Abstract

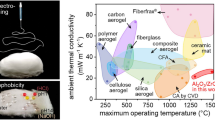

The aim of this research is to reduce the number of defects caused by the hydrophobicity of silica aerogel (SA) in the interfacial transition zone formed by this solid aggregate and a liquid binder in an alternative construction composite (paste). A new technique for controlling compatibility issues has been developed by modifying the chemicals and physical properties involved, evaluating two surfactants that function as elements that increase adhesion strength. The characteristics of wettability and free surface energy are beneficial for macroscopic morphology, microscopic structure, porosity, pore size, and physisorption, and they influence the mechanical and thermal properties of the composites. The contact angle shows that the composites obtained with the smallest SA particle size modify the wettability of the composite, increasing the contact angle to 136°, thus approaching the limit of superhydrophobic surfaces. Conversely, the composites with the large SA particles sizes decrease the angle to 94°, approaching the hydrophilic limit. The copolymer (COP) is the most efficient surfactant, achieving high surface energies, sometimes doubling those of composites integrated with only SA. Microscopy images show the presence of additional compact and homogeneous composites, with few separations and cracks. Additionally, the porosity increases to a total pore volume of 0.3376 cm3/g, and the specimen has an average pore size of 26.576 nm and a surface area of 50.811 m2/g. The compounds modified with the copolymer A3100COP and A3110COP and those modified with A3100S and silane (S) achieve great efficiency, with a mechanical strength of 5.19 MPa and a thermal conductivity of 0.141 W/(m·K) after 28 days.

Similar content being viewed by others

Data Availability

No datasets were generated or analysed during the current study.

References

Pedroso M, Flores-Colen I, Silvestre JD, Gomes MG, Silva L, Ilharco L (2020) “Physical, mechanical, and microstructural characterisation of an innovative thermal insulating render incorporating silica aerogel. Energy Build 211:109793. https://doi.org/10.1016/j.enbuild.2020.109793

Lu J, Jiang J, Lu Z, Li J, Niu Y, Yang Y (2020) Pore structure and hardened properties of aerogel/cement composites based on nanosilica and surface modification. Constr Build Mater 245:118434. https://doi.org/10.1016/j.conbuildmat.2020.118434

Kueh A, Razali A, Lee Y, Hamdan S, Yakub I, Suhaili N (2023) Acoustical and mechanical characteristics of mortars with pineapple leaf fiber and silica aerogel infills – Measurement and modeling. Mater Today Commun 35:105540. https://doi.org/10.1016/j.mtcomm.2023.105540

Buratti C, Merli F, Moretti E (2017) Aerogel-based materials for building applications: Influence of granule size on thermal and acoustic performance. Energy Build 152:472–482. https://doi.org/10.1016/j.enbuild.2017.07.071

Ślosarczyk A, Vashchuk A, Klapiszewski Ł (2022) Research development in silica aerogel incorporated cementitious composites—a review. Polymers (Basel) 14(7):1456. https://doi.org/10.3390/polym14071456

Liu X et al (2023) Insight into pyrolysis of hydrophobic silica aerogels: Kinetics, reaction mechanism and effect on the aerogels. Chin J Chem Eng 58:266–281. https://doi.org/10.1016/j.cjche.2022.10.018

Wan Y, Wang J, Li Z (2023) Effect of modified SiO2 aerogel on the properties of inorganic cementing materials. Mater Lett 341:134217. https://doi.org/10.1016/j.matlet.2023.134217

Raoufi F, Ranjbar Z, Rategar S, Nowak E, Nazari B (2019) Wettability study of super-hydrophobic silica aerogel powders. [Online]. Available: https://pccc.icrc.ac.ir/article_81597_8b3726d10c20e10ecbea26730aa97644.pdf. Accessed 20 Dec 2023

Fickler S, Milow B, Ratke L, Schnellenbach-Held M, Welsch T (2015) Development of high performance aerogel concrete. Energy Procedia 78:406–411. https://doi.org/10.1016/j.egypro.2015.11.684

Zhou G, Xu Z (2023) 3D mesoscale investigation on the compressive fracture of concrete with different aggregate shapes and interface transition zones. Constr Build Mater 393:132111. https://doi.org/10.1016/j.conbuildmat.2023.132111

