Abstract

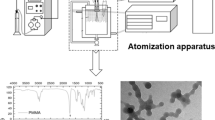

Membrane emulsification using pore sizes of 100 and 800 nm in conjunction with miniemulsion polymerization has been investigated for monomers with varying water solubilities, namely, styrene, n-butyl methacrylate (nBMA), benzyl methacrylate (BzMA), and n-butyl acrylate (nBA), and compared with previous work on methyl methacrylate (MMA). The O/W interfacial tension is an important parameter for 100 nm pore size (but less so for 800 nm pore size) — increasing O/W interfacial tension leads to an increase in membrane emulsification time as well as increases in the monomer droplet size and particle size. The most nonpolar monomer styrene required impractically long emulsification times. For the other monomers, the miniemulsions were polymerized by radical polymerization, resulting in monomodal particle size distributions. Overall, the results demonstrate that membrane emulsification in tandem with miniemulsion polymerization is a convenient method for synthesis of well-defined polymer nanoparticles of various monomers in the approximate size range 200–3500 nm.

Similar content being viewed by others

References

Charcosset C, Limayem I, Fessi H (2004) The membrane emulsification process—a review. J Chem Technolo Biotechnol 79:209–218. https://doi.org/10.1002/jctb.969

Joscelyne SM, Tragardh G (2000) Membrane emulsification - a literature review. J Membr Sci 169:107–117. https://doi.org/10.1016/S0376-7388(99)00334-8

Nakashima T, Shimizu M, Kukizaki M (2001) Particle control of emulsion by membrane emulsification and its applications. Adv Drug Deliv Rev 45:47–56. https://doi.org/10.1016/S0169-409X(00)00099-5

Oh DH, Balakrishnan P, Oh Y-K, Kim D-D, Yong CS, Choi H-G (2011) Effect of process parameters on nanoemulsion droplet size and distribution in SPG membrane emulsification. Int J Pharm 404:191–197. https://doi.org/10.1016/j.ijpharm.2010.10.045

Piacentini E, Drioli E, Giorno L (2014) Membrane emulsification technology: twenty-five years of inventions and research through patent survey. J Membr Sci 468:410–422. https://doi.org/10.1016/j.memsci.2014.05.059

Ribeiro HS, Janssen JJM, Kobayashi I, Nakajima M (2010) Membrane emulsification for food applications. In: Membr Technolo, pp 129–166

Charcosset C (2009) Preparation of emulsions and particles by membrane emulsification for the food processing industry. J Food Eng 92:241–249. https://doi.org/10.1016/j.jfoodeng.2008.11.017

Carballido L, Dabrowski ML, Dehli F, Koch L, Stubenrauch C (2020) Monodisperse liquid foams via membrane foaming. J Colloid Interface Sci 568:46–53. https://doi.org/10.1016/j.jcis.2020.02.036

Li J, Ma J, Jiang Y, Jiang T, Wang Y, Chen Y, Liu S (2016) Immobilizing enzymes in regular-sized gelatin microspheres through a membrane emulsification method. J Mater Sci 51:6357–6369. https://doi.org/10.1007/s10853-016-9932-5

Piacentini E, Yan M, Giorno L (2017) Development of enzyme-loaded PVA microspheres by membrane emulsification. J Membr Sci 524:79–86. https://doi.org/10.1016/j.memsci.2016.11.008

Omi S, Kaneko K, Nakayama A, Ki K, Taguchi T, Iso M, Nagai M, Ma G-H (1997) Application of porous microspheres prepared by SPG (Shirasu porous glass) emulsification as immobilizing carriers of glucoamylase (GluA). J Appl Polym Sci 65:2655–2664. https://doi.org/10.1002/(SICI)1097-4628(19970926)65:13%3c2655::AID-APP7%3e3.0.CO;2-A

Hatate Y, Uemura Y, Ijichi K, Kato Y, Hano T, Baba Y, Kawano Y (1995) Preparation of GPC packed polymer beads by a SPG membrane emulsifier. J Chem Eng, Jpn 28:656–659. https://doi.org/10.1252/jcej.28.656

Dowding PJ, Goodwin JW, Vincent B (2001) Production of porous suspension polymer beads with a narrow size distribution using a cross-flow membrane and a continuous tubular reactor. Colloids Surf, A Physicochem Eng Asp 180:301–309. https://doi.org/10.1016/S0927-7757(00)00777-9

Liu W, Yang X-L, Winston Ho WS (2011) Preparation of uniform-sized multiple emulsions and micro/nano particulates for drug delivery by membrane emulsification. J Pharm Sci 100:75–93. https://doi.org/10.1002/jps.22272

Piacentini E, Dragosavac M, Giorno L (2017) Pharmaceutical particles design by membrane emulsification: preparation methods and applications in drug delivery. Curr Pharm Des 23:302–318. https://doi.org/10.2174/1381612823666161117160940

Vladisavljević GT (2015) Structured microparticles with tailored properties produced by membrane emulsification. Adv Colloid Interface Sci 225:53–87. https://doi.org/10.1016/j.cis.2015.07.013

