Abstract

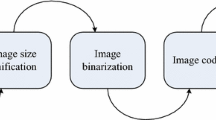

In this paper, we proposed an objective 3D evaluation system of pilling. It can be applied to fabrics with intricate patterns and textures. The major features of the pilling evaluation system include a 3D fabric surface reconstruction based on a multi-view stereo vision algorithm, an improved active contours model for pill segmentation, and objective pilling grade calculation utilizing a neural network. To improve the accuracy of pilling grade estimation, the obtained maxima algorithm is used to locate the pilling, which is then used as the seed point for curve evolution until the curve converges to the pilling’s edge. In addition, the binarization and adaptive threshold methods can also be utilized to obtain the pilling binary graph. Three feature parameters, such as the pill number, area, and coverage are extracted from the segmented binary graph, which is used to objectively evaluate the pilling grade of fabric. The experimental results show that the objective evaluation system can accurately evaluate the fabric pilling grade, which is highly consistent with the subjective evaluation results.

Similar content being viewed by others

References

Abril, H.C.: Automatic method based on image analysis for pilling evaluation in fabrics. Opt. Eng. 37(11), 2937 (1998)

Xin, B., Hu, J., Yan, H.: Objective evaluation of fabric pilling using image analysis techniques. Text. Res. J. 72(12), 1057–1064 (2002)

Chen, X., Xu, Z., Chen, T., Wang, J., Li, L.: Detecting pills in fabric images based on multi-scale matched filtering. Text. Res. J. 79(15), 1389–1395 (2009). https://doi.org/10.1177/0040517508099913

Zhang, J., Wang, X., Palmer, S.: Objective pilling evaluation of wool fabrics. Text. Res. J. 77(12), 929–936 (2007)

Yang, C.S., Lin, C.J., Chen, W.J.: Using deep principal components analysis-based neural networks for fabric pilling classification. Electronics 8(5), 474 (2019)

Jing, J., et al.: Mobile-Unet: an efficient convolutional neural network for fabric defect detection. Text. Res. J. (2020). https://doi.org/10.1177/0040517520928604

Deshpande, A.M., Minai, A.A., Kumar, M.: One-shot recognition of manufacturing defects in steel surfaces. Procedia Manuf. 48, 1064–1071 (2020)

Garg, M., Dhiman, G.: Deep convolution neural network approach for defect inspection of textured surfaces. J. Inst. Electron. Comput. 2(1), 28–38 (2020)

Pyun, P., Liu, A., Cheung, C., et al.: Automatic defect inspection using the NVIDIA end-to-end deep learning platform. https://developer.nvidia.com/blog/automatic-defect-inspection-using-the-nvidia-end-to-end-deep-learning-platform/

Mendes, A.D., Fiadeiro, P.T., Miguel, R.A., Lucas, J.M., et al.: Optical 3D-system for fabric pilling assessment: a complementary tool to avoid evaluation errors. J. Text. Inst. 112(6), 1–7 (2020)

De Oliveira Mendes, A., Torrão Fiadeiro, P., Lopes Miguel, R.A.: Virtual subjective pilling evaluation: an alternative. Text. Res. J. 81(9), 892–901 (2011). https://doi.org/10.1177/0040517510397573

Kim, S.C., Kang, T.J. Automatic evaluation of fabric pilling using a 3-D non-contact scanning system. In: IEEE Instrumentation & Measurement Technology Conference. IEEE (2005)

Ouyang, W., Wang, R., Xu, B.: Fabric pilling measurement using three-dimensional image. J. Electron. Imaging 22(4), 043031 (2013)

Saharkhiz, S., Abdorazaghi, M.: The performance of different clustering methods in the objective assessment of fabric pilling. J. Eng. Fibers Fabr. 7(4), 35–41 (2012)

Techniková, L., Tunák, M., Janáček, J.: New objective system of pilling evaluation for various types of fabrics. J. Text. Inst. 108(1), 123–131 (2016)

Telli, A.: The relationship between subjective pilling evaluation results and detecting pills and textural features in knitted fabrics. Fibers Polym. 21(8), 1841–1848 (2020)

