Abstract

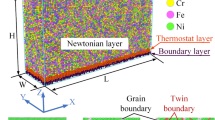

In this paper, structural evolution of single-crystal Al (SC)-metallic glass (MG) Al90Sm10 nanolaminate specimens under shock compression has been investigated using molecular dynamics simulations. Shock profile analysis of the SC-MG nanolaminate specimen reveals the presence of elastic precursor at lower piston velocity in the crystalline region of the nanolaminates eventuating due to plane-plane collision. Shock-induced martensitic phase transformation is apparent in the nanolaminate specimen at higher shock intensities. Rarefaction waves are observed to be generated at the crystalline–amorphous interface, which aid in stabilization of the transformed martensitic phase. The role of interface reverses with altering the direction of shockwave to induce from the metallic glass end of the nanolaminate. The attenuation of shockwave in the amorphous MG region and the absence of rarefaction waves at the interface impede the martensitic phase transformation. Icosahedral-like cluster < 0, 2, 8, 4 > is found to be most resistant to shockwave deformation as analyzed using Voronoi cluster analysis. Formation of shear transformation zones (STZs) plays a vital role in absorbing the shock in the metallic glass region of nanolaminate specimen.

Similar content being viewed by others

References

R. Bergman, Y. Benjamin, (2017) U.S. Patent 9.696,122.

X. Nie, A. Leyland, H.W. Song, A.L. Yerokhin, S.J. Dowey, A. Matthews, Surf. Coat. Technol. 116, 1055 (1999). https://doi.org/10.1016/S0257-8972(99)00089-4

I.J. Polmear, Metallurgy of the Light Metals, 5th edn. (Edward Arnold, 1995)

J. Suryawanshi, K.G. Prashanth, S. Scudino, J. Eckert, O. Prakash, U. Ramamurty, Acta Mater. 115, 285 (2016). https://doi.org/10.1016/j.actamat.2016.06.009

J.R. Davis, (1999) Corrosion of aluminum and aluminum alloys. ASM International

RK Yadav, N Hasan, A Yadav, F Dhauj, A Chikkani, IJCSMS 11(2)

J.Y. Zhang, G. Liu, J. Sun, Acta Mater. 66, 22 (2014). https://doi.org/10.1016/j.actamat.2013.11.061

Y. Wang, J. Zhou, S. Zhang, L. Wang, Mat. Des. 51, 88 (2013). https://doi.org/10.1016/j.matdes.2013.04.010

H. Noori, B. Mortazavi, L. Keshtkari, X. Zhuang, T. Rabczuk, Appl. Phys. A. 127, 541 (2021). https://doi.org/10.1007/s00339-021-04693-5

H. Noori, B. Mortazavi, A. Di Pierro, E. Jomehzadeh, X. Zhuang, Z. Goangseup, K. Sang-Hyun, T. Rabczuk, Comput. Mater. Contin. 65(3), 2009 (2020). https://doi.org/10.32604/cmc.2020.011256

N.K. Bourne, K. Bennett, A.M. Milne, S.A. MacDonald, J.J. Harrigan, J.C.F. Millett, Scr Mater. 58(2), 154 (2008). https://doi.org/10.1016/j.scriptamat.2007.07.044

N.K. Bourne, G.T. Gray III., J.C.F. Millett, J. Appl. Phys. 106(9), 12 (2009). https://doi.org/10.1063/1.3218758

P.J. Tan, S.R. Reid, J.J. Harrigan, Z. Zou, S. Li, J. Mech. Phys. Solids 53(10), 2206 (2005). https://doi.org/10.1016/j.jmps.2005.05.003

M.F. Rose, T.L. Berger, Philos. Mag. 17(150), 1121 (1968). https://doi.org/10.1080/14786436808223190

A.S. Appleton, J.S. Waddington, Philos. Mag. 12(116), 273 (1965). https://doi.org/10.1080/14786436508218870

