Abstract

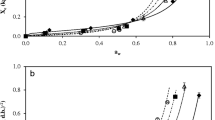

Water sorption isotherms from 5 up to 65 °C and air drying kinetics at 35, 45 and 55 °C of Mastocarpus stellatus seaweed were determined. Experimental sorption data were modelled using BET and Oswin models. A four-parameter model, based on Oswin model, was proposed to estimate equilibrium moisture content as function of water activity and temperature simultaneously. Drying experiments showed that water removal rate increased significantly with temperature from 35 to 45 °C, but at higher temperatures drying rate remained constant. Some chemical modifications of the hybrid carrageenans present in the seaweed can be responsible of this unexpected thermal trend. Experimental drying data were modelled using two-parameter Page model (n, k). Page parameter n was constant (1.31 ± 0.10) at tested temperatures, but k varied significantly with drying temperature (from 18.5 ± 0.2 10−3 min-n at 35 °C up to 28.4 ± 0.8 10−3 min-n at 45 and 55 °C). Drying experiments allowed the determination of the critical moisture content of seaweed (0.87 ± 0.06 kg water (kg d.b.)−1). A diffusional model considering slab geometry was employed to determine the effective diffusion coefficient of water during the falling rate period at different temperatures.

Similar content being viewed by others

References

van de Velde F (2008) Structure and function of hybrid carrageenans. Food Hydrocolloid 22:727–734

van de Velde F, Antipova AS, Rollema HS, Burova TV, Grinberg NV, Pereira L, Gilsenan PM, Tromp RH, Rudolph B, Grinberg VY (2005) The structure of k/i-hybrid carrageenans II. Coil-helix transition as a function of chain composition. Carbohydr Res 340:1113–1129

Necas J, Bartosikova L (2013) Carrageenan: a review. Veterinarni Medicina 58:187–205

Kanmani P, Rihm J-W (2014) Properties and characterization of bionanocomposite films prepared with various biopolymers and ZnO nanoparticles. Carbohyd Polym 106:190–199

Liang W, Mao X, Peng X, Tang S (2014) Effects of sulfate group in red seaweed polysaccharides on anticoagulant activity and cytotoxicity. Carbohyd Polym 101:776–785

Lefnaoui S, Moulai-Mostefa N (2015) Polyelectrolyte complex based on carboxymethyl-kappa-carrageenan and Eudragit RL 30D as prospective carriers for sustained drug delivery. Chem Eng Res Des 97:165–174

Prajapati VD, Maheriya PM, Jani GK, Solanki HK (2014) Carrageenan: a natural seaweed polysaccharide and its applications. Carbohydr Polym 105:97–112

Liu J, Zhan X, Wan J, Wang Y, Wang C (2015) Review for carrageenan-based pharmaceutical biomaterials: Favourable physical features versus adverse biological effects. Carbohyd Polym 121:27–36

Bixler HJ, Porse H (2011) A decade of change in the seaweed hydrocolloids industry. J Appl Phycol 23:321–335

Azevedo G, Torres MD, Sousa-Pinto I, Hilliou L (2015) Effect of pre-extraction alkali treatment on the chemical structure and gelling properties of extracted hybrid carrageenan from Chondrus crispus and Ahnfeltiopsis devoniensis. Food Hydrocolloid 50:150–158

Pereira L, van de Velde F (2011) Portuguese carrageenophytes: carrageenan composition and geographic distribution of eight species (Gigartinales Rhodophyta). Carbohydr Polym 84:614–623

Abreu MH, Pereira R, Yarish C, Buschmann AH, Sousa-Pinto I (2011) IMTA with Gracilaria vermiculophylla: productivity and nutrient removal performance of the seaweed in a land-based pilot scale system. Aquaculture 312:77–87

Hung LD, Hori K, Nang HQ, Kha T, Hoa LT (2008) Seasonal changes in growth rate, carrageenan yield and lectin content in the red alga Kappaphycus alvarezii cultivated in Camranh Bay, Vietnam. J Appl Phycol 21:265–272

Mendoza WG, Montaño MNE, Ganzon-Fortes ET, Villanueva RD (2002) Chemical and gelling profile of ice-ice infected carrageenan from Kappaphycus striatum (Schmitz) Doty “sacol” strain (Solieriaceae, Gigartinales, Rhodophyta). J Appl Phycol 14:409–418

Mujumdar AS (2006) Handbook of industrial drying. CRC Press, Boca Raton

Doymaz I (2016) Drying kinetics, rehydration and colour characteristics of convective hot-air drying of carrot slices. Heat Mass Transf. doi:10.1007/s00231-016-1796-3

