Abstract

The aim of the study was to present chemical characteristics of a potential wood protection system composed of three chemical components. The paper presents preliminary results of chemical and biological analysis of wood treated with a mixture of 30% ethanol extract of propolis, caffeine and organosilanes: methyltrimetoxysilane (MTMOS) and octyltriethoxysilane (OTEOS). The sapwood of Scots pine (Pinus sylvestris L.) was impregnated with the above mentioned solution by vacuum method. The samples of wood treated with preservative were subjected to accelerated aging procedure according to EN 84 and subsequently to mycological tests according to the modified EN 113. Structural analysis of the treated wood was performed using infrared spectroscopy FTIR. The concentration of silicon in wood samples was determined by atomic absorption spectrometry AAS. The percentage content of nitrogen in wood samples was determined by elementary analysis EA. Slight differences in nitrogen and silicon content recorded in wood samples following impregnation and leaching confirm the permanent character of bonding between the propolis-silane-caffeine preparation and wood. The stable character of Si–C and Si–O bonds was shown in IR spectra and discussed in detail in this paper.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Efficacy and stability of wood preservatives depend mainly on active ingredients—biocides. Unfortunately, traditional biocides used in wood preservatives bring the risk of pollution of the natural environment, as at certain concentrations they may be toxic and therefore constitute a threat both to human health and the environment. The strict toxicological requirements and an increasing ecological awareness of customers lead to an increasing interest in studies aimed at developing new, biocide-free wood preservatives harmless to people and the environment based on natural substances and chemical compounds.

Propolis is a resinous material collected by bees (Apis mellifera L.) from leaf buds of various tree species, such as birch, poplar, spruce, pine or alder. The chemical composition of propolis is very complex and depends mainly on vegetation of geographical location where it is collected from, time and method of harvesting and also race of honeybees (Gong et al. 2012; Kędzia 2006; Papotti et al. 2012; Silici and Kutluca 2005; Teixeira et al. 2008; Valencia et al. 2012). The main compounds in Polish propolis are phenols including flavonoids, phenolic acids and their esters, vitamins, sugars, fatty acids and micro- and macroelements (Bankova et al. 2014; Formicki et al. 2013; Kędzia 2009a, b; Socha et al. 2015; Szliszka et al. 2013; Woźniak et al. 2016). The activities of propolis samples from different world regions, in spite of differences in their chemical composition, are very similar (Kędzia 2006; Kujumgiev et al. 1999). There are numerous literature data showing that propolis from different locations possesses beneficial properties, for example antifungal, antibacterial, antiviral or antioxidant properties (Castaldo and Capasso 2002; Kujumgiev et al. 1999). The antifungal activities of propolis are the most extensively investigated ones against fungi from Candida sp.; however, propolis exhibits activity against Ganoderma applanatum, Schizophyllum commune or Pycnoporus sanguineus, which were isolated from decayed wood (Quiroga et al. 2006). Budija et al. (2008) showed the activity of ethanolic extract of propolis applied to wood against wood degrading fungi: Antrodia vaillantii, Gloeophyllum trabeum and Trametes versicolor, while Jones et al. (2011) indicated the activity of propolis in an aqueous soda solution against Coniophora puteana and Poria placenta. The authors found that propolis might be used in wood protection as a natural ingredient of a new, bio-friendly formulation (Budija et al. 2008; Jones et al. 2011). Moreover, Scots pine sapwood treated with formulation based on propolis extract and organosilanes exhibited better resistance against C. puteana than wood treated with propolis extract alone (Woźniak et al. 2015).

