Abstract

Malolactic fermentation using sea buckthorn (Hippophaë rhamnoides) juice as raw material was performed with six different strains of Lactobacillus plantarum. Increasing juice pH from 2.7 to 3.5 or adapting cells to low pH (i.e., acclimation) prior to inoculation allowed malolactic fermentation with all tested strains. Moreover, reducing pH of the growth medium from 6 to 4.5 with l-malate had little or no impact on biomass production. Volatile profile of sea buckthorn juice was analyzed with HS-SPME–GC–MS before and after fermentation. A total of 92 volatiles were tentatively identified and semi-quantified from sea buckthorn juice, majority of which were esters with fruity odor descriptors. Esters and terpenes were decreased in both inoculated and control juices during incubation. Microbial activity increased the levels of acetic acid (vinegar like), free fatty acids (cheese like), ketones (buttery like), and alcohols with fruity descriptors. Conversely, aldehydes associated with “green” aroma were decreased as a result of fermentation. Juices fermented with DSM 1055 had the highest acid and alcohol content, while fermentation with DSM 13273 resulted in the highest content of ketones. Compared to inoculation with other strains, fermentation with strains DSM 16365 and DSM 100813 resulted in rapid malolactic fermentation, less production of volatile acids, and lower loss of esters and terpenes important for natural sea buckthorn flavor.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sea buckthorn (Hippophaë L.) is a genus of deciduous shrubs belonging to the family Elaeagnaceae. Eight species have been identified within the genus, originating from different regions throughout the Eurasian continent and have been cultivated in Europe, Asia and the North America for commercial purposes [1]. Sea buckthorn produces oval shaped berries of yellow, orange or red color with strong variation both between and within species as well as among cultivars [2]. The berry mesocarp accumulates substantial amount of oil (up to 4% of FW), which consists of triacylglycerols, phospholipids, tocopherols, tocotrienols, carotenoids, and plant sterols. Hydrophilic fraction of the sea buckthorn berry contains high levels of ascorbic acid, flavonoids and organic acids [2]. Human trials have associated consumption of sea buckthorn and sea buckthorn products with improved health of mucous membranes [3, 4] and reduction in postprandial insulin response [5].

However, sensory value of sea buckthorn characterized by intensive sourness and astringency presents a great hurdle for utilization of the berry in food industry [6, 7]. Sour taste of sea buckthorn juice has been associated with the high content of organic acids, especially those of malic acid and quinic acid, with the total acid content ranging between 31 and 51 g/L, depending on the variety. Moreover, the juice has low natural sweetness, due to the low total sugar content (19–71 g/L) and low sugar/acid ratio [7, 8]. Astringency of sea buckthorn has been associated with the high content of flavonoids, especially with flavonols and procyanidins [9], as well as with the total acid content [7]. Recently, ethyl glucose, a β-d-glucopyranose derivative present in the sea buckthorn berry, was found to contribute to bitterness of sea buckthorn [10]. Additionally, the juice of sea buckthorn has high turbidity (Brix 9.3–22.7) [2] due to the presence of insoluble solids and suspended oil droplets [11].

One potential solution to reduce intense sourness of sea buckthorn is malolactic fermentation (MLF), which is used in the wine industry to reduce acidity and to alter aroma in wines. While typically performed using Oenococcus oeni, interest towards Lactobacillus plantarum as malolactic starter is increasing due to large cascade of enzyme it produces, potentially altering flavor properties of wines and other food products [12, 13]. Earlier, L. plantarum has been successfully used to improve the aroma profile of mulberry juices [14]. Besides flavor modification, benefits of using L. plantarum for bioprocessing of plant materials include improved shelf-life and food safety [15, 16], increased antioxidant capacity [14, 17, 18], and enhanced nutritional value and probiotic properties [19]. However, the changes in physicochemical properties are both raw material and strain dependent; fermentation of pomegranate juice with L. plantarum led to beneficial impact on aroma profile [20], while reducing antioxidant activity [21].

Earlier, MLF has been utilized with O. oeni to reduce acidity and, thus, to potentially affect pleasantness of sea buckthorn [8]. In addition, MLF with L. plantarum has been performed on sea buckthorn juice without pH adjustment or acclimation phase [22, 23]. MLF of sea buckthorn juice led to reduction in total acid content without affecting sugars, subsequently increasing sugar/acid ratio [22, 23]. In addition, flavonols of sea buckthorn were not affected; however, protocatechuic acid content was increased [22]. However, in general, the metabolic activity was limited under these circumstances.

Therefore, in this study, our first goal was to determine whether MLF of sea buckthorn can be enhanced by adjusting initial pH of the sea buckthorn juice or by preparing L. plantarum starter culture in acclimation medium prior to fermentation. In wine industry, acclimation is used to enhance wine malolactic fermentation by inducing stress-related gene expression prior to inoculation through exposure to ethanol, low pH, SO2 and l-malate in a medium rich in nutrients [24].

MLF with L. plantarum has potential to both improve aroma (due to ester, e.g., ethyl lactate, formation) and to produce spoilage off-aromas, such as volatile phenols with animal-like “horse sweat” aromas [25]. On the other hand, β-glucosidase activity can release aroma compounds from non-volatile precursors during fermentation [26]. Therefore, our second goal was to analyze changes in volatile profiles of sea buckthorn juice during MLF with HS-SPME–GC–MS to screen formation of potentially pleasant aromas (e.g., floral esters or alcohols) or fermentation related off-flavors. Due to the previous indication on strain-dependent functional properties of lactic acid bacteria as a result of adaptation to the specific environmental niche [19], six commercially available strains of L. plantarum originally extracted from various fermented plant-based foods were included in this study.

Materials and methods

Berry material

Frozen sea buckthorn (Hippophaë rhamnoides subsp. mongolica) berries were purchased from a professional farmer (Vinkkilän luomutuote, Vehmaa, Finland). According to the producer, the berries were a mixture of cultivars ‘Ljubitelskaja’ and ‘Prozrachnaya’. The berries were frozen right after picking and stored at − 20 °C until use.

Juice preparation

First, frozen sea buckthorn berries were thawed in a microwave at 600 W for 3.5 min. Next, berries were made into a mash with a Bamix immersion blender (ESGE Ltd., Switzerland). The juice was extracted from the mash with a fruit press (Chef Titanium XL with AT644 attachment, Kenwood, UK) in batches of ~ 400 g of mash, and the juice was filtered through a cheesecloth to remove solids. Thereafter, juice was pooled, divided into aliquots for each fermentation batch, and stored at − 20 °C until use.

