Abstract

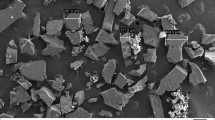

This study assesses the potential use of recycled carbon black (rCB) generated from the waste rubber pyrolysis process as a substitute for conventional carbon black series N330 (CB) in new rubber products. The rCB and conventional CBs were characterized to find elemental constituents present. The experiments were performed by replacing CB with rCB to the natural rubber (NR) matrix at various loadings. Curing characteristics were determined by rheometer and differential scanning calorimeter (DSC). The kinetic parameters of the crosslinking reaction were obtained based on DSC data, using mathematical models that do not require a comprehensive understanding of the reaction model, such as Ozawa–Flynn–Wall, Kissinger–Akahira–Sunose, Starink, Friedman, and Vyazovkin isoconversional methods. The swelling degree, mechanical properties, thermal properties, and thermal stability of prepared vulcanized rubber composites were determined. The obtained results revealed that CB could not entirely be replaced by rCB, but it may be used by mixing with commercial CB (rCB content of less than 15 phr in the NR matrix), depending on the desired properties of the end products.

Graphical abstract

Similar content being viewed by others

References

Farida E, Bukit N, Ginting EM, Bukit BF (2019) The effect of carbon black composition in natural rubber compound. Case Studies Thermal Eng 16:100566. https://doi.org/10.1016/j.csite.2019.100566

Jovanović V, Samaržija-Jovanović S, Budinski-Simendić J et al (2013) Composites based on carbon black reinforced NBR/EPDM rubber blends. Compos B Eng 45:333–340. https://doi.org/10.1016/j.compositesb.2012.05.020

Shiva M, Lakhi M (2019) Studying the effects of silica/alumina and silica/boehmite binary filler on the mechanical properties and the non-isothermal curing time of carbon black filled tyre tread composite. Compos B Eng 175:107124. https://doi.org/10.1016/j.compositesb.2019.107124

Cha JH, Shin G-J, Kang M-J et al (2018) A study on the effect of electron acceptor-donor interactions on the mechanical and interfacial properties of carbon black/natural rubber composites. Compos B Eng 136:143–148. https://doi.org/10.1016/j.compositesb.2017.10.003

Ulfah IM, Fidyaningsih R, Rahayu S et al (2015) Influence of carbon black and silica filler on the rheological and mechanical properties of natural rubber compound. Proc Chem 16:258–264. https://doi.org/10.1016/j.proche.2015.12.053

Omnès B, Thuillier S, Pilvin P et al (2008) Effective properties of carbon black filled natural rubber: experiments and modeling. Compos A Appl Sci Manuf 39:1141–1149. https://doi.org/10.1016/j.compositesa.2008.04.003

Maroufi S, Mayyas M, Sahajwalla V (2017) Nano-carbons from waste tyre rubber: an insight into structure and morphology. Waste Manage 69:110–116. https://doi.org/10.1016/j.wasman.2017.08.020

Dwivedi C, Manjare S, Rajan SK (2020) Recycling of waste tire by pyrolysis to recover carbon black: Alternative and environment-friendly reinforcing filler for natural rubber compounds. Compos B Eng 200:108346. https://doi.org/10.1016/j.compositesb.2020.108346

Balbay S (2020) Effects of recycled carbon-based materials on tyre. J Mater Cycles Waste Manage 22:1768–1779. https://doi.org/10.1007/s10163-020-01064-9

Berki P, Göbl R, Karger-Kocsis J (2017) Structure and properties of styrene-butadiene rubber (SBR) with pyrolytic and industrial carbon black. Polym Test 61:404–415. https://doi.org/10.1016/j.polymertesting.2017.05.039

Berki P, Karger-Kocsis J (2016) Comparative properties of styrene-butadiene rubbers (SBR) containing pyrolytic carbon black, Conventional Carbon Black, and Organoclay. J Macromol Sci Part B 55:749–763. https://doi.org/10.1080/00222348.2016.1197511

Cataldo F (2005) Preparation of pyrolytic carbon black from scrap tire rubber crumb and evaluation in new rubber compounds. Macromol Mater Eng 290:463–467. https://doi.org/10.1002/mame.200400388

Norris CJ, Hale M, Bennett M (2014) Pyrolytic carbon: factors controlling in-rubber performance. Plast Rubber Compos 43:245–256. https://doi.org/10.1179/1743289814Y.0000000088

Li S, Wan C, Wu X, Wang S (2016) Core-shell structured carbon nanoparticles derived from light pyrolysis of waste tires. Polym Degrad Stab 129:192–198. https://doi.org/10.1016/j.polymdegradstab.2016.04.013

Mikulova Z, Sedenkova I, Matejova L et al (2013) Study of carbon black obtained by pyrolysis of waste scrap tyres. J Therm Anal Calorim 111:1475–1481. https://doi.org/10.1007/s10973-012-2340-4

Roland CM (2016) Reinforcement of elastomers. In: Reference module in materials science and materials engineering. Elsevier. http://polymerphysics.net/pdf/Reinforcement%20of%20Elastomers%202016.pdf

Sagar M, Nibedita K, Manohar N et al (2018) A potential utilization of end-of-life tyres as recycled carbon black in EPDM rubber. Waste Manage 74:110–122. https://doi.org/10.1016/j.wasman.2018.01.003

Flory PJ, Rehner J (1943) Statistical mechanics of cross-linked polymer networks I. Rubberlike elasticity. J Chem Phys 11:512–520. https://doi.org/10.1063/1.1723791

Ravichandran K, Natchimuthu N (2005) Vulcanization characteristics and mechanical properties of natural rubber-scrap rubber compositions filled with leather particles. Polym Int 54:553–559. https://doi.org/10.1002/pi.1725