It is commonly known that plants produce endogenous substances to discourage pathogens (Hedin 1983). The first studies concerning the insecticidal activity of methylxanthine derivatives, including caffeine, were conducted using tea leaves (Camellia sinensisi) and coffee beans (Coffea arabica) (Nathanson 1984). Fungistatic properties of tea leaf and coffee bean extracts against some wood decaying fungi have also been confirmed using the agar medium method yielding positive results against Chaetomium globosum, Deadale flavida, Gloeophyllum trabeum, Aspergillus flavus and Pycnoporous sanguineus (Arora and Ohlan 1997). The aim of the previous studies concerning antimicrobial activity of natural products was to work out a proper method of selection and extraction depending on the final application (Almeida et al. 2006). Currently, there are many reports that caffeine has fungicidal properties besides insecticidal and antibacterial activity (Ashihara et al. 2008; Buchanan and Lewis 1984; Fardiaz 1995; Ibrahim et al. 2006; Pruthviraj et al. 2011; Rahman et al. 2014). It has been shown that caffeine induces cell wall alteration in fungi (Park et al. 2005). Furthermore, Lekounougou published results that caffeine inhibited totally the growth of five species of wood decay fungi and effects of caffeine on fungal growth are additive in the presence of propiconazole (Lekounougou et al. 2007, 2008). From the above mentioned papers, it is assumed that propolis and caffeine as natural biocides acting together on the wood-rotting fungi may be used in wood preservation formulations. Propolis and caffeine are well-known natural products, economically suitable and available which could facilitate their use in wood protection. Both the natural products are commercially available. Caffeine and propolis extract can be purchased from companies using these products for pharmacy and food industry.

A fundamental fact is that wood is hygroscopic. Recent findings clearly indicate that the efficiency of using wood outdoors is a function of inherent durability and moisture performance as determined by EN 113 tests (Meyer-Veltrup and Brischke 2016). Wood durability mainly decreases, and the risk of decay is greater when the wood moisture content is above fiber saturation point and it is more exposed to wood destroying organisms (Brischke and Lampen 2014). Silicon compounds have been used to increase hydrophobicity and to prevent leaching of active ingredients. Many wood properties, such as fire resistance, durability or water resistance and dimensional stability, are improved by the application of organosilanes (Mai and Militz 2004). Literature data showed that wood treated with silicon compounds without biologically active substance indicated unsatisfactory resistance against wood decay fungi (De Vetter and Van Acker 2010; Mai and Militz 2004).

The aim of this study was to determine potential properties of wood treated with a formulation based on natural substances (propolis, caffeine) and silicon compounds (methyltrimethoxysilane—MTMOS, octyltriethoxysilane—OTEOS). The paper presents results of chemical analysis of wood treated with a mixture of 30% ethanol extract of propolis, caffeine and organosilanes: MTMOS and OTEOS.

2 Materials and methods

2.1 Materials

The formulation used in this study consisted of 30% ethanolic propolis extract, 2% addition of caffeine (1,3,7-trimethylxanthine) C8H10N4O2 (Sigma–Aldrich), 2.5% MTMOS (methyltrimethoxysilane) CH3Si(OCH3)3 (Biesterfeld) and 2.5% OTEOS (octyltriethoxysilane) CH3(CH2)7Si(OCH2CH3)3 (Biesterfeld).

2.2 Preparation of ethanolic extract of propolis

Crude propolis of Apis mellifera used in this study was collected from an apiary located in Warmian-Masurian Providence in Poland. Propolis was cut into small pieces and extracted with a tenfold volume of 70% ethanol under shaking. The extraction was carried out in a darkroom at ambient temperature for 5 days. The final propolis extract was concentrated on a rotary evaporator under reduced pressure at 40 °C until constant weight. Finally, the concentration (30%) of alcoholic extract was obtained by dilution of a suitable amount of residue in 70% ethanol.

