Abstract

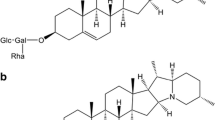

The aim of the industrial trial was to monitor the contents of the glycoalkaloids α-solanine, α-chaconine and their aglycon solanidine along the production process from unpeeled raw tubers to potato crisps. This should identify process factors that reveal possible process-related reduction or enrichment of these substances. The successful validation of an LC–MS/MS method using an external calibration for the determination of the glycoalkaloids α-solanine, α-chaconine and its aglycone solanidine met the requirements of the monitoring recommendation EU 2022/561, both, in terms of sensitivity and in view of the required enzyme inactivation. For the tested potato variety, none of the 15 industrially produced samples exceeded the proposed indicative value of 100 mg total glycoalkaloids/kg product mass (range: 13.2 mg/kg for peeled tuber to 67.6 mg/kg for potato crisps). Finally, solanidine contents were measured for the first time in-line a potato crisps production, ranging from 0.03 to 0.14 mg/kg product mass. The glycoalkaloid contents were additionally calculated as fat-free potato dry mass (ffpdm) to enable a standardized comparison of analytical values. With regard to this newly introduced reference value in this kind of process control, the ffpdm, a significant change of the glycoalkaloid contents during the production process of potato crisps after the peeling process could be excluded. This finding refutes current literature knowledge dealing with non-standardized results based on pure product weight ignoring water loss and/or fat intake along the production process. Starting from the unpeeled tuber to the final potato crisps, a glycoalkaloid reduction of 62% on average related to ffpdm could be achieved during the process, mainly related to the peeling. In contrary, the frying process contributed only insignificantly to the glycoalkaloid reduction.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Biesalski H-K (2005) Die Kartoffel – kalorienarmer Nährstofflieferant mit wertvollen Inhaltstoffen. LCI - Modere Ernährung heute:1–6

Bundesinformationszentrum Landwirtschaft (2022) Kartoffeln. https://www.landwirtschaft.de/landwirtschaftliche-produkte/wie-werden-unsere-lebensmittel-erzeugt/pflanzliche-produkte/kartoffeln. Accessed 6 Feb 2024

Deutsche Lebensmittelbuch Kommission (ed) (1997) Leitsätze für Kartoffelerzeugnisse

FAOSTAT (2023) Crops and livestock products. https://www.fao.org/faostat/en/#data/QCL/visualize. Accessed 6 Feb 2024

Milner SE, Brunton NP, Jones PW, O’Brien NM, Collins SG, Maguire AR (2011) Bioactivities of glycoalkaloids and their aglycones from solanum species. J Agric Food Chem 59:3454–3484. https://doi.org/10.1021/jf200439q

Friedman M, McDonald GM, Filadelfi-Keszi MA (1997) Potato glycoalkaloids: chemistry, analysis, safety, and plant physiology. Crit Rev Plant Sci 16:55–132. https://doi.org/10.1080/07352689709701946

Schrenk D, Bignami M, Bodin L, Chipman JK, Del Mazo J, Hogstrand C, Hoogenboom LR, Leblanc J-C, Nebbia CS, Nielsen E, Ntzani E, Petersen A, Sand S, Schwerdtle T, Vleminckx C, Wallace H, Brimer L, Cottrill B, Dusemund B, Mulder P, Vollmer G, Binaglia M, Ramos Bordajandi L, Riolo F, Roldán-Torres R, Grasl-Kraupp B (2020) Risk assessment of glycoalkaloids in feed and food, in particular in potatoes and potato-derived products. EFSA J 18:e06222. https://doi.org/10.2903/j.efsa.2020.6222

Kasimir M, Wolbeck A, Behrens M, Humpf H-U (2023) Intestinal metabolism of selected steroidal glycoalkaloids in the pig cecum model. ACS Omega 8:18266–18274. https://doi.org/10.1021/acsomega.3c01990

Bundesinstitut für Risikobewertung, Speisekartoffeln sollten niedrige Gehalte an Glykoalkaloiden (Solanin) enthalten: Stellungnahme Nr. 010/2018 des BfR vom 23. 2018. https://doi.org/10.17590/20180423-085250

Friedman M, Dao L (1992) Distribution of glycoalkaloids in potato plants and commercial potato products. J Agric Food Chem 40:419–423

Morris SC, Petermann JB (1985) Genetic and environmental effects on levels of glycoalkaloids in cultivars of potato (Solanum tuberosum L.). Food Chem 18:271–282

Jadhav SJ, Salunkhe DK (1975) Formation and control of chlorophyll and glycoalkaloids in tubers of Solanum tuberosum and evaluation of glycoalkaloid toxicity. Adv Food Res 21:307–354

Friedman M (2006) Potato glycoalkaloids and metabolites: roles in the plant and in the diet. J Agric Food Chem 54:8655–8681