Two types of juice were used for fermentation, one with natural pH (2.7) and the other with pH adjusted to 3.5 with 1 M NaOH. Study of malolactic gene of L. plantarum showed that both uptake of l-malate and malolactic fermentation rate were highest when extracellular pH was between 4 and 5 [27]. However, as pH is increased, metabolic flux towards fermentation of sugars is increased simultaneously [22], which was undesirable in our work. Therefore, pH 3.5 was selected as a compromise to increase malolactic activity, while limiting conversion of sugars to lactate.

Prior to pasteurization, the juices were diluted 1:1 (w/w) and divided into 30 mL aliquots in individual glass vials. The juice samples were pasteurized in a water bath (temperature ~ 96 °C) until temperature of the juices reached 90 °C, and this was followed by cooling the juices in an ice bath until 10 °C. Juice temperature was monitored with a thermometer (TM-947SD, Lutron Electronics, South Korea) coupled with a thermocouple probe (Supplementary Fig. S1). After cooling, the pasteurized juice samples were tempered for 1 h at + 30 °C in an IF-110Plus incubator (Memmert GmbH, Schwabach, Germany), followed by preparation for fermentation.

Fermentation

Preparation of bacterial strains as glycerol stocks

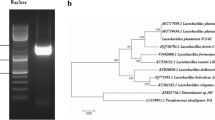

Freeze-dried cultures of five strains of Lactobacillus plantarum subsp. plantarum (DSM 100813 (originating from grape must), DSM 10492 (olive brine), DSM 1055 (bread dough), DSM 13273 (jojoba meal fermentation), DSM 20174T (pickled cabbage)) and one strain belonging to Lactobacillus plantarum subsp. argentoratensis (DSM 16365T, fermented cassava roots) were obtained from Deutsche Sammlung von Mikroorganismen und Zellkulturen (DSMZ, Braunschweig, Germany). The bacterial strains were revived in MRS plates for 48 h at + 30 °C, followed by a transfer of a single colony to 250 mL of general edible medium (GEM), prepared according to a previous report with modifications (dextrose 30 g L−1, soy peptone 20 g L−1, yeast extract 7 g L−1, MgSO4 × 7 H2O 1 g L−1, MnSO4 × H2O 0.05 g L−1, in potassium phosphate buffer 0.01 M, pH 6.3 ± 0.2) [28]. The inoculated GEM was incubated at + 30 °C for 24 h, divided into aliquots and mixed at a ratio of 1:1 with 20% glycerol solution, and stored at − 80 °C until use.

Optical density (OD600) linear regression models for estimating cell counts

To standardize inoculation rate of the SBJ, optical density (OD600) linear regression models were prepared individually for each of the used strains. First, a growth curve (measured as change in OD600 over time) for each strain was determined in GEM (Supplementary Fig. S2 and S3), showing an early stationary phase reached after approximately 24 h of fermentation with average cell count of 1–3 × 109 CFU/mL (OD600 = 2.2–2.3). Next, five dilutions were made from the cell culture with pure GEM to reach a linear range of the spectrophotometer (UV/Vis UV3100PC, VWR, PA, USA), corresponding to dilutions 1:30–1:6 and OD600 values between 0.2 and 0.7. Sterile GEM media were used as a blank. Each dilution was enumerated with the viable plate count (see Sect. “L. plantarum viability count”) to estimate CFU/mL for each OD600 value.

Acclimation medium

Cell acclimation medium (CAM) was prepared by adding l-malic acid (4 g/L) to GEM and adjusting pH to 4.5. Cell cultures with CAM was prepared similarly to those performed with GEM.

Starter culture preparation and fermentation

First, a scrape from glycerol stock was revived in a MRS plate for 36–48 h at + 30 °C. Next, a single colony was transferred from the MRS plate to 250 mL of either GEM or CAM followed by incubation at + 30 °C for 24–25 h. Next, 80–90 mL of the bacterial culture was transferred to sterile centrifuge tubes; thereafter, the cells were collected by centrifugation (4500 × g, 5 min, RT) and washed twice with PBS (140 mM NaCl, 3 mM KCl, 10 mM Na2HPO4, 2 mM KH2PO4, pH 7.4). After removal of supernatant, the cells were re-suspended to 5 mL of PBS to produce the starter culture. To estimate the cell count of the starter culture, OD600 was measured from a 1:200 dilution. Finally, 30 mL of pasteurized juice was transferred to autoclaved fermentation vessels, and starter culture was added to juice samples to reach an initial cell count of 8.30 Log CFU/mL juice. In total, four fermentation settings were ran simultaneously for each strain, juices with either initial pH 2.7 or 3.5, inoculated with cells from GEM (pH2.7/GEM and pH3.5/GEM, respectively) or CAM (pH2.7/CAM and pH3.5/CAM, respectively). The starter culture cell count was enumerated with viable cell plate count (see Sect. “L. plantarum viability count”).

The juice samples were fermented at + 30 °C for 36 or 72 h in an IF-110Plus incubator (Memmert GmbH, Schwabach, Germany). Control juices without inoculation with both initial pH 2.7 and 3.5 were incubated simultaneously with the inoculated samples for both 36 and 72 h. All fermentations were prepared as triplicates (three parallel inoculations). After fermentation, the samples were cooled down in an ice bath, each divided into aliquots and stored at –80 °C until analysis. During the whole experimental procedure, the samples were kept above + 4 °C only when necessary to limit residual enzymatic activity.

L. plantarum viability count

To estimate viable cell count in cultured media or starter cultures, the cell suspension was first serially diluted (1/10) with PBS, followed by streaking 100 µL of dilution to MRS agar plates (LabM, Heywood, UK) and incubation at + 30 °C for 36–48 h. All plates were prepared in triplicates. Colony counts between 30 and 300 on each plate were considered acceptable for enumeration.

Analysis of organic acids

The concentrations of l-malate, l-lactate and d-lactate of SBJ before and after fermentation were determined using K-LMAL, K-LATE, K-DATE enzyme kits (Megazyme, Bray, Ireland), respectively.

Determination of volatile compounds

The volatile compounds in the SBJ samples before and after fermentation were analyzed using a method described earlier [29] with modifications. Headspace volatiles from juice sample (2 mL of juice with 10% (w/v) NaCl and 10 µL ISTD (ethyl propionate 100 ppm; nonane 200 ppm)) were collected with solid phase microextraction (SPME) with a 2 cm DVB/CAR/PDMS fiber (50/30 μm, Supelco, Bellefonte, PA) at 45 °C for 20 min. Prior to headspace volatile collection, the juice sample was incubated 10 min at 45 °C and the fiber conditioned at 230 °C.

Analytical instrument of headspace volatiles consisted of a Trace 1310 gas chromatograph coupled with a TSQ 7000 single quadrupole mass spectrometer (Thermo Fisher Scientific, Waltham, MA). The gas chromatograph instrument was equipped with either DB-WAX polar capillary column (60 m × 0.25 mm i.d. × 0.25 μm film thickness, J&W Scientific, Folsom, CA) or SPB-624 mid-polarity capillary column (60 m × 0.25 mm i.d. × 1.4 μm film thickness, Supelco, Bellefonte, PA). Within each batch of analysis, the order of the samples was randomized to avoid systematic error from residual enzymatic activity.

The temperature program of the gas chromatograph oven was as follows: Tstart 50 °C, hold 3 min; Tend 200 °C, rate 5 °C/min, hold 8 min at 200 °C. For SPB-624 column, additional temperature ramp of Tend 230 °C, rate 10 °C/min, hold 4 min was added to reduce the risk of sample carry-over. The injector temperature was 220 °C and the initial injection mode was splitless; the split valve was opened after 0.10 min from injection. The carrier gas was helium at a flow rate of 1.6 and 1.4 mL/min for DB-WAX and SPB-624 columns, respectively. Mass spectra were detected in electron impact mode at 70 eV with a full scan mode (scan range of 33–300 m/z) and a scan speed 0.2 s. The temperatures of the MS transfer line was 200 °C and 210 °C for DB-WAX and SPB-624 columns, respectively. For both columns, the temperature of the ionization source was 220 °C. Each juice sample (prepared in biological triplicates) was analyzed once; no technical replicates were used. Empty vials and vials with only the internal standards were analyzed with every batch to confirm that no cross contamination occurred between the vials during the analysis.

The volatile compounds were identified by comparing mass spectra with standard NIST 08 library, literature data and Kovats retention indices (RI). The RIs of the volatile compounds were calculated based on retention times of C5–C30 alkane mixture (Sigma-Aldrich, St. Louis, MO) determined using the same gas chromatographic conditions. Individual volatile compounds were semi-quantified (µg/L) by comparing area of the base peak ion to the area of the base peak ion of ethyl propionate (internal standard) (Table 1), which was selected due to low sample to sample variation in peak area and high number of esters present in sea buckthorn juice. Results gained using DB-WAX column were used for semi-quantification, with a few exceptions (Table 1).

Statistical analysis

Results are reported as mean ± standard deviation, determined from biological triplicates. Paired Student’s t-test was used to compare pH and independent samples test to compare organic acid concentrations (unequal population size and unequal variances assumed) between untreated and fermented SBJ. For comparison of volatile profiles, Tukey’s test for population with equal variances and one-way ANOVA were performed for multiple comparisons. Differences reaching confidence level of p < 0.05 was considered as statistically significant. For comparison of the content of individual volatile compounds within each strain or juice treatment, statistical analyses were performed with software R 3.2.3 (The R Foundation for Statistical Computing, Vienna, Austria) using library agricolae (command HSD.test) [30]. Default parameters of the package was used. To study differences between L. plantarum strains (X = 6, n = 24) and the impact of fermentation time (0 h, n = 12; 36 h, n = 78; 72 h, n = 78), and juice pH and growth media as combined variable (X = 4, n = 36) in relation to the sums of volatile compound subgroups, IBM SPSS 26.0 (SPSS, Chicago, IL, USA) was used. In addition, principal component analysis (PCA) was carried out using the software Unscrambler X (version 11, Camo Inc., Norway). This was used to illustrate the relationship between volatile composition and the treatments applied to produce fermented SBJ.

Results and discussion

Production of L. plantarum starter culture

As normal basal medium (GEM) has been optimized for growing lactic acid bacteria, it was investigated whether CAM would require higher inoculation level due to reduced or limited growth rate. Earlier work has shown that L. plantarum retains moderate to high growth rate even when pH of growth medium is reduced to 4.5 [31].

The growth rate of L. plantarum strains DSM 1055 and DSM 13273 in cell acclimation media (CAM) was measured by following change in optical density (OD600) during incubation. These strains were selected as the former had the lowest and the latter highest viable cell count in GEM after 24 of incubation. Several inoculation levels were tested (single colony, 106–108 CFU/mL) (Supplementary Fig. S3). DSM 13273 showed similar growth rate in CAM as in GEM. However, DSM 1055 showed lower growth rate in CAM than in GEM, yet reached the target OD600 after 25 h of incubation. Thus, inoculation of CAM with a single colony was confirmed to be adequate.

Supplementary Table 1 shows details of the starter cultures of each L. plantarum strain used in this research. While the target inoculation level was 2 × 108 CFU/mL, viable plate counts of the starter cultures gave inoculation levels between 1.64 and 2.61 × 108 CFU/mL. While the linear regression models vary between the strains, it should be noted that the model for DSM 1055 underestimated, and the model for DSM 13273 overestimated, the expected cell count.

Malolactic fermentation of sea buckthorn juice

In MLF, decarboxylation of l-malate produces d- or l-lactate, thus increasing pH of the fermented material, unlike the fermentation of sugars by homolactic bacteria, which increases acidity of the food material. Hence, pH of the juice fermented for 36 h increased in correspondence to reduction of l-malate content and to increase of d- and l-lactate (Table 2). More importantly, acclimation of bacterial cells made it possible to ferment SBJ with natural pH with all the studied strains. Here, acclimation medium consisted of normal basal medium for lactic acid bacteria supplemented with l-malate at the concentration of 4 g/L and pH adjusted to 4.5. It has been observed that low pH and presence of l-malate induce expression of mle (malolactic enzyme gene) [12]. Increasing pH of the SBJ to 3.5 prior to fermentation improved MLF to comparable degree as obtained using acclimation medium.

Among the studied strains, only strain DSM 20174 showed production of d- and l-lactate without acclimation in juice with initial pH of 2.7. Comparing results between the two fermentation times (36 h and 72 h) in the samples where MLF was successful, there was no substantial difference in pH, decrease in l-malate content or increase in d- or l-lactate contents. A small decrease in pH occurred after 36 h of fermentation suggesting increase in conversion of sugars into acids. To summarize, with the parameters used here, fermentation time of 36 h was enough for an almost complete malolactic conversion. Compared to other strains, DSM 1055 was an exception, retaining 1.8–3.23 g/L of malate even after 72 h of fermentation.

To summarize, acclimation of the L. plantarum strains in a growth media with added l-malate allowed fermentation of SBJ with the natural pH of 2.7 without compromising biomass production during starter culture production. Alternatively, adjusting pH from 2.7 to 3.5 also allowed the successful fermentation of SBJ, without acclimation of the bacteria before fermentation.

Volatile profile of initial sea buckthorn juice

In total, 91 volatile compounds (Table 2) were identified or tentatively identified from fresh sea buckthorn juice, of which were 53 esters, 7 acids, 6 alcohols, 7 aldehydes, 3 alkenes, 8 ketones, 4 terpenes and 3 sulfur-containing compounds. All of the volatile compounds detected from fresh juice were present also in fermented samples in addition to 2-undecanone (compound 87) which was present solely in the fermented samples. The semi-quantification results for individual compounds are presented in Supplementary Table 2.

Non-branched, branched, and aromatic esters were detected. Identified non-branched fatty acid esters with varying acyl carbon numbers were, in the descending order of abundance, C6, C8, C3, C10, C5, C7 and C2. The most abundant branched esters were those with acyl group of 3-methylbutanoates, 2-methylbutanoates, 2-methylpropanoates, or 3-methyl-2-butenoates. Esters of benzoate were the main aromatic esters.

The most abundant compounds in the GC–MS chromatograms were, in the descending order, 3-methylbutyl 3-methylbutanoate, 3-methylbutyl hexanoate and ethyl hexanoate. A majority of the tentatively identified esters have fruity odor descriptor, while esters and terpenes with floral odor description were also detected. Earlier, ethyl and 3-methylbutyl esters with 3-methylbutanoic or hexanoic acids have been found highest in abundance in SBJ. The volatile profile of sea buckthorn berry is dependent on genetic background (i.e., species and cultivar) and growth conditions [32,33,34].

The main volatile acids detected were acetic acid and medium-chain fatty acids (C6–C9), while fatty acid-derived aldehydes with the same carbon numbers were also detected. Other aldehydes detected were benzaldehyde and acetaldehyde. Fatty acid-derived ketones with acyl chain lengths of 3, 4, 5, 7, 9, and 11 were detected. However, except for ethanol and 1-heptanol, no corresponding alcohols to aldehydes or ketones were detected.

As sea buckthorn berry accumulates oil in its mesocarp, mostly as triacylglycerols [7, 35], many of the volatile compounds detected here, including esters, free fatty acids, aldehydes and ketones, are derived from metabolism of fatty acids [36].

Non-microbial impact of incubation time on volatile profile

Volatile compounds of food materials are susceptible to alterations due to thermal processing or extended storage [37, 38]. Therefore, it was necessary to separate the effect of incubation on the volatile profile from the impact of microbial metabolism during fermentation of SBJ.

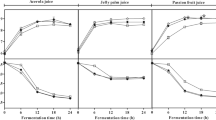

To determine how individual volatile compounds and subgroups (volatile acids, esters, terpenes, alcohols, aldehydes, ketones) were affected by fermentation variables (strain, fermentation time, juice pH, growth media), unsupervised classification with principal component analysis was performed for non-fermented juice samples (fermentation time 0 h) in addition to the fermented samples (total n = 168). (Fig. 1). Principal components 1 and 2 together explained 73% of total variance, PC-1 48%, and PC-2 25%. The PCA scores plot (Fig. 1a) shows that PC-1 clearly separates the non-treated juice from the fermented samples, corresponding to practically all esters and majority of terpenes (all except linalool) clustering at the left end of PC-1 along with the dummy variable for non-treated juice (“0 h”) in the loadings plot (Fig. 1b). In addition, the content of total esters and total terpenes was decreased significantly (p < 0.001) as incubation time was increased (Fig. 2). Moreover, similar decrease was observed in both inoculated juices and non-inoculated control samples. This suggests that the changes in these esters and terpenes were not related to microbial activity but rather by extended exposure to the fermentation conditions (i.e., incubation temperature). In fruit juices in general, esters are important volatile compounds contributing to the fruity aroma and overall flavor [38], and also in sea buckthorn [39], and thus, limiting loss of the key aroma compounds is important when optimizing the MLF process.

Principal component analysis (PCA) score plots and correlation loadings plots based on the data of volatile compounds (99 X-variables) of both non-treated sea buckthorn juice and juice fermented with Lactobacillus plantarum (168 samples). The variable numbers in the correlation loadings plots refer to Table 1. Dummy variables are with green font in the loadings plot. Variables written as T(“compound group”) refer to the sum variable for that compound group. Abbreviations: NT, non-treated juice; FC, fermentation control without inoculation

Sums of volatile compound subgroups over different fermentation variables. Results are mean ± standard deviation. For fermentation control (n = 12) and strains (n = 24), and pH and growth media as combined variable (n = 36) different letter represents groups that are statistically different (p < 0.05). For fermentation time (0 h, n = 12; 36 h, n = 78; 72 h, n = 78) asterisks mark groups that are statistically different (*p < 0.05; **p < 0.01; ***p < 0.001). Tukey’s HSD test of significance was used for comparisons. Y-axis represents semi-quantified volatile content (µg/L)

Regarding esters, the highest loss of over 50% in normalized peak area (0 h vs. 72 h) was observed in ethyl, methyl and propyl esters of butyric acid, 2-methylpropanoic acid, 3-methylbutanoic acid and hexanoic acid (26–34, 36, 39 and 40) (Supplementary Table 2). Similarly, Tiitinen et al. (2006b) observed the reduced content of ethyl 2-methylpropanoate (26), ethyl 3-methylbutanoate (30) and ethyl hexanoate (40) in SBJ after MLF with O. oeni.

Changes in volatile profile by microbial activity and strain-dependent differences

To investigate in detail the impact of microbial activity on the volatile composition of SBJ, compounds affected by fermentation conditions, separated by PC-1 in Fig. 1 (esters and terpenes) were excluded from the second PCA (Fig. 3). In Fig. 3, PC-1 explains 57% of the variance, separating the samples with no or low malolactic activity (on the left) from those with high activities (on the right side). Variables for fermentation times ('36 h' and '72 h') are located close to origo in the loadings plot (Fig. 3b) indicating that fermentation time explains only little variance, as intended, on the first two PCs in the model. However, scores plot (Fig. 3a) shows that different time points are often separated within each strain with samples fermented for 72 h appearing further to the right side along PC-1 compared to the samples fermented with 36 h. Interestingly, the samples fermented with DSM 20174 (pH 2.7/GEM) separated from other strains with the same fermentation variables. This shows that even modest malolactic activity can produce detectable changes in volatile composition.

Principal component analysis (PCA) score plots and correlation loadings plots based on the data of volatile compounds (36 X-variables; terpenes and esters excluded) of sea buckthorn juice fermented with Lactobacillus plantarum. Both inoculated and control samples are included (156 samples; excluding samples that have not been incubated). The variable numbers in the correlation loadings plots refer to Table 1. Dummy variables are with green font in loadings plot. Variables written as T(“compound group”) refer to the sum variable for that compound group

Total aldehydes, as seen in Fig. 2, were significantly reduced in the fermented samples compared to juice without inoculation. Loadings plot (Fig. 3b) shows that the content of all aldehydes (14–20, green and aldehydic aromas) detected was decreased by fermentation, except 3-methyl-2-butenal (17, fruity aroma) which was increased in abundance. While decrease in aldehydes was universal in all samples with high malolactic conversion, the decrease was less in the juices fermented with DSM 10492 due to the lower reduction of acetaldehyde compared to other strains (Fig. 2, Supplementary Table 2). Previously, fermentation of pineapple, cherry, carrot and tomato juices with L. plantarum caused decrease of almost all detected aldehydes [41]; while, significantly reduced amount of fatty acid-derived aldehydes, namely hexanal, octanal, and nonanal, was observed in rice after fermentation with L. plantarum [36]. In vegetable and fruit juices fermented with L. plantarum, some aldehydes can be reduced to corresponding alcohols [41]. Here, negative correlation between ethanol (8) and acetaldehyde (14), as well as between 1-heptanol (10, green aroma) and heptanal (16) was observed in the fermented juices (Fig. 3b). While both 10 and 16 have green odor descriptor, heptanol has a higher odor threshold [42]. In combination with the overall decrease in aldehydes, changes in aldehyde profile by fermentation with L. plantarum could result in the reduction of greenish notes and increase in fruity aroma (17) in SBJ.

To highlight the strain-dependent impact on the volatile profiles, a third PCA model was created including only samples that were inoculated with L. plantarum at initial pH = 3.5 (Fig. 4). Although the pH2.7/CAM had high malolactic fermentation, these were excluded from the model as these samples influenced the model too extensively, as reflected by PC-1 in Fig. 3, where pH2.7/CAM forms a separate cluster from pH3.5/GEM and pH3.5/CAM (effect of pH discussed separately in Sect. “Impact of acclimation and initial juice pH on the volatile profile”). Nonetheless, comparing PCA modeled with only the pH2.7/CAM samples (Supplementary Fig. S4) to Fig. 4 suggests that the strain-dependent differences in volatile profiles appear similar in pH 2.7/CAM, pH 3.5/GEM and pH 3.5/CAM.

Principal component analysis (PCA) score plots and correlation loadings plots based on the data of volatile compounds (36 X-variables; terpenes and esters excluded) of sea buckthorn juice fermented with Lactobacillus plantarum (72 samples; with inoculation and initial pH adjusted to 3.5). Blue and orange colors refer to fermentation time of 36 and 72 h, respectively. A. components 1 and 2; B. components 2 and 3. The variable numbers in the correlation loadings plots refer to Table 1. Dummy variables are with green font in loadings plots. Variables written as T(“compound group”) refer to the sum variable for that compound group

The alcohol with the highest abundance in fermented samples was 3-methyl-1-butanol (9, fermented aroma) (Supplementary Table 2). Due to differences in concentrations of this compound, the juices fermented with strains DSM 1055 and DSM 100813 had elevated volatile alcohol content (p < 0.05), while the lowest content was in samples inoculated with DSM 16365 (Fig. 2). In PC-1 and PC-3 loadings plots (Fig. 4) the two former strains are associated with ethanol (8), 3-methyl-1-butanol (9), and benzyl alcohol (13, floral aroma). This suggests that L. plantarum can introduce potentially both negative fermented aroma (8, 9) and positive floral (13) notes in MLF of sea buckthorn juice.

Loadings plot (Fig. 4b) shows that acetic acid (1), 3-methylbutanoic acid (2, cheesy aroma) and medium-chain fatty acids (4–7, fatty and cheesy aromas) are correlated with total acids. Acetic acid is typically produced through heterofermentive pathways in lactic acid bacteria. While predominantly homofermentive species, genomic studies on L. plantarum have showed the ability to alternate between homo- and heterofermentive routes [43]. On the other hand, citrate metabolism (via citrate lyase) into oxaloacetic acid produces acetate as a by-product [12]. In food models, acetic acid has been detected earlier in vegetable and fruit juices fermented with L. plantarum [41].

Compounds 2 and 4–7 are produced possibly due to increased hydrolysis of the corresponding esters during fermentation, possibly due to lipase and/or esterase activity of L. plantarum [44]. Compared to other strains, fermentation with DSM 1055 introduced significantly more volatile acids to SBJ. Significantly lowest levels were in juices fermented with DSM 100813 and DSM 16365, respectively (Fig. 2). As acetic acid has vinegar-like aroma and free fatty acids have been associated with rancid aroma, optimizing fermentation to limit formation of volatile acids is preferable.

All identified ketones except 2-butanone (80, ethereal aroma) were positively correlated with samples of high microbial metabolic activity (Fig. 3). 2-Undecanone (87, fruity aroma) was the only compound that was detected solely in fermented samples. 3-Hydroxybutan-2-one (acetoin, 84) was the most abundant ketone in all fermented samples (Supplementary Table 2). Additionally, loadings plot (Fig. 4b) shows that acetoin and butane-2,3-dione (diacetyl, 82) correlated positively with the strain DSM 13273 on PC-2; juices fermented with this strain also had the highest total ketone content (p < 0.05). Similarly to volatile acids, lowest ketone contents were detected in juices fermented with DSM 100813 and DSM 16365 (Fig. 2). Earlier, the content of 82 and 84 was increased in elderberry juice fermented with L. plantarum [45]. In MLF of wines, acetoin and diacetyl are important ketones to enhance buttery and fatty notes. Both acetoin and diacetyl are produced from pyruvate, which in turn originates from either citrate or carbohydrate metabolism [12]. Acetoin can be further converted to 2,3-butanediol; however, L. plantarum lacks the enzyme for this conversion (2,3-butanediol hydrogenase) [43], possibly explaining why diacetyl and acetoin, but not 2,3-butanediol, were detected in the fermented juices.

While L. plantarum possesses genes to metabolize phenolic acids into vinyl derivatives, and further to ethyl derivatives [25], no formation of these off-aromas was detected after MLF of sea buckthorn juice.

Impact of acclimation and initial juice pH on the volatile profile

Exposure of L. plantarum cells to sub-optimal pH and l-malic acid prior inoculation to sea buckthorn (i.e., acclimation) likely led to activation of genes related to acid stress [12], which in turn allowed MLF of sea buckthorn juice at pH 2.7 (Table 2). However, no significant differences was observed between GEM and CAM juices at pH 3.5 in any of the volatile compound classes (Fig. 2). Additionally, growth mediums explained only little variance in the PCA models (Fig. 4). These together indicate that acclimation in CAM had no secondary effect on the aroma-related metabolism in L. plantarum during the fermentation of sea buckthorn juices.

On the other hand, the initial juice pH had significant impact on the observed volatile profiles of the fermented juices. First, the total ester and total terpene content was significantly higher (p < 0.05) in the samples fermented with the initial pH of 3.5 (with high malolactic activity) compared to the pH 2.7/GEM samples with low malolactic activity (Fig. 2). Second, pH 3.5/GEM and pH 3.5/CAM samples had higher total alcohol, acid and ketone content compared to the pH2.7/CAM samples, despite the fact that MLF proceeded efficiently in all these samples (Fig. 2). While the difference was not significant in any of the groups, in Fig. 3 scores plot, pH2.7/CAM samples are clustered into separate group. Here we speculate three possible explanations. First is pH-related matrix effect, as volatile compounds with pH-dependent dissociable group are absorbed in SPME preferably in neutral form, as supported by the previous findings of higher extraction rate of monoterpenols and norisoprenoids from Madeira wines at pH 3.9 compared to pH 2.7 [46, 47]. Second explanation is pH-depentent rate of ester hydrolsis since based on mathematical models, esters are hydrolyzed at a slower rate at a higher pH [48]. Third explanation is reduced or inhibited activity of enzymes related to volatile compound formation when extracellular pH is 2.7 [26, 44, 49]. Further research is required to elucidate if the pH-dependent differences in volatile profiles were matrix related or due to enzyme activity (or lack thereof) of L. plantarum.

Conclusions

We investigated changes in organic acid content and volatile profile of sea buckthorn juice after malolactic fermentation with different strains of Lactobacillus plantarum. Acclimation of L. plantarum allowed malolactic fermentation of sea buckthorn juice with its original pH (2.7) with all the studied strains. Increasing juice pH to 3.5 prior to fermentation allowed MLF with the all tested strains regardless the media used for pre-cultivation. Acclimation medium for malolactic fermentation of wines often require high inoculation rates (109 CFU/mL) [50], as the composition of the medium inhibits effective biomass production. In our study, growth rate of L. plantarum in acclimation medium was comparable to growth rate in typical basal medium.

While majority of the volatile compounds detected in SBJ were esters of hexanoic and 3-methylbutanoic acid with fruity odor descriptor, a number of alcohols, ketones, aldehydes, terpenes and acids were also detected. Fermentation time explained most of the variance between the samples, as all of the esters and majority of terpenes were decreased when fermentation time was increased, mostly due to the incubation conditions instead of microbial activities. Microbial activities during the fermentation significantly increased the content of volatile acids, ketones, alcohols, while those of aldehydes were decreased.

Increase in acid content was due to production of acetic acid by L. plantarum and increased hydrolysis of fatty acid-derived esters. Formation of 3-hydroxybutan-2-one, butane-2,3-dione and 2-undecanone explained the increase in the ketone content. Fermentation with all the strains reduced content of fatty acid-derived aldehydes. The juices fermented with DSM 1055 had significantly more volatile acids and alcohols compared with the samples fermented with other strains, while fermentation with DSM 13273 produced more compounds associated with buttery notes. In contrast, strains DSM 100813 and DSM 16365 produced less volatile acids that contribute to vinegar, fatty and cheesy aromas. In addition, malolactic fermentation proceeded rapidly with these two strains, leading to lower losses of esters and terpenes important for the original fruity and floral aromas of sea buckthorn.

General shortcoming when relating volatile compound analysis to aroma properties is that odor thresholds of volatiles vary significantly between compounds and are strongly dependent on sample matrix. Thus, sensory analyses with human subjects are ultimately required to complement the chemical analyses. However, in studies of organoleptic properties, the number of samples need to be kept limited to avoid exhausting the panelists. Therefore, studies screening chemical responses to various fermentation parameters are required. This study provided novel information related to changes in volatile compound profile of sea buckthorn juice in response to acclimation, juice pH, microbial strain and fermentation time. This information can be utilized for development of fermented sea buckthorn products or when designing sensory studies or consumer trials of such products.

Abbreviations

- MLF:

-

Malolactic fermentation

- SBJ:

-

Sea buckthorn juice

- GEM:

-

General edible medium

- CAM:

-

Cell acclimation medium

References

Yongshan L, Xuelin C, Hong L (2003) Taxonomy of seabuckthorn (Hippophae L.). In: Seabuckthorn (Hippophae L.): a multipurpose wonder plant, Vol. I. Indus Publishing Company, New Delhi, India, pp 35–46

Bal LM, Meda V, Naik SN, Satya S (2011) Sea buckthorn berries: a potential source of valuable nutrients for nutraceuticals and cosmoceuticals. Food Res Int 44:1718–1727. https://doi.org/10.1016/j.foodres.2011.03.002

Larmo P, Löyttyniemi E, Yang B et al (2019) Effects of a sea buckthorn oil cream on vulvovaginal atrophy. Maturitas 124:145–146. https://doi.org/10.1016/j.maturitas.2019.04.105

Larmo P, Järvinen R, Laihia J et al (2019) Effects of a sea buckthorn oil spray emulsion on dry eye. Contact Lens Anterior Eye J Br Contact Lens Assoc 42:428–433. https://doi.org/10.1016/j.clae.2018.11.011

Mortensen MW, Spagner C, Cuparencu C et al (2018) Sea buckthorn decreases and delays insulin response and improves glycaemic profile following a sucrose-containing berry meal: a randomised, controlled, crossover study of Danish sea buckthorn and strawberries in overweight and obese male subjects. Eur J Nutr 57:2827–2837. https://doi.org/10.1007/s00394-017-1550-8

Laaksonen O, Knaapila A, Niva T et al (2016) Sensory properties and consumer characteristics contributing to liking of berries. Food Qual Prefer 53:117–126. https://doi.org/10.1016/j.foodqual.2016.06.004

Tiitinen K, Hakala MA, Kallio HP (2005) Quality components of sea buckthorn (Hippophaë rhamnoides) varieties. J Agric Food Chem 53:1692–1699. https://doi.org/10.1021/jf0484125

Tiitinen K, Vahvaselkä M, Hakala M et al (2006) Malolactic fermentation in sea buckthorn (Hippophaë rhamnoides L.) juice processing. Eur Food Res Technol 222:686–691. https://doi.org/10.1007/s00217-005-0163-2

Ma X, Yang W, Laaksonen O et al (2017) Role of flavonols and proanthocyanidins in the sensory quality of sea buckthorn (Hippophaë rhamnoides L.) Berries. J Agric Food Chem 65:9871–9879. https://doi.org/10.1021/acs.jafc.7b04156

Ma X, Laaksonen O, Heinonen J et al (2017) Sensory profile of ethyl β-d-glucopyranoside and its contribution to quality of sea buckthorn (Hippophaë rhamnoides L.). Food Chem 233:263–272. https://doi.org/10.1016/j.foodchem.2017.04.073

Zeb A (2004) Chemical and nutritional constituents of sea buckthorn juice. Pak J Nutr 3:99–106. https://doi.org/10.3923/pjn.2004.99.106

Brizuela N, Tymczyszyn EE, Semorile LC et al (2019) Lactobacillus plantarum as a malolactic starter culture in winemaking: a new (old) player? Electron J Biotechnol 38:10–18. https://doi.org/10.1016/j.ejbt.2018.12.002

Rodríguez H, Curiel JA, Landete JM et al (2009) Food phenolics and lactic acid bacteria. Int J Food Microbiol 132:79–90. https://doi.org/10.1016/j.ijfoodmicro.2009.03.025

Kwaw E, Ma Y, Tchabo W et al (2018) Effect of lactobacillus strains on phenolic profile, color attributes and antioxidant activities of lactic-acid-fermented mulberry juice. Food Chem 250:148–154. https://doi.org/10.1016/j.foodchem.2018.01.009

Behera SS, Ray RC, Zdolec N (2018) Lactobacillus plantarum with functional properties: an approach to increase safety and shelf-life of fermented foods. BioMed Res Int. https://doi.org/10.1155/2018/9361614

Guimarães A, Santiago A, Teixeira JA et al (2018) Anti-aflatoxigenic effect of organic acids produced by Lactobacillus plantarum. Int J Food Microbiol 264:31–38. https://doi.org/10.1016/j.ijfoodmicro.2017.10.025

Filannino P, Cavoski I, Thlien N et al (2016) Lactic acid fermentation of cactus cladodes (Opuntia ficus-indica L.) generates flavonoid derivatives with antioxidant and anti-inflammatory properties. PLoS ONE 11:e0152575. https://doi.org/10.1371/journal.pone.0152575

Kim J, Choi K-B, Park JH, Kim KH (2019) Metabolite profile changes and increased antioxidative and antiinflammatory activities of mixed vegetables after fermentation by Lactobacillus plantarum. PLoS ONE 14:e0217180. https://doi.org/10.1371/journal.pone.0217180

Szutowska J (2020) Functional properties of lactic acid bacteria in fermented fruit and vegetable juices: a systematic literature review. Eur Food Res Technol 246:357–372. https://doi.org/10.1007/s00217-019-03425-7

Di Cagno R, Filannino P, Gobbetti M (2017) Lactic acid fermentation drives the optimal volatile flavor-aroma profile of pomegranate juice. Int J Food Microbiol 248:56–62. https://doi.org/10.1016/j.ijfoodmicro.2017.02.014

Filannino P, Azzi L, Cavoski I et al (2013) Exploitation of the health-promoting and sensory properties of organic pomegranate (Punica granatum L.) juice through lactic acid fermentation. Int J Food Microbiol 163:184–192. https://doi.org/10.1016/j.ijfoodmicro.2013.03.002

Markkinen N, Laaksonen O, Nahku R et al (2019) Impact of lactic acid fermentation on acids, sugars, and phenolic compounds in black chokeberry and sea buckthorn juices. Food Chem 286:204–215. https://doi.org/10.1016/j.foodchem.2019.01.189

Tkacz K, Chmielewska J, Turkiewicz IP et al (2020) Dynamics of changes in organic acids, sugars and phenolic compounds and antioxidant activity of sea buckthorn and sea buckthorn-apple juices during malolactic fermentation. Food Chem 332:127382. https://doi.org/10.1016/j.foodchem.2020.127382

Succi M, Pannella G, Tremonte P et al (2017) Sub-optimal pH preadaptation improves the survival of Lactobacillus plantarum strains and the malic acid consumption in wine-like medium. Front Microbiol. https://doi.org/10.3389/fmicb.2017.00470

Santamaría L, Reverón I, de Felipe FL et al (2018) Ethylphenol formation by Lactobacillus plantarum: Identification of the enzyme involved in the reduction of vinylphenols. Appl Env Microbiol 84:e01064-e1118. https://doi.org/10.1128/AEM.01064-18

Spano G, Rinaldi A, Ugliano M et al (2005) A beta-glucosidase gene isolated from wine Lactobacillus plantarum is regulated by abiotic stresses. J Appl Microbiol 98:855–861. https://doi.org/10.1111/j.1365-2672.2004.02521.x

Olsen EB, Russell JB, Henick-Kling T (1991) Electrogenic L-malate transport by Lactobacillus plantarum: a basis for energy derivation from malolactic fermentation. J Bacteriol 173:6199–6206. https://doi.org/10.1128/JB.173.19.6199-6206.1991

Saarela M, Rantala M, Hallamaa K et al (2004) Stationary-phase acid and heat treatments for improvement of the viability of probiotic lactobacilli and bifidobacteria. J Appl Microbiol 96:1205–1214. https://doi.org/10.1111/j.1365-2672.2004.02286.x

Liu S, Laaksonen O, Yang B (2019) Volatile composition of bilberry wines fermented with non-Saccharomyces and Saccharomyces yeasts in pure, sequential and simultaneous inoculations. Food Microbiol 80:25–39. https://doi.org/10.1016/j.fm.2018.12.015

de Mendiburu F (2016) agricolae: Statistical Procedures for Agricultural Research. R package version 1.2-4

Fessard A, Remize F (2019) Genetic and technological characterization of lactic acid bacteria isolated from tropically grown fruits and vegetables. Int J Food Microbiol 301:61–72. https://doi.org/10.1016/j.ijfoodmicro.2019.05.003

Leung G-S, Marriott R (2016) Year to year variation in sea buckthorn juice volatiles using headspace solid phase microextraction. Flavour Fragr J 31:124–136. https://doi.org/10.1002/ffj.3290

Socaci SA, Socaciu C, Tofană M et al (2013) In-tube extraction and GC–MS analysis of volatile components from wild and cultivated sea buckthorn (Hippophae rhamnoides L. ssp. carpatica) berry varieties and juice. Phytochem Anal 24:319–328. https://doi.org/10.1002/pca.2413

