Abstract

Nowadays, taking into account environmental degradation, climate changes, as well as, environmentally friendly regulations and increasing ecological awareness of consumers, methods of wood protection without negative impact on the environment are being intensively developed. In this study, a mixture of chitosan and caffeine was proposed as ecological wood preservative. The aim of the research was to evaluate the application of chitosan (medium and high molecular weight) as an agent limiting the leaching of caffeine from the structure of treated wood. The resistance of pine wood treated with chitosan–caffeine preparations and ingredients of these preparations (caffeine and chitosan) to brown rot fungus—Coniophora puteana was assessed. The degree of caffeine leaching from the treated wood was determined by chromatographic analysis (caffeine concentration) and elemental analysis (nitrogen concentration). The results showed that chitosan limited caffeine leaching from wood, which was confirmed by chromatographic analysis and changes in the wood structure observed in FTIR spectra. Moreover, wood treated with chitosan–caffeine preparations showed resistance against C. puteana (mass loss about 0.5%); however, antifungal activity was reduced when treated wood was subjected to leaching with water (mass loss about 10%). The obtained results suggest that the chitosan–caffeine preparations can be promising ecological preservatives for the wood treatment.

Similar content being viewed by others

Introduction

Wood is a natural renewable material playing a significant role in the world economy, especially in furniture and building sectors. Among many advantages of wood, including attractive mechanical and physical properties or aesthetic qualities, it is characterized by susceptibility to biodegradation by microorganisms, especially by fungi. Therefore, in order to extend the service life of wood and wood products mainly used in outdoor applications, various methods of modification and impregnation are employed. Nowadays, taking into account environmental degradation, climate changes, as well as environmentally friendly regulations and increasing ecological awareness of consumers, methods of wood protection without negative impact on the environment are being intensively developed by both industry and scientists (Daniel 2003; Ugolev 2013).

An interesting and bio-friendly method to improve the wood durability against microorganisms is the treatment with natural substances and chemical compounds isolated from natural sources, such as essential oils (oregano, clove, lavender, savory, thyme, mint, lemongrass or tea tree) and their individual components, including eugenol, cinnamaldehyde, carvacrol or citral (Taylor et al. 2006; Chittenden and Singh 2011; Pánek et al. 2014; Xie et al. 2015; Sablík et al. 2016; Zhang et al. 2016; Bahmani and Schmidt 2018). Among the products of natural origin with potential application in wood protection, it is also worth mentioning, among others, propolis, tannins, natural oils, extracts of various plants and trees, chitosan and caffeine (Alfredsen et al. 2004; Humar and Lesar 2013; Kwaśniewska-Sip et al. 2018; Teacă et al. 2019; Woźniak et al. 2020).

Caffeine is a purine alkaloid with the chemical name 1,3,7-trimethyxantine, but also termed theine or guaranine. It is the most widely consumed drug in the world and also a waste product of the coffee and tea industry side-streams, which is a significant advantage of caffeine in its potential for various applications including wood protection (de Mejia and Ramirez-Mares 2014; Faudone et al. 2021). Caffeine showed resistance against decay wood fungi and molds. Wood impregnated with caffeine solutions was effectively protected against brown rot fungi (C. puteana, Poria placenta and Gloeophyllum trabeum), white rot fungi (Trametes versicolor), wood-staining fungi (Aureobasidium pullulans and Sclerophoma pythiophila) and molds (Aspergillus niger, Aspergillus terreus, Cladosporium herbarum, Penicillium brevicompactum, Penicillium cyclopium, Penicillium funiculosum, Trichoderma viride, Chaetomium globosum and Paecilomyces variotii) (Kwaśniewska-Sip et al. 2018; Pánek et al. 2021; Šimůnková et al. 2021). However, resistance against fungi of caffeine-treated wood decreases when the wood samples were subjected to leaching procedure, which is caused by partially extracted caffeine from the wood structure under the influence of water (Kwaśniewska-Sip et al. 2018; Šimůnková et al. 2021). Chemical analysis and molecular simulation indicated that caffeine does not interact with the main component of wood–cellulose, while it bonds with other wood constituents, including lignin, hemicelluloses, coniferyl alcohol and coumaryl alcohol (Kobetičová et al. 2021; Kwaśniewska-Sip et al. 2021). One of the most important challenges in the search for ecological wood preservatives is to prevent leaching of the active substances from the wood. Caffeine has been combined with various agents and impregnation methods in order to reduce its extraction from the wood structure. Kwaśniewska-Sip et al. (2019a) showed that thermal modification of caffeine-treated wood improved its resistance against A. niger after artificial aging (leaching procedure and UV radiation). The combination of caffeine with propolis extract and silicon compounds (methyltrimethoxysilane and octyltrimethoxysilane) caused resistance of pine wood against C. puteana, also after the leaching procedure (Ratajczak et al. 2018). In turn, Šimůnková et al. (2021) showed that caffeine was sensitive to extraction from the wood structure even in the presence of an additional layer with hydrophobic properties and thus showed lower resistance against microorganisms after leaching.

Chitosan can also be included among the natural products with potential use in the ecological protection of wood. Chitosan as a natural biopolymer derived by deacetylation of chitin and with minimal toxicity in mammals is an important contribution to various applications, including pharmaceutical, medical, food and food packaging (Díaz-Montes and Castro-Muñoz 2021). Chitosan has also been found as an application in wood protection, as a single protective agent or as a constituent of multicomponent formulations. The literature data showed that chitosan limited the growth of decay fungi (C. puteana, P. placenta and T. versicolor); however, the mass loss of treated wood was related to chitosan concentration, strain of fungi and molecular weight of chitosan (Alfredsen et al. 2004; Eikenes et al. 2005). The molecular size of chitosan and its concentration also impact the anti-mold properties of chitosan-treated wood (Gorgij et al. 2014; El-Gamal et al. 2016; Oldertrøen et al. 2017). Chitosan was also applied to wood treatment in combination with other substances, including cinnamaldehyde, polyethylene glycol, propolis extract and silver nanoparticles (Silva-Castro et al. 2018; Casado-Sanz et al. 2019; Bi et al. 2021; Fang et al. 2021).

