Abstract

The production of high-quality wines requires the use of high-quality grapes. Tasting represents a widespread method for the determination of grape maturity and quality aspects such as the corresponding aroma profile. However, sensory analysis always remains subjective and it is not possible to judge only aroma compounds because the overall impression is also influenced by main components (e.g. sugars and acids). In contrast, the use of near-infrared (NIR) spectroscopy allows the simultaneous determination of various compounds without being affected by personal preferences. In this study, grape mash samples were examined under comparable conditions to those in the mouth. Differences between grape mashes with varying phytosanitary status of the corresponding grapes as well as for different grape varieties were detected. The quantified concentrations of the detected aroma compounds were used to develop calibration models for determination by NIR spectroscopy. Using global calibration models, the single aroma compounds could be determined by NIR spectroscopy with accuracies reaching from R2C = 0.365 to R2C = 0.976. Separate calibration models for cultivation region and grape colour improved the prediction accuracy. Instrumental analysis cannot totally replace sensory evaluation, however, NIR spectroscopy has the potential to be used as an objective, additional method for the evaluation of grape aroma quality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wine aroma compounds are formed at different stages of wine production. Various compounds already occur in grape skins and flesh or can be formed by enzymatic and catalytic processes induced by the disruption of cell walls. While some compounds are precursors for aroma compounds formed during fermentation and ageing processes, others pass unmodified into the resulting wine during processing and contribute to the resulting wine aroma [1]. Most grape varieties do not contain specific volatile compounds, which are mainly responsible for its typical aroma. Instead, the varying combinations and concentrations of the same compounds result in a characteristic varietal aroma [2]. Fermentation and ageing substantially affect characteristic wine taste and aroma, however, compounds originating from the grapes play an important role as well. Depending on, e.g. the phytosanitary status of the grapes, not only desired, but also undesired compounds can be transferred into the wine and thereby may influence its aroma considerably [3].

Grape tasting is a widespread method among winegrowers to determine grape maturity and harvesting time. Unpleasant aroma can also partly be sensed, but the impression is subjective due to factors influencing individual perception of aroma compounds. Saliva and salivary composition as well as chewing and swallowing patterns play an important role in aroma release and perception [4]. Moreover, other grape compounds influence the overall impression of the taste, like the sugar/acid-ratio, which significantly affects the sensory acceptance of grapes [5, 6].

Nowadays, sophisticated analytical methods and instrumentation allow the precise and accurate determination of aroma compounds without being affected by personal impressions and preferences. The common determination method of aroma compounds is gas chromatography coupled with mass spectrometric detection (GC–MS). The high sensitivity of gas chromatography allows the simultaneous determination of compounds present in even very low concentrations, while mass spectrometry facilitates the identification of the detected compounds [7]. In case of aroma analysis, it has to be kept in mind that absolute concentrations of aroma compounds are determined. However, different aroma compounds show different odour and taste thresholds, so the contribution of single compounds to the overall aroma does not necessarily correlate with their concentrations. Some compounds may be precursors for off-odours and -flavours in wine, although their concentrations lie below the odour and taste threshold in grapes [7, 8]. Despite the high precision and accuracy of GC–MS analysis, various disadvantages have to be regarded, like the requirement of expensive analytical equipment and high-purity chemicals. Moreover, sample preparation, analysis and data evaluation are very time-consuming and require a trained user.

In contrast, NIR spectroscopy allows the simultaneous determination of various compounds with minimal to no sample preparation, while instrumentation is considerably cheaper and easier to use [9]. Due to the ongoing improvement of spectrometers and chemometric methods, analysis becomes increasingly precise and large amounts of data can be processed. NIR spectroscopy has already been used successfully for semi-quantitative determination of glycosylated aroma compounds in white grape juice [10] and in Tannat grapes [11]. Furthermore, the detection of smoke taint in grapes exposed to bushfires has been examined successfully [12]. Despite the low concentrations of aroma compounds (often present in a ppb range), high prediction accuracies were reached.

However, the above-mentioned studies only cover a very small range of grape aroma analysis, which leaves a large field for further research on NIR applications. Glycosylated compounds play an important role, however, they represent only a part of the overall grape aroma and do not have the same importance in all grape varieties. Smoke contamination in grapes affects various growing areas, such as Australia, South Africa, Greece, Chile or USA. The detection of smoke contamination provides important information about the grapes, but smoke-derived volatile phenols also accumulate as glycosidic bound forms after absorption [12]. Moreover, previous studies on grape aroma compounds only focussed on the determination of absolute concentrations of aroma compounds without considering the influence of tasting. Due to various aspects (e.g. salivary composition), the perception during tasting differs from the composition and absolute concentrations of aroma compounds [4, 13]. Therefore, the conditions for analysis should be as similar as possible to those in the mouth to avoid the determination of compounds, which are not released during tasting. Moreover, artefacts may be formed (e.g. during sample preparation), which are not naturally present in grapes, such as monoterpene oxides.

