Abstract

To obtain the optimum conditions for encapsulation of metronidazole in sodium alginate, a response surface methodology (RSM) was used to find out the effect of independent variables (alginate concentration and drug to alginate ratio) on dependent variables including mean particle size, yield, drug loading, and encapsulation efficiency. Furthermore, the effect of alginate concentration on swelling behavior of microbeads was evaluated, and the mechanism of drug release was also studied. On the basis of the results, it can be declared that spherical microbeads with mean particle sizes of 443–665 µm were obtained with process yields, drug loading, and encapsulation efficiencies of almost 79.5%, 54.9%, and 79.9%, respectively. The metronidazole release was found to be 68% in 7 h with a formulation containing the drug to polymer ratio of 2:1. The optimum values for alginate concentration and drug to alginate ratio were determined to be within 1.4% (w/v) and 2.85 (w/w), respectively.

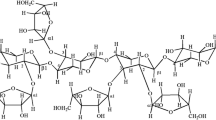

Graphic abstract

Similar content being viewed by others

Abbreviations

- CF-KRH:

-

Calcium-free Krebs ringer herpes

- CR:

-

Controlled release

- DL:

-

Drug loading

- EE:

-

Encapsulation efficiency

- FE-SEM:

-

Field emission scanning electron microscopy

- GI:

-

Gastrointestinal

- IR:

-

Immediate release

- MZ:

-

Metronidazole

- PBS:

-

Phosphate-buffered saline

- RMSE:

-

Root-mean-square error

- RSM:

-

Response surface methodology

- SEM:

-

Scanning electron microscopy

- SGF:

-

Simulated gastric fluid

- SIF:

-

Simulated intestinal fluid

- Uv:

-

Ultraviolet

References

Deshpande AA, Rhodes CT, Shah NH, Malick AW (1996) Controlled-Release Drug Delivery Systems for Prolonged Gastric Residence: An Overview. Drug Dev Ind Pharm 22(6):531–539

Vasir JK, Tambwekar K, Garg S (2003) Bioadhesive microspheres as a controlled drug delivery system. Int J Pharm 255(1–2):13–32

Uhrich KE, Cannizzaro SM, Langer RS, Shakesheff KM (1999) Polymeric Systems for Controlled Drug Release. Chem Rev 99(11):3181–3198

Luo Y, Wang Q (2014) Recent development of chitosan-based polyelectrolyte complexes with natural polysaccharides for drug delivery. Int J Biol Macromol 64:353–367

Motwani SK, Chopra S, Talegaonkar S, Kohli K, Ahmad FJ, Khar RK (2008) Chitosan–sodium alginate nanoparticles as submicroscopic reservoirs for ocular delivery: Formulation, optimisation and in vitro characterisation. Eur J Pharm Biopharm 68(3):513–525

Sultana K, Godward G, Reynolds N, Arumugaswamy R, Peiris P, Kailasapathy K (2000) Encapsulation of probiotic bacteria with alginate–starch and evaluation of survival in simulated gastrointestinal conditions and in yoghurt. Int J Food Microbiol 62(1–2):47–55

Zielinski A, B. and P. Aebischer, (1994) Chitosan as a matrix for mammalian cell encapsulation. Biomaterials 15(13):1049–1056

Ninan N, Muthiah M, Park I-K, Elain A, Thomas S, Grohens Y (2013) Pectin/carboxymethyl cellulose/microfibrillated cellulose composite scaffolds for tissue engineering. Carbohyd Polym 98(1):877–885

Oliveira MB, Mano JF (2011) Polymer-based microparticles in tissue engineering and regenerative medicine. Biotechnol Prog 27(4):897–912

Grøndahl L, Lawrie G, Jejurikar A (2010) Alginate-based drug delivery devices. Biointegration of Medical Implant Materials. Elsevier, pp 236–266

Tønnesen HH, Karlsen J (2002) Alginate in Drug Delivery Systems. Drug Dev Ind Pharm 28(6):621–630

Bolai Paul SA, Qureshi MJ (2018) Development and evaluation of metronidazole loaded carbopol 934P mucoadhesive microcapsules for sustained drug release at the gastric mucosa. J Appl Pharmaceutical Sci 8(12):020–031

Taylor MJ, Tanna S, Sahota T (2010) In Vivo Study of a Polymeric Glucose-Sensitive Insulin Delivery System Using a Rat Model. J Pharm Sci 99(10):4215–4227

de Souza Ferreira SB, de Assis Dias BR, Obregón CS, Gomes CC, de Araújo Pereira RR, Ribeiro Godoy JS, Estivalet Svidzinski TI, Bruschi ML (2014) Microparticles containing propolis and metronidazole: in vitro characterization, release study and antimicrobial activity against periodontal pathogens. Pharm Dev Technol 19(2):173–180