G.I. Kanel, S.V. Razorenov, V.E. Fortov, J. Phys. Condens. Matter. 16(14), S1007 (2004). https://doi.org/10.1088/0953-8984/16/14/010

X. He, J.L. Rong, D.L. Xiang, H.Y. Wei, C.H. Hu, X. Wang, J. Mech. 35(2), 267 (2019). https://doi.org/10.1017/jmech.2017.98

V. Skripnyak, AIP Conf. Proc. 1426(1), 965 (2012)

Z.J. Jiang, J.Y. He, H.Y. Wang, H.S. Zhang, Z.P. Lu, L.H. Dai, Mater Res Lett 4(4), 226 (2016). https://doi.org/10.1080/21663831.2016.1191554

A. Neogi, N. Mitra, Modell. Simul. Mater. Sci. Eng. 25(2), 025013 (2017). https://doi.org/10.1088/1361-651X/aa5850

P. Wen, B. Demaske, D.E. Spearot, S.R. Phillpot, J. Mater. Sci. 53(8), 5719 (2018). https://doi.org/10.1007/s10853-017-1666-5

K.V. Reddy, C. Deng, S. Pal, Acta Mater. 164, 347 (2019). https://doi.org/10.1016/j.actamat.2018.10.062

S. Mishra, S. Pal, J. Non-Cryst, Solids. 500, 249 (2018). https://doi.org/10.1016/j.jnoncrysol.2018.08.006

M. Meraj, C. Deng, S. Pal, J. Appl. Phys. 123(4), 044306 (2018). https://doi.org/10.1063/1.5012960

S.N. Luo, T.C. Germann, D.L. Tonks, Q. An, J. Appl. Phys. 108(9), 093526 (2010). https://doi.org/10.1063/1.3506707

B.J. Demaske, P. Wen, S.R. Phillpot, D.E. Spearot, J. Appl. Phys. 123(21), 215101 (2018). https://doi.org/10.1063/1.5025650

X.C. Tang, W.R. Jian, J.Y. Huang, F. Zhao, C. Li, X.H. Xiao, X.H. Yao, S.N. Luo, J. Mater. Sci. Eng. A 711, 284 (2018). https://doi.org/10.1016/j.msea.2017.11.032

C.T. Wang, Y. He, C. Ji, Y. He, W. Han, X. Pan, Intermetallics 93, 383 (2018). https://doi.org/10.1016/j.intermet.2017.11.004

S. Zhao, T.C. Germann, A. Strachan, Phys. Rev. B. 76(1), 014103 (2007). https://doi.org/10.1103/PhysRevB.76.014103

H. Xiang, H. Li, T. Fu, W. Zhu, C. Huang, B. Yang, X. Peng, Appl. Surf. Sci. 427, 219 (2018). https://doi.org/10.1016/j.apsusc.2017.07.268

M. Xiang, Y. Liao, K. Wang, G. Lu, J. Chen, Int. J. Plast. 103, 23 (2018). https://doi.org/10.1016/j.ijplas.2017.12.005

M.I. Mendelev, F. Zhang, Z. Ye, Y. Sun, M.C. Nguyen, S.R. Wilson, C.Z. Wang, K.M. Ho, Modell. Simul. Mater. Sci. Eng. 23(4), 045013 (2015). https://doi.org/10.1088/0965-0393/23/4/045013

S. Plimpton, J. Comput. Phys. 117(1), 1 (1995). https://doi.org/10.1006/jcph.1995.1039

G.B. Bokas, L. Zhao, J.H. Perepezko, I. Szlufarska, Scr. Mater. 124, 99 (2016). https://doi.org/10.1016/j.scriptamat.2016.06.045

Y. Sun, Y. Zhang, F. Zhang, Z. Ye, Z. Ding, C.Z. Wang, K.M. Ho, J. Appl. Phys. 120(1), 015901 (2016). https://doi.org/10.1063/1.4955223