The aims of the present work were to examine the aroma profiles of grape mash samples and to evaluate the potential of NIR spectroscopy for on-line determination of grape aroma compounds under tasting conditions. This should provide a method for objective evaluation of grape aroma upon receival at the winery and support the decision about the treatment of the grapes for an improved wine quality. As far as we know, this is the first approach of on-line determination of grape aroma compounds.

Materials and methods

Samples

Grape mash samples were provided by two wineries (Felsengartenkellerei Besigheim eG, Hessigheim/Germany and Badischer Winzerkeller eG, Breisach/Germany) from the vintages 2017 and 2018 (Table 1). Samples were taken directly from the grape reception line to assure that the grape mash for reference analysis was identical to the grape mash analysed by the NIR sensor. The samples were filled into 500 mL-plastic bottles, which contained sodium azide (150–200 mg) for preservation (except the samples from 2017 from Badischer Winzerkeller eG). Samples were deep-frozen and stored at − 20 °C until analysis.

NIR measurements

Near-infrared spectra were collected using a X-Three V3 sensor (Büchi NIR-Online, Walldorf/Germany) with an InGaAs detector (NIR range) and a Si detector (visible range). The sensor was integrated into the grape reception line. Spectra were acquired in diffuse reflectance mode in the wavelength range between 400 and 1700 nm (intervals of 5 nm). A number of 20 spectra per second were acquired during a total measurement time of 15 s. This resulted in a total amount of 300 spectra per measurement, which were averaged. The software SX-Center (Version 2.13.1000.453, Büchi NIR-Online, Walldorf/Germany) was used for data acquisition.

Reference analysis

Aroma profiles of the grape mash samples

To avoid changes in chemical composition before the beginning of the measurement, every sample was thawed overnight at ambient temperature and homogenised directly before analysis using a commercial hand blender (ESGE-Zauberstab 2007-5, Unold AG, Hockenheim/Germany). 5 g of homogenised sample material were weighed into a 20-mL headspace vial (crimp top/clear/round bottom, neoLab Migge GmbH, Heidelberg/Germany) and covered with a cap (PTFE/Gray Butyl septum, Perkin Elmer, Rodgau/Germany). Ten minutes after homogenisation, the vial was gently shaken to avoid possible sedimentation. 10 µL of a solution of 2-heptanone (analytical grade, Frey & Lau GmbH, Henstedt-Ulzburg/Germany) in HPLC grade water (c = 25 mg/L) were added as internal standard. The cap was closed and the vial was placed into the headspace sampler for analysis.

Headspace GC–MS analysis has already been used in previous studies on aroma compounds in fresh fruits, such as strawberries and gooseberries [14, 15]. Good results were obtained in both studies, so for the analysis of fresh grapes mainly the same settings were chosen. Slight modifications were done to keep the measurement conditions as close to reality as possible, but also regarding the technical possibilities. GC–MS analyses were conducted using a Turbomatrix 40 Trap Headspace Sampler, a Clarus 600 Gas Chromatograph and a Clarus 600C Mass Spectrometer (Perkin Elmer, Rodgau/Germany). Headspace parameters can be found in Table 2. An Elite-624 capillary column (30 m length, 0.25 mm inner diameter (i.d.), 1.4 µm film thickness; Perkin Elmer, Rodgau/Germany) and Helium (BIP grade; Tyczka Industrie-Gase GmbH, Mannheim/Germany) as carrier gas were used for analysis. Oven temperature was set at 40 °C (held for 5 min), raised to 220 °C at 20 °C/min and held for 10 min. For mass spectrometry, the electron ionisation mode (EI+) was used (70 eV). Mass range was scanned between 40.00 and 200.00 m/z. The TurboMass software (Ver. 5.4.2) was used for data analysis. Identification of the compounds was carried out by comparing the retention times to reference substances and the mass spectra to reference substances and the NIST library (spectra library: NIST/EPA/NIH Mass spectral library; search program: NIST MS search, Ver. 2.0). Quantification was based on 3-point calibration curves of reference substances in HPLC grade water. Reference substances were provided by Frey & Lau (Frey & Lau GmbH, Henstedt-Ulzburg/Germany), Sigma-Aldrich (Merck KGaA, Darmstadt/Germany), Alfa Aesar (Thermo Fisher GmbH, Kandel/Germany) and VWR (VWR International GmbH, Darmstadt/Germany) with a purity of at least 95%.