AATCC Test Method 143: Appearance of Apparel and Other Textile End Products After Repeated Home Laundering. AATCC, Research Triangle Park, NC (2011)

Wang, Y., Deng, N., Xin, B., et al.: A novel three-dimensional surface reconstruction method for the complex fabrics based on the MVS. Opt. Laser Technol. 131, 106415 (2020)

ASTM Standard D3512: Random Tumble Pilling Test Method. ASTM International, West Conshohocken, PA (1999)

Furukawa, Y., Ponce, J.: Accurate, dense, and robust multiview stereopsis. IEEE Trans. Pattern Anal. Mach. Intell. 32(8), 1362–1376 (2009)

Furukawa, Y., Hernández, C.: Multi-view stereo: a tutorial. Found. Trends® Comput. Graph. Vis. 9(1–2), 1–148 (2015)

Snavely, N., Seitz, S.M., Szeliski, R.: Photo tourism: Exploring photo collections in 3D. ACM Trans. Graph. 25(3), 835–846 (2006)

Keith, N.: Snavely. Scene Reconstruction and Visualization from Internet Photo Collections. University of Washington, Seattle (2008)

Wang, Y., Deng, N., Xin, B.: Investigation of 3D surface profile reconstruction technology for automatic evaluation of fabric smoothness appearance. Measurement 166, 108264 (2020)

Deng, Z., Wang, L., Wang, X.: An integrated method of feature extraction and objective evaluation of fabric pilling. J. Text. Inst. 102(1), 1–13 (2011)

Nister, D.: Preemptive RANSAC for live structure and motion estimation. In: IEEE International Conference on Computer Vision IEEE (2008)

Obuchowski, J., Wyłomańska, A., Zimroz, R.: The local maxima method for enhancement of time–frequency map and its application to local damage detection in rotating machines. Mech. Syst. Signal Process. 46(2), 389–405 (2014)

Chan, T.F., Vese, L.A.: Active contours without edges. IEEE Trans. Image Process. 10(2), 266–277 (2001)

Kim, Y., Kim, S.: Study on the integration of fabric pilling generation and evaluation system. Text. Sci. Eng. 53(5), 360–365 (2016)

Sadeghi, B.H.M.: A BP-neural network predictor model for plastic injection molding process. J. Mater. Process. Technol. 103(3), 411–416 (2000)

Liu, L., Deng, N., Xin, B., et al.: Objective evaluation of fabric pilling based on multi-view stereo vision. J. Text. Inst. (2020). https://doi.org/10.1080/00405000.2020.1862479

Mendes, A.D.O., Torrao Fiadeiro, P., Lopes Miguel, R.A.: Subjective and objective pilling evaluations of textile fabrics: a comparison. Text. Res. J. 56(18), 136–149 (2010)

Mendes, A.O., Fiadeiro, P.T., Miguel, R.A.L.: Three-dimensional surface reconstruction for evaluation of the abrasion effects on textile fabrics. In: Three-Dimensional Image Capture & Applications VII. International Society for Optics and Photonics (2006)

Zhang, S., Li, X., et al.: Efficient kNN classification with different numbers of nearest neighbors. IEEE Trans. Neural Netw. Learn. Syst. 29(5), 1774–1785 (2018)

Yang, X., Yu, Q., He, L., et al.: The one-against-all partition based binary tree support vector machine algorithms for multi-class classification. Neurocomputing 113(aug.3), 1–7 (2013)

Funding

This study was funded by the Shanghai Natural Science Foundation of China (18ZR1416600), National Natural Science Foundation of China (61876106), Shanghai Local Capacity-Building Project (No. 19030501200) and Zhihong Scholars Plan of Shanghai University of Engineering Science (2018RC032017).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fan, M., Liu, L., Deng, N. et al. Digital 3D system for classifying fabric pilling based on improved active contours and neural network. Vis Comput 39, 5085–5095 (2023). https://doi.org/10.1007/s00371-022-02647-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00371-022-02647-3