D. Faken, H. Jónsson, Comput. Mater. Sci. 2(2), 279 (1994). https://doi.org/10.1016/0927-0256(94)90109-0

C.L. Kelchner, S.J. Plimpton, J.C. Hamilton, Phys. Rev. B. 58(17), 11085 (1998). https://doi.org/10.1103/PhysRevB.58.11085

S.D. Feng, W. Jiao, S.P. Pan, L. Qi, W. Gao, L.M. Wang, G. Li, M.Z. Ma, R.P. Liu, J Non-Cryst Solids 430, 94 (2015). https://doi.org/10.1016/j.jnoncrysol.2015.10.012

J.D. Honeycutt, H.C. Andersen, J. Phys. Chem. 91(19), 4950 (1987). https://doi.org/10.1021/j100303a014

R. Ravelo, T.C. Germann, O. Guerrero, Q. An, B.L. Holian, Phys. Rev. B 88(13), 134101 (2013). https://doi.org/10.1103/PhysRevB.88.134101

R.A. Austin, J. Appl. Phys. 123(3), 035103 (2018). https://doi.org/10.1063/1.5008280

W.H. Lee, X.H. Yao, W.R. Jian, Q. Han, Comput. Mater. Sci. 98, 297 (2015). https://doi.org/10.1016/j.commatsci.2014.11.029

N. Gunkelmann, E.M. Bringa, H.M. Urbassek, J. Appl. Phys. 118(18), 185902 (2015). https://doi.org/10.1063/1.4935452

A.S. Rogachev, S.G. Vadchenko, A.S. Aronin, S. Rouvimov, A.A. Nepapushev, I.D. Kovalev, F. Baeas, O. Politano, S.A. Rogachev, A.S. Mukasyan, Appl. Phys. Lett. 111(9), 093105 (2017). https://doi.org/10.1063/1.4985261

E.B. Zaretsky, G.I. Kanel, J. Appl. Phys. 112(7), 073504 (2012). https://doi.org/10.1063/1.4755792

G.I. Kanel, S.V. Razorenov, K. Baumung, J. Singer, J. Appl. Phys. 90(1), 136 (2001). https://doi.org/10.1063/1.1374478

G. Agarwal, A.M. Dongare, J. Appl. Phys. 119(14), 145901 (2016). https://doi.org/10.1063/1.4944942

L. Wu, K. Wang, S. Xiao, H. Deng, W. Zhu, W. Hu, Comput. Mater. Sci. 122, 1 (2016). https://doi.org/10.1016/j.commatsci.2016.05.010

A. Neogi, N. Mitra, In AIP Conference Proceedings. 1832(1), 030011 (2017)

K.V. Reddy, S. Pal, Steel Res. Int. 1800636, 1 (2019). https://doi.org/10.1002/srin.201800636

Y.E. Kalay, L.S. Chumbley, M.J. Kramer, I.E. Anderson, Intermetallics 18(8), 1676 (2010). https://doi.org/10.1016/j.intermet.2010.05.005

J. Hwang, (2011) Ph.D. thesis, Harvard University.

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

Srishti Mishra performed data curation, formal analysis, investigation, software, methodology, visualization, validation, writing—original draft. K. Vijay Reddy contributed to validation, resources, project administration, supervision, writing—review and editing. Snehanshu Pal done conceptualization, data curation, funding acquisition, investigation, methodology, project administration, resources, software, supervision, validation, and writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Data Availability

The raw/processed data required to reproduce these findings can be shared upon request.

Code availability

The code for the simulations can be provided upon request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mishra, S., Reddy, K.V. & Pal, S. Impact of crystalline–amorphous interface on shock response of metallic glass Al90Sm10/crystalline Al nanolaminates. Appl. Phys. A 127, 774 (2021). https://doi.org/10.1007/s00339-021-04929-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04929-4