2.3 Biological tests

Scots pine (Pinus sylvestris L.) wood samples of dimensions 5 mm × 10 mm × 40 mm (the last dimension along the fibres) were used for the study. The samples were treated by vacuum method (15 min under vacuum conditions 0.08 MPa, and 2 h under atmospheric pressure) according to EN 113 (1996). After treatment all the samples were cured for 3 weeks under room conditions and then oven-dried to a constant weight. Part of the treated samples was subjected to accelerated leaching procedure according to EN 84 (2000). Part of the samples was treated by 20 min vacuum method and then kept under deionized water at a temperature of 20 ± 2 °C at the proportion of around 5 volumes of water to one volume of wood, during 14 days, within which period the water was exchanged after 2 h, 1 day, 2 days and every 2 days thereafter. Mycological tests were performed according to modified EN-113. Scots pine was exposed to brown-rot fungus C. puteana (Schumacher ex Fries) Karstein strain BAM Ebw. 15. After 8 weeks of exposure at 22 ± 2 °C and relative humidity of 70 ± 5%, the sample was removed and weight loss was measured.

2.4 Infrared spectroscopy

Wood in the form of powder was mixed with KBr at a 1/200 mg ratio. Spectra were registered using the Infinity spectrophotometer by Mattson with Fourier transform at a range of 500–4000 cm−1 at a resolution of 2 cm−1, registering 64 scans. The FTIR analyses of wood were conducted for basic spectra. Band intensity was determined from the measured absorbance in the peak maximum, taking into consideration the base line plotted separately for each peak. The band of 1506 cm−1 was used as the internal standard for the determination of relative absorbance.

2.5 Atomic absorption spectrometry

Representative samples of 0.5 g wood in the form of powder were mineralized in the Marsexpress CEM International microwave mineralization system. Concentration of Si in treated wood samples and in samples after leaching procedure was determined by AAS using the Spectra 200 AA spectrometer by Varian. The final results were mean values of three simultaneous measurements. Prior to the assay, analytical curves were prepared on the basis of a series of freshly prepared standard obtained from standard solution of silicon with the concentration of 1000 mg kg−3. To confirm the reliability of the results obtained during the analyses, a validation was performed in every tenth sample using certified plant reference material NCS DC 73350 (Leaves of Poplar). Silicon concentration in this study was compared with certified reference material (certified value: 0.71 ± 0.08%, determined value: 0.72 ± 0.11%).

2.6 Elementary analysis

The content of nitrogen was determined using the Elemental Analyzer Flash 2000 Series. Instrument calibration was performed with the BBOT (2,5-bis-(5-tert-butyl-benzoxazol-2-yl)thiophene) using linear matching as the calibration method. The method was used to estimate the degree of leaching nitrogen which is part of caffeine molecule.

3 Results and discussion

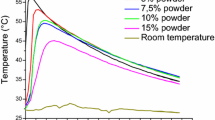

Results of antifungal efficacy against C. puteana were expressed as average mass loss and standard deviation of treated samples with the tested formulation (Table 1). Wood decay activity was high, which is evidenced by mass loss of the untreated samples (above 50%) and therefore, the results are reliable. Samples which were not subjected to accelerated aging were protected against the activity of C. puteana about five times better than control samples. The samples after the leaching procedure acquired such resistance against the tested fungus; the weight loss was equal 1.61% (weight loss < 3% is accepted in EN 113). Most probably the reason of this phenomenon is connected with hydrolysis of silanes which ensured the final wood moisture content of samples at 31.58% and it may be seen that the wood acquires hydrophobic properties (Donath et al. 2004, 2007; Mai and Militz 2004).

The percentage content of nitrogen according to elementary analysis (coming from amine groups present in the caffeine), determined in wood before and after leaching at 0.549 and 0.519%, respectively, shows that the applied propolis-silane-caffeine preparation permanently binds with wood. The degree of caffeine leaching from treated wood was 5.46%. Silicon concentration, in Table 2, was detected in impregnated wood at 202.633 mg kg−1 after impregnation and 154.767 mg kg−1 after leaching, confirming permanent bonding of the preparation with wood. The degree of leaching silicone (coming from Si(OCH3)3 and Si(OCH2CH3)3 groups presented in compounds from protected wood) was 23.62%.

The permanent character of bonding between the preparation and wood was confirmed by the results of atomic absorption spectrometry (AAS) and infrared spectroscopy (IR).

