Abstract

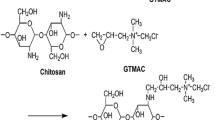

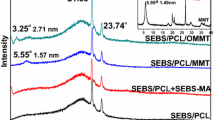

Sodium humate was oxidized with nitric acid to obtain fulvic acid (FA), which was further quaternized to obtain quaternary fulvic acid (QFA). QFA-intercalated saponite (QFA-saponite) was prepared ultrasonically. Thermoplastic poly(lactic acid) (PLA)/quaternary fulvic acid-intercalated saponite nanocomposites were prepared by melt intercalation technique. The morphology and dispersion of QFA-saponite were investigated by X-ray diffraction, scanning electron microscopy, and transmission electron microscopy. Mechanical properties, thermal stability and crystallization behavior of PLA/QFA-saponite nanocomposites were also tested. Results showed a predominantly flocculated structure and partially intercalated morphology for QFA-saponite. Mechanical testing and thermogravimetric analysis showed that the tensile strength, impact properties, and thermostability of PLA/QFA-saponite nanocomposites improved significantly compared to pure PLA. Differential scanning calorimetry results showed that crystallinity of PLA increased from 22.5 to 68.3 % on addition of QFA-saponite. Polarized optical microscopy showed QFA-saponite as a nucleating agent for PLA that enhanced its crystallization rate. Rotational rheological behaviors of PLA/QFA-saponite nanocomposites demonstrated that incorporation of QFA-saponite increased rigidity of the network structure in PLA matrix.

Similar content being viewed by others

References

Yu L, Dean K, Li L (2006) Polymer blends and composites from renewable resources. Prog Polyme Sci 6:576–602

Wang L, Cheng S, Zhuo R (2014) Syntheses and properties of novel copolymers of polycaprolactone and aliphatic polycarbonate based on ketal-protected dihydroxyacetone. Polym Bull 1:47–56

Dadbin S, Naimian F, Akhavan A (2011) Poly (lactic acid)/layered silicate nanocomposite films: morphology, mechanical properties, and effects of γ-radiation. J Appl Polym Sci 1:142–149

Perego G, Cella GD, Bastioli C (1996) Effect of molecular weight and crystallinity on poly (lactic acid) mechanical properties. J Appl Polym Sci 1:37–43

Gattin R, Copinet A, Bertrand C, Coutuier Y (2003) Biodegradation study of a coextruded starch and poly (lactic acid) material in various media. J Appl Polym Sci 3:825–831

Ali F, Chang YW, Kang SC, Yoon Yong J (2009) Thermal, mechanical and rheological properties of poly (lactic acid)/epoxidized soybean oil blends. Polym Bull 1:91–98

Harris AM, Lee EC (2008) Improving mechanical performance of injection molded PLA by controlling crystallinity. J Appl Polym Sci 107:2246–2255

Yuan Y, Ruckenstein E (1998) Polyurethane toughened polylactide. Polym Bull 4–5:485–490

Picard E, Espuche E, Fulchiron R (2011) Effect of an organo-modified montmorillonite on PLA crystallization and gas barrier properties. Appl Clay Sci 1:58–65

Su ZZ, Guo WH, Liu YJ, Li QY, Wu CF (2009) Non-isothermal crystallization kinetics of poly (lactic acid)/modified carbon black composite. Polym Bull 5:629–642

Nunez K, Rosales C, Perera R, Villarreal N, Pastor JM (2011) Nanocomposites of PLA/PP blends based on sepiolite. Polym Bull 9:1991–2016

Ahmadi SJ, Huang YD, Li W (2004) Synthetic routes, properties and future applications of polymer-layered silicate nanocomposites. J Mater Sci 39:1919–1925

Shen Z, Simon GP, Cheng YB (2002) Comparison of solution intercalation and melt intercalation of polymer–clay nanocomposites. Polymer 15:4251–4260

Pandey JK, Raghunatha Reddy K, Pratheep Kumar A, Sinch RP (2005) An overview on the degradability of polymer nanocomposites. Polym Degrad Stabil 2:234–250

Su XF, Zhang G, Xu K, Wang CL, Wang PX (2008) The effect of MMT/modified MMT on the structure and performance of the superabsorbent composite. Polym Bull 1:69–78

Paul MA, Alexandre M, Degee P, Henrist C, Rulmont A, Dubois P (2003) New nanocomposite materials based on plasticized poly (l-lactide) and organo-modified montmorillonites: thermal and morphological study. Polymer 2:443–450

Leu YY, Mohd Ishak ZA, Chow WS (2012) Mechanical, thermal, and morphological properties of injection molded poly (lactic acid)/SEBS-g-MAH/organo-montmorillonite nanocomposites. J Appl Polym Sci 2:1200–1207

Lee JW, Lim YT, Park OO (2000) Thermal characteristics of organoclay and their effects upon the formation of polypropylene/organoclay nanocomposites. Polym Bull 2:191–198

Katti KS, Sikdar D, Katti DR, Ghosh P, Verna D (2006) Molecular interactions in intercalated organically modified clay and clay-polycaprolactam nanocomposites: experiments and modeling. Polymer 1:403–414

Hayes MHB, Clapp CE (2001) Humic substances: considerations of compositions, aspects of structure, and environmental influences. Soil Sci 11:723–737

MacCarthy P (2001) The principles of humic substances. Soil Sci 11:738–751

Stevenson IL, Schnitzer M (1982) Transmission electron microscopy of extracted fulvic and humic acids 1. Soil Sci 3:179–185

Gondar D, Lopez R, Fiol S, Antelo JM, Arce F (2005) Characterization and acid–base properties of fulvic and humic acids isolated from two horizons of an ombrotrophic peat bog. Geoderma 3:367–374