Machado RMD, Toledo MCF, Garcia LC (2007) Effect of light and temperature on the formation of glycoalkaloids in potato tubers. Food Control 18:503–508. https://doi.org/10.1016/j.foodcont.2005.12.008

Porter WL (1972) A note on the melting point of α-solanine. Am Potato J 49:403–406

Commission Recommendation (EU) 2022/561 of 6 April 2022 on monitoring the presence of glycoalkaloids in potatoes and potato-derived products. In: Official Journal of the European Union

Commission Regulation (EU) 2017/2158 of 20 November 2017 establishing mitigation measures and benchmark levels for the reduction of the presence of acrylamide in food. In: Official Journal of the European Union

Haase NU (2010) Glycoalkaloid concentration in potato tubers related to storage and consumer offering. Potato Res 53:297–307. https://doi.org/10.1007/s11540-010-9162-1

Tajner-Czopek A, Jarych-Szyszka M, Lisinska G (2008) Changes in glycoalkaloids content of potatoes destined for consumption. Food Chem 106:706–711

Tajner-Czopek A, Rytel E, Kita A, Peksa A, Hamouz K (2012) The influence of thermal process of coloured potatoes on the content of glycoalkaloids in the potato products. Food Chem 133:1117–1122

Rytel E, Tajner-Czopek A, Kita A, Miedzianka J, Bronkowska M (2015) The influence of washing and selection processes on the contents of glycoalkaloid and other toxic compounds during industrial chip production. Int J Food Sci Technol 50:1737–1742. https://doi.org/10.1111/ijfs.12840

Peksa A, Lubowska G, Anilowski K, Lisinska G, Rytel E (2006) Changes of glycoalkaloids and nitrate contents in potatoes during chip processing. Food Chem 97:151–156

Beuth Verlag (1996) DIN EN 12145:1996-10 Fruit and vegetable juices - Determination of total dry matter - Gravimetric method with loss of mass on drying; German version

AOAC (1973) AOAC Official Method 925.07: Fat in Cacao Products

Matsuda F, Morino K, Miyazawa H, Miyashita M, Miyagawa H (2004) Determination of potato glycoalkaloids using high-pressure liquid chromatography-electrospray ionisation/mass spectrometry. Phytochem Anal PCA 15:10. https://doi.org/10.1002/pca.755

EURACHem (2014) The fitness for purpose of analytical methods. https://www.eurachem.org/index.php/publications/guides/mv. Accessed 6 Feb 2024

Commission Implementing Regulation (EU) 2023/2783 of 14 December 2023 laying down the methods of sampling and analysis for the control of the levels of plant toxins in food and repealing Regulation (EU) 2015/705

Barceloux DG (2009) Potatoes, tomatoes, and solanine toxicity (Solanum tuberosum L., Solanum lycopersicum L.). Dis Mon 55:391–402

Knuthsen P, Jensen U, Schmidt B, Larsen IK (2009) Glycoalkaloids in potatoes: Content of glycoalkaloids in potatoes for consumption. J Food Compos Anal 22:577–581

Nema PK, Ramayya N, Duncan E, Niranjan K (2008) Potato glycoalkaloids: formation and strategies for mitigation. J Sci Food Agric 88:1869–1881

Ruprich J, Rehurkova I, Boon PE, Svensson K, Moussavian S, van der Voet H, Bosgra S, van Klaveren JD, Busk L (2009) Probabilistic modelling of exposure doses and implications for health risk characterization: glycoalkaloids from potatoes. Food Chem Toxicol 47:2899–2905

Rytel E (2012) Changes in the levels of glycoalkaloids and nitrates after the dehydration of cooked potatoes. Am J Potato Res 89:501–507

Liu W, Zhang N, Li B, Fan S, Zhao R, Li L-P, Wu G-H, Zhao Y (2014) Determination of α-chaconine and α-solanine in commercial potato crisps by QuEChERS extraction and UPLC-MS/MS. Chem Pap 68:1099. https://doi.org/10.2478/s11696-014-0617-8

Acknowledgements

We would like to thank the Intersnack Group GmbH & Co KG, The Lorenz Bahlsen Snack-World GmbH & Co KG and Agrarfrost GmbH & Co KG for the intensive support of our project, for numerous discussions on the topic of GAs and for the opportunity to carry out the industrial trial and providing the samples along the production chain for the production of potato crisps.

We would also like to thank Ms. Lisa Weltermann for her very helpful assistance in the laboratory and the statistical evaluations.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

None.

Compliance with ethics requirements

This research does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Raters, M., Strohmaier, R. & Heckel, F. Glycoalkaloid transformation during potato crisps production? Method validation and industrial trial. Eur Food Res Technol 250, 1341–1351 (2024). https://doi.org/10.1007/s00217-023-04463-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04463-y