Abstract

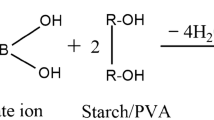

The research reported here focuses on developing wood adhesive by mixing liquid glucose (LG) and polyvinyl alcohol (PVA) in water. Here, boric acid is used as a crosslinking agent to improve the LG–PVA blend’s thermomechanical characteristics. The impact of crosslinking was measured using a variety of analytical techniques, including viscosity testing, Fourier transform infrared spectroscopy (FTIR), differential scanning calorimetry (DSC), and water contact angle testing. By pouring LG–PVA blends onto Teflon sheets, a film was made. On performance parameters like tensile strength, pencil hardness, and thermal properties like glass transition temperature, the impacts of several variables, such as increasing the amount of LG and boric acid, were examined. In the water contact angle test, the crosslinked blend films showed decreased hydrophilic behavior and increased pencil hardness. The films glass transition temperature (Tg) was positively impacted by the higher BA concentration. For the crosslinking reaction with boric acid, the free hydroxyl groups present in LG and PVA serve as an active sites. Crosslinks between the hydroxyl groups of LG and PVA are expected to take place as a trivalent boron attracts these nucleus-loving groups. FTIR spectrum measurements confirmed the interaction of boric acid with the LG–PVA mixture. The reaction was accelerated by the acidic pH, and its effects were shown in the rise in thermomechanical properties. By lowering the free volumes between the chains, the crosslinking improved cohesion, and as a result, an increase in strength on glued wood specimens was observed.

Similar content being viewed by others

References

Jin T, Zeng H, Huang Y, Liu L, Yao W, Lei H, Shi S, Du G, Zhang L (2023) Bio-hyperbranched polyesters synthesized from citric acid and bio-polyols and applications on wood adhesives. Polym Test 120:107974. https://doi.org/10.1016/j.polymertesting.2023.107974

Hill K (2010) Surfactants based on carbohydrates and proteins for consumer products and technical applications. Surf Renew Resour. https://doi.org/10.1002/9780470686607.ch4

Wang Y, Xiong H, Wang Z, Chen L (2017) Effects of different durations of acid hydrolysis on the properties of starch-based wood adhesive. Int J Biol Macromol 103:819–828. https://doi.org/10.1016/j.ijbiomac.2017.05.102

Pokeržnik N, Krajnc M (2015) Synthesis of a glucose-based surfmer and its copolymerization with n-butyl acrylate for emulsion pressure sensitive adhesives. Eur Polym J 68:558–572. https://doi.org/10.1016/j.eurpolymj.2015.03.038

Lim JC, Lee MC, Lim T, Kim BJ (2014) Synthesis of sorbital based nonionic surfactants and characterization of interfacial and adhesive properties for waterborne pressure sensitive adhesives. Coll Surf A Physicochem Eng Asp 446:80–89. https://doi.org/10.1016/j.colsurfa.2014.01.018

Aguirre M, Hamzehlou S, González E, Leiza JR (2020) Renewable feedstocks in emulsion polymerization: coating and adhesive applications. Adv Chem Eng. 56:139–186. https://doi.org/10.1016/bs.ache.2020.07.004

Gadhave RV, Kasbe PS, Mahanwar PA, Gadekar PT (2018) To study the effect of boric acid modification on starch–polyvinyl alcohol blend wood adhesive. J Ind Acad Wood Sci. https://doi.org/10.1007/s13196-018-0225-2

Gadhave RV, Vineeth SK (2022) Synthesis and characterization of starch stabilized polyvinyl acetate-acrylic acid copolymer-based wood adhesive. Polym Bull. https://doi.org/10.1007/s00289-022-04558-8

Umemura K, Mihara A, Kawai S (2010) Development of new natural polymer-based wood adhesives III: effects of glucose addition on properties of chitosan. J Wood Sci 56:387–394. https://doi.org/10.1007/s10086-010-1117-2

Gadhave RV (2023) Comparative study of effect of addition of calcium carbonate and clay on the performance properties of polyvinyl acetate wood glue. Open J Polym Chem 13:1–13. https://doi.org/10.4236/ojpchem.2023.131001

Nie Y, Tian X, Liu Y, Wu K, Wang J (2013) Research on starch- g -polyvinyl acetate and epoxy resin-modified corn starch adhesive. Polym Compos 34:77–87. https://doi.org/10.1002/pc.22379

Shu K (2022) Adhesive for packaging fine cigarettes and preparation method, CN114032051A, https://patents.google.com/patent/CN114032051A/en?oq=CN114032051A.