Effect of saliva on the concentration of aroma compounds

To ensure reproducibility, an artificial saliva solution was used instead of human saliva. A basic solution was prepared according to DIN 53160-1:2010-10. The concentrations of the enzymes were selected according to a solution used during examinations in the dental area [16]. 300 µL of Lysozyme (Lallzyme Lyso, 22,800 u/mg, Lallemand Inc., Vienna/Austria) solution (5 mg dissolved in 1 mL of HPLC grade water) and 84 µL of α-Amylase (BAN 480L, 480 KNU-B/g, Novozymes Switzerland AG, Dittingen/Switzerland) were added to 25 mL of the basic solution and used for measurement. The mixture of basic solution and enzymes was freshly prepared daily.

Grape mash samples were prepared as described above, except 2 mL of artificial saliva solution were added before shaking the vial.

Additional analyses on the effect of artificial saliva solution

The effect of the used artificial saliva solution was examined more precisely in two additional approaches to consider further aspects, which may influence the perception of aroma compounds.

In a first approach, four different grape mash samples were measured before and after addition of varying solutions (water, artificial saliva solution without enzymes and artificial saliva solution with enzymes) to verify the effect of enzyme addition. Samples were prepared as described above with addition of the different solutions.

In a second approach, four different grape mash samples were examined after various contact times with artificial saliva solution (2 min, 30 min, 2 h, 4 h, 24 h). Samples were prepared as described above and stored at room temperature for the different times before measurement.

Chemometrics and data analysis

A principal component analysis (PCA) was carried out for the reference data using Origin 2020 software (Version 9.7.0.185, OriginLab Corporation, Northampton/USA) to evaluate the influence of artificial saliva solution. Discriminant analysis was performed using XLStat (Version 2021.2.2.1132, Addinsoft, Paris/France).

Spectral data and reference data were processed using the software SX-Plus (Version 2.13.1000.453, Büchi Labortechnik GmbH, Essen/Germany). The used regression method was XLS regression, which combines partial least squares (PLS) regression with the first derivative. Calibration models were calculated without spectral pre-treatment, after normalisation by standard normal variate transformation (SNVT) and after normalisation by multiplicative scatter correction (MSC). The maximum number of latent variables (LV) calculated was 15. First, a global calibration model based on all samples was calculated for each compound. Second, the dataset was divided into subsets per origin, grape colour and both aspects (totally eight subsets per compound). Thereafter, from each subset separate models for both vintages were developed. Calibration models were only calculated for datasets containing 30 or more samples. Validation was carried out by segmented cross-validation (S = 5) due to the different sizes of the datasets. The overall smallest standard error of cross-validation (SECV) was determined to select the spectral pre-treatment and the number of LVs for each model. Model performance was judged by the coefficients of determination of the calibration (R2C) and the cross-validation (R2CV), the standard error of calibration (SEC) and the SECV.

Results

Aroma profiles of the grape mash samples

In the grape mash samples, 36 aroma compounds were identified (Table 3).

Most of the detected aroma compounds result from various metabolic pathways of grapevines and were already reported being present in grapes and wine [17,18,19]. The majority of grape berry volatiles is formed from fatty acids in different processes. The C6- and C9-aldehyds and their corresponding alcohols result from the lipoxygenase pathway and are described having a “fresh” or “green” odour, such as hexanal, 2-hexenal and 1-hexanol. During β-oxidation of fatty acids, a large number of esters is formed, which contribute to the aroma of many fruits including grape berries. Terpenoids affect the flavour profiles of most fruits and are synthesized either from acetyl-CoA and pyruvate in the berry cytoplasm (mevalonate pathway) or can be formed in the plastids (DOXP pathway) [20]. Another important source of volatiles are amino acids, from which a large number of different compounds is formed by degradation [21].

Differences between the aroma profiles of the grape mash samples were detected according to two aspects. First, some compounds were only detected in specific grape varieties. This is particularly noticeable for the terpenoids β-myrcene, limonene, ocimene and linalool. Regarding these four compounds, further differences between grape varieties become obvious. All four terpenoids occur in the varieties Muskateller and Muskat-Trollinger, which show the highest amounts of β-myrcene and linalool among all measured samples with significantly higher concentrations for Muskateller grapes. Moreover, β-myrcene was detected in all samples of Kerner and Gewürztraminer, in most Riesling samples and in few Lemberger samples. Differences also occur in the concentrations of the other compounds. Linalool does not occur in Gewürztraminer samples, while low concentrations (14.1–19.0 µg kg) were measured in Kerner grapes and medium concentrations (14.4–79.7 µg/kg) in most Riesling samples and individual Lemberger samples. Limonene was detected in few Riesling and Gewürztraminer samples, while ocimene occurs partly in Riesling and Lemberger grapes. According to their concentrations of 12 monoterpenoids, white grape varieties can be divided into three sensory different aroma types: the “Muscat type” (e.g. Muskateller), the “Riesling type” (e.g. Riesling, Müller-Thurgau, Kerner) and the “Silvaner-” or “Pinot blanc type” (e.g. Silvaner, Pinot blanc) [22]. Based on the determined concentrations of the four terpenoids in the analysed samples, the belonging of the grape varieties to the various aroma types already becomes roughly apparent, especially for “Muscat type” samples (Fig. 1).

Only free terpenoids could be measured, because no hydrolysis was carried out before analysis. Because terpenoids in grapes occur in free and glycosidic bound forms with varying ratios for every compound, no conclusion can be drawn about the total concentrations of the single substances. Furthermore, the whole concentration of the free terpenoids could probably not be determined either due to the low temperature and short equilibration time during the measurement. This might explain why no terpenoids were detected in grape varieties belonging to a certain aroma type (e.g. Müller–Thurgau).

Moreover, the phytosanitary status of the grapes substantially influences the concentration of various aroma compounds. For almost half of the determined aroma compounds (especially higher alcohols and various esters) higher concentrations were measured in grape mashes with increased concentrations of ergosterol, glycerol, gluconic acid and acetic acid. In earlier studies, increased concentrations of these four compounds were identified as indicators for deficient phytosanitary status of grapes due to the presence of grape rot [23, 24]. It has been shown that higher concentrations of phytosterols affect the intracellular availability of acetyl-CoA, which leads to increasing formation of higher alcohols such as isobutanol, 3-methylbutanol and the corresponding acetate esters [25]. Most of the grape varieties analysed for aroma compounds included samples with differing phytosanitary status, so a direct comparison was possible. The only exceptions are the samples from the varieties Hegel (four samples) and Portugieser (one sample), which all showed high concentrations of grape rot indicators. Therefore, it cannot be concluded, whether high concentrations of the above-mentioned aroma compounds in these samples result from the phytosanitary status of the grapes or from the varietal aroma itself.

Effect of artificial saliva solution on the concentration of aroma compounds

Volatile aroma compounds can be released from glycosidic forms by salivary enzymes, which significantly influences the aroma perception [13]. Grape mash samples were measured with and without addition of artificial saliva solution. Results are shown in Fig. 2.

No significant differences were detected between grape mash samples with and without addition of artificial saliva solution. Outliers on the right side of the x-axis belong to samples with conspicuous phytosanitary status and outliers on the upper y-axis belong to the samples from the variety Muskat–Trollinger (with and without addition of artificial saliva).

Further examinations focussed on the four terpenoids β-myrcene, limonene, ocimene and linalool, which are released from their glycosidic bound forms by enzymatic hydrolysis [1]. In the first approach, samples were measured after addition of different solutions. Slight differences were detected between grape mash samples with various additives, but to the same degree for all four terpenoids. The results were consistent for grape mash samples from different grape varieties (data not shown). Terpenoids are mainly located in grape skins [26], therefore differences between the grape mash samples probably result from varying ratios of grape skins, seeds and juice caused by different berry sizes. In the second approach regarding the effect of artificial saliva solution on terpenoid concentrations, grape mash samples were measured after various contact times of artificial saliva solution. Slight differences occurred for the concentrations of various compounds. Aldehydes showed a continuous increase in concentration with prolonged contact time, while the concentrations of terpenoids varied. The results were consistent for samples with and without addition of artificial saliva solution (data not shown). Therefore, it can be concluded that addition of the used artificial saliva solution had no measurable effect on the concentrations of aroma compounds. However, salivary enzymes can release aroma compounds from glycosidic bound forms and thus noticeably influence aroma perception, so further research on the optimum conditions of simulated grape tasting is required.

Calibration models of selected aroma compounds

The results from the GC–MS measurements were related to the NIR spectra of the corresponding samples. This way, NIR calibration models were developed for rapid and easy determination of the single aroma compounds.

Spectral properties

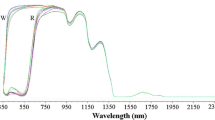

A characteristic NIR spectrum is shown in Fig. 3. In the visible range, absorption maxima occurred around 520 nm and around 680 nm, which have been reported referring to anthocyanins (540 nm) and to chlorophyll (680 nm) [27]. Due to the high water content of grapes and its high absorption of near-infrared radiation, water bands dominate the spectrum. The NIR range of the spectrum shows absorption maxima around 980 nm, 1200 nm and 1440 nm. Water-related bands have been reported at 975 nm, 1200 nm and 1470 nm [28, 29]. Similar spectral properties have been observed during earlier analysis of red grape homogenates [30, 31].

Regarding the single aroma compounds, various absorption maxima can be observed, however, they cannot be related only to aroma compounds because main components of grapes (water, sugar, acids) often show the same functional groups. Moreover, it is unlikely that compounds occurring in such a low concentration have a direct impact on the spectra. A main component of the sample, which directly influences the spectrum, may correlate with an aroma compounds, so an indirect correlation is probable. However, it requires detailed further research to verify such indirect correlations and to determine how much of the spectral variance thereby can be explained.

Development of calibration models

Model accuracy was evaluated according to the correlation coefficients of calibration and cross-validation and by the residual predictive deviation (RPD), which is defined as the ratio of the standard deviation to the SECV. An RPD between 1.5 and 2.0 allows differentiation between high and low values. A rough quantitative estimation is possible for values between 2.0 and 2.5, while a value between 2.5 and 3.0 or higher indicates high prediction accuracy [32].

Global calibration models

Results for global calibration models from the total sample set (n = 725) are shown in Table 4. All global calibration models gave the best results with 15 selected LVs. Spectral pre-treatment had varying effects with normalisation by SNVT giving the best results in most cases.

The correlation coefficients ranged from 0.365 (calibration)/0.251 (cross-validation) for acetic acid to 0.976 (calibration)/0.926 (cross-validation) for linalool. An RPD value of 1.5 or higher was obtained for 18 out of 31 compounds (58%). For the majority of the compounds, the RPD value lies between 1.5 and 1.9. Higher values are obtained for β-myrcene (2.0), propyl acetate (2.5), ethyl isobutanoate (2.7) and linalool (3.6).

The best results were obtained for models built from small amounts of data (n < 100), but larger datasets did not necessarily result in lower model performance, e.g. comparing 1-hexanol (n = 725) and isobutanol (n = 366). However, smaller datasets are often more homogeneous regarding factors like cultivation region and grape colour. The datasets for β-myrcene and linalool mainly contain white samples from Hessigheim due to the varying presence of free terpenoids in different grape varieties while the datasets for propyl acetate, ethyl isobutanoate and 2-methylbutyl acetate mainly contain red samples from Hessigheim caused by the phytosanitary status of the grapes. Moreover, small datasets only cover a very narrow concentration range for some compounds.

Grape aroma is influenced by grape variety and growing conditions, such as climate, soil, water supply and nutrients supply [7]. A wide variation of conditions may probably limit the prediction accuracy of global calibration models, because all of these factors should be considered in the calibration for obtaining more reliable results. Despite the grape variety, particular knowledge about further factors is often missing for the examined samples, so the sample set might not sufficiently cover the variability of all factors influencing grape aroma.

Cultivation region-, grape colour- and vintage-specific calibration models

Separate calibration models were calculated only for datasets containing 30 or more samples. Tables 5 and 6 show essential values for the separate calibration models with the lowest and highest model performance for cultivation region and grape colour and the RPD values of all separate calibration models.

Compared to the global models, separate calibration models resulted in higher coefficients of determination for calibration and cross-validation with few exceptions. Simultaneously, the SEC and SECV for most of the separate models are lower, equal or just slightly higher than for the global models. On average, calibration models for samples from Breisach gave better results than for samples from Hessigheim. Despite comparable vinification processes, grapes grown in different regions may result in different wines due to varying soil characteristics or agronomic factors. Although the direct effect of the soil on wine flavour is controversial, the effect of different fertilizers has been proven [33]. Separate calibration models for red and white grape mashes also show higher prediction accuracies than global models. Calibration models for white grape mash samples gave slightly better results than for red grape mash samples, which may result from the inclusion of less different grape varieties (9 white varieties vs. 11 red varieties, Table 1). The increase of prediction accuracy for separate calibration models shows a large variance between the single compounds, which probably depends on the differences between the composition of the dataset for global and separate calibration models.

Separation of the datasets by both cultivation region and grape colour further improved the results (Table 7).

The SEC and SECV decline again for the majority of the region- and grape colour-specific models. The RPD values further increase with only few exceptions. With the further specification of the models, more RPD values allow a semi-quantitative or quantitative determination of the aroma compounds. Region- and grape colour-specific calibration models consider both local geographical conditions and less grape varieties, which may explain the improved the prediction accuracy.

Separate calibration models from the vintages 2017 and 2018 showed no clear trend compared to the models from both vintages (data not shown).

