Abstract

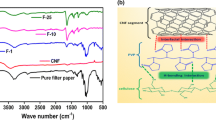

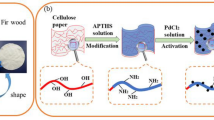

The aim of this project was to fabricate electroless nickel-coated cellulose fibres. Ultimately, these nickel-coated cellulose fibres will be used to develop a cost-effective polymer composite for electromagnetic interference (EMI) shielding and/or electrostatic discharge (ESD) applications. An attempt has been made to impart electrical conductivity onto cellulose fibres via an electroless nickel plating process. The aim was to achieve a homogeneous, continuous layer of Ni on the cellulose fibres, and the plating conditions were optimized to achieve this. The relationship between the coating morphology and the performance of the coated fibre was also of interest. Testing was carried out using cellulose filter paper and then loose cellulose fibres. Scanning electron microscopic (SEM) images of nickel-coated filter paper showed that nickel particles are bonded to the cellulose fibres. The coating appeared more compacted and continuous as plating time increased, corresponding to lower surface resistivity. This observation suggested a correlation between morphology and electrical conductivity of the coating. For nickel-coated cellulose fibres, after optimization of plating conditions, a uniform deposition of nickel particles around the cellulose surfaces was confirmed by SEM images. EDS and XRD results confirmed similar coating could be produced on filter paper and cellulose fibres. SEM images of cross-sectioned nickel-coated cellulose fibres illustrated nickel particles had penetrated into the inner walls of the cellulose fibres. This impregnation of the fibres should act to increase the bonding between nickel coating and cellulose fibres. These nickel-impregnated cellulose fibres could now be incorporated into a polymer matrix to create an electrically conducting composite with the right processing parameters.

Similar content being viewed by others

References

Allen RM, VanderSande JB (1982) The structure of electroless Ni–P films as a function of composition. Scr Metall 16(10):1161–1163

Geetha S, Kumar KKS, Rao CRK, Vijayan M, Trivedi DC (2009) EMI shielding: methods and materials: a review. J Appl Polym Sci 112:2073–2086

Hardwick N, RTP Company (2011) EMI shielding thermoplastic compounds dramatic cost reductions for electronic device protection. Compliance

Harizanov OA, Stefchev PL, Iossifova A (1998) Metal coated alumina powder for metalloceramics. Mater Lett 33(5–6):297–299

Huang C-Y, Pai J-F (1997) Studies on processing parameters and thermal stability of ENCF/ABS composites for EMI shielding. J Appl Polym Sci 63(1):115–123

Huang C-Y, Pai J-F (1998) Optimum conditions of electroless nickel plating on carbon fibres for EMI shielding effectiveness of ENCF/ABS composites. Eur Polymer J 34(2):261–267

Huang C-Y, Wu C-C (2000) The EMI shielding effectiveness of PC/ABS/nickel-coated-carbon-fibre composites. Eur Polymer J 36(12):2729–2737

Jiang SX, Guo RH (2011) Electromagnetic shielding and corrosion resistance of electroless Ni–P/Cu–Ni multilayer plated polyester fabric. Surf Coat Technol 205(17–18):4274–4279

Li J, Wang L, Liu H (2010) A new process for preparing conducting wood veneers by electroless nickel plating. Surf Coat Technol 204(8):1200–1205

Li-juan W, Jian L, Yi-xing L (2005) Surface characteristics of electroless nickel plated electromagnetic shielding wood veneer. J For Res 16(3):233–236

Liu H, Li J, Wang L (2010) Electroless nickel plating on APTHS modified wood veneer for EMI shielding. Appl Surf Sci 257(4):1325–1330

Lu Y, Xue L, Li F (2011) Adhesion enhancement between electroless nickel and polyester fabric by a palladium-free process. Appl Surf Sci 257(7):3135–3139

Nagasawa C, Kumagai Y, Urabe K, Shinagawa S (1999) Electromagnetic shielding particleboard with nickel-plated wood particles. J Porous Mater 6(3):247–254

Osawa Z, Kobayashi K (1987) Thermal stability of shielding effectiveness of electromagnetic interference of composites. J Mater Sci 22(12):4381–4387

Parkinson R (1997) Properties and applications of electroless nickel. Technical paper 10081, Nickel Development Institute, Toronto

Rupprecht L (1999) Conductive polymers and plastics in industrial applications. William Andrew Publishing/Plastics Design Library, Norwich

Shinagawa S, Kumagai Y, Urabe K (1999) Conductive papers containing metallized polyester fibers for electromagnetic interference shielding. J Porous Mater 6(3):185–190

Stremsdoerfer G, Wang Y, Nguyen D, Clechet P, Martin JR (1993) Electroless Ni as a refractory ohmic contact for n-InP. J Electrochem Soc 140(7):2022–2028

Wang L, Li J, Liu H (2011) A simple process for electroless plating nickel–phosphorus film on wood veneer. Wood Sci Technol 45(1):161–167

Zabetakis D, Dinderman M, Schoen P (2005) Metal-coated cellulose fibers for use in composites applicable to microwave technology. Adv Mater 17(6):734–738

Zhang YZ, Yao M (1999) Studies of electroless nickel deposit with low phosphorus content. Trans IMF 77(2):78–83

Acknowledgments

The author, Pongphat Sittisart, would like to acknowledge the financial support from Materials Accelerator—contract UOAX0819 as well as the advice received from John Kennedy (GNS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sittisart, P., Hyland, M.M., Hodgson, M.A. et al. Preparation and characterization of electroless nickel-coated cellulose fibres. Wood Sci Technol 48, 841–853 (2014). https://doi.org/10.1007/s00226-014-0643-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-014-0643-2