The goal of this research was to determine the possibility of chitosan (medium and high molecular weight) application as an agent limiting the leaching of caffeine from the wood structure. The resistance of pine wood treated with chitosan–caffeine preparations and ingredients of these preparations (caffeine and chitosan) to brown rot fungus—C. puteana was assessed. The degree of leaching of caffeine from the treated wood was determined by chromatographic analysis (caffeine concentration) and elemental analysis (nitrogen concentration). To the best of the authors` knowledge, this article is the first report on the biological resistance and chemical characteristics of wood treated with a mixture of caffeine and chitosan.

Materials and methods

Chitosan–caffeine preparations

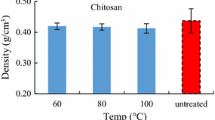

Two types of chitosan were used in the study: medium molecular weight (75–85% deacetylated, molecular weight (MW): 90,000–310,000 Da) (chitosan M) and high molecular weight (> 75% deacetylated, molecular weight (MW): 310,000–375,000 Da) (chitosan H). Chitosan samples and caffeine in form of powder were purchased from Sigma-Aldrich (Steinheim, Germany). Caffeine sample was dissolved in 2% acetic acid (Avantor Performance Materials, Gliwice, Poland), and after dissolving the caffeine, chitosan was added to the solution, resulting in a final concentration of both caffeine and chitosan equal to 1%. The 1% caffeine concentration was selected based on literature reports, which showed that wood treated with an aqueous caffeine solution at 1% concentration exhibited resistance to wood-decay fungi (Kwaśniewska-Sip et al. 2018). The concentration of 1% chitosan was also selected based on the literature data (Eikenes et al. 2005). In turn, acetic acid to dissolve the chitosan was selected according to the data described by Larnøy et al. 2006b, which showed that the use of acetic acid to dissolve chitosan results in a better binding of chitosan to the wood components than the use of hydrochloric acid. The previous research indicated that formulations consisting of caffeine and chitosan showed antifungal activity (Kwaśniewska-Sip et al. 2019b). Prior to wood impregnation, the formulations were homogenized using a laboratory homogenizer (IKA Poland, Warszawa, Poland).

Wood impregnation

The investigated wood was Scots pine (Pinus sylvestris L.) sapwood with a dimension of 5 × 10 × 40 mm (the last dimension along the fibers). Scots pine wood is a tree species mainly found in Polish forests, and it also is a popular wood used in outdoor applications. The wood specimens were prepared from several logs with nine to thirteen growth rings per 10 mm and an average density of 540 kg/m3 supplied by the Faculty of Forestry and Wood Technology from Poznan University of Life Sciences. The wood samples were without biotic infections, knots and other inhomogeneity.

Prior to impregnation, the wood samples were dried at 103 °C for 24 h and then weighted to obtain initial mass of samples. The wood specimens were impregnated with 1% caffeine solution, 1% solutions of two types of chitosan, and two formulations consisting of caffeine and both types of chitosan, for 15 min under a vacuum of 0.08 MPa followed by soaking for 2 h under atmospheric pressure at 20 °C. For each treatment variant, 10 wood samples were used. After impregnation, all the wood samples were removed from impregnation solutions and weighted to determine the retention of the preparations.

Half of the treated wood was subjected to a leaching procedure according to EN 84 (1997). The treated wood was impregnated with deionized water under vacuum condition of 0.08 MPa and then soaked in water for 2 weeks, where the water was changed 10 times. After impregnation and leaching, the wood samples were cured for 4 weeks in room conditions (relative humidity (RH) = 65 ± 5% and temperature (T) = 20 ± 2 °C) to constant weight.

Resistance of treated wood against brown rot fungus C. puteana

The decay resistance of control (untreated) and treated wood samples (5 unleached and 5 leached samples for each treatment) was determined before and after the leaching procedure (Sect. 2.2) according to the modified EN 113 (1996) standard. The size of the wood samples and the time of their exposure to the fungus were modified. Decay resistance of wood was assessed against brown rot fungus Coniophora puteana (Schumacher ex Fries) Karsten BAM 112 (BAM Ebw. 15). The wood samples (five replicates for each formulation variant, before and after leaching procedure) were placed into Petri dishes on completely colonized medium and exposure to the fungus at 22 ± 2 °C and RH = 70 ± 5% for 8 weeks. After this time, the fungus mycelium was removed from the surface of each sample, and the samples were weighted to determine the mass loss of wood caused by decay fungus.

Chemical analysis of treated wood

Attenuated total reflectance-Fourier transform infrared spectroscopy (ATR-FTIR)

The spectra of control and treated wood samples were recorded by a Nicolet iS5 spectrophotometer (Thermo Fisher Scientific, Waltham, MA, USA) with Fourier transform, deuterated triglycine sulfate (DTGS) detector and attenuated total reflection (ATR) attachment. The spectra were recorded over the range of 4000–400 cm−1, at a resolution of 4 cm−1 and 16 co-added scans. Three measurements for each wood sample, by re-sampling at different locations across entire sample, were recorded.

High-performance liquid chromatography (HPLC)

To assess the caffeine leaching from treated wood, the two wood samples treated with caffeine and chitosan–caffeine formulations were subjected to extraction with deionized water (25 ml) during 30 days, where water was changed every day. The solutions were filtered through a syringe filter (PTFE 25 mm, 0.22 µm, Chromafil, Macherey–Nagel, Duren, Germany) and transferred to chromatographic vials. The concentration of caffeine in water was determined by a Waters 2695 high-performance liquid chromatograph with a Waters 2996 Array Detector (Waters Corporation, Milford, MA, USA) at λmax = 272 nm. The reverse-phase column was a C-18 Nova Pak column (3.9 × 150 mm), while the mobile phase was water:methanol (70:30, v/v), at a flow rate of 0.5 ml/min. Caffeine standard and reagents for analysis were supplied by Sigma-Aldrich (Steinheim, Germany).

Elemental analyzer (EA)

The treated wood before and after leaching procedure (according to the procedure described in Sect. 2.2) was ground in a laboratory mill (IKA Poland, Warszawa, Poland) and weighed (2–3 mg) in zinc vessels. In wood samples, the concentration of nitrogen, coming from caffeine and chitosan molecules, was determined by elemental analyzer (FLASH 2000 Series analyzer, Thermo Fisher Scientific, Waltham, MA, USA). The instrument was calibrated with BBOT (2,5-bis(5-tert-butyl-benzoxazol-2-yl)thiophene) (Thermo Fisher Scientific, Waltham, MA, USA) and certified reference materials—Birch leaf (Elemental Microanalysis Ltd., Okehampton, UK). The result is the average of three measurements from two wood samples.

Scanning electron microscopy (SEM)

The surface morphologies of unleached treated wood samples exposed to C. puteana action were examined by a Zeiss EVO 40 scanning electron microscope (Carl Zeiss AG, Oberkochen, Germany), which used an electron acceleration voltage of 10 keV. Prior to microscope analysis, small wood samples (10 mm square) were trimmed from treated wood and then coated with a layer of gold using a Balzers SCD00 sputter coater (BalTec Maschinenbau AG, Pfäffikon, Switzerland).

Results and discussion

Decay resistance of treated wood

The resistance of pine wood treated with caffeine, chitosan and a mixture of caffeine and chitosan against C. puteana was determined, and the results expressed as weight loss values are presented in Table 1.

The results indicated that fungus action caused the mass loss of wood treated with caffeine solution equal 0.44%, which confirms its high antifungal activity against the fungi causing brown rot decay. The strong and wide antifungal potential of caffeine was confirmed against wood decay fungi (C. puteana, P. placenta, G. trabeum and T. versicolor), wood-staining fungi (A. pullulans and S. pythiophila) and molds (A. niger, A. versicolor, A. terreus, Ch. globosum, C. herbarum, P. variotti, P. cyclopium, P. funiculosum, Phoma violacea, P. brevicompactum and T. viride) (Lekounougou et al. 2007; Barbero-López et al. 2018; Kwaśniewska-Sip et al. 2018, 2019a; Pánek et al. 2021; Šimůnková et al. 2021). A significant reduction in fungal resistance of caffeine-treated wood was observed, when the wood samples were subjected to leaching with water according to EN 84 (1997). The average weight loss of leached caffeine-treated wood was about 21% and was slightly lower than the mass loss of untreated wood (~ 37%). The literature data also confirmed that leaching with water caused reduction in biocidal resistance of wood impregnated with caffeine solution (Kwaśniewska-Sip et al. 2018; Šimůnková et al. 2021).

The wood treated with chitosan, both medium and high molecular weight, showed no resistance against C. puteana, before and after water leaching. The mass loss of chitosan-treated wood was in the range 18.75–28.10%. The presented results are consistent with data described in the literature, where poplar wood treated with chitosan oligomers showed no resistance against T. versicolor after 16 weeks of exposure and moderate activity of wood treated with medium molecular weight chitosan after 30 days of exposure to fungus (Silva-Castro et al. 2018; Casado-Sanz et al. 2019). Wood samples treated with chitosan solutions at 1% concentration showed no resistance against brown rot fungi (C. puteana and P. placenta); however, higher chitosan concentration (equal 5%) caused total protection of treated wood against these brown rot fungi (Eikenes et al. 2005). Moreover, the results obtained by Larnøy et al. (2006a) confirmed that wood treated with 5% low molecular weight chitosan shows resistance against P. placenta (mass loss 1.6%), C. puteana (mass loss 4.9%) and T. versicolor (mass loss 2.8%). In turn, wood treated with chitosan (low and medium MW) showed no resistance against blue stain fungi A. pullulans (Bardage et al. 2014). The literature data show that the molecular weight of chitosan and its concentration affect the fungal resistance of treated wood, where its fungicidal activity increased with increasing chitosan molecular weight and concentration (Alfredsen et al. 2004; Eikenes et al. 2005). Moreover, the results presented in the literature indicated that chitosan even applied in high concentrations leached from impregnated wood, and thus biological resistance of chitosan-treated wood after water extraction was significantly reduced (Alfredsen et al. 2004; Eikenes et al. 2005; Larnøy et al. 2006b).

The mass loss of wood treated with preparations consisting of caffeine and two types of chitosan (0.32% for chitosan M and 0.50% for chitosan H) indicated their high resistance against C. puteana, which is comparable to that of caffeine-treated wood (mass loss 0.44%). However, the fungal resistance of caffeine–chitosan-treated wood was reduced when wood samples were subjected to leaching with water. The weight loss of wood treated with solution of caffeine and chitosan after the leaching procedure was about 10%, which suggests that application of chitosan limited leaching of caffeine from the wood structure, but it did not completely retain caffeine in the wood. According to the literature data, wood was impregnated with a mixture of chitosan and various bioactive compounds or substances, including propolis, silver nanoparticles, cinnamaldehyde, (3-(2-aminoethylamino)propyl) trimethoxysilane or as a chitosan–copper complex with organic fungicides (tebuconazole and propiconazole), and showed resistance against decay wood fungi (C. puteana, T. versicolor and G. trabeum) and molds (A. niger, P. citrinum and T. viride) (Sun et al. 2012; Silva-Castro et al. 2018; Casado-Sanz et al. 2019; Bi et al. 2021; Fang et al. 2021). The results of the preliminary research indicated that addition of chitosan from crab shells to caffeine solution resulted in a reduction in the caffeine concentration needed to inhibit the mold (A. niger, P. funiculosum, P. variotti and T. viride) growth (Kwaśniewska-Sip et al. 2019b). The most promising results were obtained for two strains of fungi—P. funiculosum and T. virens, where the caffeine–chitosan formulation inhibited the growth of fungi in a caffeine concentration of 1 × 10–7%. The results of antifungal activity of caffeine–chitosan formulation indicated that the addition of chitosan to the caffeine solution resulted in a reduction in alkaloid concentration needed to inhibit the mold growth. Therefore, it seems important to search for new combinations of chitosan with substances and chemical compounds with antifungal properties for environmentally friendly wood protection.

ATR-FTIR analysis

Characterization of wood treated with chitosan–caffeine preparations

The spectra of untreated wood and wood treated with caffeine and chitosan–caffeine formulations before and after water leaching are presented in Figs. 1, 2 and 3.

FTIR-ATR spectra of wood (A), wood treated with caffeine and chitosan medium MW (B), wood treated with caffeine and chitosan medium MW, after leaching (C), wood treated with caffeine and chitosan medium MW exposed to C. puteana (D), wood treated with caffeine and chitosan medium MW, after leaching and exposed to C. puteana (E)

FTIR-ATR spectra of wood (A), wood treated with caffeine and chitosan high MW (B), wood treated with caffeine and chitosan high MW, after leaching (C), wood treated with caffeine and chitosan high MW exposed to C. puteana (D), wood treated with caffeine and chitosan high MW, after leaching and exposed to C. puteana (E)

The spectrum of caffeine-treated wood (Fig. 1, spectrum B) showed characteristic bands assigned to caffeine molecule at 1700 and 1650 cm−1 attributed to stretching vibrations of C=O bonds of acetamide groups of amide I, 1550 and 765 cm−1, which can be assigned to stretching vibration of N–H and/or C–N groups of amide II (Gunasekaran et al. 2005; Belscak-Cvitanovic et al. 2015; Kwaśniewska-Sip et al. 2021; Morrish et al. 2022). The intensity of these characteristic bands of the caffeine molecule observed in the spectrum of wood impregnated before leaching (Fig. 1, spectrum B) significantly decreased in the spectrum of treated wood after leaching (Fig. 1, spectrum C), which is consistent with the literature data showing that caffeine is removed from the structure of the wood under the influence of water (Kwaśniewska-Sip et al. 2021).

In the spectra of wood treated with caffeine and chitosan M (Fig. 2, spectrum B) and chitosan H (Fig. 3, spectrum B), caffeine characteristic bands are observed at 1700, 1650, 1550 and 765 cm−1, the appearance of which indicates the presence of caffeine in the structure of the wood after impregnation with chitosan–caffeine formulations. In the spectra of wood treated with both chitosan–caffeine formulations, the bands characteristic for chitosan (1650 and 1550 cm−1) were also observed; however, these bands attributed to mainly amide I and II were overlapped with bands of caffeine (Lawrie et al. 2007; Papadopoulos et al. 2020). Moreover, the bands from the fingerprint of chitosan in a range 1148–896 cm−1 attributed to the polysaccharides skeleton (vibrations of the glycoside bands and C–O/C–O–C stretching vibrations) were also present in the spectra of wood treated with chitosan–caffeine solutions; however, their intensities were low (Papadopoulos et al. 2020). Moreover, caffeine characteristic bands observed in the spectra of unleached wood samples treated with chitosan–caffeine formulations (Figs. 2, 3, spectrum B) are also present in the spectra of treated wood samples subjected to leaching procedure (Figs. 2, 3, spectrum C), which indicates that caffeine remains in the wood structure despite the extraction of water.

Characterization of wood treated with chitosan–caffeine preparations after exposure to C. puteana

The ATR-FTIR analysis was also used to determine changes in the structure of wood impregnated with caffeine and chitosan–caffeine preparations caused by the action of C. puteana. The ATR-FTIR spectra of treated wood samples exposed to the fungus are presented in Figs. 1, 2 and 3 (spectra D and E), and the spectra of untreated wood before and after exposure to tested fungus are presented in Fig. 4.

The changes in the structure of untreated wood after exposure to brown rot fungi, including C. puteana, are described in the literature (Pandey and Pitman 2003; Fackler et al. 2010; Tomak et al. 2013; Tomak 2014; Durmaz et al. 2016). Decayed pine wood showed peak changes, especially in the fingerprint region (1700–700 cm−1) in the ATR-FTIR spectrum compared to the pine wood spectrum before exposure to C. puteana. The action of the fungus reduced the intensity of carbohydrate bands at 1735 cm−1 (unconjugated C=O from xylanes in hemicelluloses), 1375 cm−1 (C–H deformation in cellulose and hemicelluloses), 1320 cm−1 (C–O in syringyl and guaiacyl rings and O–H in plane bending in cellulose), 1160 cm−1 (C–O–C vibration in cellulose and hemicelluloses) and 895 cm−1 (C–H deformation in cellulose and hemicelluloses) in the spectrum of decayed wood compared to the spectrum of wood before exposure to C. puteana. In turn, the intensity of the transmittance of lignin characteristic bands at 1600 cm−1 (aromatic skeletal vibration in lignin), 1510 cm−1 (C=C aromatic skeletal vibration in lignin) and 1260 cm−1 (guaiacyl ring breathing) increased in spectrum of decayed wood, when compared to the spectrum of undecayed wood (Pandey and Pitman 2003, 2004; Irbe et al. 2011; Durmaz et al. 2016; Ratajczak et al. 2018).

The ATR-FTIR spectra of wood treated with caffeine and its mixture with chitosan M indicated that the tested fungus has a slight effect on the wood structure, which confirmed inconsiderable changes in intensities of characteristic bands of cellulose, hemicelluloses and lignin (Figs. 1, 2, spectra D), compared to intensities of these bands in the spectra of treated wood before exposure to C. puteana (Figs. 1, 2, spectra B), whereas in the spectra of wood impregnated with caffeine and chitosan H after exposure to C. puteana changes in intensities of bands were observed at 1375 and 1510 cm−1 (Fig. 3, spectra D) compared to band intensities in spectra of treated wood not exposed to the fungus (Fig. 3, spectra B). To sum up, the FTIR analysis indicated that caffeine and chitosan–caffeine formulations prevent the destruction action of C. puteana in treated wood, which agrees with the biological results presented in Table 1.

In the spectra of caffeine-treated wood and samples impregnated with chitosan–caffeine solutions subjected to water leaching and exposed to C. puteana, changes in intensities of some bands were observed and also the appearance of new bands, compared to the spectra of wood samples without leaching procedure exposed to fungus. In the IR spectra of wood treated with caffeine (Fig. 1, spectrum E) and mixture of caffeine and chitosan M (Fig. 2, spectrum E) subjected to water extraction, the intensities of bands at 1510 and 1320 cm−1 increased, when compared to band intensities in the spectra of unleached wood samples (Figs. 1, 2, spectrum D), which indicated that the tested fungus caused changes in the wood structure. The confirmation of the influence of the fungus on the structure of the treated and leached wood can also be the appearance of new bands at 1630 and 780 cm−1, which may be attributed to N–H deformation in chitin (β-1,4-polysaccharide made up of N-acetylglucosamine units) from the fungal cell walls (Fabiyi et al. 2011). However, it is worth mentioning that most of the bands in the fingerprint region in the IR spectra have contributions from all components of wood and additionally of constituents of impregnated solutions; therefore, the bands observed in the spectra may overlap. In turn, in the spectra of wood impregnated with caffeine and chitosan H, no changes are observed in the bands (1510 and 1320 cm−1) intensities, but only new bands (1630 and 780 cm−1) appeared, however, in lower intensities compared to spectra of caffeine-treated wood or wood impregnated with solution of caffeine and chitosan M. The observed changes in ATR-FTIR spectra agree with the results of biological resistance expressed as a mass loss and presented in Table 1.

The structural changes of untreated and treated wood samples before the leaching procedure caused by C. puteana action were also evaluated by scanning electron microscope, and the SEM images are presented in Fig. 5. The SEM analysis was used to determine wood degradation caused by fungi in the literature data (Hamed 2013; Durmaz et al. 2016; Ozgenc et al. 2018).

The micrograph shows differences in hyphal colonization in the treated wood samples. The SEM images of the control wood and wood treated with both types of chitosan show very well the presence of the tested fungus hyphae. In turn, the SEM images of wood treated with caffeine and caffeine–chitosan formulations do not contain visible C. puteana hyphae. The results of the SEM analysis are consistent with the results of the mass loss of wood (Table 1), as well as the FTIR analysis (Figs. 1, 2, 3 and 4).

Leaching of treatment agents from wood

One of the most important challenges in the search for ecological wood preservatives is to prevent leaching of the active substance from the wood due to its low chemical interaction with the wood material. Leachability of many natural substances and chemical compounds, which has been described in the literature as a potential wood preservative, is an important issue limiting their application to protect wood used in outdoor applications. Therefore, in water after the leaching procedure of caffeine-treated wood samples, the caffeine concentration was determined by HPLC and the results are presented in Fig. 6.

As indicated by the curves showing the kinetics of leaching caffeine from wood impregnated with caffeine and chitosan–caffeine solutions, it was extracted most quickly from the structure of wood impregnated with caffeine without addition of chitosan. In turn, caffeine from wood treated with both chitosan–caffeine preparations was extracted to a much lower extent in the initial stage of the leaching process, compared to caffeine-treated wood. After 13 days of wood leaching, the caffeine concentration determined in the water after the extraction process of the wood samples was similar (about 0.03 mg/ml) for each treatment preparation. Moreover, in total, the highest amount of caffeine was extracted from wood treated with caffeine, while the lowest total content of leached caffeine was determined in water after extraction of wood impregnated with caffeine and high molecular weight chitosan.

To confirm the leaching degree of the ingredients of the protective preparation, in the impregnated wood before and after the leaching procedure, the concentration of nitrogen, which is a part of both the caffeine and chitosan molecules, was determined. The results presented in Table 2 showed that degree of caffeine leaching from wood structure was 50%, which agrees with the literature data (Kwaśniewska-Sip et al. 2021). Moreover, almost 50% of medium molecular weight chitosan molecules were extracted from the wood structure impregnated with this chitosan. In turn, molecules of chitosan H were less susceptible to water extraction from the structure of wood impregnated with this chitosan. The obtained results are consistent with data presented in the literature, indicating that chitosan with higher molecular weight has the tendency to fixate better in wood, and therefore prevent leaching compared to lower molecular weight chitosan (Eikenes et al. 2005). However, various factors (molecular weight, pH of solution, chitosan concentration and the type of acid used for dissolving chitosan) influence the fixation rate of chitosan in wood (Larnøy et al. 2006b). When comparing the degree of nitrogen leaching from wood treated with chitosan–caffeine formulations, it can be stated that wood treated with caffeine and chitosan H was characterized by lower leaching of caffeine and chitosan from the wood structure than from wood impregnated with solution of chitosan M and caffeine.

The results of leaching components of impregnation preparations (caffeine and chitosan), expressed as a degree of caffeine (Fig. 5) and nitrogen leaching (Table 2), agree with the results of wood weight loss caused by C. puteana (Table 1)—higher leaching of protective formulations ingredients caused lower resistance against fungus and higher values of mass loss. Moreover, obtained results indicated that chitosan, especially high molecular weight, limited extraction of caffeine from treated wood structure. The literature data showed that caffeine was sensitive for extraction from the wood structure even when wood was treated with caffeine and additional hydrophobic protective layer (Šimůnková et al. 2021). In turn, the degree of nitrogen (coming from caffeine molecule) leaching from wood impregnated with solution of caffeine, propolis extract and silicon compounds was about 5.5%, which suggested that caffeine was slightly leached from wood (Ratajczak et al. 2018).

Conclusion

The paper presents the results of fungal resistance and chemical characterization of wood treated with caffeine, chitosan (medium and high molecular weight) and chitosan–caffeine preparations. The wood treated with caffeine and chitosan–caffeine solutions showed resistance against brown rot fungus C. puteana, with weight loss of treated samples of about 0.5%. In turn, wood impregnated with two types of chitosan did not show resistance against the fungus. The caffeine–treated wood after leaching with water exhibited reduction in antifungal activity and mass loss about 21%. The wood treated with chitosan–caffeine preparations and subjected to leaching procedure showed higher antifungal resistance compared to caffeine-treated wood. The weight loss of wood treated with mixture of caffeine and chitosan was about 10% for medium molecular weight chitosan and 8% for high molecular weight chitosan, which suggests that chitosan limited caffeine leaching from the treated wood structure, but it does not completely retain it in the wood. The presence of caffeine and chitosan in the wood structure impregnated with their mixtures was confirmed by FTIR analysis, where the spectra of treated wood contained characteristic bands for caffeine and chitosan molecules also in the spectra of treated wood after leaching. The chromatographic analysis of caffeine concentration in water after the leaching process of caffeine-treated wood showed that chitosan limited caffeine extraction from the structure of wood impregnated with caffeine–chitosan mixture. The elemental analysis also indicated that wood treated with caffeine and high molecular weight chitosan exhibited lower values of nitrogen leaching from the wood structure, than from wood treated with caffeine and medium molecular weight chitosan.

In summary, based on the obtained results, it can be concluded that the chitosan–caffeine preparations can be promising ecological preservatives for the treatment of wood in both indoor and outdoor applications.

References

Alfredsen G, Eikenes M, Militz H, Solheim H (2004) Screening of chitosan against wood-deteriorating fungi. Scand J For Res 19:4–13. https://doi.org/10.1080/02827580410017807

Bahmani M, Schmidt O (2018) Plant essential oils for environment-friendly protection of wood objects against fungi. Maderas Cienc y Tecnol 20:325–332. https://doi.org/10.4067/S0718-221X2018005003301

Barbero-López A, Ochoa-Retamero A, López-Gómez Y et al (2018) Activity of spent coffee ground cinnamates against wood-decaying fungi in vitro. BioResources 13:6555–6564. https://doi.org/10.15376/biores.13.3.6555-6564

Bardage S, Westin M, Fogarty HA, Trey S (2014) The effect of natural product treatment of southern yellow pine on fungi causing blue stain and mold. Int Biodeterior Biodegrad 86:54–59. https://doi.org/10.1016/j.ibiod.2013.09.001

Belscak-Cvitanovic A, Komes D, Karlović S et al (2015) Improving the controlled delivery formulations of caffeine in alginate hydrogel beads combined with pectin, carrageenan, chitosan and psyllium. Food Chem 167:378–386. https://doi.org/10.1016/J.FOODCHEM.2014.07.011

Bi Z, Fang S, Gao Q et al (2021) Improvement of mould resistance of wood with cinnamaldehyde chitosan emulsion. Wood Sci Technol 56:187–204. https://doi.org/10.1007/s00226-021-01349-8

Casado-Sanz MM, Silva-Castro I, Ponce-Herrero L et al (2019) White-rot fungi control on Populus spp. wood by pressure treatments with silver nanoparticles, chitosan oligomers and propolis. Forests 10:885. https://doi.org/10.3390/f10100885

Chittenden C, Singh T (2011) Antifungal activity of essential oils against wood degrading fungi and their applications as wood preservatives. Int Wood Prod J 2:44–48. https://doi.org/10.1179/2042645311Y.0000000004

Daniel G (2003) Microview of wood under degradation by bacteria and fungi. ACS Symp Ser 845:34–72. https://doi.org/10.1021/BK-2003-0845.CH004

de Mejia EG, Ramirez-Mares MV (2014) Impact of caffeine and coffee on our health. Trends Endocrinol Metab 25:489–492. https://doi.org/10.1016/j.tem.2014.07.003

Díaz-Montes E, Castro-Muñoz R (2021) Trends in chitosan as a primary biopolymer for functional films and coatings manufacture for food and natural products. Polym 213:767. https://doi.org/10.3390/POLYM13050767

Durmaz S, Özgenç Ö, Boyaci IH et al (2016) Examination of the chemical changes in spruce wood degraded by brown-rot fungi using FT-IR and FT-Raman spectroscopy. Vib Spectrosc 85:202–207. https://doi.org/10.1016/j.vibspec.2016.04.020

Eikenes M, Alfredsen G, Christensen BE et al (2005) Comparison of chitosans with different molecular weights as possible wood preservatives. J Wood Sci 51:387–394. https://doi.org/10.1007/s10086-004-0659-6

El-Gamal R, Nikolaivits E, Zervakis GI et al (2016) The use of chitosan in protecting wooden artifacts from damage by mold fungi. Electron J Biotechnol 24:70–78. https://doi.org/10.1016/j.ejbt.2016.10.006

EN 113 (1996) Wood preservatives. Test method for determining the protective effectiveness against wood destroying Basidiomycetes. Determination of the toxic values. European Committee for Standardization, Bruxelles, Belgium

EN 84 (1997) Wood Preservatives—accelerated ageing of treated wood prior to biological testing—Leaching procedure. European Committee for Standardization, Brussels, Belgium

Fabiyi JS, McDonald AG, Morrell JJ, Freitag C (2011) Effects of wood species on durability and chemical changes of fungal decayed wood plastic composites. Compos Part A Appl Sci Manuf 42:501–510. https://doi.org/10.1016/j.compositesa.2011.01.009

Fackler K, Stevanic JS, Ters T et al (2010) Localisation and characterisation of incipient brown-rot decay within spruce wood cell walls using FT-IR imaging microscopy. Enzyme Microb Technol 47:257–267. https://doi.org/10.1016/J.ENZMICTEC.2010.07.009

Fang S, Feng X, Lei Y et al (2021) Improvement of wood decay resistance with cinnamaldehyde chitosan emulsion. Ind Crops Prod 160:113118. https://doi.org/10.1016/J.INDCROP.2020.113118

Faudone G, Arifi S, Merk D (2021) The medicinal chemistry of caffeine. J Med Chem 64:7156–7178. https://doi.org/10.1021/acs.jmedchem.1c00261

Gorgij R, Tarmian A, Karimi AN (2014) Effect of chitosan on the mold resistance of wood and its surface properties. Int J Lignocellul Prod 1:39–49

Gunasekaran S, Sankari G, Ponnusamy S (2005) Vibrational spectral investigation on xanthine and its derivatives - theophylline, caffeine and theobromine. Spectrochim Acta Part A Mol Biomol Spectrosc 61:117–127. https://doi.org/10.1016/J.SAA.2004.03.030

Hamed SAM (2013) In-vitro studies on wood degradation in soil by soft-rot fungi: Aspergillus niger and Penicillium chrysogenum. Int Biodeterior Biodegradation 78:98–102. https://doi.org/10.1016/J.IBIOD.2012.12.013

Humar M, Lesar B (2013) Efficacy of linseed- and tung-oil-treated wood against wood-decay fungi and water uptake. Int Biodeterior Biodegrad 85:223–227. https://doi.org/10.1016/j.ibiod.2013.07.011

Irbe I, Andersone I, Andersons B et al (2011) Characterisation of the initial degradation stage of Scots pine (Pinus sylvestris L.) sapwood after attack by brown-rot fungus Coniophora puteana. Biodegradation 22:719–728. https://doi.org/10.1007/s10532-010-9449-6

Kobetičová K, Ďurišová K, Nábělková J (2021) Caffeine interactions with wood polymers. Forests 12:1–8. https://doi.org/10.3390/f12050533

Kwaśniewska-Sip P, Cofta G, Nowak PB (2018) Resistance of fungal growth on Scots pine treated with caffeine. Int Biodeterior Biodegrad 132:178–184. https://doi.org/10.1016/j.ibiod.2018.03.007

Kwaśniewska-Sip P, Bartkowiak M, Cofta G, Nowak PB (2019a) Resistance of Scots pine (Pinus sylvestris L.) after treatment with caffeine and thermal modification against Aspergillus niger. BioResources 14:1890–1898. https://doi.org/10.15376/biores.14.1.1890-1898

Kwaśniewska-Sip P, Woźniak M, Szulc A et al (2019b) The biological activity of caffeine-chitosan formulation towards mould attack. In: 3rd International Scientific Conference WOOD-SCIENCE-ECONOMY

Kwaśniewska-Sip P, Woźniak M, Jankowski W et al (2021) Chemical changes of wood treated with caffeine. Mater 14:497. https://doi.org/10.3390/MA14030497

Larnøy E, Dantz S, Eikenes M, Militz H (2006a) Screening of properties of modified chitosan-treated wood. Wood Mater Sci Eng 1:59–68. https://doi.org/10.1080/17480270600861118

Larnøy E, Eikenes M, Militz H (2006b) Evaluation of factors that have an influence on the fixation of chitosan in wood. Wood Mater Sci Eng 1:135–148. https://doi.org/10.1080/17480270701200562

Lawrie G, Keen I, Drew B et al (2007) Interactions between alginate and chitosan biopolymers characterized using FTIR and XPS. Biomacromol 8:2533–2541. https://doi.org/10.1021/bm070014y

Lekounougou S, Jacquot JP, Gérardin P (2007) Gelhaye E (2007) Effects of propiconazole on extra-cellular enzymes involved in nutrient mobilization during Trametes versicolor wood colonization. Wood Sci Technol 422(42):169–177. https://doi.org/10.1007/S00226-007-0158-1

Morrish C, Whitehead F, Istivan T, Kasapis S (2022) The effect of trisodium phosphate crosslinking on the diffusion kinetics of caffeine from chitosan networks. Food Chem 381:132272. https://doi.org/10.1016/J.FOODCHEM.2022.132272

Oldertrøen K, H-Kittikun A, Aam BB, Larnøy E (2017) Resistance of rubberwood (Hevea brasiliensis) treated with chitosan or silane against surface molds. Eur J Wood Prod 75:101–112. https://doi.org/10.1007/s00107-016-1071-9

Ozgenc O, Durmaz S, Hakki Boyaci I, Eksi-Kocak H (2018) ATR-FTIR spectroscopic analysis of thermally modified wood degraded by rot fungi. Wood 61(201):91–105. https://doi.org/10.12841/wood.1644-3985.247.02

Pandey KK, Pitman AJ (2003) FTIR studies of the changes in wood chemistry following decay by brown-rot and white-rot fungi. Int Biodeterior Biodegrad 52:151–160. https://doi.org/10.1016/S0964-8305(03)00052-0

Pandey KK, Pitman AJ (2004) Examination of the lignin content in a softwood and a hardwood decayed by a brown-rot fungus with the acetyl bromide method and Fourier transform infrared spectroscopy. J Polym Sci Part A Polym Chem 42:2340–2346. https://doi.org/10.1002/pola.20071

Pánek M, Borůvka V, Nábělková J et al (2021) Efficacy of caffeine treatment for wood protection—influence of wood and fungi species. Polymers (Basel) 13:3758. https://doi.org/10.3390/polym13213758

Pánek M, Reinprecht L, Hulla M (2014) Ten essential oils for beech wood protection—efficacy against wood-destroying fungi and moulds, and effect on wood discoloration. BioResources 9:5588–5603. https://doi.org/10.15376/biores.9.3.5588-5603

Papadopoulos AN, Foti D, Kyzas GZ (2020) Sorption behavior of water vapor of wood treated by chitosan polymer. Eur J Wood Prod 78:483–491. https://doi.org/10.1007/s00107-020-01528-7

Ratajczak I, Woźniak M, Kwaśniewska-Sip P et al (2018) Chemical characterization of wood treated with a formulation based on propolis, caffeine and organosilanes. Eur J Wood Prod 76:775–781. https://doi.org/10.1007/s00107-017-1257-9

Sablík P, Giagli K, Pařil P et al (2016) Impact of extractive chemical compounds from durable wood species on fungal decay after impregnation of nondurable wood species. Eur J Wood Prod 74:231–236. https://doi.org/10.1007/s00107-015-0984-z

Silva-Castro I, Casados-Sanz M, Alonso-Cortés AL et al (2018) Chitosan-based coatings to prevent the decay of Populus spp. wood caused by Trametes versicolor. Coatings 8:415. https://doi.org/10.3390/coatings8120415

Šimůnková K, Reinprecht L, Nábělková J et al (2021) Caffeine—perspective natural biocide for wood protection against decaying fungi and termites. J Clean Prod 304:127110. https://doi.org/10.1016/J.JCLEPRO.2021.127110

Sun F, Bao B, Ma L et al (2012) Mould-resistance of bamboo treated with the compound of chitosan-copper complex and organic fungicides. J Wood Sci 58:51–56. https://doi.org/10.1007/s10086-011-1223-9

Taylor AM, Gartner BL, Morrell JJ, Tsunoda K (2006) Effects of heartwood extractive fractions of Thuja plicata and Chamaecyparis nootkatensis on wood degradation by termites or fungi. J Wood Sci 52:147–153. https://doi.org/10.1007/s10086-005-0743-6

Teacă CA, Roşu D, Mustaţă F et al (2019) Natural bio-based products for wood coating and protection against degradation: a review. BioResources 14:4873–4901. https://doi.org/10.15376/biores.14.2.Teaca

Tomak ED (2014) Changes in chemical composition of decayed Scots pine and beech wood. Sci Eng Compos Mater 21:589–595. https://doi.org/10.1515/SECM-2013-0180/MACHINEREADABLECITATION/RIS

Tomak ED, Topaloglu E, Gumuskaya E et al (2013) An FT-IR study of the changes in chemical composition of bamboo degraded by brown-rot fungi. Int Biodeterior Biodegrad 85:131–138. https://doi.org/10.1016/j.ibiod.2013.05.029

Ugolev BN (2013) Wood as a natural smart material. Wood Sci Technol 483(48):553–568. https://doi.org/10.1007/S00226-013-0611-2

Woźniak M, Kwaśniewska-Sip P, Waśkiewicz A et al (2020) The possibility of propolis extract application in wood protection. Forests 11:465. https://doi.org/10.3390/F11040465

Xie Y, Yang Z, Cao D et al (2015) Antitermitic and antifungal activities of eugenol and its congeners from the flower buds of Syzgium aromaticum (clove). Ind Crops Prod 77:780–786. https://doi.org/10.1016/j.indcrop.2015.09.044

Zhang Z, Yang T, Mi N et al (2016) Antifungal activity of monoterpenes against wood white-rot fungi. Int Biodeterior Biodegrad 106:157–160. https://doi.org/10.1016/j.ibiod.2015.10.018

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Woźniak, M., Gromadzka, K., Kwaśniewska-Sip, P. et al. Chitosan–caffeine formulation as an ecological preservative in wood protection. Wood Sci Technol 56, 1851–1867 (2022). https://doi.org/10.1007/s00226-022-01426-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-022-01426-6