Discussion

Aroma profiles of the grape mash samples

A large variety of aroma compounds was detected in the examined grape mash samples, from which the most had already been detected in grapes and wine. Depending on the grape variety and the phytosanitary status of the grapes, varying concentrations of different aroma compounds were determined. A study on the influence of sour rotten grapes on grape must and wine only showed a reduced taste intensity after 1 year of storage for wines made from grapes with a high percentage of sour rot [34]. Various changes occurred in grape must composition, however, only the main compounds were determined. In another study, analytical and sensorial characteristics of the aroma of wines produced from sour rotten grapes were examined [3]. The results showed a significant effect of sour rot on the chemical and sensory profiles of the wines. Furthermore, a possible effect on the secondary metabolism of yeast was suggested. In our study, the addition of artificial saliva solution had no significant effect on the concentrations of the aroma compounds. However, the used artificial saliva solution simulated only the effect of enzymes. The complexity of the human oral cavity leaves many further aspects to be considered [4, 35]. Moreover, large inter-individual differences can occur during tasting depending on numerous factors, which influence sensory perception [13]. Therefore, simulation of conditions in the mouth to create a more objective method to judge sensory perception of aroma compounds is a very complex issue, which requires extensive further research. Evaluation of grape aroma quality by an objective method before winemaking can be advantageous to prevent possible negative effects on the resulting wine quality.

Calibration models of selected aroma compounds

The calibration models showed varying prediction accuracies for the single aroma compounds. Separate calibration models for cultivation region or grape colour improved the prediction accuracy compared to global models, probably by decreasing the number of factors influencing grape aroma compounds (e.g. soil). Separation by both aspects gave even better results. An improvement of the model accuracy for separate models compared to global models has also been observed in earlier on-line measurements of grape mash [23]. Examinations on aroma compounds have been done before for glycosylated compounds in homogenized Tannat grapes [11]. Calibration models have been developed for groups and for single aroma compounds, from which two compounds were also present in our study (1-hexanol and linalool). The calibration models showed lower values for R2 (0.5320 for 1-hexanol and 0.5655 for linalool) and RPD (1.4 for 1-hexanol and 1.5 for linalool), while SECV was considerably better for both compounds (30.6 µg/kg for 1-hexanol and 6.8 µg/kg for linalool). In the above-mentioned study, calibration models have been developed for a single grape variety, while the global calibration models of our study contained a larger number of red and white grape varieties. Detailed examinations are necessary to determine which factors need separate calibration models and which can be merged in a common model. For practical use, the number of calibration models needs to stay low, which may limit the prediction accuracy. A high prediction accuracy is not necessarily reliable for calibration models based on very few samples due to low model robustness. The possibility of drawing conclusions about the final wine aroma from the aroma of the grapes is limited [6]. However, a semi-quantitative determination of aroma compounds originating from the grapes enables a more objective judgement of the aroma quality of grapes. Furthermore, the detection of possible undesired aroma compounds or their precursors can be helpful for the decision about the treatment of grapes before winemaking (e.g. warming of the grape mash) to improve wine quality.

Conclusion

Aroma compounds of winemaking grapes have been analysed under conditions similar to those in the mouth and NIR calibration models were developed to evaluate the potential of on-line measurement as an objective and rapid determination method. The grape mash samples showed differences in the presence and concentration of various aroma compounds for several grape varieties and regarding the phytosanitary status of the grapes, while the addition of artificial saliva solution caused no significant differences. The first approach for on-line determination of grape aroma compounds by NIR spectroscopy showed promising results for a large variety of compounds. However, large differences occurred between the prediction accuracies of the calibration models. Separate calibration models by cultivation region and/or grape colour gave better results compared to global calibration models and allow at least semi-quantitative determination for most of the compounds. The datasets should be extended regarding different factors influencing grape aroma composition, however, it should also be evaluated for which of these factors separate calibration models are actually necessary. Instrumental analysis cannot totally replace sensory evaluation, however, on-line NIR spectroscopy has the potential to be used as an objective additional method for the judgement of grape aroma quality.

References

Ferreira V, Lopez R (2019) The actual and potential aroma of winemaking grapes. Biomolecules. https://doi.org/10.3390/biom9120818

Ribéreau-Gayon P, Glories Y, Maujean A, Dubourdieu D (2006) Handbook of enology (volume 2): the chemistry of wine stabilization and treatments, 2nd edn. Wiley, New York

Barata A, Campo E, Malfeito-Ferreira M, Loureiro V, Cacho J, Ferreira V (2011) Analytical and sensorial characterization of the aroma of wines produced with sour rotten grapes using GC–O and GC–MS: identification of key aroma compounds. J Agric Food Chem 59:2543–2553. https://doi.org/10.1021/jf104141f

Buettner A, Beauchamp J (2010) Chemical input–sensory output: diverse modes of physiology–flavour interaction. Food Qual Prefer 21:915–924. https://doi.org/10.1016/j.foodqual.2010.01.008

Jayasena V, Cameron I (2008) °Brix/acid ratio as a predictor of consumer acceptability of Crimson Seedless table grapes. J Food Qual 31:736–750. https://doi.org/10.1111/j.1745-4557.2008.00231.x