The permanent character of carbon-silicon and oxygen-silicon bonds was confirmed by infrared spectroscopy results, discussed in detail later in the paper.

The infrared spectroscopy measurement was also used to determine the degree of the effect of the cellar fungus C. puteana on wood. Interpretation of IR spectra was based on various studies (Fackler and Schwanninger 2010, 2012; Irbe et al. 2006, 2011; Körner et al. 1992; Pandey and Nagveni 2007; Shang et al. 2013). Figure 1 presents a comparison of pine wood spectrum (a) with the spectrum of pine exposed to C. puteana (b).

In the spectra of treated wood there are visible changes in the intensities of carbohydrate bands (Fig. 1). These bands are connected mainly with vibrations in the fingerprint region, namely 1735 cm−1 (unconjugated C=O in hemicellulose), 1373 cm−1 (deformation of C–H– cellulose and hemicellulose), 1160 cm−1 (C–O–C vibration in cellulose and hemicellulose) and 895 cm−1 (C–O–C stretching at β-1,4-glucoside linkages of cellulose and hemicellulose). In the spectrum of wood exposed to the fungus (b) the intensity of these bands decreases as compared with the spectra of untreated wood (a). In contrast, intensities of absorption bands resulting from lignin at 1600, 1506, 1260 cm−1 increase as decay progresses. This fungus showed an obvious preference for cellulose and hemicellulose-related groups because of the dramatic decline in the absorption peaks at 898 and 1161 cm−1 compared with the control (Shang et al. 2013). The same phenomenon has been found for the brown-rot decay process of C. puteana (Pandey and Pitman 2003). In their work, they showed that: “in the case of Scots pine the intensities of carbohydrate bands at 1734, 1375, 1320, 1158, 1060 and 898 cm−1 decrease and carbohydrate bands at 1320, 1158 and 898 cm−1 are almost absent after 12 weeks of decay”. Furthermore, they found that: “intensity of absorption bands at 1596, 1511, 1462, 1425, 1268 and 1030 cm−1 increases significantly and well-resolved lignin bands at 1220 and 1140 cm−1 develop in decayed Scots pine”.

The intensity of the 1160 cm−1 band (C–O–C vibration in cellulose and hemicellulose) decreases, which may indicate a reduction of the mean rate of polymerization of polycarbohydrates. A reduction of intensity in the 895 cm−1 band (C–O–C stretching at β-1,4-glucoside linkages of cellulose and hemicellulose) also confirms changes in carbohydrate systems of wood. Thus, assessment of changes within 1160 and 895 cm−1 may be justified when evaluating resistance of wood to fungi.

In the spectra presented in Fig. 1, simultaneously to the increase in the intensity of band at 1735, 1373, 1160 and 895 cm−1, a decrease in the intensity of bands generated by lignin at 1600, 1506 and 1462 cm−1 was observed.

Changes occurring in wood under the activity of fungi were assessed based on relative absorbance of bands in carbohydrate systems. A considerable reduction of intensity was observed for all these bands. At the same time, the greatest changes were found in the 1160 cm−1 band, for which relative absorbance was 1.4535 for the untreated wood sample, while for the control exposed to the fungus it was 0.2089, showing a considerable destruction of carbohydrate systems.

To confirm the presence of the formulation in treated wood and to compare the results with data from elemental analyses of nitrogen and AAS analyses of silicon, Fig. 2 presents spectra of untreated pine wood (a), impregnated wood (b) and treated wood after leaching (c). The appearance of new spectra (Fig. 2) in the case of impregnated wood samples at 1705 cm−1 (C=O), 1640 cm−1 (N–H), 830, 810, 765 and 744 cm−1 (Si–C, Si–O), as well as a lack of changes in spectra of wood after the leaching process may indicate permanent bonding of the preparation components with wood.