Darmstadt H, Roy C, Kaliaguine S (1995) Characterization of pyrolytic carbon blacks from commercial tire pyrolysis plants. Carbon N Y 33:1449–1455. https://doi.org/10.1016/0008-6223(95)00096-V

Ahmed II, Gupta AK (2010) Pyrolysis and gasification of food waste: Syngas characteristics and char gasification kinetics. Appl Energy 87:101–108. https://doi.org/10.1016/j.apenergy.2009.08.032

Liu CY, Cheng WT (2019) Surface modification and characterization of carbon black through oxidation. Surf Interface Anal 51:316–325. https://doi.org/10.1002/sia.6581

Kojic D, Lazic N, Budinski-Simendic J et al (2018) The influence of combined active fillers on the properties of elastomeric materials for eco-friendly tyres. Hem Ind 72:293–303. https://doi.org/10.2298/HEMIND180227021K

Flynn JH, Wall LA (1966) General treatment of the thermogravimetry of polymers. J Res Natl Bureau Stand Sect A Phys Chem 70A:487. https://doi.org/10.6028/jres.070A.043

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706. https://doi.org/10.1021/ac60131a045

Starink MJ (2003) The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta 404:163–176. https://doi.org/10.1016/S0040-6031(03)00144-8

Friedman HL (2007) Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Part C Polym Symp 6:183–195. https://doi.org/10.1002/polc.5070060121

Vyazovkin S, Sbirrazzuoli N (2006) Isoconversional kinetic analysis of thermally stimulated processes in polymers. Macromol Rapid Commun 27:1515–1532. https://doi.org/10.1002/marc.200600404

Vyazovkin S (2001) Modification of the integral isoconversional method to account for variation in the activation energy. J Comput Chem 22:178–183. https://doi.org/10.1002/1096-987x(20010130)22:2%3c178::aid-jcc5%3e3.0.co;2-%23

Vyazovkin S (2015) Isoconversional kinetics of thermally stimulated processes. Springer International Publishing, Cham

Ke Q, Wu C, Chen X (2020) Model-free cure kinetics of additional liquid silicone rubber. Thermochim Acta 688:178584. https://doi.org/10.1016/j.tca.2020.178584

Leroy E, Souid A, Deterre R (2013) A continuous kinetic model of rubber vulcanization predicting induction and reversion. Polym Test 32:575–582. https://doi.org/10.1016/j.polymertesting.2013.01.003

Roy C, Darmstadt H, Benallal B, Amen-Chen C (1997) Characterization of naphtha and carbon black obtained by vacuum pyrolysis of polyisoprene rubber. Fuel Process Technol 50:87–103. https://doi.org/10.1016/S0378-3820(96)01044-2

Zedler Ł, Colom X, Saeb MR, Formela K (2018) Preparation and characterization of natural rubber composites highly filled with brewers’ spent grain/ground tire rubber hybrid reinforcement. Compos B Eng 145:182–188. https://doi.org/10.1016/j.compositesb.2018.03.024

Chalid M, Husnil YA, Puspitasari S, Cifriadi A (2020) Experimental and modelling study of the effect of adding starch-modified natural rubber hybrid to the vulcanization of sorghum fibers-filled natural rubber. Polymers 12:3017. https://doi.org/10.3390/polym12123017

Manohar N, Jayaramudu J, Suchismita S et al (2017) A unique application of the second order derivative of FTIR–ATR spectra for compositional analyses of natural rubber and polychloroprene rubber and their blends. Polym Test 62:447–453. https://doi.org/10.1016/j.polymertesting.2017.07.030

Song P, Zhao X, Cheng X et al (2018) Recycling the nanostructured carbon from waste tires. Compos Commun 7:12–15. https://doi.org/10.1016/j.coco.2017.12.001

Li Y, Wu J, Zhang Q et al (2020) Novel architecture of ZnO nanobundles grown on porous silica as high performance vulcanization accelerators that reinforce rubber composites. Ind Eng Chem Res 59:4493–4503. https://doi.org/10.1021/acs.iecr.9b06235

Fröhlich J, Niedermeier W, Luginsland H-D (2005) The effect of filler–filler and filler–elastomer interaction on rubber reinforcement. Compos A Appl Sci Manuf 36:449–460. https://doi.org/10.1016/j.compositesa.2004.10.004

Song P, Wan C, Xie Y et al (2018) Vegetable derived-oil facilitating carbon black migration from waste tire rubbers and its reinforcement effect. Waste Manage 78:238–248. https://doi.org/10.1016/j.wasman.2018.05.054

Hassan MM, Badway NA, Gamal AM et al (2010) Effect of carbon black on the properties of irradiated recycled polyamide/rubber waste composites. Nucl Instrum Methods Phys Res Sect B 268:2527–2534. https://doi.org/10.1016/j.nimb.2010.05.049

Acknowledgements

This research was financially supported by the Ministry of Education, Science and Technological Development of the Republic of Serbia (project No 451-03-9/2021-14/2000134) and Provincial Secretariat for Higher Education and Scientific Research Autonomous Province of Vojvodina (project No 142-451-2654/2021). The authors would like to express great gratitude to Jelena Bera and factory Edos, Zrenjanin, for allowing us to use their laboratory resources and for all the support as well. The students, Jovana Radosavkić, Jelena Bosnjačić, and Aleksandra Djurašinović, from the Faculty of Technology Novi Sad, have done the experimental work connected with their bachelor assignment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jovičić, M., Bera, O., Stojanov, S. et al. Effects of recycled carbon black generated from waste rubber on the curing process and properties of new natural rubber composites. Polym. Bull. 80, 5047–5069 (2023). https://doi.org/10.1007/s00289-022-04307-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04307-x