Moreira R, Chenlo F, Torres MD (2016) Gelling characteristics and rheology of kappa/iota-hybrid carrageenans extracted from Mastocarpus stellatus dried at different temperatures. J Appl Phycol. doi:10.1007/s10811-016-0879-3

Moreira R, Chenlo F, Torres MD, Silva C, Prieto DM, Sousa AMM, Hillou L, Gonçalves MP (2011) Drying kinetics of biofilms obtained from chestnut starch and carrageenan with and without glycerol. Dry Technol 29:1058–1065

Lemus RA, Pérez M, Andrés A, Roco T, Tello CM, Vega A (2008) Kinetic study of dehydration and desorption isotherms of red alga Gracilaria. LWT-Food Sci Technol 41:1592–1599

Fudholi A, Sopian K, Othman MY, Ruslan MH (2014) Energy and exergy analyses of solar drying system of red seaweed. Energ Buildings 68:121–129

Barbosa-Cánovas GV, Vega-Mercado H (1996) Dehydration of foods. Springer, Netherlands

Imeson A (2010) Food stabilisers, thickeners and gelling agents. Wiley-Blackwell, United Kingdom

Bell LN, Labuza TP (2000) Moisture sorption: practical aspects of isotherm measurement and use. American Association of Cereal Chemists, Minnesota

Greenspan L (1977) Humidity fixed points of binary saturated aqueous solutions. J Re Natl Stand 81:89–102

Labuza TP, Knnane A, Chen JY (1985) Effect of temperature on the moisture sorption isotherm and water activity shift of two dehydrated foods. J Food Sci 50:385–392

AOAC (1995) Official methods of analysis of AOAC international. Association of Official Analytical Chemists, Washington

Brunauer S, Deming L, Deming W, Teller E (1940) On a theory of the van der Waals adsorption of gases. J Am Chem Soc 62:1723–1732

Oswin CR (1946) The kinetics of package life III. The isotherm. J Chem Ind 65:419–421

Moreira R, Chenlo F, Sineiro J, Arufe S, Sexto S (2016) Water sorption isotherms and air drying kinetics of Fucus vesiculosus Brown seaweed. J Food Process Preserv. doi:10.1111/jfpp.12997

Page G (1949) Factors influencing the maximum rates of air drying shelled corn in thin layers. MS Thesis, Purdue University, Purdue

Mayor L, Sereno AM (2004) Modelling shrinkage during convective drying of food materials: a review. J Food Eng 61:373–386

Crank J (1975) The mathematics of diffusion. Clarendon Press, Oxford

Hnini MC, Benchana M, El Hammioui M (2013) Study of the interaction between water and Gelidium sesquipedale (Rhodophyta). Part I: thermodynamic aspect of the sorption equilibrium. J Taiwan Inst Chem Eng 44:795–801

Torres MD, Moreira R, Chenlo F, Vázquez MJ (2012) Water adsorption isotherms of carboxymethyl cellulose, guar, locust bean, tragacanth and xanthan gums. Carbohydr Polym 89:592–598

Williams PA (2007) Handbook of industrial water soluble polymers. Blackwell Publishing Ltd, Oxford

Larotonda FDS, Torres MD, Gonçalves MP, Sereno AM, Hilliou L (2015) Hybrid carrageenan-based formulations for edible film preparation: benchmarking with kappa carrageenan. J Appl Polym Sci. doi:10.1002/APP.42263

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) Reporting physisorption data for gas solid systems with special references to the determination of surface-area and porosity. Pure Appl Chem 57:603–619

Rouquerol J, Rouquerol F, Kenneth SW (1999) Adsorption by powders and porous solids: principles. Methodology and applications. Academic Press, New York

Rizvi S (1986) Thermodynamics of foods in dehydration. In: Rao M, Datta A, Rizvi S (eds) Engineering properties of food. Marcel Dekker, New York, pp 133–214

Fu BA, Chen MQ (2015) Thin-layer drying kinetics of lignite during hot air forced convection. Chem Eng Res Des 102:416–428

Vega-Gálvez A, Tello-Ireland C, Lemus-Mondaca R (2007) Mathematical simulation of drying process of chilean gracilaria (Gracilaria chilensis). Ingeniare Rev chil Ing 15:55–64

Acknowledgements

This work was partly supported by the Ministerio de Economía y Competitividad of Spain and the European Regional Development Funds (ERDF) with the project CTQ-2013-43616/P.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Arufe, S., Torres, M.D., Chenlo, F. et al. Air drying modelling of Mastocarpus stellatus seaweed a source of hybrid carrageenan. Heat Mass Transfer 54, 177–184 (2018). https://doi.org/10.1007/s00231-017-2117-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-2117-1