeish TC, Milner ST (2003) Microscopic theory of linear, entangled polymer chains under rapid deformation including chain stretch and convective constraint release. J Rheol (1978-present) 47:1171–1200

Hengeller L, Huang Q, Dorokhin A, Alvarez N J, Almdal K, Hassager O (2016) Stress relaxation of bi-disperse polystyrene melts. Rheol Acta 55:303–314

Huang Q, Agostini S, Hengeller L, Shivokhin M, Alvarez N J, Hutchings LR, Hassager O (2016) Dynamics of star polymers in fast extensional flow and stress relaxation. Macromolecules 49:6694–6699

Inoue T, Okamoto H, Osaki K (1991) Birefringence of amorphous polymers. 1. Dynamic measurement on polystyrene. Macromolecules 24:5670–5675

Jensen MK, Khaliullin R, Schieber JD (2012) Self-consistent modeling of entangled network strands and linear dangling structures in a single-strand mean-field slip-link model. Rheol Acta 51:21–35

Kashyap T (2011) Development of a modified lubricated squeezing flow technique for generating equibiaxial elongational flows in polymer melts. Ph.D. thesis, Illinois Institute of Technology

Katzarova M, Andreev M, Sliozberg YR, Mrozek RA, Lenhart JL, Andzelm JW, Schieber J D (2014) Rheological predictions of network systems swollen with entangled solvent. AIChE J 60:1372–1380

Katzarova M, Yang L, Andreev M, Córdoba A, Schieber JD (2015) Analytic slip-link expressions for universal dynamic modulus predictions of linear monodisperse polymer melts. Rheol Acta 54:169–183

Khaliullin RN, Schieber JD (2009) Self-consistent modeling of constraint release in a single-chain mean-field slip-link model. Macromolecules 42:7504–7517

Khaliullin RN, Schieber JD (2010) Application of the slip-link model to bidisperse systems. Macromolecules 43:6202–6212

Likhtman AE (2005) Single-chain slip-link model of entangled polymers: simultaneous description of neutron spin-echo, rheology, and diffusion. Macromolecules 38:6128–6139

Likhtman AE, McLeish TCB (2002) Quantitative theory for linear dynamics of linear entangled polymers. Macromolecules 35:6332–6343

Masubuchi Y (2014) Simulating the flow of entangled polymers. Annu Rev Chem Biomol Eng 5:11–33

Masuda T, Kitagawa K, Inoue T, Onogi S (1970) Rheological properties of anionic polystyrenes. II. Dynamic viscoelasticity of blends of narrow-distribution polystyrenes. Macromolecules 3:116–125

McLeish TC, Milner ST (1999) Entangled dynamics and melt flow of branched polymers. Springer, Berlin, pp 195–256

Neergaard J, Schieber JD (2000) A full-chain network model with sliplinks and binary constraint release

Nielsen JK, Rasmussen HK, Hassager O, McKinley GH (2006) Elongational viscosity of monodisperse and bidisperse polystyrene melts. J Rheol (1978-present) 50:453–476

Pilyugina E, Andreev M, Schieber JD (2012) Dielectric relaxation as an independent examination of relaxation mechanisms in entangled polymers using the discrete slip-link model. Macromolecules 45:5728–5743

Rouse PE (1953) A theory of the linear viscoelastic properties of dilute solutions of coiling polymers. J Chem Phys 21:1272–1280

Schausberger A, Schindlauer G, Janeschitz-Kriegl H (1985) Linear elastico-viscous properties of molten standard polystyrenes. Rheol Acta 24:220–227

Schieber JD (2003a) Fluctuations in entanglements of polymer liquids. J Chem Phys 118:5162–5166

Schieber JD (2003b) Generic compliance of a temporary network model with sliplinks, chain-length fluctuations, segment-connectivity and constraint release. J Non-Equilib Thermodyn 28:179–188

Schieber JD, Andreev M (2014) Entangled polymer dynamics in equilibrium and flow modeled through slip links. Annu Rev Chem Biomol Eng

Schieber JD, Indei T, Steenbakkers RJA (2013a) Fluctuating entang- lements in single-chain mean-field models. Polymers 5:643–678