Moreover, Fig. 2 presents a comparison of IR spectra of wood impregnated with the tested preparation (b) and treated wood exposed to the fungus (d). Spectra b and d overlap, which is particularly evident in the range of 1800–1300 and 1300–800 cm−1 presented in Fig. 2. Spectra of impregnated wood exposed to the C. puteana (d) showed no changes in values of relative absorbance.

A lack of changes within carbohydrate groups may indicate a positive effect of the wood protection system. This is also confirmed by the comparable relative absorbance values (Table 3), amounting to A 1375/1506 = 0.5256, A 1375/1506 = 0.5313, A 1158/1506 = 0.7271, A 1158/1506 = 0.6516, A 898/1506 = 0.0990 and A 898/1506 = 0.0890. In comparison to the control, these values (Fig. 1) are definitely higher and may indicate a greater stability and resistance of impregnated samples to the brown-rot fungi.

4 Conclusion

Wood protectant based on propolis, caffeine and organosilanes inhibited the growth of brown-rot fungus C. puteana on wood samples. Slight differences in nitrogen and silicon content recorded in wood samples following impregnation and leaching confirm the permanent character of bonding between the propolis-silane-caffeine preparation and wood. The stable character of Si–C and Si–O bonds was shown in IR spectra and discussed in detail in this paper. The characteristic vibrations of bonds between silicon and carbon and oxygen were observed in spectra of wood both before and after leaching at 830, 810, 765 and 745 cm−1. Moreover, in that spectra the bands coming from the amine group present in caffeine were found at 1640 cm−1, as well as the bands typical for carbonyl groups from caffeine and propolis—at 1705 cm−1. The reduction in the intensity of IR spectra was compared with literature data for wood exposed to fungus degradation in comparison with untreated wood at 1735, 1373, 1160 and 895 cm−1.

It should be stressed that there were no changes found in IR spectra of the treated wood between both types of samples, i.e. exposed and unexposed to the fungus. The above mentioned observation confirms the effectiveness of the objective formulation.

References

Almeida AAP, Farah A, Silva DAM, Nunan E, Gloäria BM (2006) Antibacterial activity of coffee extracts and selected coffee chemical compounds against enterobacteria. J Agr Food Chem 54(23):8738–8743

Arora DS, Ohlan D (1997) In vitro studies on antifungal activity of tea (Camellia sinensis) and coffee (Coffea arabica) against wood-rotting fungi. J Basic Microbiol 37(3):159–165

Ashihara H, Sano H, Crozier A (2008) Caffeine and related purine alkaloids: biosynthesis, catabolism, function and genetic engineering. Phytochem 69:841–856

Bankova V, Popova M, Trusheva B (2014) Propolis volatile compounds: chemical diversity and biological activity: a review. Chem Cent J 8:28–35

Brischke C, Lampen SC (2014) Resistance based moisture content measurements on native,modified and preservative treated wood. Eur J Wood Prod 72(2):289–292

Buchanan RL, Lewis DF (1984) Caffeine inhibition of aflatoxin synthesis: probable site of action. Appl Environ Microbiol 47(6):1216–1220

Budija F, Humar M, Kricej B, Petric M (2008) Propolis for wood finishing. IRG/WP/ 08-30464. The International Research Group on Wood Protection, Stockholm, Sweden

Castaldo S, Capasso F (2002) Propolis, an old remedy used in modern medicine. Fitoterapia 1:1–6

De Vetter L, Van Acker (2010) Accelerated L-joint performance testing of organosilicon treated wood. IRG/WP/10-30551. The International Research Group on Wood Protection, Stockholm, Sweden

Donath S, Militz H, Mai C (2004) Wood modification with alkoxysilanes. Wood SciTechnol 38:555–566

Donath S, Militz H, Mai C (2007) Weathering of silane treated wood. Holz Roh Werkst 65:35–42

EN 113 (1996) Wood preservatives—test method for determining the protective effectiveness against wood destroying Basidiomycetes—determination of the toxic values. European Committee for Standardization, Brussels

EN 84 (2000) Wood preservatives—accelerated ageing of treated wood prior to biological testing—leaching procedure. European Committee for Standardization Brussels

Fackler K, Schwanninger M (2010) Polysaccharide degradation and lignin modification during brown-rot of spruce wood: a polarised Fourier transform near infrared study. J Near Infrared Spectrosc 18:403–416

Fackler K, Schwanninger M (2012) How spectroscopy and microspectroscopy of degraded wood contribute to understand fungal wood decay. Appl Microbiol Biotechnol 96:587–599

Fardiaz S (1995) Antimicrobial activity of coffee (Coffee robusta) extract. ASEAN Food J 10:103–106

Formicki G, Greń A, Stawarz R, Zyśk B, Gał A (2013) Metal content in honey, propolis, wax, and bee pollen and implications for metal pollution monitoring. Pol J Environ Stud 22(1):99–106

Gong S, Luo L, Gong W, Gao Y, Xie M (2012) Multivariate analyses of element concentration revealed the groupings of propolis from different regions in China. Food Chem 134:583–588

Hedin PA (ed) (1983) Plant resistance to insects. American Chemical Society, Washington, DC

Ibrahim SA, Salameh MM, Phetsomphou S, Yang H, Seo CW (2006) Application of caffeine, 1,3,7-trimethylxanthine, to control Escherichia coli O157:H7. Food Chem 99(4):645–650

Irbe I, Andersons B, Chirkova J, Kallavus U, Andersone I, Faix O (2006) On the changes of pinewood (Pinus sylvestris L.) Chemical composition and ultrastructure during the attack by brown-rot fungi Postia placenta and Coniophora puteana. Int Biodeterior Biodegrad 57(2):99–106

Irbe I, Andersone I, Andersons B, Noldt G, Dizhbite T, Kournosova N, Nuopponen M, Stewart D (2011) Characterisation of the initial degradation stage of Scots pine (Pinus sylvestris L.) sapwood after attack by brown-rot fungus Coniophora puteana. Biodegradation 22:719–728

Jones D, Howard N, Wales E (2011) The potential of propolis and other naturally occurring products for preventing biological decay. IRG/WP/11-30575. The International Research Group on Wood Protection, Stockholm, Sweden

Kędzia B (2006) Chemical content and biological activity of propolis from different world regions. Post Fitoter 1:23–35

Kędzia B (2009a) Chemical composition of Polish propolis. Part I. The initial period of investigations. Post Fitoter 1:39–44

Kędzia B (2009b). Chemical composition of Polish propolis. Part II. New studies. Post Fitoter 2:122–128

Körner I, Faix O, Wienhaus O (1992) Attempt to determine brown-rot breakdown of Scots pine wood with the aid of FTIR spectroscopy. Holz Roh- Werkst 50:363–367

Kujumgiev A, Tsvetkova I, Serkedjieva Y, Bankova V, Christov R, Popov S (1999) Antibacterial, antifungal and antiviral activity of propolis of different geographic origin. J Ethnopharmacol 64:235–240

Lekounougou S, Ondo JP, Jacquot J, Nevers G, Gérardin P, Gelhaye E (2007) Effects of caffeine on growth of wood-decaying fungi. IRG/WP/07-30427. The International Research Group on Wood Protection, Stockholm, Sweden

Lekounougou S, Jacquot J-P, Gérardin P, Gelhaye E (2008) Effects of propiconazole on extra-cellular enzymes involved in nutrient mobilization during Trametes versicolor wood colonization. Wood Sci Technol 42(2):169–177

Mai C, Militz H (2004) Modification of wood with silicon compounds. Inorganic silicon compounds and sol-gel systems - a review. Wood Sci Technol 37:339–348

Meyer-Veltrup L, Brischke C (2016) Moisture induced risk and fungal development in variousfield test set-ups in and above ground. IRG/WP/16-20577. The International Research Group on Wood Protection, Stockholm, Sweden

Nathanson JA (1984) Caffeine and related methylxanthines: possible naturally occurring pesticides. Science 226(4671):184–187

