Abstract

Solid lipid nanoparticles (SLN) have emerged as a potential delivery system for bioactive ingredients, as they are associated with improving the stability of incorporated bioactive components by preventing their diffusion to the particle surface. The aim of this study was to investigate the impact of carrier lipid composition and surfactant type on the physical stability and thermal behavior of SLN containing β-carotene. As carrier lipids we used cocoa butter and/or tristearin and as surfactants we used Quillaja saponin extract in a combination with high- or low-melting lecithin. All the ingredients were food-grade. The results showed that all the SLN were physically stable and had a particle diameter < 200 nm, except for SLN containing only tristearin as carrier lipid and Quillaja saponins and low-melting lecithin as emulsifier, which showed slightly increased particle sizes during storage due to polymorphic transition. In general, this study indicated that the introduction of heterogenous lipids can improve the physical stability of the SLN due to the more random crystal structures formed. Moreover, the polymorphic stability is dependent on the surfactants applied. These results are of interest for manufacturers in food, pharmaceutical, cosmetic and personal care industries using cocoa butter or any lipid blend to enrich their products with bioactive components.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Healthy eating and natural products are increasingly important for consumers. Cocoa butter derived from the seeds of Theobroma cacao tree is one of the main component in chocolate manufacturing, but it is also widely used in personal care, cosmetics and pharmaceutical products [1, 2]. The incorporation of active ingredients into cocoa butter-based products is one possible way to deliver novel functionalities, for example, by enhancing the overall stability of cocoa butter-based commodities or improving nutritional value of foods rich in cocoa butter. Such active ingredients for health purposes include, for example, β-carotene, which is a provitamin A and performs vital functions for growth and development in the body [3]. However, as β-carotene is highly susceptible to oxidation [3], it needs to be incorporated into a protective delivery system that can maintain its chemical stability.

Solid lipid nanoparticles (SLN) have emerged as such a potential delivery system for bioactive ingredients such as β-carotene [4, 5]. The advantage of SLN is due to the solidified lipid matrix that limits the mass transport of the incorporated ingredients to the surface of the particle, where oxygen and other pro-oxidants are in abundance, thus limiting the oxidation of the incorporated ingredient [5, 6].

For the stabilization of SLN and the incorporated bioactive, an appropriate selection of lipids and emulsifiers is of a key importance [5]. This is because the solid lipids are prone to polymorphic transition, which describes the changes in the lipid crystal morphology and packing from a thermodynamically unstable α-subcell crystals to thermodynamically favored β-subcell crystals [7]. In emulsified lipids such as SLN, the polymorphic transition of the solid lipids often leads to physical instability because the spherical shape of the SLN allowed by the hexagonal α-polymorph transitions via a needle shaped orthorhombic β′-polymorph to a platelet-shaped β-polymorph with a triclinic crystal structure [8, 9]. This increases the surface area of the particles, and if sufficient amounts of emulsifier are not present to adsorb to these newly created interfaces, the particles will aggregate or even gel [10]. Moreover, the packing density of the lipids increases upon polymorphic transition, which may also result in the expulsion of any incorporated ingredients [11].

Polymorphic transition in SLN depends on the used lipid(s), and emulsifiers, but also on the generated particle size as well as the applied temperature during cooling and storage [5]. In our previous studies we revealed that the emulsifier type had a major impact on the crystallization behavior and polymorphic stability [4, 12,13,14]. Specifically, food-grade Quillaja saponins with high-melting lecithin as emulsifiers facilitated the formation of physically stable SLN (tristearin as carrier lipid), which also inhibited the degradation of the encapsulated bioactive components such as β-carotene and ω-3 polyunsaturated fish oils [4]. Quillaja saponins are plant glycosides found in the Chilean Quillaja saponaria tree [15]. These amphiphilic saponins are composed of a hydrophobic triterpene aglycone to which hydrophilic sugar moieties are bound [15]. Quillaja saponin extracts are known for their excellent emulsifying and foaming properties [16,17,18]. On the other hand, lecithins are a complex mixture of different naturally occurring phospholipids and their amphiphilicity is due to the hydrophilic head group attached to a phosphate moiety and hydrophobic fatty acid chains [19]. Lecithins are widely used in foods, pharmaceuticals, cosmetics and technical products.

The purpose of this study was to investigate the effect of heterogeneous lipids, namely cocoa butter and tristearin, on the physical stability and polymorphic behavior in SLN containing β-carotene. In addition, SLN without β-carotene was investigated as control. We hypothesized that the stability of the SLN will be enhanced through the use of the selected heterogeneous lipids (cocoa butter and tristearin), i.e. they may form more unordered crystallized lipid structures that will affect the polymorphic transition process. Using mixed lipids differing in their melting characteristics may prevent polymorphic transition and associated instabilities of solid lipid particles [20, 21]. Furthermore, we studied the influence of two emulsifier mixtures, Quillaja saponin extract and high- or low-melting lecithins, on the physical and polymorphic stability of the SLN. We expected that the application of Quillaja saponins and high-melting lecithin will lead to slower polymorphic transition of the SLN than when applying low-melting lecithin. This phenomenon has been reported for purely saturated triacylglyceride-based SLN [4].

Materials and methods

Materials

Cocoa butter (#800/ Item BPPPQ1000) was donated by Cargill GmbH (Berlin, Germany). It contained ≥ 99% lipids comprising 60.4% saturated fatty acids, 35.5% monounsaturated fatty acids, 4.0% polyunsaturated fatty acids, < 0.5% trans fatty acids, ≤ 0.1% water, ≤ 2.0% free fatty acids, 41 μg vitamin A, 4.5 μg vitamin D, 1050.0 μg vitamin E, and 15.0 μg vitamin K. It had a peroxide value ≤ 2.0 meq O2/kg. Tristearin (Dynasan 118, purity ≥ 97%) was obtained from Cremer Oleo GmbH & Co. KG (Witten, Germany). High-melting lecithin Phospholipon 80H from soy (≥ 70% hydrogenated phosphatidylcholine and ≤ 6% hydrogenated lysophosphatidylcholine with 85% stearic acid and 15% palmitic acid as fatty acids) and low-melting lecithin Lipoid S75 (≥ 68% lysophosphatidylcholine, ≥ 7% phosphatidylethanolamine, and ≥ 3% lysophosphatidylcholine with 58–65% linoleic acid, 12–17% palmitic acid, 8–12% oleic acid, 4–6% linolenic acid, and 2–5% stearic acid as fatty acids) were from Lipoid AG (Ludwigshafen, Germany). Quillaja saponaria wood extract (Andean QDP Ultra Organic), a product of Desert King International (San Diego, CA, USA), was purchased from PERA GmbH (Springe-Eldagsen, