Abstract

Bilberries (Vaccinium myrtillus) are the most common wild berries in Northern Europe. A substantial amount of the berries are picked with the objective to extract highly valued products such as anthocyanins. A smaller amount of the bilberries is used to make jams and drinks, and these are generally restricted to the domestic market. One reason is the sour taste, partly as a result of the high content of malic acid. By using certain strains of lactic acid bacteria with the ability to convert malic acid to lactic acid, the taste is predicted to be more pleasant. This process is called malolactic fermentation, and historically it has mostly been used in winemaking. After testing five different starter cultures, we identified that the strain, Lactiplantibacillus plantarum LP58, can rapidly convert malic acid to lactic acid without any loss of sugar or citric acid, which strongly indicates a successful malolactic acid fermentation. As it has been reported that other strains of L. plantarum can be used as biopreservative agents, the resulting product was also tested in terms of microbial safety after prolonged storage, and by means of metagenome sequencing. The obtained product was quite tolerant to microbial growth, but this observation was rather due to an initial heat treatment than the addition of lactobacilli. Potentially, starter cultures with documented biopreservative activity can be combined with L. plantarum LP58 to obtain a more stable product. Until then, the fermented bilberry juice must be processed and preserved like non-fermented bilberry products.

Similar content being viewed by others

Introduction

In Sweden, bilberries, or European blueberry (Vaccinium myrtillus), are the most naturally abundant wild berry species. It covers 11% of the Swedish forests with a natural production of more than 400,000 tons per year. Most of the bilberries harvested in Sweden are usually cleaned and frozen after picking. Subsequently, they are exported and used for extraction of high valued bio-products like anthocyanins from the skin and omega-3 oil from the seeds for health supplements and cosmetic products [1]. A smaller volume, limited to the domestic market, is used for berry-based food and drink products, e.g. jams, juice concentrates, soups, and dried berries [2]. To promote the use of Swedish bilberries as a food product globally, there is a need to design more sustainable processes and products that take advantage of the bilberry nutritional profile and limit waste. In this work, the focus is on non-alcoholic bilberry beverages that are naturally rich in sugars, but the sour taste can be one explanation why they are not widely used as beverages. Controlling the acidity of bilberry juice is a key for promoting consumption. The main substance that is responsible for the sour taste is malic acid [3]. Therefore, malolactic fermentation (MLF) can be a strategy for deacidification of the juice and improving its sensory acceptance. During this fermentation, l-malic acid is converted into equimolar amounts of l-lactic acid, which gives rise to a more pleasant taste since it is perceived as less acidic at invariant pH. Historically, MLF has been mostly studied in wine as secondary fermentation to modify the flavour properties and reduce sourness [4,5,6]. Recently, this process has been getting more attention for the fermentation of berry juices including bilberries [3, 7, 8].

MLF is dependent on lactic acid bacteria (LAB) and there are several strains with reported activity, e.g. in the species of Oenococcus oeni, Lactoplantibacillus plantarum (formerly Lactobacillus plantarum), Lactobacillus acidophilis, Pediococcus pentosaceus and Pediococcus acidilactici [9,10,11,12]. L. plantarum is of particular interest because of its large diversity of enzymes, shorter incubation time, better conversion of malic acid into lactic acid and better aromatic profile given in wine and mulberry juice [7, 13, 14]. Furthermore, L. plantarum can improve the shelf life of fermented foods [15, 16] and thereby shows an interesting potential for fermenting berry juice. The mechanisms are not fully elucidated, but several L. plantarum strains have the capacity to produce antimicrobial substances, e.g. cyclic dipeptides and phenyllactic acid that have antifungal activities and thereby the potential to improve product shelf-life [17, 18].

The main goal of this work is to identify LAB strains that are able to perform malolactic fermentation in bilberry juices for exclusive and maximum malic acid reduction. In addition, we investigate the microbial community and the potential of improved product stability as a result of fermentation.

Materials and methods

Microorganisms

Frozen organic bilberries (Vaccinium myrtillus) were locally purchased and stored at −20 °C. The following bacterial starter cultures were obtained from SACCO S.R.L. (Italy): Lactiplantibacillus plantarum (LP58, LP01), Pediococcus pentosaceus (PP02), Lactobacillus acidophilus (LA03), Pediococcus acidilactici (PA09). All strains were supplied as freeze-dried products and stored at −20 °C until use.

Juice making

Berries were thawed overnight at 5 °C before pressing. Bilberry juice was prepared with a hydraulic press (Hafico, Germany) applying a pressure of 50 kg/cm2 for 1 min, followed by a pressure of 100 kg/cm2 for 1 min. Every pressing was performed with a load of 700 g of berries. The juice was filled in sterile bottles and kept at −20 °C for at least 24 h before fermentation.

Heat treatment and inoculation with starter cultures

Heat treatments of bilberry juices prior to fermentation were performed in 500 mL aliquots using a water bath (Julabo SW23) set at 65 °C and 50 rpm shaking speed. The temperature in the juice was monitored using a thermocouple (Armatherm GTH 1160 digital thermometer, Germany) and when the temperature of the juice reached 64.5 °C, the treatment continued for another 5 min, and the juice was cooled down quickly to room temperature for subsequent addition of starter cultures.

The starter cultures were rehydrated by resuspending approximately 1 g in 10 mL of sterile 0.5% NaCl water for 1 h before inoculation. Each sample consisting of 200 mL of bilberry juice was inoculated with approximately 7*107 CFU/mL LAB and incubated during 14 days at 25 °C, and for some samples, with an additional inoculation, also with 7*107 CFU/mL LAB, after 7 days. In addition, two different controls without inoculation were prepared, with and without heat treatment.

Determination of microbial counts and shelf life

During fermentation, viable LAB were estimated using De Man, Rogosa and Sharpe (MRS) agar supplemented with 1 mg/L Amphotericin B. Colonies on the MRS plates were enumerated after incubation under anaerobic conditions at 30 °C for 2–3 days. Yeast and mould growth was monitored using the selective dichloran rose bengal chloramphenicol (DRBC) media and counted after 5 days at 25 °C. Total aerobic count was monitored using Tryptic soy agar (TSA) plates and counted after 2–3 days at 30 °C. Using the same methodology, the effect of the different treatments on the shelf life of the juices after storage at 4 and 25 °C was examined. Samples were taken after 1, 2 and 3 months.

Nutritional quantities

During the malolactic fermentation process, l-malic acid and l-lactic acid concentrations were continuously measured using an absorbance detection method (l-Malic Acid Assay Kit K-LMAL-116A and l-Lactic Acid Assay Kit, K-LATE, Megazyme) according to the manufacturer’s instructions. The juice samples were diluted ten times with deionized water before analysis. The absorbances were measured at 340 nm by a spectrophotometer (BECKMAN DU530 UV–Vis).

To monitor the sugar level throughout the MLF, a refractometer was used to monitor °Brix, where 1 degree Brix (°Bx) represents 1 g of sucrose in 100 g of solution [19]. The pH was monitored during the fermentation using a pH-meter (HI-8418 HANNA instruments). For a subset of samples, the quantities of organic acids and of individual sugars were analyzed externally at Eurofins Food & Feed Testing. The organic acids were analysed using HPLC (Eurofins, Cuneo, Italy), whereas the total sugar content was analysed using high-performance anion-exchange chromatography with pulsed amperometric detection (HPAEC–PAD) according to AOAC official method 982.14 (Eurofins, Lidköping, Sweden).

Metagenome sequencing

The following samples of bilberry juices were analysed with metagenomic sequencing: non-heat-treated juice before and after 14 days of incubation, and heat-treated juice inoculated with LP58 after 14 days (with and without reinoculation of LP58 at day 7). DNA was extracted from the remaining pellet after centrifugation of the juice samples at approximately 10 000g for 10 min. The pellet was washed in physiological saline solution and DNA extraction was performed using Invitrogen PureLink™ Microbiome DNA Purification Kit (ThermoFisher Scientific). The sequencing was performed externally by Eurofins Genomics including taxonomic profiling using Krona plots [20].

Results

Screening of bacterial strains

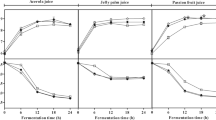

Bilberry juice was obtained by pressing frozen bilberries. Applied press conditions were based on previous experiences (unpublished data) and each batch containing 5.5 kg bilberries resulted in 3 L of bilberry juice. Five different starter-culture strains were added to heat-treated bilberry juice. During the fermentation, the pH, the concentrations of l-malic acid and l-lactic acid, and total sugar contents were frequently measured for up to 16 days. From these initial experiments, two Lactiplantibacillus plantarum strains (LP01 and LP58) were efficient in transforming l-malic to l-lactic acid without sugar consumption. The two Pediococcus strains, PA09 and PP02, and Lactobacillus acidophilus (LA03) were not able to perform MLF efficiently under the tested conditions. Examples of individual and valid fermentations with the different starter cultures are shown in Fig. 1a–e. The fermentations shown in Fig. 1 had stable °Brix and pH values during the fermentation and were between 12–13°Brix with a pH ranging from 2.9 to 3.1 (a typical pattern is shown in Fig. 1f). When comparing the results from the two L. plantarum strains, it was evident that LP58 was the most efficient starter culture with respect to successful acid conversion. Therefore, additional fermentations for subsequent experiments in this study were performed using the L. plantarum LP58 starter culture. To verify the necessity of heat treatment prior to addition, the L. plantarum LP58 was added to bilberry juice without an initial heat treatment. In this fermentation, the total level of sugar was reduced, similar to the non-heated control, and thereby considered unsuccessful (data not shown).

Representative evolution of l-lactic acid and l-malic acid concentration for the different strains: L. plantarum LP58 (a), L. plantarum LP01 (b), P. pentoaceus PP02 (c), L. acidophilus LA03 (d) and P. acidilactici PA09 (e), and evolution of °Brix and pH for L. plantarum LP01 to demonstrate a standard °Brix and pH evolution in the fermentations (f)

Nutritional analysis and conversion of juice fermented with L. plantarum LP58

To verify the MLF and to further elaborate on the change of nutrient composition obtained by fermentation with LP58, samples were externally analysed using chromatography-based methods rather than the enzymatic assays used previously. The results obtained were similar and are shown in Fig. 2. Besides conversion of malic and lactic acids, and sugars, the concentration of citric acid was intact during fermentation. Other measured sugars and organic acids were under the limit of detection and are thus not presented.

Glucose, fructose and total sugar concentration before and after fermentation (a). Concentrations of citric, malic and lactic acid concentrations before and after fermentation analysed with HPLC (b). Striped bars represent heat-treated bilberry juice prior to fermentation, whereas dark grey bars represent bilberry juice after 13 days of inoculation with L. plantarum LP58

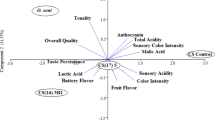

Additional fermentations to confirm the MLF potential of L. plantarum LP58 and to evaluate the conversion efficacy in different juice preparations

New fermentations, using juices from different batches were carried out using the best performing starter culture, L plantarum LP58. There were some differences compared to the initial screening experiments: The fermentations were always terminated after 14 days, and for some fermentations the starter culture was added again after 7 days. The reason for this reinoculation was to ensure that all malic acid was converted to lactic acid. Samples for pH and nutritional analyses were taken at fixed time points. Also, from the same fermentations, samples were taken for microbial counting during and after the fermentation, and for some samples, and time points, microbial DNA was extracted. In essence, results from the initial screening were confirmed, i.e. showing reduced concentration of malic acid and increased concentration of lactic acid, with a slight increase in conversion observed for the reinoculated samples (Fig. 3). The initial °Brix values varied between 7 and 13 between the samples. but remained constant during the fermentations, except for the non-heat-treated samples (sample 1 decreased with one °Brix during fermentation and sample 2 decreased with two °Brix). Notably, the four samples with lower starting l-malic acid (see Fig. 3a) concentration also had lower °Brix values (data not shown). The pH values differed between 2.6 and 3.1 for the samples and were stable during the 2-week fermentation for all samples except the non-heat-treated samples which decreased by 0.4 and 0.2 in samples 1 and 2, respectively (data not shown).

Evolution of l-malic acid concentration (a) and l-lactic acid concentration (b) as a function of the fermentation time. Non-heat-treated controls (filled and non-filled rhomb), heat-treated controls (filled and non-filled circle), inoculated with L. plantarum LP58 (filled and non-filled square), and inoculated with L. plantarum LP58 and reinoculated after day 7 with the same strain (filled and non-filled triangle). Filled symbols indicate odd number samples and non-filled symbols indicate even number samples. R indicates the time of reinoculation for samples 7 and 8

The efficacy of the l-malic conversion into l-lactic was calculated by dividing the l-lactic production (l-lactic acid content at after 13/14 days—l-lactic acid content from start) with the amount of l-malic acid degraded (l-malic acid from the beginning—l-malic acid content at 13/14 days). This was done with values from a total of eight individual fermentations with L. plantarum LP58, where two of them were derived from reinoculated samples (Table 1).

Microbial flora during fermentation and effects of treatment on shelf life

To test the population dynamics of the starter culture and the potential of prolonged storage of the fermented juices, microbial contents were estimated during fermentation and after storage for up to 3 months. Traditional plating techniques were used on the same eight samples that previously were used to confirm the MLF. Estimated numbers of the starter culture are depicted in in Fig. 4. In the samples without addition of starter cultures, never more than one colony could be observed on MRS media in non-diluted samples (data not shown).

Representation of the LAB evolution during fermentation (a). Striped bar on the day of inoculation, dark grey bar after 1 week (before reinoculation for sample 7–8) and light grey bar at the end of fermentation. Number of lactic acid bacteria after 1 month, 2 months and 3 months are shown at two different temperatures, 4 and 25 °C (b). The striped bar represents the number of LAB after 1 month at 25 °C, black bar represents LAB after 1 month at 4 °C and the light grey bar represents LAB after 2 months at 4 °C. As in Fig. 3, the sample numbers 5–6 refer to samples only inoculated at the start of the fermentation, while samples 7–8 also were reinoculated at day 7. Samples without bars are below limit of detection that were 1 CFU/mL (a) and 10 CFU/mL (b)

Besides population dynamics of the starter culture, the total growth of bacteria and fungi was estimated during fermentation and after storage (Fig. 5). When counting fungi (Fig. 5b, e, f), a noticeable observation was that yeasts were dominant in samples 1 and 2 (non-heat-treated controls), while moulds were dominant in all the other samples where fungal growth was observed (data not shown).

Observed colony forming units of bacteria (TSA plates) and fungi (DRBC) plates. Total bacterial growth during fermentation (a), total fungal growth during fermentation (b), bacterial growth after storage of 1, 2 and 3 months at 4 °C (c), bacterial growth at 25 °C (d), fungal growth at 4 °C (e) and fungal growth at 25 °C (f). Striped bars represent start of fermentation in (a, b) and month 1 in (c–f), dark grey bars represent day 7 in (a, b) and month 2 in (c–f), whereas a light grey bar represents day 14 in (a, b) and month 3 in (c–f). The individual samples used are the same as used in previous experiments (see Fig. 3), i.e. non-heat-treated controls (1–2), heat-treated controls (3–4), inoculated with L. plantarum LP58 (5–6) and inoculated with L. plantarum LP58 and reinoculated after day 7 with the same strain (7–8). Note, for some samples, in figures c–f, with high numbers (> 4 log CFU/mL), exacts numbers are rather unprecise due to very high number of colonies on some of the plates. On day 0, the number of bacteria after inoculation is shown, and after 7 days the number of bacteria before reinoculation for sample 7–8 is presented (a, b). Samples without bars are below limit of detection that were 1 CFU/mL (a, b) and 10 CFU/mL (c–f)

Fermentation effects on the microbial community

To obtain more insight into how fermentation affects the overall microbial community with focus on potential spoilage microorganisms, the bilberry juices were subjected to metagenome sequencing before and after fermentation. As a result of the DNA extraction protocol, it was not possible to perform any analyses on the thermal-treated control. Hence, results are restricted to the non-heated control before and after 14 days of incubation at 25 °C, and with samples with LP58 as starter culture after 14 days (with and without reinoculation of LP58 at day 7). Before heat treatment, the dominant microbe in the bilberry juice was Frateuria aurantia. After 14 days, it was still common but partly outcompeted by other bacteria. In the samples inoculated with starter culture, L. plantarum was totally dominant. To identify potential spoilage organisms, the species distributions were also analysed using Krona plots. For none of the four samples, no common spoilage bacterium or yeast was detected. For filamentous fungi, approximately 50 different species could be identified and among those were up to 35 Aspergilli, with little variation between samples. The two dominant fungi in all samples were Aspergillus lentelus and Botrytis cinerea.

A short summary of sequencing results is given in Table 2 and the sequencing reports can be found as supplementary data (technical report and Krona plots as separate HTML files).

Discussion

In the present work, several LAB starter cultures were evaluated in terms of MLF efficacy. Based on experimental observations, it is evident that the two L. plantarum strains were the most efficient of the tested starter cultures to perform MLF in bilberry juice. However, no firm conclusions can be drawn regarding why the other strains were not as efficient, at least not in the tested time frame of 2 weeks. It could be due to the inability to perform MLF under the tested conditions, or due to the bilberry juice not being a preferred substrate for these particular strains.

The superior strain with respect to the ability to perform MLF effectively was L. plantarum LP58, in which we could observe a molar conversion rate of malic acid to lactic acid close to 1.0 with no sugar consumption. Unless there is a degradation of more complex carbohydrates, not detected in the analysis, it can be concluded that all lactic acid molecules were derived from malic acid. This observation is further supported by the fact that citric acid is not consumed, as this is also a known metabolic pathway to synthesize lactic acid through the intermediate oxaloacetate [21]. This in in contrast to the reports by Viljakainen and Laakso where citric acid was consumed using O. oeni as starter culture, with less efficient conversion of malic acid, and some indication of sugar reduction. [3] As observed, initial concentration of malic and citric acids and the sugar concentration in the bilberries juices in the two studies are mostly identical, and the observed difference in MLF efficacy can probably be explained by the use of different starter cultures.

The metagenome sequencing of some of the samples of bilberry juices did not provide any results of great interest in relation to MLF. However, it did support that the starter culture LP58 was correctly classified and that even after heat treatment and successful fermentation, there were several potential spoilage microorganisms that could grow, a fact also confirmed in the shelf-life studies. Moreover, to our knowledge, this is the first observation of F. aurantia in bilberries; originally this bacterium was identified in raspberries and in the lily flower Lilium auratum [22]. The presence of B. cinerea was not surprising and justifies previous use of this fungus as model in shelf-life studies of bilberries [23, 24].

The microbial count during the fermentation and the subsequent shelf-life study can be interpreted, as addition of L. plantarum LP58 did not have a huge impact on microbial growth compared to the unfermented control. Another observation is that the viability of L. plantarum LP58 is rather low, as the number of countable LAB starts to decline during fermentation. After longer storage, other bacteria and fungi start to grow but in less number. This indicates that the bilberry juice is not a suitable habitat for the starter culture and that the strain is outcompeted by other microorganisms, an observation also noted by Viljakainen and Laakso [3]. When examining total bacterial counts, there are some variations even between identical samples, although most pronounced in the controls without starter culture. Despite this variation, the total numbers of microorganisms in bilberry juice are not in contrast to what has been reported previously [25]. For inoculated samples, the variation is smaller, and a plausible explanation is that most of the countable total bacteria refers to the starter culture. Although, less fungal growth observed in fermented samples, based on the high variation in fungal growth after storage, it is not possible to draw any firm conclusion related to fungal growth and thereby not supporting that the starter culture has any antifungal activity. The sample variation and inaccuracy in colony counting do not change the overall conclusion related to food safety, as stored samples cannot be considered as safe after storage under the tested conditions. When counting yeasts and moulds, an interesting observation is that in the non-heat-treated controls, only yeast growth was observed, while in the other samples only moulds. As vegetative mould spores, in general, have lower inactivation temperatures than yeasts [26], it is likely that observed mould growth has been originating from germinated ascospores that survived the heat treatment, but are not dependent on a thermal activation, e.g. Aspergillus nidulans [27], which was identified in the metagenome sequencing. This fact could explain why mould growth was not observed in all samples stored at 4 °C and with delayed growth at 25 °C (see Fig. 5e, f). However, any comparison between colony counting and metagenome sequencing must be considered with caution. For example, all extracted DNA might not derive from viable microorganisms, and the used culture media might not enable growth of all the present microorganisms.

To conclude, the L. plantarum strain LP58 can efficiently be used as a starter strain when fermenting bilberry juice. The rapid conversion of malic acid to lactic acid without reducing the sugar concentration, make it a potential strain that can be used to improve the taste of bilberry juice. However, as there is no significant evidence of microbial inhibition in inoculated samples compared to the control, it cannot efficiently be used to improve the rather short shelf life of the product at ambient temperatures. It could be possible to isolate strains with high MLF ability that also has strong antimicrobial properties, or L. plantarum LP58 can be combined with one or more additional starter cultures providing a product with additional antimicrobial properties [28]. Alternatively, if the intention is to produce alcoholic beverages, the MLF can be combined with wine yeast and produced ethanol can serve as a microbial inhibitor [29]. Evidently, at this stage, to produce a safe bilberry juice that has underwent MLF, it is necessary to, like for other juices, include an inactivation step, probably using higher temperatures than the 65 °C used here, combined with safe production processes and packaging, and possibly combined with addition of weak acid preservatives [30].

References

Vanekova Z, Rollinger JM (2022) Bilberries: curative and miraculous—a review on bioactive constituents and clinical research. Front Pharmacol. https://doi.org/10.3389/fphar.2022.909914

Plummer P, Andersson J, Lennerfors T, Forsberg P (2021) Rewilding sustainability transitions: a socio-techno-ecological systems perspective on the Swedish wild berry industry. In: International sustainability transitions conference (IST 2021), Karlsruhe, Germany, October 5–8, 2021. urn:nbn:se:uu:diva-457390

Viljakainen SK, Laakso SV (2002) Acidity reduction in northern region berry juices by the malolactic bacterium Oenococcus oeni. Eur Food Res Technol 214:412–417. https://doi.org/10.1007/s00217-001-0470-1

Viljakainen S, Laakso S (2000) The use of malolactic oenococcus oeni (ATTC 39401) for deacidification of media containing glucose, malic acid and citric acid. Eur Food Res Technol 211:438–442

Versari A, Parpinello G, Cattaneo M (1999) Leuconostoc oenos and malolactic fermentation in wine: a review. J Ind Microbiol Biotechnol 23:447–455

Paramithiotis S, Stasinou V, Tzamourani A, Kotseridis Y, Dimopoulou M (2022) Malolactic fermentation—theoretical advances and practical considerations. Fermentation. https://doi.org/10.3390/fermentation8100521

Wu Y, Li S, Tao Y, Li D, Han Y, Show PL, Wen G, Zhou J (2021) Fermentation of blueberry and blackberry juices using Lactobacillus plantarum, Streptococcus thermophilus and Bifidobacterium bifidum: growth of probiotics, metabolism of phenolics, antioxidant capacity in vitro and sensory evaluation. Food Chem. https://doi.org/10.1016/j.foodchem.2021.129083

Behrends A, Weber F (2017) Influence of different fermentation strategies on the phenolic profile of bilberry wine (Vaccinium myrtillus L.). J Agric Food Chem 65:7483–7490. https://doi.org/10.1021/acs.jafc.7b0226

duToit M, Engelbrecht L, Lerm E, Krieger-Weber S (2011) Lactobacillus: the next generation of malolactic fermentation starter cultures—an overview. Food Bioprocess Technol 4:876–906. https://doi.org/10.1007/s11947-010-0448-8

Sharma A, Noda M, Sugiyama M, Kumar B, Kaur B (2021) Application of Pediococcus acidilactici BD16 (alaD +) expressing L-alanine dehydrogenase enzyme as a starter culture candidate for secondary wine fermentation. Biotechnol Biotechnol Equip 35:1643–1661. https://doi.org/10.1080/13102818.2021.1995496

Rozès N, Lluìs A, Bordons A (2003) Effect of phenolic compounds on the co-metabolism of citric acid and sugars by Oenococcus oeni from wine. Lett Appl Microbiol 36:337–341. https://doi.org/10.1046/j.1472-765x.2003.01323.x

Chen R, Chen W, Chen H, Zhang G, Chen W (2018) Comparative evaluation of the antioxidant capacities, organic acids, and volatiles of papaya juices fermented by Lactobacillus acidophilus and Lactobacillus plantarum. J Food Qual. https://doi.org/10.1155/2018/9490435

Brizuela N, Tymczyszyn EE, Semorile LC, La Hens DV, Delfederico L, Hollmann B-F (2019) Lactobacillus plantarum as a malolactic starter culture in winemaking: a new (old) player? Electron J Biotechnol 38:10–18. https://doi.org/10.1016/j.ejbt.2018.12.002

Kwaw E, Ma Y, Tchabo W, Wu AMTM, Sackey AS, Xiao L, Tahit HE (2018) Effect of lactobacillus strains on phenolic profile, color attributes and antioxidant activities of lactic-acid-fermented mulberry juice. Food Chem 250:148–154. https://doi.org/10.1016/j.foodchem.2018.01.009

Behera SS, Ray RC, Zdolek N (2018) Lactobacillus plantarum with functional properties: an approach to increase safety and shelf-life of fermented foods. Biomed Res Int. https://doi.org/10.1155/2018/9361614

Guimaraes A, Santiago A, Teixeira JA, Venancio A, Abrunhosa L (2018) Anti-aflatoxigenic effect of organic acids produced by Lactobacillus. Int J Food Microbiol 264:31–38. https://doi.org/10.1016/j.ijfoodmicro.2017.10.025

Svanström Å, Boveri S, Boström E, Melin P (2013) The lactic acid bacteria metabolite phenyllactic acid inhibits both radial growth and sporulation of filamentous fungi. BMC Res Notes 6:464. https://doi.org/10.1186/1756-0500-6-464

Ström K, Schnürer J, Melin P (2005) Co-cultivation of antifungal Lactobacillus plantarum MiLAB 393 and Aspergillus nidulans, evaluation of effects on fungal growth and protein expression. FEMS Microbiol Lett 246:119–124. https://doi.org/10.1016/j.femsle.2005.03.047

Jaywant S, Singh H, Arif KM (2022) Sensors and instruments for brix measurement: a review. Sensors 22:2290. https://doi.org/10.3390/s22062290

Ondov BD, Bergman NH, Phillippy AM (2011) Interactive metagenomic visualization in a web browser. BMC Bioinform 12:385. https://doi.org/10.1186/1471-2105-12-385

Wang Y, Wu JW, Lv M, Shao Z, Hungwe M, Wang J, Bai X, Xie J, Wang Y, Geng W (2021) Metabolism characteristics of lactic acid bacteria and the expanding applications in food industry. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2021.612285

Swings J, Gillis M, Kersters K, deVos P, Gosselé F, De Ley J (1980) Frateuria, a new genus for “Acetobacter aurantius”. Int J Syst Bacteriol 30:547–556

Hefft DI (2018) Effects of chitosan-coated paperboard trays. Int J Fruit Sci 18:300–306

Koskimäki JJ, Hokkanen J, Jaakola L, Suorsa M, Tolonen A, Mattia S, Pirttilä AM, Hohtola A (2009) Flavonoid biosynthesis and degradation play a role in early. Eur J Plant Pathol 125:629–640. https://doi.org/10.1007/s10658-009-9511-6

Dinkova R, Heffels P, Shikov V, Weber F, Schieber A, Mihalev K (2014) Effect of enzyme-assisted extraction on the chilled storage stability of bilberry (Vaccinium myrtillus L.) anthocyanins in skin extracts and freshly pressed juices. Food Res Int 65:35–41. https://doi.org/10.1016/j.foodres.2014.05.066

Shearer AEH, Mazzotta AS, Chuyate R, Gombas DE (2002) Heat resistance of juice spoilage microorganisms. J Food Protect 65:1271–1275. https://doi.org/10.4315/0362-028x-65.8.1271

Kaminskyj SGW (2001) Fundamentals of growth, storage and microscopy of Aspergillus nidulans. Fungal Genet Rep. https://doi.org/10.4148/1941-4765.1175

Sadiq FA, Yan B, Tian F, Zhao J, Zhang H, Chen W (2019) Lactic acid bacteria as antifungal and anti-mycotoxinegic agents: a comprehensive review. Compr Rev Food Sci Food Saf 18:1403–1436. https://doi.org/10.1111/1541-4337.12481

Dao T, Dantigny P (2011) Control of food spoilage fungi by ethanol. Food Control 22:360–368. https://doi.org/10.1016/j.foodcont.2010.09.019

Beales N (2006) Adaptation of microorganisms to cold temperatures, weak acid preservatives, low pH, and osmotic stress: a review. Compr Rev Food Sci Food Saf 3(1–20):2006. https://doi.org/10.1111/j.1541-4337.2004.tb00057.x

Acknowledgements

All bacterial starter cultures tested and used in this study were kindly supplied by SACCO. Xinmei Feng and Roger Uddstål are greatly acknowledged for their valuable ideas during the early stages of the project. We also acknowledge Unn Tjörnstrand, Ingela Persson, Alexander Plovie and Karin Bjerre for assistance with shelf-life test and preparation and analyses of metagenomic samples. This study was performed within FINEST, a research programme financed by the Swedish research council FORMAS, and by Region Västerbotten.

Funding

Open access funding provided by RISE Research Institutes of Sweden. Svenska Forskningsrådet Formas, 2020-02839_Formas.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests or fundings that are directly or indirectly related to the submitted work.

Compliance with ethics requirement

In the study, the work was restricted to harvested bilberries and microorganisms. Hence, this study does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

File 1

Metagenome analysis report. The individual fermentations are the same as previously used in Figs.3-5 where sample s221206_2_FINEST refers to sample 2 at day 0, and s221220_2_FINEST after 14 days incubation in at 25 °C (i.e., non-heat-treated control). Sample s221220_6 refers to sample 2 (i.e., inoculated with LP58) after 14 days of fermentation, and Sample s221220_8 refers to sample 8 (i.e., inoculated with LP58 and reinoculated after 7 days) after 14 days of fermentation. Supplementary file1 (HTML 5693 KB)

File 2

Krona plots illustrating detailed species distribution of non-heated control prior to fermentation and after day 14, as well as samples with starter cultures after day 14 with or without re-inoculation at day 7. The key for sample identification is identical to what is described in the Fig. 1s caption [1]. Supplementary file2 (HTML 1036 KB)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bergentall, M.K., Malafronte, L., As, D. et al. Reduction of malic acid in bilberry juice by Lactiplantibacillus plantarum-mediated malolactic fermentation. Eur Food Res Technol 250, 811–820 (2024). https://doi.org/10.1007/s00217-023-04435-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04435-2