Aminoroaya A, Bagheri R, Khorasani SN, Talebi Z, Derakhshanfar P, Neisiany RE (2022) Mesoporous silica aerogel reinforced dental composite: Effects of microstructure and surface modification. J Mech Behav Biomed Mater 125:104947. https://doi.org/10.1016/j.jmbbm.2021.104947

Adhikary SK, Rudžionis Ž, Tučkutė S (2022) Characterization of novel lightweight self-compacting cement composites with incorporated expanded glass, aerogel, zeolite and fly ash. Case Stud Constr Mater 16:e00879. https://doi.org/10.1016/j.cscm.2022.e00879

de FátimaJúlio M, Soares A, Ilharco LM, Flores-Colen I, de Brito J (2016) Aerogel-based renders with lightweight aggregates: Correlation between molecular/pore structure and performance. Constr Build Mater 124:485–495. https://doi.org/10.1016/j.conbuildmat.2016.07.103

Dang C, Wang X, Li H, Yin L, Song M (2023) Study on droplet wettability of low surface tension working medium based on special-shaped microstructure surface. Colloids Surf C Environ Aspects 1:100001. https://doi.org/10.1016/j.colsuc.2023.100001

Parale VG, Mahadik DB, Mahadik SA, Kavale MS, Venkateswara Rao A, Wagh PB (2012) Wettability study of surface modified silica aerogels with different silylating agents. J Solgel Sci Technol 63(3):573–579. https://doi.org/10.1007/s10971-012-2788-5

Tian J, Shafi S, Tan H, Zhao Y (2020) Mechanical and thermal-insulating performance of silica aerogel enhanced jointly with glass fiber and fumed silica by a facile compressing technique. Chem Phys Lett 739:136950. https://doi.org/10.1016/j.cplett.2019.136950

Anagnostopoulos A, Navarro ME, Ding Y (2022) Microstructural improvement of solar salt based MgO composites through surface tension/wettability modification with SiO2 nanoparticles. Sol Energy Mater Sol Cells 238:111577. https://doi.org/10.1016/j.solmat.2022.111577

Starinskiy S et al (2023) Spreading of impacting water droplet on surface with fixed microstructure and different wetting from superhydrophilicity to superhydrophobicity. Water (Basel) 15(4):719. https://doi.org/10.3390/w15040719

Dawson J et al (2023) Dynamics of droplets impacting on aerogel, Liquid infused, and liquid-like solid surfaces. ACS Appl Mater Interfaces 15(1):2301–2312. https://doi.org/10.1021/acsami.2c14483

Brumaud C et al (2013) Cellulose ethers and water retention. Cem Concr Res 53:176–184. https://doi.org/10.1016/j.conbuildmat.2020.118434

Rangappa SM, Parameswaranpillai J, Yorseng K, Pulikkalparambil H, Siengchin S (2021) Toughened bioepoxy blends and composites based on poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol) triblock copolymer and sisal fiber fabrics: A new approach. Constr Build Mater 271:121843. https://doi.org/10.1016/j.cemconres.2013.06.010

González-López JR, Guerra-Cossío MA, Figueroa-Torres MZ, Zaldívar-Cadena AA, Valdez-Cano R (2023) Effect of adding silica fume, Calcium carbonate or silicon carbide on the properties of an alternative binder based on anhydrite and blast furnace slag. Silicon 15(5):2211–2220. https://doi.org/10.1016/j.cscm.2023.e02312

Cabot Corporation, “No Title,” https://www.cabotcorp.com/, 2021. https://www.cabotcorp.com/solutions/products-plus/aerogel/particles. (accessed Nov. 08, 2023)

Liu S, Zhu K, Cui S, Shen X, Tan G (2018) A novel building material with low thermal conductivity: Rapid synthesis of foam concrete reinforced silica aerogel and energy performance simulation. Energy Build 177:385–393. https://doi.org/10.1016/j.enbuild.2018.08.014

Valdez-Cano R, González-López JR, Guerra-Cossío MA (2023) Effects on the mechanical and thermal behaviors of an alternative mortar when adding modified silica aerogel with aminopropyl triethoxysilane and PEG-PPG-PEG triblock copolymer additives. Silicon 15(12):5353–5366. https://doi.org/10.1007/s12633-023-02445-z