Katoh R, Asano Y, Furuya A, Sotoyama K, Tomita M (1996) Preparation of food emulsions using a membrane emulsification system. J Membr Sci 113:131–135. https://doi.org/10.1016/0376-7388(95)00227-8

Katoh R, Asano Y, Furuya A, Sotoyama K, Tomita M (1997) Methods for preparation of W/O food emulsions using the membrane immersed with oils and fats. Nippon Shokuhin Kogyo Gakkai-Shi 44:238–242. https://doi.org/10.3136/nskkk.44.238

Katoh R, Asano Y, Furuya A, Sotoyama K, Tomita M (1997) Conditions for preparation of w/o food emulsions using a membrane emulsification system. Nippon Shokuhin Kogyo Gakkai-Shi 44:44–49. https://doi.org/10.3136/nskkk.44.44

Mine Y, Shimizu M, Nakashima T (1996) Preparation and stabilization of simple and multiple emulsions using a microporous glass membrane. Colloid Surf, B 6:261–268. https://doi.org/10.1016/0927-7765(95)01264-8

Zanatta V, Rezzadori K, Penha FM, Zin G, Lemos-Senna E, Petrus JCC, Di Luccio M (2017) Stability of oil-in-water emulsions produced by membrane emulsification with microporous ceramic membranes. J Food Eng 195:73–84. https://doi.org/10.1016/j.jfoodeng.2016.09.025

Williams RA, Peng S, Wheeler D, Morley N, Taylor D, Whalley M, Houldsworth D (1998) Controlled production of emulsions using a crossflow membrane: part II: industrial scale manufacture. Chem Eng Res Des 76:902–910. https://doi.org/10.1205/026387698525702

Omi S, Ma G-H, Nagai M (2000) Membrane emulsification a versatile tool for the synthesis of polymeric microspheres. Macromol Symp 151:319–330. https://doi.org/10.1002/1521-3900(200002)151:13.0.co;2-x

Schröder V, Behrend O, Schubert H (1998) Effect of dynamic interfacial tension on the emulsification process using microporous, ceramic membranes. J Colloid Interface Sci 202:334–340. https://doi.org/10.1006/jcis.1998.5429

Schröder V, Schubert H (1998) Influence of emulsifier and pore size on membrane emulsification. Spec Publ-R Soc Chem 227:70–80

Nakashima T, Shimizu M, Kukizaki M (1991) Membrane emulsification operation manual. In: Department of Chemistry, Industrial Research Institute of Miyazaki Prefecture, Miyazaki

Yuyama H, Watanabe T, Ma GH, Nagai M, Omi S (2000) Preparation and analysis of uniform emulsion droplets using SPG membrane emulsification technique. Colloids Surf, A Physicochem Eng Asp 168:159–174. https://doi.org/10.1016/S0927-7757(00)00452-0

Joscelyne SM, Trägårdh G (1999) Food emulsions using membrane emulsification: conditions for producing small droplets. J Food Eng 39:59–64. https://doi.org/10.1016/S0260-8774(98)00146-0

Kobayashi I, Yasuno M, Iwamoto S, Shono A, Satoh K, Nakajima M (2002) Microscopic observation of emulsion droplet formation from a polycarbonate membrane. Colloids Surf, A Physicochem Eng Asp 207:185–196. https://doi.org/10.1016/S0927-7757(02)00093-6

Scherze I, Marzilger K, Muschiolik G (1999) Emulsification using micro porous glass (MPG): surface behaviour of milk proteins. Colloids Surf, B 12:213–221. https://doi.org/10.1016/S0927-7765(98)00076-9

Vladisavljevic GT, Schubert H (2002) Preparation and analysis of oil-in-water emulsions with a narrow droplet size distribution using Shirasu-porous-glass (SPG) membranes. Desalination 144:167–172. https://doi.org/10.1016/S0011-9164(02)00307-7

Kandori K, Kishi K, Ishikawa T (1991) Formation mechanisms of monodispersed W/O emulsions by SPG filter emulsification method. Colloids Surf 61:269–279. https://doi.org/10.1016/0166-6622(91)80315-F

Kandori K, Kishi K, Ishikawa T (1991) Preparation of monodispersed W/O emulsions by Shirasu-porous-glass filter emulsification technique. Colloids Surf 55:73–78. https://doi.org/10.1016/0166-6622(91)80083-Z

Kukizaki M, Goto M (2006) Effects of interfacial tension and viscosities of oil and water phases on monodispersed droplet formation using a Shirasu-porous-glass (SPG) membrane. Membrane 31:215–220. https://doi.org/10.5360/membrane.31.215

Schork JF, Luo Y, Smulders W, Russum JP, Butte A, Fontenot K (2005) Miniemulsion Polymerization. Adv Polym Sci 129–255

Antonietti M, Landfester K (2002) Polyreactions in miniemulsions. Prog Polym Sci 27:689–757. https://doi.org/10.1016/S0079-6700(01)00051-X

Asua JM (2002) Miniemulsion polymerization. Prog Polym Sci 27:1283–1346. https://doi.org/10.1016/S0079-6700(02)00010-2

