Abstract

Operational and structural modifications were numerically investigated in an effort to improve the performance of a liquid-cooled heatsink. The water/silver nanofluid was utilized as coolant, where the effects of nanoparticle concentration and Reynolds number were the operational variables considered, while the effect of rifling the inlet tube of coolant was a structural parameter investigated. The considered range for nanoparticle concentration and Reynolds number was 0–1% and 5000–20,000, respectively. The overall hydrothermal performance of the heatsink with rifled inlet was found to be 1.073–1.541 times higher than that of heatsink with plain inlet. In addition, it was revealed that rifling the inlet tube of heatsink entails a 4.26–21.79% decrement in the thermal entropy and a 9.90–110.97% increase in the frictional entropy. Moreover, it was demonstrated that friction is the main source of entropy generation in the flow, and the second-law performance of the heatsink with plain inlet is better than that of heatsink with rifled inlet.

Similar content being viewed by others

Abbreviations

- \(A\) :

-

Solid–liquid interfacial surface area (m2)

- \({c}_{\rm p}\) :

-

Heat capacity (J kg−1 K−1)

- \(f\) :

-

Friction factor

- \(FoM\) :

-

Figure of merit

- \({G}_{k}\) :

-

Generation of \(k\) because of the mean velocity gradient (kg m−1 s−3)

- \(h\) :

-

Convection coefficient (W m−2 K−1)

- \(k\) :

-

Turbulent kinetic energy (m2 s−2)

- \(PEC\) :

-

Performance evaluation criterion

- \(p\) :

-

Instantaneous pressure (Pa)

- \(\overline{p }\) :

-

Mean pressure (Pa)

- \({p}^{^{\prime}}\) :

-

Pressure fluctuation (Pa)

- q″:

-

Heat flux (W m−2)

- \(R\) :

-

Effective thermal resistance (K m2 W−1)

- \(\mathrm{Re}\) :

-

Reynolds number

- \({\dot{S}}_{\text{g,fr}}\) :

-

Global rate of entropy generated because of flow friction (W K−1)

- \({\dot{S}}_{\text{g,t}}\) :

-

Global rate of total entropy generation (W K−1)

- \({\dot{S}}_{\text{g,th}}\) :

-

Global rate of entropy generated because of heat transfer (W K−1)

- \(\dot{S}^{\prime\prime\prime}_{\text{g,fr}}\) :

-

Local rate of entropy generated because of flow friction (W m−3 K−1)

- \(\dot{S}^{\prime\prime\prime}_{\text{g,t}}\) :

-

Local rate of total entropy generation (W m−3 K−1)

- \(\dot{S}^{\prime\prime\prime}_{\text{g,th}}\) :

-

Local rate of entropy generated because of heat transfer (W m−3 K−1)

- \(T\) :

-

Instantaneous temperature (K)

- \(\overline{T }\) :

-

Mean temperature (K)

- \({T}^{^{\prime}}\) :

-

Temperature fluctuation (K)

- \({u}_{\rm i}\) :

-

Instantaneous velocity vector (m s−1)

- \({\overline{u} }_{\rm i}\) :

-

Mean velocity vector (m s−1)

- \({u}_{\rm i}^{^{\prime}}\) :

-

Velocity fluctuation vector (m s−1)

- \(\dot{V}\) :

-

Volumetric flow rate (m3 s−1)

- \({\dot{W}}_{\mathrm{pump}}\) :

-

Pumping power (W

- \(\alpha \) :

-

Thermal diffusivity (m2 s−1)

- \({\alpha }_{\mathrm{t}}\) :

-

Eddy thermal diffusivity (m2 s−1)

- \(\varepsilon \) :

-

Dissipation rate (m2 s−3)

- \(\varphi \) :

-

Nanoparticle concentration (%)

- \(\lambda \) :

-

Thermal conductivity (W m−1 K−1)

- \(\mu \) :

-

Viscosity (kg m−1 s−1)

- \({\mu }_{\mathrm{t}}\) :

-

Turbulent viscosity (kg m−1 s−1)

- \(\theta \) :

-

Uniformity of temperature distribution in the heatsink (K m2 W−1)

- \(\rho \) :

-

Density (kg m−3)

- \({\sigma }_{\rm k}\) :

-

Turbulent Prandtl number for \(k\)

- \({\sigma }_{\varepsilon }\) :

-

Turbulent Prandtl number for \(\varepsilon \)

- \(\mathrm{bf}\) :

-

Base fluid

- \(\mathrm{HIS}\) :

-

Heat input surface

- \(in\) :

-

Inlet

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- \(m\) :

-

Average of solid–liquid interfacial surface

- \(\mathrm{max}\) :

-

Maximum

- \(\mathrm{mean}\) :

-

Mean

- \(\mathrm{min}\) :

-

Minimum

- \(\mathrm{nf}\) :

-

Nanofluid

- \(\mathrm{out}\) :

-

Outlet

- \(p\) :

-

Nanoparticle

- \(\mathrm{plain}\) :

-

Heatsink with plain inlet

- \(\mathrm{rifled}\) :

-

Heatsink with rifled inlet

- \(s\) :

-

Solid wall

References

Ahmadi MH, Mirlohi A, Nazari MA, Ghasempour R. A review of thermal conductivity of various nanofluids. J Mol Liq. 2018;265:181–8.

Zheng Y, Shahsavar A, Afrand M. Sonication time efficacy on Fe3O4-liquid paraffin magnetic nanofluid thermal conductivity: an experimental evaluation. Ultrason Sonochem. 2020;64:105004.

Ambreen T, Kim MH. Influence of particle size on the effective thermal conductivity of nanofluids: a critical review. Appl Energy. 2020;264:114684.

Alsarraf J, Shahsavar A, Mahani RB, Sardari PT. Turbulent forced convection and entropy production of a nanofluid in a solar collector considering various shapes for nanoparticles. Int Commun Heat Mass Transf. 2020;117:104804.

Arora N, Gupta M. An updated review on application of nanofluids in flat tubes radiators for improving cooling performance. Renew Sust Energ Rev. 2020;134:110242.

Abbas F, Ali HM, Shah TR, Babar H, Janjua MM, Sajjad U, Amer M. Nanofluid: potential evaluation in automotive radiator. J Mol Liq. 2020;297:112014.

Balaji T, Selvam C, Lal DM, Harish S. Enhanced heat transport behavior of micro channel heat sink with graphene based nanofluids. Int Commun Heat Mass Transf. 2020;117:104716.

Awais AA, Kim MH. Experimental and numerical study on the performance of a minichannel heat sink with different header geometries using nanofluids. Appl Therm Eng. 2020;171:115125.

Ho CJ, Hsieh YJ, Rashidi S, Orooji Y, Yan WM. Thermal-hydraulic analysis for alumina/water nanofluid inside a mini-channel heat sink with latent heat cooling ceiling-An experimental study. Int Commun Heat Mass Transf. 2020;112:104477.

Zhang B, Zhu J, Gao L. Topology optimization design of nanofluid-cooled microchannel heat sink with temperature-dependent fluid properties. Appl Therm Eng. 2020;176:115354.

Kumar V, Sarkar J. Experimental hydrothermal characteristics of minichannel heat sink using various types of hybrid nanofluids. Adv Powder Technol. 2020;31:621–31.

Bazkhane S, Zahmatkesh I. Taguchi–based sensitivity analysis of hydrodynamics and heat transfer of nanofluids in a microchannel heat sink (MCHS) having porous substrates. Int Commun Heat Mass Transf. 2020;118:104885.

Dehghan M, Daneshipour M, Valipour MS. Nanofluids and converging flow passages: a synergetic conjugate-heat-transfer enhancement of micro heat sinks. Int Commun Heat Mass Transf. 2018;97:72–7.

Dehghan M, Vajedi H, Daneshipour M, Pourrajabian A, Rahgozar S, Ilis GG. Pumping power and heat transfer rate of converging microchannel heat sinks: errors associated with the temperature dependency of nanofluids. J Therm Anal Calorim. 2020;140:1267–75.

Atashafrooz M, Sajjadi H, Amiri Delouei A, Yang TF, Yan WM. Three-dimensional analysis of entropy generation for forced convection over an inclined step with presence of solid nanoparticles and magnetic force. Numer Heat Transf A: Appl. 2021;80:318–35.

Atashafrooz M, Sajjadi H, Amiri Delouei A. Interacting influences of Lorentz force and bleeding on the hydrothermal behaviors of nanofluid flow in a trapezoidal recess with the second law of thermodynamics analysis. Int Commun Heat Mass Transf. 2020;110:104411.

Atashafrooz M, Sheikholeslami M, Sajjadi H, Amiri DA. Interaction effects of an inclined magnetic field and nanofluid on forced convection heat transfer and flow irreversibility in a duct with an abrupt contraction. J Magn Magn Mater. 2019;478:216–26.

Bhatti MM, Riaz A, Zhang L, Sait SM, Ellahi R. Biologically inspired thermal transport on the rheology of Williamson hydromagnetic nanofluid flow with convection: an entropy analysis. J Therm Anal Calorim. 2021;144:2187–202.

Riaz A, Bobescu E, Ramesh K, Ellahi R. Entropy analysis for cilia-generated motion of Cu-blood flow of nanofluid in an annulus. Symmetry. 2021;13:2358.

Shaheen S, Maqbool K, Ellahi R, Sait SM. Heat transfer analysis of tangent hyperbolic nanofluid in a ciliated tube with entropy generation. J Therm Anal Calorim. 2021;144:2337–46.

Alfaryjat AA, Dobrovicescu A, Stanciu D. Influence of heat flux and Reynolds number on the entropy generation for different types of nanofluids in a hexagon microchannel heat sink. Chin J Chem Eng. 2019;27:501–13.

Shen H, Xie G, Wang CC. Thermal performance and entropy generation of novel X-structured double layered microchannel heat sinks. J Taiwan Inst Chem Eng. 2020;111:90–104.

Paniagua-Guerra LE, Ramos-Alvarado B. Efficient hybrid microjet liquid cooled heat sinks made of photopolymer resin: thermo-fluid characteristics and entropy generation analysis. Int J Heat Mass Transf. 2020;146:118844.

Salimi MR, Taeibi-Rahni M, Rostamzadeh H. Heat transfer and entropy generation analysis in a three-dimensional impinging jet porous heat sink under local thermal non-equilibrium condition. Int J Therm Sci. 2020;153:106348.

Bazdidi-Tehrani F, Khanmohammadi SM, Vasefi SI. Evaluation of turbulent forced convection of non-Newtonian aqueous solution of CMC/CuO nanofluid in a tube with twisted tape inserts. Adv Powder Technol. 2020;31:1100–13.

Sarafraz MM, Hormozi F. Intensification of forced convection heat transfer using biological nano-fluid in a double-pipe heat exchanger. Exp Therm Fluid Sci. 2015;66:279–89.

Sun Q, Cai X, Li J, Zheng M, Chen Z, Yu CP. Green synthesis of silver nanoparticles using tea leaf extract and evaluation of their stability and antibacterial activity. Colloids Surf A: Physicochem Eng Asp. 2014;444:226–31.

Al-Rashed AAAA, Shahsavar A, Rasooli O, Moghimi MA, Karimipour A, Tran MD. Numerical assessment into the hydrothermal and entropy generation characteristics of biological water-silver nano-fluid in a wavy walled microchannel heat sink. Int Commun Heat Mass Transf. 2019;104:118–26.

Chiu HCC, Hsieh RHH, Wang K, Jang JHH, Yu CRR. The heat transfer characteristics of liquid cooling heat sink with micro pin fins. Int Commun Heat Mass Transf. 2017;86:174–80.

Ijam A, Saidur R. Nanofluid as a coolant for electronic devices (cooling of electronic devices). Appl Therm Eng. 2012;32:76–82.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

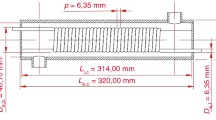

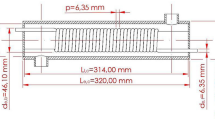

Shahsavar, A., Roohani, S. & Jahangiri, A. Evaluation of the effect of rifled inlet on the hydrothermal performance and entropy generation of biological silver/water nanofluid-cooled heatsink. J Therm Anal Calorim 147, 11561–11575 (2022). https://doi.org/10.1007/s10973-022-11342-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11342-3