ASTM (2013) Standard specification for slag cement for use in concrete and mortars. ASTM Standards, 44, pp 1–8. https://doi.org/10.1016/j.enbuild.2018.08.014

Guerra-Cossío MA (2020) Desarrollo de las propiedades térmicas de un material ligero aireado a base de anhidrita y escoria de alto horno.,” Universidad Autónoma de Nuevo León, 2020. http://eprints.uanl.mx/view/creators/Guerra_Coss=EDo=3AMiguel_=C1ngel=3A=3A.html

American Society of Testing and Materials(2000) ASTM C1240 – 05 Standard Specification for silica fume used in cementitious mixtures. ASTM International, 4,(2):1–6, 2000, https://www.astm.org/c1240-20.html

Sigma-Aldrich Química S, de RL, de CV (2023) Poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol).” [Online]. Available: https://www.sigmaaldrich.com/MX/es/product/aldrich/435465?gclid=Cj0KCQjwma6TBhDIARIsAOKuANxlUXGWjIJa66vhlw-qPVs8QkgF--7bgT8ysvr37-06NOR_qEMeXaMaAg4_EALw_wcB (accessed Nov. 29, 2023)

Sigma-Aldrich Química S, de RL, de CV (2023) Triethoxysilane.” [Online]. Available: https://www.sigmaaldrich.com/MX/en/search/440140-100ml?focus=products&page=1&perPage=30&sort=relevance&term=440140-100ml&type=product#. (accessed Nov. 29, 2023)

Ebnesaajjad S (2014) Surface treatment of materials for adhesive bonding, Elsevier. https://doi.org/10.1016/C2013-0-12914-5

ASTM (2010) Standard test method for compressive strength of hydraulic cement mortars ( Using 2-in . or [ 50-mm ] Cube Specimens ) 1. Chemical Analysis, no. C109/C109M – 11b, pp 1–9, 2010, https://doi.org/10.1520/C0109_C0109M-20

Tempos thermal properties analyzer (2023) [Online]. Available: https://www.metergroup.com/en/meter-environment/products/tempos-thermal-properties-analyzer, (accessed nov. 8, 2023)

ASTM, “D 5334–14 Standard test method for determination of thermal conductivity of soil and soft rock by thermal needle probe procedure. Annual Book of ASTM Standards, vol. 04(November):6–13, 2011, https://doi.org/10.1520/D5334-22A

A. International ASTM C305–06: Standard practice for mechanical mixing of hydraulic cement pastes and mortars of plastic consistency. Annual Book of ASTM Standard. https://doi.org/10.1520/C0305-06

American Society for Testing and Materials (2019) ASTM C31–19_Standard practice for making and curing concrete test specimens in the field. ASTM International 04:1–5. https://doi.org/10.1520/C0031_C0031M-22

Acknowledgements

The authors acknowledge the Consejo Nacional de Ciencia y Tecnología and the Instituto de Ingeniería Civil of the Universidad Autónoma de Nuevo León, for the support and facilities granted for the development of laboratory tests necessary for this research project.

Funding

This work was supported by CONACYT through a scholarship granted to R. Valdez-Cano.

Author information

Authors and Affiliations

Contributions

Valdez-Cano: Conceptualization, methodology, Investigation, supervision, Writing-original draft preparation, Writing-reviewing and editing; Gonzalez-Lopez: Conceptualization, methodology, Resources; De-Los-Santos: Methodology, Investigation; Amaya-Gallardo: Validation; Inzunza-Aragón Validation; Mendoza-Rangel: Writing- Reviewing and Editing; Díaz-Aguilera: Writing- Reviewing and Editing.

Corresponding author

Ethics declarations

Ethical Approval

The authors have complied with ethical standards.

Consent for Participation and Publication

Consent was obtained from all the authors for the publication of this manuscript.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Valdez-Cano, R., Gonzalez-Lopez, J.R., De-Los-Santos, E.U. et al. Physicochemical Characterization of Interfacial Defect Reduction in Superficially Modified Hydrophobic SiO2-Aerogel Composites. Silicon (2024). https://doi.org/10.1007/s12633-024-02978-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12633-024-02978-x