Fischer U, Nopora J (2019) Sensory evaluation of grape berries: predictive power for sensory properties of sauvignon blanc, riesling and pinot noir wines. In: Book of abstracts ŒnoIVAS 2019, p 122

Clarke RJ, Bakker J (2004) Wine flavour chemistry, 1st edn. Blackwell, Oxford

Cayuela JA, Puertas B, Cantos-Villar E (2017) Assessing wine sensory attributes using Vis/NIR. Eur Food Res Technol 243:941–953. https://doi.org/10.1007/s00217-016-2807-9

Gehlken J, Pour Nikfardjam M, Kleb M, Zörb C (2021) Near-infrared spectroscopy in process control and quality management of fruits and wine. J Appl Bot Food Qual 94:26–38. https://doi.org/10.5073/JABFQ.2021.094.004

Cynkar WU, Cozzolino D, Dambergs RG, Janik L, Gishen M (2007) Effect of variety, vintage and winery on the prediction by visible and near infrared spectroscopy of the concentration of glycosylated compounds (G–G) in white grape juice. Aust J Grape Wine R 13:101–105. https://doi.org/10.1111/j.1755-0238.2007.tb00240.x

Boido E, Fariña L, Carrau F, Dellacassa E, Cozzolino D (2013) Characterization of glycosylated aroma compounds in tannat grapes and feasibility of the near infrared spectroscopy application for their prediction. Food Anal Methods 6:100–111. https://doi.org/10.1007/s12161-012-9423-5

Fuentes S, Tongson EJ, de Bei R, Gonzalez Viejo C, Ristic R, Tyerman S, Wilkinson K (2019) Non-invasive tools to detect smoke contamination in grapevine canopies, berries and wine: a remote sensing and machine learning modeling approach. Sensors 19:3335. https://doi.org/10.3390/s19153335

Parker M, Barker A, Pearson W, Hayasaka Y, Hixson J, Francis L (2018) Flavour release from wine glycosides during tasting. In: Siegmund B, Leitner E (eds) Flavour science. Verlag der Technischen Universität Graz, Graz, pp 31–36

Koch E, Volgenandt S, Becker M, Pour Nikfardjam M (2018) Einfluss von Düngergaben auf den Gehalt an α-Amino-Stickstoff und Nitrat sowie das Aromaprofil in Erdbeeren. Mitteilungen Klosterneuburg 68:11–26

Hempfling K, Fastowski O, Kopp M, Pour Nikfardjam M, Engel K-H (2013) Analysis and sensory evaluation of gooseberry (Ribesuva crispa L.) volatiles. J Agric Food Chem 61:6240–6249. https://doi.org/10.1021/jf401310v

Ehrenfeld ML (2013) Untersuchungen zur Adhäsion von oralen Streptokokken an zahnärztliche Werkstoffe in Abhängigkeit von der Auswertmethodik in vitro. Dissertation, Universität Regensburg

Schreier P, Drawert F, Junker A (1976) Identification of volatile constituents from grapes. J Agric Food Chem 24:331–336. https://doi.org/10.1021/jf60204a032

Panighel A, Flamini R (2014) Applications of solid-phase microextraction and gas chromatography/mass spectrometry (SPME-GC/MS) in the study of grape and wine volatile compounds. Molecules 19:21291–21309. https://doi.org/10.3390/molecules191221291

Boss PK, Kalua CM, Nicholson EL, Maffei SM, Böttcher C, Davies C (2018) Fermentation of grapes throughout development identifies stages critical to the development of wine volatile composition. Aust J Grape Wine R 24:24–37. https://doi.org/10.1111/ajgw.12296

Fang L, Hampel D, Olszewski K, Wüst M (2003) Mevalonate-independent biosynthesis of monoterpenoids in grape berry exocarp and mesocarp and in grape leaves. In: Le Quere J-L, Etievant PX (eds) Flavour research at the dawn of the twenty-first century: proceedings of the 10th Weurman flavour research symposium. Editions Tec & Doc, Paris, pp 332–337

Schwab W, Davidovich-Rikanati R, Lewinsohn E (2008) Biosynthesis of plant-derived flavor compounds. Plant J 54:712–732. https://doi.org/10.1111/j.1365-313X.2008.03446.x

Rapp A (1992) Aromastoffe des Weines. Chem unserer Zeit 26:273–284. https://doi.org/10.1002/ciuz.19920260606

Porep JU, Mattes A, Pour Nikfardjam MS, Kammerer DR, Carle R (2015) Implementation of an on-line near infrared/visible (NIR/VIS) spectrometer for rapid quality assessment of grapes upon receival at wineries. Aust J Grape Wine R 21:69–79. https://doi.org/10.1111/ajgw.12120