Sierra MMD, Giovanela M, Parlanti E, SorianoSierra EJ (2005) Fluorescence fingerprint of fulvic and humic acids from varied origins as viewed by single-scan and excitation/emission matrix techniques. Chemosphere 6:715–733

Islam KMS, Schuhmacher A, Gropp JM (2005) Humic acid substances in animal agriculture. Pakistan J Nutr 3:126–134

Trckova M, Matlova L, Hudcova H, Faldyna M, Zraly Z, Dvorska L, Beran V, Pavlik I (2005) Peat as a feed supplement for animals: a review. Vet Med 50:361–377

Van Rensburg CEJ, Malfeld SCK, Dekker J (2001) Topical application of oxifulvic acid suppresses the cutaneous immune response in mice. Drug Develop Res 1:29–32

Lagaly G, Dekany I (2005) Adsorption on hydrophobized surfaces: clusters and self-organization. Adv Colloid Interface Sci 114–115:189–204

Brown JM, Curliss D, Vaia RA (2000) Thermoset-layered silicate nanocomposites. Quaternary ammonium montmorillonite with primary diamine cured epoxies. Chem Mater 12:3376–3384

Li Y, Ishida H (2003) Concentration-dependent conformation of alkyl tail in the nanoconfined space: hexadecylamine in the silicate galleries. Langmuir 6:2479–2484

Tsou CH, Suen MC, Yao WH, Yeh JT, Wu CS, Tsou CY, Chiu SH, Chen JC, Wang RY, Lin SM, Hung WS, Guzman MD, Hu CC, Lee KR (2014) Preparation and characterization of bioplastic-based green renewable composites from tapioca with acetyl tributyl citrate as a plasticizer. Materials 8:5617–5632

Jia QM, Zheng M, Chen HX, Shen RJ (2005) Synthesis and characterization of polyurethane/epoxy interpenetrating network nanocomposites with organoclays. Polym Bull 1–2:65–73

LeBaron PC, Wang Z, Pinnavaia TJ (1999) Polymer-layered silicate nanocomposites: an overview. J Appl Clay Sci 15:11–29

Mathew AP, Oksman K, Sain M (2005) Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose (MCC). J Appl Polym Sci 97:2014–2025

Aslzadeh MM, Abdouss M, Sadeghi GMM (2013) Preparation and characterization of new flame retardant polyurethane composite and nanocomposite. J Appl Polym Sci 3:1683–1690

Barick AK, Tripathy DK (2010) Preparation and characterization of thermoplastic polyurethane/organoclay nanocomposites by melt intercalation technique: effect of nanoclay on morphology, mechanical, thermal, and rheological properties. J Appl Polym Sci 2:639–654

Cheng S, Lau K, Liu T, Zhao YQ, Lam PM, Yin YS (2009) Mechanical and thermal properties of chicken feather fiber/PLA green composites. Composites Part B: Eng 40:650–654

Chow WS, Lok SK (2009) Thermal properties of poly (lactic acid)/organo-montmorillonite nanocomposites. J Therm Anal Calorim 95:627–632

Song P, Chen GY, Wei ZY, Zhang WX, Liang JC (2012) Rapid crystallization of poly (l-lactic acid) induced by a nanoscaled zinc citrate complex as nucleating agent. Polymer 19:4300–4309

Lopez RG, Trevino ME, Salazar LV, Peralta RD, Becerra F, Puig JE, Mendizabal E (1997) Polymerization of vinyl acetate in ternary microemulsions stabilized with hexadecyltrimethylammonium bromide. Polym Bull 4:411–417

Sathe SN, Devi S, Srinivasa Rao GS, Rao KV (1996) Relationship between morphology and mechanical properties of binary and compatibilized ternary blends of polypropylene and nylon 6. J Appl Polym Sci 61:97–107

Sathe SN, Srinivasa Rao GS, Rao KV, Devi S (1996) The effect of composition on morphological, thermal, and mechanical properties of polypropylene/nylon-6/polypropylene-g-butyl acrylate blends. J Eng Sci 36:2443–2450

Li B, Dong FX, Wang XL, Yang J, Wang DY, Wang YZ (2009) Organically modified rectorite toughened poly (lactic acid): nanostructures, crystallization and mechanical properties. Euro Polym J 11:2996–3003

Chow WS, Neoh SS (2009) Mechanical, morphological and thermal properties of polycarbonate/SEBS-G-MA/montmorillonite nanocomposites. Polym-Plast Technol Eng 49:62–68

Ray SS, Yamada K, Okamoto M, Ueda K (2003) Control of biodegradability of polylactide via nanocomposite technology. Macromol Mater Eng 3:203–208

Pluta M, Jeszka JK, Boiteux G (2007) Polylactide/montmorillonite nanocomposites: structure, dielectric, viscoelastic and thermal properties. Euro Polym J 7:2819–2835

Iannace S, Sabatini G, Ambrosio L, Nicolais L (1995) Mechanical behavior of composite artificial tendons and ligaments. Biomaterials 9:675–680

Ray SS, Okamoto M (2003) Biodegradable polylactide and its nanocomposites: opening a new dimension for plastics and composites. Macromol Rapid Commun 14:815–840

Lertwimolnun W, Vergnes B (2005) Influence of compatibilizer and processing conditions on the dispersion of nanoclay in a polypropylene matrix. Polymer 10:3462–3471

Acknowledgments

We greatly appreciate that this work is financially supported by National Science Foundation of China (51163013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhen, W., Wang, W. Structure, properties and rheological behavior of thermoplastic poly(lactic acid)/quaternary fulvic acid-intercalated saponite nanocomposites. Polym. Bull. 73, 1015–1035 (2016). https://doi.org/10.1007/s00289-015-1532-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-015-1532-z