Pandey KK, Nagveni HC (2007) Rapid characterisation of brown rot and white rot degraded pine and rubberwood by FTIR spectroscopy. Holz Roh- Werkst 65:477–481

Pandey KK, Pitman AJ (2003) FTIR studies of the changes in wood chemistry following decay by brown-rot and white-rot fungi. Int Biodeterior Biodegrad 52:151–160

Papotti G, Bertelli D, Bortolotti L, Plessi M (2012) Chemical and functional characterization of Italian propolis obtained by different harvesting methods. J Agric Food Chem 60:2852–2862

Park J-I, Collinsonn EJ, Grant CM, Dawes IW (2005) Rom2p, the Rho1 GTP/GDP exchange factor of Saccharomyces cerevisiae, can mediate stress responses via the Ras-cAMP pathway. J Biol Chem 280(4):2529–2535

Pruthviraj P, Suchita B, Shital K, Shilpa K (2011) Evaluation of antibacterial activity of caffeine. Int J Res Ayurveda Pharm 2(4):1354–1357

Quiroga EN, Sampietro DA, Soberon JR, Sgariglia MA, Vattuone MA (2006) Propolis from the northwest of Argentina as a source of antifungal principles. J Apply Microbiol 101:103–110

Rahman NAA, Muharram SH, Abiola O (2014) Antibacterial activity of NESCAFÉ instant coffee beverages and pharyngitis-causing Streptococcus species. Brunei Darussalam J Health 5:70–79

Shang J, Yan S, Wang Q (2013) Degradation mechanism and chemical component changes in Betula platyphylla wood by wood-rot fungi. BioResources 8(4):6066–6077

Silici S, Kutluca S (2005) Chemical composition and antibacterial activity of propolis collected by three different races of honeybees in the same region. J Ethnopharmacol 99: 69–73

Socha R, Gałkowksa D, Bugaj M, Juszczak L (2015) Phenolic composition and antioxidant acitivity of propolis from various regions of Poland. Nat Prod Res 29(5):416–422

Szliszka E, Sokół˗Łętowska A, Kucharska AZ, Jaworska D, Czuba ZP, Król W (2013) Ethanolic extract of Polish propolis: chemical composition and TRAIL˗R2 death receptor targeting apoptotic activity against prostate cancer cells. Evid Based Compl Alt 2013:12 (Article ID 757628)

Teixeira EW, Message D, Negri G, Salatino A, Stringheta PC (2008) Seasonal variation, chemical composition and antioxidant activity of Brazilian propolis samples. Evid Based Compl Alt 7(3):307–315

Valencia D, Alday E, Robles˗Zepeda R, Garibay˗Escobar A, Galvez˗Ruiz JC, Salas˗Reyes M, Jimenez˗Estrada M, Velazquez˗Contreras E, Hernandez J, Velazquez C (2012) Seasonal effect on chemical composition and biological activities of Sonoran propolis. Food Chem 131:645–651

Woźniak M, Ratajczak I, Szentner K, Kwaśniewska P, Mazela B (2015) Propolis and organoislanes in wood protection. Part I: FTIR analysis and biological tests. Ann WULS-SGGW, For Wood Technol 91: 218–224

Woźniak M, Ratajczak I, Kędzia B, Rogoziński T (2016) The content of some elements inpropolis and its ethanolic extract. Post Fitoter 17(1):3–7

Acknowledgements

The study was funded by the research project: “Superior bio-friendly systems for enhanced wood durability” (No. Pol-Nor/203119/32, DURAWOOD)—supported by Norway Grants and the National Centre for Research and Development of Poland (NCRD) as a part of Polish-Norwegian Research Program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Ratajczak, I., Woźniak, M., Kwaśniewska-Sip, P. et al. Chemical characterization of wood treated with a formulation based on propolis, caffeine and organosilanes. Eur. J. Wood Prod. 76, 775–781 (2018). https://doi.org/10.1007/s00107-017-1257-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1257-9