Abstract

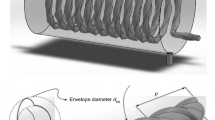

Multi tubes in tube helically coiled heat exchanger is proposed as a compact heat exchanger. Effects of heat exchanger geometric parameters and fluid flow parameters; namely number of inner tubes, annulus hydraulic diameter, Reynolds numbers and input heat flux, on performance of the heat exchanger are experimentally investigated. Different coils with different numbers of inner tubes, namely 1, 3, 4 and 5 tubes, were tested. Results showed that coils with 3 inner tubes have higher values of heat transfer coefficient and compactness parameter (\(\bar{h}\,A_{h}\)). Pressure drop increases with increasing both of Reynolds number and number of inner tubes. Correlations of average Nusselt number were deduced from experimental data in terms of Reynolds number, Prandtl number, Number of inner coils tubes and coil hydraulic diameter. Correlations prediction was compared with experimental data and the comparison was fair enough.

Similar content being viewed by others

Abbreviations

- A c :

-

Annulus cross sectional area of test section (m2)

- Cp:

-

Specific heat of cooling water (J/kg K)

- De :

-

Dean number, dimensionless

- D h :

-

Annulus hydraulic diameter (m)

- D i :

-

Annulus inner diameter (m)

- D o :

-

Annulus outer diameter (m)

- d o :

-

Inner rod heater outside diameter (m)

- \(\bar{h}\) :

-

Average convection heat transfer coefficient (W/m2 K)

- \(\bar{h}\,A_{h}\) :

-

Compactness factor (W/K)

- I :

-

Applied current to rod heater (A)

- k w :

-

Water thermal conductivity (W/m K)

- L :

-

Heater rod length (m)

- \({\dot{\text{m}}}_{\text{w}}\) :

-

Cooling water mass flow rate (kg/s)

- \(\overline{\text{Nu}}\) :

-

Average Nusselt number, dimensionless

- n :

-

Number of inner rod heaters

- Pr :

-

Prandtl number, dimensionless

- Q :

-

Heat transfer rate (W)

- R :

-

Curvature ratio, dimensionless

- Re :

-

Reynolds number, dimensionless

- T s :

-

Average surface temperature of heater rods (°C)

- T si :

-

Average surface temperature of heater rod at inlet of test section (°C)

- T so :

-

Average surface temperature of heater rod at exit of test section (°C)

- T w :

-

Mean temperature of cooling water between inlet and outlet (°C)

- T wi :

-

Cooling water temperature at inlet of test section (°C)

- T wo :

-

Cooling water temperature at exit of test section (°C)

- V :

-

Applied voltage to rod heater (V) dry air

- \(\mathop V\limits^{.}\) :

-

Water volumetric flow rate (m3/s)

- ΔP:

-

Pressure drop (Pa)

- Ρ w :

-

Density of water (kg/m3)

- μ w :

-

Dynamic viscosity of water

References

Dean WR (1927) Note on the motion of fluid in a curved pipe. Philos Mag 20:208–223

Dravid AN, Smith KA, Merrill EW, Brian PLT (1971) Effect of secondary fluid motion on laminar flow heat transfer in helically coiled tubes. AIChE J 17(5):1114–1122

Akiyama M, Cheng KC (1972) Laminar forced convection heat transfer in curved pipes with uniform wall temperature. Int J Heat Mass Transf 15:1426–1431

Kalb CE, Seader JD (1983) Entrance region heat transfer in a uniform wall-temperature helical coil with transition from turbulent to laminar flow. Int J Heat Mass Transf 26(1):23–32

Janssen LAM, Hoogendoorn CJ (1978) Laminar convective heat transfer in helical coiled tubes. Int J Heat Mass Transf 21:1197–1206

Austen DS, Soliman HM (1988) Laminar flow and heat transfer in helically coiled tubes with substantial pitch. Exp Thermal Fluid Sci 1:183–194

Liu S, Masliyah JH (1993) Axially invariant laminar flow in helical pipes with a finite pitch. J Fluid Mech 251(1993):315–353

Liu S, Masliyah JH (1994) Developing convective heat transfer in helical pipes with finite pitch. Int J Heat Fluid Flow 15:66–74

Yamamoto K, Akita T, Ikeuchi H, Kita Y (1995) Experimental study of the flow in a helical circular tube. Fluid Dyn Res 16:237–249

Yamamoto K, Yanase S, Jiang R (1998) Stability of the flow in a helical tube. Fluid Dyn Res 22:153–170

Yang G, Dong F, Ebadian MA (1995) Laminar forced convection in a helicoidal pipe with finite pitch. Int J Heat Mass Transf 38(5):853–862

Xin RC, Ebadian MA (1997) The effects of Prandtl numbers on local and average convective heat transfer characteristic in helical pipes. J Heat Transf 119:467–473

Karahalios GT (1990) Mixed convection flow in a heated curved pipe with core. Phys Fluids A 2:2164–2175

Petrakis MA, Karahalios GT (1996) Technical note: steady flow in a curved pipe with a coaxial core. Int J Numer Methods Fluids 22(12):1231–1237

Xin RC, Awwad A, Dong ZF, Ebadian MA (1997) An experimental study of the single-phase and two-phase flow pressure drop in annular helicoidal pipes. Int J Heat Fluid Flow 18(1997):482–488

Petrakis MA, Karahalios GT (1999) Fluid flow behavior in a curved annular conduit. Int J Non Linear Mech 34(1):13–35

Louw WI (2002) The influence of annular tube contact in a helical-wound tube-in-tube heat exchanger, master in mechanical engineering in the Faculty of Engineering of the Rand Afrikaans University

Rennie TJ (2004) Numerical and experimental studies of a double-pipe helical heat exchanger, Ph.D. dissertation, McGill University, Montreal, Canda

Rennie TJ, Raghavan VGS (2005) Experimental studies of a double-pipe helical heat exchanger. Exp Thermal Fluid Sci 29:919–924

Kumar S, Sharma SM, Nigam KDP (2006) Pressure drop and heat transfer study in tube-in-tube helical heat exchanger. Chem Eng Sci 61:4403–4416

Al Shaer WG (2010) Heat transfer and pressure drop characteristics of multi tubes-in-tube helically coiled heat exchanger, M.SC. thesis, Benha University, Egypt

Holman JP, Gajda WJ (1989) Experimental method for engineering. McGraw Hill, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nada, S.A., El Shaer, W.G. & Huzayyin, A.S. Performance of multi tubes in tube helically coiled as a compact heat exchanger. Heat Mass Transfer 51, 973–982 (2015). https://doi.org/10.1007/s00231-014-1469-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-014-1469-z