Abstract

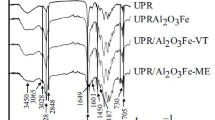

Composites based on poly(methyl methacrylate), dimethyl itaconate matrix and alumina particles were prepared. Ferrous oxide-doped alumina particles (Al2O3 Fe) and commercial alumina nanoparticles (Al2O3 n) modified with (3-aminopropyl)trimethoxysilane (AM) and methyl esters of linseed oil fatty acids (biodiesel—BD) were used as reinforcement. The mechanical properties of the prepared composites, containing 1, 3 and 5 wt% of surface-modified alumina particles, are compared to a neat polymer matrix. The particles were characterized by single-beam Fourier transform infrared spectroscopy, thermogravimetry and differential scanning calorimetry. The mechanical properties of the composites were determined by micro-Vickers hardness and impact testing. The morphology of the surface of the composites exposed to cavitation was observed through a field emission scanning electron microscope. AFM analysis was used to compare surface features seen using the SEM and to interpret the surface degradation properties. The hardness, cavitation resistance and high-impact energy resistance of the composites are better in the case of AM surface modification of alumina fillers, but biodiesel modified particles have comparable mechanical properties and a stabilized Al–O–Si bond that could be important when a composite is exposed to humidity or a wet environment.

Similar content being viewed by others

References

Frazer RQ, Byron RT, Osborne PB, West KP (2005) PMMA: an essential material in medicine and dentistry. J Long Term Eff Med Implants 15:629–639

Bhola R, Bhola SM, Liang H, Mishra B (2010) Biocompatible denture polymers—a review. Trends Biomater Artif Organs 23:129–136

Park SE, Chao M, Raj PA (2009) Mechanical properties of surface-charged poly(methyl methacrylate) as denture resins. Int J Dent 2009:1–6

Ali U, Bt. Abd Karim KJ, Buang NA (2015) A Review of the properties and applications of poly (Methyl Methacrylate) (PMMA). J Polym Rev 55:678–705

Domínguez Almaraza GM, Gutiérrez Martínez A, Hernández Sánchez R, Correa Gómeza E, Guzmán Tapia M, Verduzco Juárez JC (2017) Ultrasonic fatigue testing on the polymeric material PMMA, used in odontology applications. Proc Struct Integr 3:562–570

Spasojevic P, Zrilic M, Panic V, Stamenkovic D, Seslija S, Velickovic S (2015) The mechanical properties of a poly(methyl methacrylate)denture base material modified with dimethyl itaconate and di-n-butyl itaconate. Int J Polym Sci 2015:1–9

Veličković J, Vasović S (1972) Kuhn–Mark–Houwink–Sakurada relations and unperturbed dimensions of poly(di-n-alkyl itaconates). Die Makromolekulare Chemie 153:207–218

Fernandez-Garcia M, De La Fuente JL, Madruga EL (2001) Thermal behaviour of poly(dimethyl itaconate) and poly(di-n-butyl itaconate) copolymerized with methyl methacrylate. Polym Eng Sci 41:1616–1625

Ahmed Ben Hasan S, Dimitrijević MM, Kojović A, Stojanović DB, Obradović-Đuričić K, Jančić-Heinemann RM, Aleksić R (2014) The effect of alumina nano fillers size and shape on mechanical behaviour of PMMA matrix composite. J Serb Chem Soc 79:1–19

Cordier A, Peigney A, De Grave E, Flahaut E, Laurent C (2006) Synthesis of the metastable a-Al1.8Fe0.2O3 solid solution from precursors prepared by combustion. J Eur Ceram Soc 26:3099–3111

Ashor AA, Vuksanović MM, Tomić NZ, Marinković A, Jančić Heinemann R (2018) The influence of alumina particle modification on the adhesion of the polyacrylate matrix composite films and the metal substrate. Compos Interface. https://doi.org/10.1080/09276440.2018.1506240

Algellai AA, Vuksanovic MM, Tomic NZ, Marinkovic AD, Obradovic-Djuricic K, Radojevic VJ, Jancic-Heinemann RM (2018) The implementation of image analysis for the visualization of adhesion assessment of a composite film. Mater Lett 227:25–28

Dimitrijevic MM, Dojčinović M, Trifunović D, Volkov-Husovic T, Jancic Hainneman R (2016) Comparison of morphological parameters of ceramic materials surface damage exposed to thermal shock and cavitation erosion. Sci Sinter 49:371–377

Vuksanović MM, Gajić-Kvaščev M, Dojčinović M, Volkov Husović T, Jančić Heinemann R (2018) New surface characterization tools for alumina based refractory material exposed to cavitation—image analysis and pattern recognition approach. Mater Charact 144:113–119

Lazouzi GA, Vuksanović MM, Tomić N, Petrović M, Spasojević P, Radojević V, Jančić Heinemann R (2018) Dimethyl itaconate modified PMMA—alumina fillers composites with improved mechanical properties. Polym Compos. https://doi.org/10.1002/pc.24952

Algellai AA, Vuksanovic MM, Tomić N, Marinković A, Dojčinović M, Volkov-Husović T, Jančić Heinemann R (2018) Improvement of cavitation resistance of composite films using functionalized alumina particles. Hem Ind 72:205–213

Lazouzi G, Vuksanović MM, Tomić NZ, Mitrić M, Petrović M, Radojević V, Jančić Hainemann R (2018) Optimized preparation of alumina based fillers for tuning composite properties. Ceram Int 44:7442–7449

ASTM E384 - 16, ASTM E384 - 16 - Stand. Test Method Micro indentation. Hardness Mater. 201528

Standard Method of Vibratory Cavitation Erosion Test (1992) G32-92, Annual Book of ASTM Standards, Vol. 03.02. ASTM, Philadelphia

Obradović V, Stojanović DB, Živković I, Radojević V, Uskoković PS, Aleksić R (2015) Dynamic mechanical and impact properties of composites reinforced with carbon nanotubes. Fiber Polym 16:138–145

Zec J, Tomić NZ, Zrilić M, Lević S, Marinković A, Jančić Heinemann R (2018) Optimization of Al2O3 particle modification and UHMWPE fiber oxidation of EVA based hybrid composites: compatibility, morphological and mechanical properties. Compos Part B Eng 153:36–48

Algellai AA, Tomić N, Vuksanovic MM, Dojčinović M, Volkov-Husović T, Radojević V, Jančić Hainemann R (2018) Adhesion testing of composites based on Bis-GMA/TEGDMA monomers reinforced with alumina-based fillers on brass substrate. Compos Part B Eng 140:164–173

Elia P, Nativ-Roth E, Zeiri Y, Porat Z (2016) Determination of the average pore-size and total porosity in porous silicon layers by image processing of SEM micrographs. Micropor Mesopor Mater 225:465–471

Dojcinovic MB, Volkov-Husovic TD (2008) Cavitation damage of the medium carbon steel: implementation of image analysis. Mater Lett 62:953–956

Acknowledgements

This research was funded by the Ministry of Education, Science and Technological Development of the Republic of Serbia, under Project TR34011.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ashor, A.A., Vuksanović, M.M., Tomić, N.Z. et al. Optimization of modifier deposition on the alumina surface to enhance mechanical properties and cavitation resistance. Polym. Bull. 77, 3603–3620 (2020). https://doi.org/10.1007/s00289-019-02923-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02923-8