Abstract

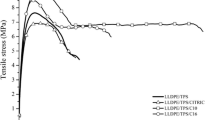

Preparing blends from fully biodegradable resources is an important alternative in the production of materials less harmful to the environment. Among these materials, thermoplastic cornstarch (TPS) and polycaprolactone (PCL) are an interesting possibility for replacing conventional synthetic materials, and it is desirable that they present relative stability under conditions of processing and use. In the present work, PCL/TPS blends with up to 30% TPS, obtained from cornstarch plasticized with water and glycerin, coconut or babassu oil, were processed in an internal laboratory mixer. Adjusted torque variation rate during the last processing stage is a very sensitive indicator of molar mass alterations with processing time. Rheometry data indicate that TPS obtained with babassu and coconut vegetable oils have a higher molar mass compared to that obtained with glycerin. In addition, the incorporation of TPS promotes thermal degradation in PCL/TPS mixtures, which is more pronounced the higher the TPS content and with TPS-glycerin, except for the PCL/20%TPS blends obtained with glycerin and babassu oil. The mechanical properties of the extruded films decreased with the addition of TPS, this reduction being more evident with the increase in the TPS content and in systems with TPS obtained with babassu oil. In contrast, only in blends containing 10 and 20% TPS of glycerin, there was an increase in elongation at break, being a good feature for flexible films, this property is desirable in certain applications.

Similar content being viewed by others

References

Machado T AM (2016) Obtaining fibers from polycaprolactone/poly (n-isopropylacrylamide) blends using the electrospinning technique. 2016. 84f. Course Conclusion Paper (Degree in Chemistry), Federal Technological University of Paraná-UTFPR, Londrina-Paraná

Averous F, Bouquillon N (2004) Biocomposites based on plasticized starch: thermal and mechanical behaviors. Carbohyd Polym 56(2):111–122

Stepto RFT (2003) The processing of starch as a thermoplastic. Macromolecular Symposia, vol 201, pp 203–212

Curvelo AAS, Carvalho AJF, Agnelli JAM (2001) Thermoplastic starch-cellulosic fibers composites: preliminary results. Carbohyd Polym 45:183–188

Shogren RL, Fanta GF, Doane WM (1993) Development of starch based plastics—a reexamination of selected polymer systems in historical perspective. Starch 45(8):276–280

Doane WM, Swanson C, Fanta G (1992) Emerging polymeric materials based on starch. In: Rowell RM, Schietz TP, Narayan R (eds) Emerging technologies for materials and chemicals from biomass. American Chemical Society, Washington, p 469

Avérous L (2004) Biodegradable multiphase systems based on plasticized starch: a review. J Macromol Sci Polym C24:231–274

Ma XF, Yu JG, Ma YB (2005) Urea and formamide as a mixed plasticizer for thermoplastic wheat flour. Carbohidrate Polym 60:111–116

Corradini E, Lotti C, Medeiros ES, Carvalho AJF, Curvelo AAS, Mattoso LHC (2005) Comparative study of corn-derived thermoplastic starches with different amylose contents. Polymers 15(4):268–273

Hagenmaier RD, Shaw PE (1992) Gas pertmeability of fruit coating waxes. J Am Soc Hortic Sci 1:105–109

Moretto E, Fett R (1998) Technology of vegetable oils and fats in the food industry. São Paulo, Varela

Reda SY, Carneiro PIB (2007) Oils and fats: applications and implications. Anal Mag 27:60–67

Andersen PJ, Ong S, Christensen BJ, Hodson SK (2001) Compositions and methods for manufacturing starch-based compositions. USA: Patent n. 6, pp 168–857

Lawton JW, Shogren RL, Tiefenbacher KF (1999) Effect of batter solids and starch type on the structure of baked starch foams. Cereal Chem 76(5):682–687

Soykeabkaew N, Supaphol P, Rujiravanit R (2004) Preparation and characterization of jute and flax reinforced starch-based composite foams. Carbohydrate Polym 58(1):53–63

Hayashi T (1994) Biodegradable polymers for biomedical uses. Progress Polym Sci 19:663–702

Woodruff MA, Hutmacher DW (2010) The return of a forgotten polymer—Polycaprolactone in the 21st century. Prog Polym Sci 35:1217–1256

Labet M, Thielemans W (2009) Synthesis of polycaprolactone: a review. Chem Soc Rev 38:3484–3504

Dealy JM, Larson RG (2006) Structure and rheology of molten polymers. Hanser, Munich & Cincinnati

Reul LTA, Pereira CAB, Sousa FM, Santos RM, Carvalho LH, Canedo EC (2019) Polycaprolactone/babassu compounds: rheological, thermal, and morphological characteristics. Polym Compos 40:E540–E549

Canedo EL, Wellen RMR, Almeida YMB (2016) Polymer Crystallization—Data Treatment and Macrokinetic Modeling. ANP PRH-28/DEQ/UFPE, Recife

Acknowledgements

The authors are grateful for the financial support of the Coordination for the Improvement of Higher Education Personnel (CAPES/Brazil) and to the Scientic and Technological Council (CNPq) for the fellowships of Carvalho, Vinhas and Almeida.

Funding

The funding was provided by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, 88882.455375/2019-01,Vithoria Alexandre Duarte Marinho.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Marinho, V.A.D., Sousa, F.M., Vinhas, G.M. et al. Influence of the content of corn thermoplastic starches (TPS) prepared with different plasticizers on the rheological and mechanical properties of PCL/TPS blends. Polym. Bull. 80, 7627–7640 (2023). https://doi.org/10.1007/s00289-022-04416-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04416-7