Schieber JD, Neergaard J, Gupta S (2003b) A full-chain, temporary network model with sliplinks, chain-length fluctuations, chain connectivity and chain stretching. J Rheol (1978-present) 47:213–233

Schultheisz CR, Leigh SD (2002) Certification of the rheological behavior of SRM 2490, polyisobutylene dissolved in 2, 6, 10, 14- tetramethylpentadecane. NIST Spec Publ 260:2–27

Schweizer T, Hostettler J, Mettler F (2008) A shear rheometer for measuring shear stress and both normal stress differences in polymer melts simultaneously: the MTR 25. Rheol Acta 47:943–957

Steenbakkers RJA, Schieber J D (2012) Derivation of free energy expressions for tube models from coarse-grained slip-link models. J Chem Phys 137:034901

Steenbakkers RJA, Tzoumanekas C, Li Y, Liu WK, Kröger M, Schieber JD (2014) Primitive-path statistics of entangled polymers: mapping multi-chain simulations onto single-chain mean-field models. New J Phys 16:015027

Van Ruymbeke E, Masubuchi Y, andWatanabe H (2012) Effective value of the dynamic dilution exponent in bidisperse linear polymers: from 1 to 4/3. Macromolecules 45:2085–2098

Wang Z, Chen X, Larson RG (2010) Comparing tube models for predicting the linear rheology of branched polymer melts. J Rheol (1978-present) 54:223–260

Watanabe H, Kotaka T (1984) Viscoelastic properties and relaxation mechanisms of binary blends of narrow molecular weight distribution polystyrenes. Macromolecules 17:2316–2325

Watanabe H, Sakamoto T, Kotaka T (1985) Entanglements in linear polystyrenes. Macromolecules 18:1436–1442

Watanabe H, Ishida S, Matsumiya Y, Inoue T (2004) Test of full and partial tube dilation pictures in entangled blends of linear polyisoprenes. Macromolecules 37:6619–6631

Zheng W, Simon S (2006) Polystyrene freeze-dried from dilute solution: Tg depression and residual solvent effects. Polymer 47:3520–3527

Acknowledgments

Professor DCV would like to acknowledge the financial support provided by the National Science Foundation (NSF Grant CBET-1236576) and Professor JDS gratefully thanks the Army Research Office (Grants W911NF-08-2-0058 and W911NF-09-2-0071) and the National Science Foundation (NSF Grant CBET-1336442).

Author information

Authors and Affiliations

Corresponding author

Appendix A: Error propagation

Appendix A: Error propagation

The well-known expressions for experimentally determining G′ and G″ in parallel disk flow are given by

where R is the sample radius, H is the gap, M is the torque, 𝜃 is the deflection angle, and δ is the phase angle. It is clear from Eqs. A1 and A2, the moduli have a strong dependence on R, which means that small uncertainties can have a large impact on measured values. The unknown shape of the sample free surface leads to an estimated uncertainty in R of ± 0.5 mm (Kashyap 2011). In order to propogate these errors through to the measured values of G′ and G″, we use the following error propagation expressions:

After taking the corresponding partial derivatives using Eqs. A1 and A2 and substituting back into Eqs. A3 and A4, we obtain the following error in G′ and G″,

Since most (if not all) commercial rheometers used to measure G∗ only report values for the torque (M) and rotation angle (𝜃) amplitudes and the phase angle (δ), determining uncertainties for these quantities is a challenge. In Table 4, we give estimates for these along with those for the sample geometry (H, R). In Fig. 8, we present the uncertainty of measured G′ and G″ for PS105 due to uncertainty in the radius, gap, torque, phase, and deflection angles. It can be observed that the slip-link prediction with self-consistent parameters obtained from PS206 is within this error.

Rights and permissions

About this article

Cite this article

Katzarova, M., Kashyap, T., Schieber, J.D. et al. Linear viscoelastic behavior of bidisperse polystyrene blends: experiments and slip-link predictions. Rheol Acta 57, 327–338 (2018). https://doi.org/10.1007/s00397-018-1079-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-018-1079-7