Porep JU, Mrugala S, Pour Nikfardjam MS, Carle R (2015) Online determination of ergosterol in naturally contaminated grape mashes under industrial conditions at wineries. Food Bioprocess Technol 8:1455–1464. https://doi.org/10.1007/s11947-015-1509-9

Rollero S, Mouret J-R, Bloem A, Sanchez I, Ortiz-Julien A, Sablayrolles J-M, Dequin S, Camarasa C (2017) Quantitative 13 C-isotope labelling-based analysis to elucidate the influence of environmental parameters on the production of fermentative aromas during wine fermentation. Microb Biotechnol 10:1649–1662. https://doi.org/10.1111/1751-7915.12749

Lukić I, Lotti C, Vrhovsek U (2017) Evolution of free and bound volatile aroma compounds and phenols during fermentation of Muscat blanc grape juice with and without skins. Food Chem 232:25–35. https://doi.org/10.1016/j.foodchem.2017.03.166

Agati G, Meyer S, Matteini P, Cerovic ZG (2007) Assessment of anthocyanins in grape (Vitis vinifera L.) berries using a noninvasive chlorophyll fluorescence method. J Agric Food Chem 55:1053–1061. https://doi.org/10.1021/jf062956k

Clevers JGPW, Kooistra L, Schaepman ME (2010) Estimating canopy water content using hyperspectral remote sensing data. Int J Appl Earth Obs Geoinf 12:119–125. https://doi.org/10.1016/j.jag.2010.01.007

Cao Q, Zhegalova NG, Wang ST, Akers WJ, Berezin M (2013) Multispectral imaging in the extended near-infrared window based on endogenous chromophores. J Biomed Opt 18:101318/1–101318/7. https://doi.org/10.1117/1.JBO.18.10.101318

Janik LJ, Cozzolino D, Dambergs R, Cynkar W, Gishen M (2007) The prediction of total anthocyanin concentration in red-grape homogenates using visible-near-infrared spectroscopy and artificial neural networks. Anal Chim Acta 594:107–118. https://doi.org/10.1016/j.aca.2007.05.019

Cozzolino D, Cynkar WU, Dambergs RG, Mercurio MD, Smith PA (2008) Measurement of condensed tannins and dry matter in red grape homogenates using near infrared spectroscopy and partial least squares. J Agric Food Chem 56:7631–7636. https://doi.org/10.1021/jf801563z

Nicolaï BM, Beullens K, Bobelyn E, Peirs A, Saeys W, Theron KI, Lammertyn J (2007) Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: a review. Postharvest Biol Technol 46:99–118. https://doi.org/10.1016/j.postharvbio.2007.06.024

Lang CP, Merkt N, Klaiber I, Pfannstiel J, Zörb C (2019) Different forms of nitrogen application affect metabolite patterns in grapevine leaves and the sensory of wine. Plant Physiol Biochem 143:308–319. https://doi.org/10.1016/j.plaphy.2019.09.009

Barata A, Pais A, Malfeito-Ferreira M, Loureiro V (2011) Influence of sour rotten grapes on the chemical composition and quality of grape must and wine. Eur Food Res Technol 233:183–194. https://doi.org/10.1007/s00217-011-1505-x

Muñoz-González C, Cueva C, Ángeles Pozo-Bayón M, Victoria Moreno-Arribas M (2015) Ability of human oral microbiota to produce wine odorant aglycones from odourless grape glycosidic aroma precursors. Food Chem 187:112–119. https://doi.org/10.1016/j.foodchem.2015.04.068

Acknowledgements

The authors would like to thank Ute Bader, Dr. Hermann Morast and Tobias Moll (Baden-Württembergischer Genossenschaftsverband e.V., Stuttgart/Germany) for project management and Felsengartenkellerei Besigheim eG, Hessigheim/Germany and Badischer Winzerkeller eG, Breisach/Germany for providing the sample material. Further thanks go to Dr. Christian Krapf (NIR-Online GmbH, Walldorf/Germany, part of BÜCHI Labortechnik AG, Flawil/Switzerland) for his support with the SX-Plus software and Maria Ilieva-Dachkova for assistance with sample preparation and measurements.

Funding

This work was financially supported by Ministerium für Ländlichen Raum und Verbraucherschutz (MLR) Stuttgart as part of the project “Nahinfrarotspektroskopie (NIRS) als innovative Messmethode zur Beurteilung der Traubenqualität in Zeiten des Klimawandel”. Open access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no potential conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gehlken, J., Pour Nikfardjam, M. & Zörb, C. Determination of aroma compounds in grape mash under conditions of tasting by on-line near-infrared spectroscopy. Eur Food Res Technol 248, 2325–2337 (2022). https://doi.org/10.1007/s00217-022-04048-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04048-1