Tiitinen K, Hakala M, Kallio H (2006) Headspace volatiles from frozen berries of sea buckthorn (Hippophaë rhamnoides L.) varieties. Eur Food Res Technol 223:455–460. https://doi.org/10.1007/s00217-005-0224-6

Vuorinen AL, Markkinen N, Kalpio M et al (2015) Effect of growth environment on the gene expression and lipids related to triacylglycerol biosynthesis in sea buckthorn (Hippophaë rhamnoides) berries. Food Res Int 77:608–619. https://doi.org/10.1016/j.foodres.2015.08.023

Park MK, Kim Y-S (2019) Distinctive formation of volatile compounds in fermented rice inoculated by different molds, yeasts, and lactic acid bacteria. Molecules. https://doi.org/10.3390/molecules24112123

Altisent R, Graell J, Lara I et al (2008) Regeneration of volatile compounds in Fuji apples following ultra low oxygen atmosphere storage and its effect on sensory acceptability. J Agric Food Chem 56:8490–8497. https://doi.org/10.1021/jf8005728

Perestrelo R, Silva C, Silva P et al (2019) Differentiation of fresh and processed fruit juices using volatile composition. Molecules 24:974. https://doi.org/10.3390/molecules24050974

Lundén S, Tiitinen K, Kallio H (2010) Aroma Analysis of Sea Buckthorn Berries by Sensory Evaluation, Headspace SPME and GC-Olfactometry. In: Expression of Multidisciplinary Flavour Science. Proceedings of the 12th Weurman Symposium. pp 490–493

Tiitinen K, Vahvaselkä M, Hakala M et al (2006) Effect of malolactic fermentation on the volatile aroma compounds in four sea buckthorn varieties. Dev Food Sci 43:101–104. https://doi.org/10.1016/S0167-4501(06)80024-5

Filannino P, Cardinali G, Rizzello CG et al (2014) Metabolic responses of Lactobacillus plantarum strains during fermentation and storage of vegetable and fruit juices. Appl Environ Microbiol 80:2206–2215. https://doi.org/10.1128/AEM.03885-13

Laing DG, Legha PK, Jinks AL, Hutchinson I (2003) Relationship between molecular structure, concentration and odor qualities of oxygenated aliphatic molecules. Chem Senses 28:57–69. https://doi.org/10.1093/chemse/28.1.57

Huang T, Xiong T, Peng Z et al (2020) Genomic analysis revealed adaptive mechanism to plant-related fermentation of Lactobacillus plantarum NCU116 and Lactobacillus spp. Genomics 112:703–711. https://doi.org/10.1016/j.ygeno.2019.05.004

Esteban-Torres M, Reverón I, Santamaría L et al (2016) The Lp_3561 and Lp_3562 Enzymes Support a Functional Divergence Process in the Lipase/Esterase Toolkit from Lactobacillus plantarum. Front Microbiol. https://doi.org/10.3389/fmicb.2016.01118

Ricci A, Cirlini M, Levante A et al (2018) Volatile profile of elderberry juice: Effect of lactic acid fermentation using L. plantarum, L. rhamnosus and L. casei strains. Food Res Int 105:412–422. https://doi.org/10.1016/j.foodres.2017.11.042

Câmara JS, Alves MA, Marques JC (2006) Development of headspace solid-phase microextraction-gas chromatography–mass spectrometry methodology for analysis of terpenoids in Madeira wines. Anal Chim Acta 555:191–200. https://doi.org/10.1016/j.aca.2005.09.001

Feng L, Huang Y, Wang H (2008) Solid-phase microextraction in combination with GC-FID for quantification of the volatile free fatty acids in wastewater from constructed wetlands. J Chromatogr Sci 46:577–584. https://doi.org/10.1093/chromsci/46.7.577

Rayne S, Forest K (2016) Carboxylic acid ester hydrolysis rate constants for food and beverage aroma compounds. Flavour Fragr J 31:385–394. https://doi.org/10.1002/ffj.3327

Palles B, Condon C (1998) Citrate metabolism in Lactobacillus casei and Lactobacillus plantarum. J Appl Microbiol 85:147–154. https://doi.org/10.1046/j.1365-2672.1998.00486.x

Brizuela N, Bravo-Ferrada BM, Pozo-Bayón MÁ et al (2018) Changes in the volatile profile of Pinot noir wines caused by Patagonian Lactobacillus plantarum and Oenococcus oeni strains. Food Res Int 106:22–28. https://doi.org/10.1016/j.foodres.2017.12.032

Fang C, Du H, Xiaojiao Z et al (2018) Flavor compounds in fermented Chinese alcoholic beverage alter gut microbiota and attenuate ethanol-induced liver damages. bioRxiv. https://doi.org/10.1101/437731

The Good Scents Company Information System. In: Good Scents Co. http://www.thegoodscentscompany.com/. Accessed 31 Jan 2020

Flavornet and human odor. Gas chromatography-olfactometry (GCO) of natural products. http://www.flavornet.org/flavornet.html. Accessed 2 Jan 2020

Flament I (2001) Coffee Flavor Chemistry, 1st edn. John Wiley & Sons, England

Rodríguez-Burruezo A, Kollmannsberger H, González-Mas MC et al (2010) HS-SPME comparative analysis of genotypic diversity in the volatile fraction and aroma-contributing compounds of Capsicum Fruits from the annuum−chinense−frutescens complex. J Agric Food Chem 58:4388–4400. https://doi.org/10.1021/jf903931t

Sampaio KL, Garruti DS, Franco MRB et al (2011) Aroma volatiles recovered in the water phase of cashew apple (Anacardium occidentale L.) juice during concentration. J Sci Food Agric 91:1801–1809. https://doi.org/10.1002/jsfa.4385

Acknowledgements

We acknowledge PhD Annelie Damerau for her technical support operating the SPME–GC–MS instrument.

Funding

Open Access funding provided by University of Turku (UTU) including Turku University Central Hospital. This work was supported by the Doctoral Programme in Molecular Life Sciences (DPMLS) in University of Turku and by personal grants from Raisio Research Foundation, Niemi foundation, OLVI foundation, and Magnus Ehrnrooth foundation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Markkinen, N., Laaksonen, O. & Yang, B. Impact of malolactic fermentation with Lactobacillus plantarum on volatile compounds of sea buckthorn juice. Eur Food Res Technol 247, 719–736 (2021). https://doi.org/10.1007/s00217-020-03660-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-020-03660-3