Rath G, Johal ES, Goyal AK (2011) Development of Serratiopeptidase and Metronidazole Based Alginate Microspheres for Wound Healing. Artificial Cells, Blood Substitutes Biotechnol 39(1):44–50

Gao P, Nie X, Zou M, Shi Y, Cheng G (2011) Recent advances in materials for extended-release antibiotic delivery system. J Antibiot 64:625

Takka S, Ocak ÖH, Acartürk F (1998) Formulation and investigation of nicardipine HCl–alginate gel beads with factorial design-based studies. Eur J Pharm Sci 6(3):241–246

Nayak AK, Pal D (2011) Development of pH-sensitive tamarind seed polysaccharide–alginate composite beads for controlled diclofenac sodium delivery using response surface methodology. Int J Biol Macromol 49(4):784–793

Li G-Y, Zhong M, Zhou Z-D, Zhong Y-D, Ding P, Huang Y (2011) Formulation optimization of chelerythrine loaded O-carboxymethylchitosan microspheres using response surface methodology. Int J Biol Macromol 49(5):970–978

Lin C-C, Metters AT (2006) Hydrogels in controlled release formulations: Network design and mathematical modeling. Adv Drug Deliv Rev 58(12–13):1379–1408

Dash S, PN Murthy, L Nath, and PJAPP Chowdhury (2010). Kinetic modeling on drug release from controlled drug delivery systems. 67(3), 217–223

Serra L, Doménech J, Peppas NA (2006) Drug transport mechanisms and release kinetics from molecularly designed poly(acrylic acid-g-ethylene glycol) hydrogels. Biomaterials 27(31):5440–5451

Higuchi T (1963) Mechanism of sustained-action medication Theoretical analysis of rate of release of solid drugs dispersed in solid matrices. J Pharmaceutical Sci 52(12):1145–1149

Ritger PL, Peppas NA (1987) A simple equation for description of solute release I Fickian and non-fickian release from non-swellable devices in the form of slabs, spheres, cylinders or discs. J Controlled Release 5(1):23–36

Siepmann J, Siepmann F (2012) Modeling of diffusion controlled drug delivery. J Control Release 161(2):351–362

Caballero F, Foradada M, Miñarro M, Pérez-Lozano P, García-Montoya E, Ticó JR, Suñé-Negre JM (2014) Characterization of alginate beads loaded with ibuprofen lysine salt and optimization of the preparation method. Int J Pharm 460(1–2):181–188

Korsmeyer RW, Gurny R, Doelker E, Buri P, Peppas NA (1983) Mechanisms of solute release from porous hydrophilic polymers. Int J Pharm 15(1):25–35

Badwan AA, Abumalooh A, Sallam E, Abukalaf A, Jawan O (1985) A Sustained Release Drug Delivery System Using Calcium Alginate Beads. Drug Dev Ind Pharm 11(2–3):239–256

Odeku OA, Okunlola A, Lamprecht A (2013) Microbead design for sustained drug release using four natural gums. Int J Biol Macromol 58:113–120

Manjanna KM, Rajesh KS, Shivakumar B (2013) Formulation and Optimization of Natural Polysaccharide Hydrogel Microbeads of Aceclofenac Sodium for Oral Controlled Drug Delivery. Am J Medical Sci Medicine 1(1):5–17

Angadi SC, Manjeshwar LS, Aminabhavi TM (2012) Novel composite blend microbeads of sodium alginate coated with chitosan for controlled release of amoxicillin. Int J Biol Macromol 51(1–2):45–55

Patel YL, Sher P, Pawar AP (2006) The effect of drug concentration and curing time on processing and properties of calcium alginate beads containing metronidazole by response surface methodology. AAPS PharmSciTech 7(4):E24–E30

Murata Y, Sasaki N, Miyamoto E, Kawashima S (2000) Use of floating alginate gel beads for stomach-specific drug delivery. Eur J Pharm Biopharm 50(2):221–226

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they do not have any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharifi, E., Rahbar Shahrouzi, J., Jafarizadeh-Malmiri, H. et al. Optimization of microencapsulation of metronidazole in alginate microbeads for purpose of controlled release. Polym. Bull. 79, 8883–8903 (2022). https://doi.org/10.1007/s00289-021-03933-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03933-1