Abstract

Silver–water nanofluids used in this paper, has been prepared by a one step method adopting an ultrasound-assisted membrane reaction. Experimental investigations on heat transfer of submerged jet in plate and pin–fin heat sinks were carried out with different concentrations of silver nanofluids. The results indicate that the silver nanoparticles can be uniformly distributed in the base fluid with an average grain size of 4.8 nm. The used surfactant had a great influence on the viscosity of the nanofluids. Compared with the base fluid (water and surfactant), the heat transfer coefficient of the nanofluids, for the same jet velocity, increases in average by 6.23, 9.24 and 17.53 % for the silver nanoparticles weight fractions of 0.02, 0.08 and 0.12 %, respectively. Compared with water, the heat transfer coefficient is enhanced by 6.61 % with a silver nanoparticles weight fraction of 0.12 %. The Nu of pin fin heat sink are obviously higher than that of plate one, at corresponding Re. The exit of nanoparticles can intense internal energy transmission of fluids, and then enhance the heat transfer, while the Re is small.

Similar content being viewed by others

Abbreviations

- d :

-

Diameter of jet (mm)

- D :

-

Diameter of heat transfer surface (mm)

- H :

-

Length of jet (mm)

- H s :

-

Thickness of jet board (mm)

- k :

-

Thermal conductivity (W m−1 K−1)

- L :

-

Characteristic length (mm)

- n :

-

Number of jet hole

- q :

-

Heat flux (W m−2)

- Q v :

-

Volume flow of fluid (ml min−1)

- S :

-

Spacing of jet (mm)

- T w :

-

Mean temperature of heat transfer surface (K)

- T nf :

-

Inlet temperature of nanofluids (K)

- u :

-

Jet velocity (m s−1)

- μ :

-

Fluid dynamic viscosity (Pa s)

- ν nf :

-

Kinematic viscosity of nanofluids (m2 s−1)

- ρ :

-

Fluid density (kg m−3)

- φ m :

-

Particle weight fraction of (%)

- φ v :

-

Particle volume fraction of (%)

- Φ s :

-

Diameter of jet board (mm)

- p:

-

Nanoparticles

- f:

-

Base fluid

- nf:

-

Nanofluids

References

Guo Z (1988) Hot subject of the international heat transfer community—microelectronic cooling. China Sci Found 2:20–25

Choi SUS (1995) Enhancing thermal conductivity of fluid wit hnanoparticles. ASME FED 231:99–105

Xuan YM, Li Q (2000) Heat transfer enhancement of nanofluids. Int J Heat Fluid Flow 21(1):58–64

Patel HE, Das SK, Sundararajan T et al (2003) Thermal conductivity of naked monolayer protected metal nanoparticle based nanofluids: manifestation of anomalous enhancement and chemical effects. Appl Phys Lett 83:2931–2933

Kang HU, Kim SH, Oh JM (2006) Estimation of thermal conductivity of nanofluid using experimental effective particle volume. Exp Heat Transf 19:181–191

Wu X, Wu H, Qu J, Zheng P (2008) Flow and heat transfer characteristics of nanofluids in silicon chip microchannels. J Chem Ind Eng (China) 59(9):2181–2187

Ma CF (2002) Impingement heat transfer with meso-scale fluid jets. Proc 12th Int Heat Transf Conf 1:287–297

Maveety JG, Hendrieks JF (1999) A heat sink performance study considering material, geometry, nozzle placement, and Reynolds number with air impingement. J Electron Packag 121:156–161

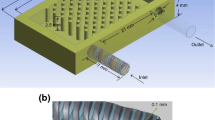

Xia GD, Jia Z, Chen Y (2009) Investigation on heat transfer of micro-jet array impinging on pin-fin surface. J Aerosp Power 24(1):7–12

Ruibo Y (2010) Experiment investigation in heat transfer and pressure drop of confined and sub-merged water jet array impingement on pin–fin heat sinks. Beijing University of technology, Beijing

Nguyen CT, Galanis N, Polidori G et al (2009) An experimental study of a confined and submerged impinging jet heat transfer using Al2O3–water nanofluid. Int J Therm Sci 48:401–411

Gherasim I, Roy G, Nguyen CT, Vo-Ngoc D (2010) Heat transfer enhancement and pumping power in confined radial flows using nanoparticle suspensions (nanofluids). Int J Therm Sci 49:1–9

Wang Z, Guan X, He H (2007) Preparation of Ag nanoparticles by ultrasound-assisted membrane reaction. Chem J Chin Univ 28(9):1756–1758

Xuan YM, Li Q (2000) Heat transfer enhancement of nanofluids. Int J Heat Fluid Flow 21:58–64

Zielinskaa A, Skwarekb E, Zaleskaa A (2009) Preparation of silver nanoparticles with controlled particle size. Procedia Chem 1:1560–1566

Xuan YM, Li Q (2010) Theory and application of nanofluids energy transfer. Science Press, Beijing, pp 120–145

Pak BC, Choi YI (1998) Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf 11(2):151–170

Acknowledgments

The work is supported by the National Natural Science Foundation of China (51176002), the National Basic Research Program of China (2011CB710704) and the Research Fund for the Doctoral Program of Higher Education (20111103110009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, M., Xia, G. & Chai, L. Heat transfer performance of submerged impinging jet using silver nanofluids. Heat Mass Transfer 51, 221–229 (2015). https://doi.org/10.1007/s00231-014-1387-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-014-1387-0