Huang Y (2018) A kind of production method of the dedicated glutinous rice glue of wallpaper, CN108929643A, https://patents.google.com/patent/CN108929643A/en?oq=CN108929643A

Guo L, Wang Y, Xue L (2016) A kind of preparation method of plant base high viscosity glue, CN106244096A, https://patents.google.com/patent/CN106244096A/en?oq=CN106244096A#patentCitations

Wang J (2013) Adhesive agent for high-strength paper box and preparation method thereof, CN103333644A https://patents.google.com/patent/CN103333644A/en?oq=CN103333644A

Tondi G, Wieland S, Wimmer T, Schnabel T, Petutschnigg A (2012) Starch-sugar synergy in wood adhesion science: basic studies and particleboard production. Eur J Wood Wood Prod 70:271–278. https://doi.org/10.1007/s00107-011-0553-z

Moukarzel W, Marty J-D, Appelhans D, Mauzac M, Fitremann J (2013) Synthesis of linear and hyperbranched sugar-grafted polysiloxanes using N -hydroxysuccinimide-activated esters. J Polym Sci Part A Polym Chem 51:3607–3618. https://doi.org/10.1002/pola.26755

Rong Huei C (1996) Effect of molecular weight of chitosan with the same degree of deacetylation on the thermal, mechanical, and permeability properties of the prepared membrane. Carbohydr Polym 29:353–358. https://doi.org/10.1016/S0144-8617(96)00007-0

Qian X (2021) Anti-wrinkle glue and preparation method thereof, CN110591600A, https://patents.google.com/patent/CN110591600A/en?oq=CN110591600+A

Tian Y, Jiang B, Peng Z, Hu S, Xu L, Tian Y (2014) Preparation method of soy protein adhesive, CN103665270A, https://patents.google.com/patent/CN103665270A/en?oq=CN103665270+A

Chen Y, Zhang S, Wang L (2005) Green nontoxic adhesive agent and prepration method, CN1539902A, https://patents.google.com/patent/CN1539902A/en?oq=CN1539902+A

Othman N, Azahari N (2011) Thermal properties of polyvinyl alcohol (PVOH)/corn starch blend film. Malaysian Polym J 6(6):147–154

Stauffer SR, Peppast NA (1992) Poly(vinyl alcohol) hydrogels prepared by freezing-thawing cyclic processing. Polymer (Guildf) 33:3932–3936. https://doi.org/10.1016/0032-3861(92)90385-A

Gadhave RV, Mahanwar PA, Gadekar PT (2017) Bio-renewable sources for synthesis of eco-friendly polyurethane adhesives—review. Open J Polym Chem 07:57–75. https://doi.org/10.4236/ojpchem.2017.74005

Sanchez LM, Shuttleworth PS, Waiman C, Zanini G, Alvarez VA, Ollier RP (2020) Physically-crosslinked polyvinyl alcohol composite hydrogels containing clays, carbonaceous materials and magnetic nanoparticles as fillers. J Environ Chem Eng 8:103795. https://doi.org/10.1016/j.jece.2020.103795

Gérard C (2001) Amylose determination in genetically modified starches. Carbohydr Polym 44:19–27. https://doi.org/10.1016/S0144-8617(00)00194-6

Monroy Y, Seré P, Rivero S, García MA (2020) Sustainable panels based on starch bioadhesives: an insight into structural and tribological performance. Int J Biol Macromol 148:898–907. https://doi.org/10.1016/j.ijbiomac.2020.01.205

Kuo M-I, Wang Y-J (2006) Effects of urea concentration on thermal and rheological properties of rice starches. Cereal Chem J 83:478–481. https://doi.org/10.1094/CC-83-0478

Zeng Y, Xu P, Yang W, Chu H, Wang W, Dong W, Chen M, Bai H, Ma P (2021) Soy protein-based adhesive with superior bonding strength and water resistance by designing densely crosslinking networks. Eur Polym J 142:110128. https://doi.org/10.1016/j.eurpolymj.2020.110128

Yin Y, Li J, Liu Y, Li Z (2005) Starch crosslinked with poly(vinyl alcohol) by boric acid. J Appl Polym Sci 96:1394–1397. https://doi.org/10.1002/app.21569

Gadhave RV, Mahanwar PA, Gadekar PT (2019) Study of cross-linking between boric acid and different types of polyvinyl alcohol adhesive. Open J Polym Chem 09:16–26. https://doi.org/10.4236/ojpchem.2019.91002

Vineeth SK, Gadhave RV (2023) Corn starch blended polyvinyl alcohol adhesive chemically modified by crosslinking and its applicability as polyvinyl acetate wood adhesive. Polym Bull. https://doi.org/10.1007/s00289-023-04746-0

Sheng B (2022) Environment-friendly paper tube glue, CN115305033A, https://patents.google.com/patent/CN115305033A/en?oq=CN115305033+A

Yu Y, Zhang P, Zhang N (2021) Adhesive for bonding paper products and preparation method thereof, CN112795317A. https://patents.google.com/patent/CN112795317A/en?oq=CN112795317+A

Gadhave RV, Vineeth SK, Mahanwar PA, Gadekar PT (2021) Effect of addition of boric acid on thermo-mechanical properties of microcrystalline cellulose/polyvinyl alcohol blend and applicability as wood adhesive. J Adhes Sci Technol 35:1072–1086. https://doi.org/10.1080/01694243.2020.1832775

Zhu S, Huang X, Li X, Li Z (2020) Starch adhesive for cigarette paper, CN112080223A, https://patents.google.com/patent/CN112080223A/en?oq=CN112080223+A

Zhu S, Huang X, Li X, Li Z (2020) Starch adhesive for beer label paper, CN112080224A, https://patents.google.com/patent/CN112080224A/en?oq=CN112080224+A

Acknowledgments

We would like to thank Institute of Chemical Technology, Mumbai, India, for the support throughout this work.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dhawale, P., Gadhave, S. & Gadhave, R.V. Boric acid-crosslinked liquid glucose–polyvinyl alcohol blend-based wood adhesive. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05219-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05219-8