Abstract

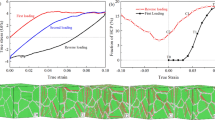

The strengthening and strain hardening behaviors of a CoNiCrFeMn high-entropy alloy were investigated by molecular dynamics (MD) simulation. Two gradient structures, i.e., grain size and composition gradient, were introduced into the alloy, and the alloy is characterized by a high strain hardening rate of 13.84 GPa, the maximum one among reported Cantor-like alloys in MD simulation, within a multistage strain hardening behavior. Distinct phase transformations dependent on the variations of both grain size and stacking fault energy were proposed to play crucial roles in determining the strengthening and the unusual strain hardening behaviors, and the corresponding microstructural evolution at increased strain was provided and discussed.

Similar content being viewed by others

Data availability

The data forming the basis of this study are available from the authors upon reasonable request.

References

W. Li, D. Xie, D. Li, Y. Zhang, Y. Gao, P.K. Liaw, Prog. Mater. Sci. 118, 100777 (2021). https://doi.org/10.1016/j.pmatsci.2021.100777

Z. Li, S. Zhao, R.O. Ritchie, M.A. Meyers, Prog. Mater. Sci. 102, 296–345 (2019). https://doi.org/10.1016/j.pmatsci.2018.12.003

E.P. George, W.A. Curtin, C.C. Tasan, Acta Mater. 188, 435–474 (2020). https://doi.org/10.1016/j.actamat.2019.12.015

S.Z. Han, E.-A. Choi, S.H. Lim, S. Kim, J. Lee, Prog. Mater. Sci. 117, 100720 (2021). https://doi.org/10.1016/j.pmatsci.2020.100720

R.O. Ritchie, Nat. Mater. 10(11), 817–822 (2011). https://doi.org/10.1038/nmat3115

P. Shi, Y. Zhong, Y. Li, W. Ren, T. Zheng, Z. Shen, B. Yang, J. Peng, P. Hu, Y. Zhang, P.K. Liaw, Y. Zhu, Mater. Today 41, 62–71 (2020). https://doi.org/10.1016/j.mattod.2020.09.029

X. Li, L. Lu, J. Li, X. Zhang, H. Gao, Nat. Rev. Mater. 5(9), 706–723 (2020). https://doi.org/10.1038/s41578-020-0212-2

K. Lu, Nat. Rev. Mater. (2016). https://doi.org/10.1038/natrevmats.2016.19

L. Guo, W.Q. Wu, S. Ni, Z. Yuan, Y. Cao, Z.W. Wang, M. Song, J. Alloys Compd. 841, 10 (2020). https://doi.org/10.1016/j.jallcom.2020.155688

Z. Tong, H. Liu, J. Jiao, W. Zhou, Y. Yang, X. Ren, Addit. Manuf. 35, 101417 (2020). https://doi.org/10.1016/j.addma.2020.101417

G. Chen, L.T. Li, J.W. Qiao, Z.M. Jiao, S.G. Ma, F.L. Ng, Z.G. Zhu, D. Zhao, Z.H. Wang, Mater. Lett. 238, 163–166 (2019). https://doi.org/10.1016/j.matlet.2018.11.176

T.A. Listyawan, H. Lee, N. Park, U. Lee, J. Mater. Sci. Technol. 57, 123–130 (2020). https://doi.org/10.1016/j.jmst.2020.02.083

I. Basu, J.T.M. De Hosson, Scr. Mater. 187, 148–156 (2020). https://doi.org/10.1016/j.scriptamat.2020.06.019

X.H. An, S.D. Wu, Z.G. Wang, Z.F. Zhang, Prog. Mater. Sci. 101, 1–45 (2019). https://doi.org/10.1016/j.pmatsci.2018.11.001

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, C.C. Tasan, Nature 534(7606), 227–230 (2016). https://doi.org/10.1038/nature17981

S. Chen, H.S. Oh, B. Gludovatz, S.J. Kim, E.S. Park, Z. Zhang, R.O. Ritchie, Q. Yu, Nat. Commun. 11(1), 826 (2020). https://doi.org/10.1038/s41467-020-14641-1

J. Yang, Y.H. Jo, D.W. Kim, W.-M. Choi, H.S. Kim, B.-J. Lee, S.S. Sohn, S. Lee, Mater. Sci. Eng. A-Struct. 772, 138809 (2020). https://doi.org/10.1016/j.msea.2019.138809

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Mater. Sci. Eng. A-Struct. 375, 213–218 (2004). https://doi.org/10.1016/j.msea.2003.10.257

B. Cantor, Entropy 16(9), 4749–4768 (2014). https://doi.org/10.3390/e16094749

G. Chen, J.W. Qiao, Z.M. Jiao, D. Zhao, T.W. Zhang, S.G. Ma, Z.H. Wang, Scr. Mater. 167, 95–100 (2019). https://doi.org/10.1016/j.scriptamat.2019.04.002

W. Guo, Z. Pei, X. Sang, J.D. Poplawsky, S. Bruschi, J. Qu, D. Raabe, H. Bei, Acta Mater. 170, 176–186 (2019). https://doi.org/10.1016/j.actamat.2019.03.024

W.-M. Choi, Y.H. Jo, S.S. Sohn, S. Lee, B.-J. Lee, NPJ Comput. Mater. 4, 9 (2018). https://doi.org/10.1038/s41524-017-0060-9

J. Li, Q. Fang, B. Liu, Y. Liu, Acta Mater. 147, 35–41 (2018). https://doi.org/10.1016/j.actamat.2018.01.002

A. Stukowski, Model. Simul. Mater. Sci. Eng. 18(1), 015012 (2010). https://doi.org/10.1088/0965-0393/18/1/015012

J. Li, L. Li, C. Jiang, Q. Fang, F. Liu, Y. Liu, P.K. Liaw, J. Mater. Sci. Technol. 57, 85–91 (2020). https://doi.org/10.1016/j.jmst.2020.03.064

Q. Fang, Y. Chen, J. Li, C. Jiang, B. Liu, Y. Liu, P.K. Liaw, Int. J. Plast. 114, 161–173 (2019). https://doi.org/10.1016/j.ijplas.2018.10.014

Y. Qi, M. Zhao, M. Feng, J. Alloys Compd. 851, 156923 (2021). https://doi.org/10.1016/j.jallcom.2020.156923

J. Hou, Q. Li, C. Wu, L. Zheng, Materials (2019). https://doi.org/10.3390/ma12071010

Y. Qi, X. Chen, M. Feng, Appl. Phys. A (2020). https://doi.org/10.1007/s00339-020-03714-z

M. Kawamura, M. Asakura, N.L. Okamoto, K. Kishida, H. Inui, E.P. George, Acta. Mater. 203, 116454 (2021). https://doi.org/10.1016/j.actamat.2020.10.073

C.W. Sinclair, R.G. Hoagland, Acta. Mater. 56(16), 4160–4171 (2008). https://doi.org/10.1016/j.actamat.2008.04.043

J. Liu, Phys. Let. A 384(22), 126516 (2020). https://doi.org/10.1016/j.physleta.2020.126516

Y. Yang, Q. He, Acta. Metall. Sin 57(4), 385–392 (2021). https://doi.org/10.11900/0412.1961.2020.00359

T.Y. Gao, X. Jin, J.W. Qiao, H.J. Yang, Y. Zhang, Y.C. Wu, J. Appl. Phys (2021). https://doi.org/10.1063/5.0041352

S.F. Liu, Y. Wu, H.T. Wang, W.T. Lin, Y.Y. Shang, J.B. Liu, K. An, X.J. Liu, H. Wang, Z.P. Lu, J. Alloys Compd. 792, 444–455 (2019). https://doi.org/10.1016/j.jallcom.2019.04.035

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, Z. Fu, Intermetallics 56, 24–27 (2015). https://doi.org/10.1016/j.intermet.2014.08.008

H. Wang, D. Chen, X. An, Y. Zhang, S. Sun, Y. Tian, Z. Zhang, A. Wang, J. Liu, M. Song, S.P. Ringer, T. Zhu, X. Liao, Sci. Adv. 7(14), eabe3105 (2021). https://doi.org/10.1126/sciadv.abe3105

S. Zhao, Z. Li, C. Zhu, W. Yang, Z. Zhang, D.E.J. Armstrong, P.S. Grant, R.O. Ritchie, M.A. Meyers, Sci. Adv. (2021). https://doi.org/10.1126/sciadv.abb3108

J. Li, H. Chen, H. Feng, Q. Fang, Y. Liu, F. Liu, H. Wu, P.K. Liaw, J. Mater. Sci. Technol. 54, 14–19 (2020). https://doi.org/10.1016/j.jmst.2020.02.070

P.R. Budarapu, R. Gracie, S.P.A. Bordas, T. Rabczuk, Comput. Mech. 53(6), 1129–1148 (2013). https://doi.org/10.1007/s00466-013-0952-6

H. Talebi, M. Silani, S.P.A. Bordas, P. Kerfriden, T. Rabczuk, Comput. Mech. 53(5), 1047–1071 (2013). https://doi.org/10.1007/s00466-013-0948-2

Acknowledgements

The present work was supported by the Natural Science Basic Research Plan in Shaanxi Province of China (No. 2020JM-41, No. 2020JM-33) and the Natural Science Foundation of Shaanxi Province (No. 2019TD-020).

Author information

Authors and Affiliations

Contributions

YY contributed to conceptualization, methodology, software, writing—original draft, formal analysis, investigation, visualization. SZ contributed to conceptualization, software, methodology. PH involved in methodology, writing—review and feedback, supervision, funding acquisition. FW helped in conceptualization, methodology, writing—review and feedback, supervision, funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yang, Y., Zhang, S., Huang, P. et al. Phase transformation-induced strengthening and multistage strain hardening in double-gradient-structured high-entropy alloys. Appl. Phys. A 128, 258 (2022). https://doi.org/10.1007/s00339-022-05382-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-05382-7