Asua JM (2014) Challenges for industrialization of miniemulsion polymerization. Prog Polym Sci 39:1797–1826. https://doi.org/10.1016/j.progpolymsci.2014.02.009

Zetterlund PB, Thickett SC, Perrier S, Bourgeat-Lami E, Lansalot M (2015) Controlled/living radical polymerization in dispersed systems: an update. Chem Rev 115:9745–9800. https://doi.org/10.1021/cr500625k

Landfester K (2003) Miniemulsions for nanoparticle synthesis. In: Colloid Chemistry II. Springer, pp 75–123

McClements DJ, Rao J (2011) Food-grade nanoemulsions: formulation, fabrication, properties, performance, biological fate, and potential toxicity. Crit Rev Food Sci Nutr 51:285–330. https://doi.org/10.1080/10408398.2011.559558

Zetterlund PB, Kagawa Y, Okubo M (2008) Controlled/living radical polymerization in dispersed systems. Chem Rev 108:3747–3794. https://doi.org/10.1021/cr800242x

Zetterlund PB, Saka Y, Okubo M (2009) Gelation and hollow particle formation in nitroxide-mediated radical copolymerization of styrene and divinylbenzene in miniemulsion. Macromol Chem Phys 210:140–149. https://doi.org/10.1002/macp.200800451

Landfester K (2009) Miniemulsion polymerization and the structure of polymer and hybrid nanoparticles. Angew Chem Int Ed Engl 48:4488–4507. https://doi.org/10.1002/anie.200900723

Nauman N, Zaquen N, Junkers T, Boyer C, Zetterlund PB (2019) Particle size control in miniemulsion polymerization via membrane emulsification. Macromolecules 52:4492–4499. https://doi.org/10.1021/acs.macromol.9b00447

Chaiyasat P, Namwong S, Okubo M, Chaiyasat A (2016) Synthesis of micrometer-sized poly(methyl methacrylate) particles by microsuspension iodine transfer polymerization (ms ITP). RSC Adv 6:95062–95066. https://doi.org/10.1039/C6RA19288B

Nauman N, Zaquen N, Boyer C, Zetterlund PB (2020) Miniemulsion photopolymerization in a continuous tubular reactor: particle size control via membrane emulsification. Polym Chem 11:4660–4669. https://doi.org/10.1039/D0PY00654H

Agustina S, Tokuda M, Minami H, Boyer C, Zetterlund PB (2017) Synthesis of polymeric nano-objects of various morphologies based on block copolymer self-assembly using microporous membranes. React Chem Eng 2:451–457. https://doi.org/10.1039/C7RE00032D

Chang H-C, Lin Y-Y, Chern C-S, Lin S-Y (1998) Determination of critical micelle concentration of macroemulsions and miniemulsions. Langmuir 14:6632–6638. https://doi.org/10.1021/la971109w

Dong Y, Sundberg DC (2003) hydrophobic homopolymer/water interfaces. J Colloid Interface Sci 258:97–101. https://doi.org/10.1016/S0021-9797(02)00060-7

Gijsbertsen-Abrahamse A (2003) Membrane emulsification: process principles. Wageningen University

Matos González M (2013) Production of emulsions with controlled droplet size containing bioactive compounds using membranes. University of Oviedo

Walstra P (1993) Principles of emulsion formation. Chem Eng Sci 48:333–349. https://doi.org/10.1016/0009-2509(93)80021-H

Lloyd DM, Norton IT, Spyropoulos F (2014) Processing effects during rotating membrane emulsification. J Membr Sci 466:8–17. https://doi.org/10.1016/j.memsci.2014.04.035

Peng SJ, Williams RA (1998) Controlled production of emulsions using a crossflow membrane: part I: droplet formation from a single pore. Chem Eng Res Des 76:894–901. https://doi.org/10.1205/026387698525694

Matos M, Suárez MA, Gutiérrez G, Coca J, Pazos C (2013) Emulsification with microfiltration ceramic membranes: a different approach to droplet formation mechanism. J Membr Sci 444:345–358. https://doi.org/10.1016/j.memsci.2013.05.033

Zetterlund PB, D’hooge DR, (2019) The nanoreactor concept: kinetic features of compartmentalization in dispersed phase polymerization. Macromolecules 52:7963–7976. https://doi.org/10.1021/acs.macromol.9b01037

Barner-Kowollik C, Beuermann S, Buback M, Castignolles P, Charleux B, Coote M, Hutchinson R, Junkers T, Lacík I, Russell GT, Stach M, Herk AM (2014) Critically evaluated rate coefficients in radical polymerization 7. Secondary-radical propagation rate coefficients for methyl acrylate in the bulk. J Polym Chem 5:204–212. https://doi.org/10.1039/C3PY00774J

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nauman, N., Boyer, C. & Zetterlund, P.B. Miniemulsion polymerization via membrane emulsification: Exploring system feasibility for different monomers. Colloid Polym Sci 300, 309–317 (2022). https://doi.org/10.1007/s00396-021-04918-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-021-04918-2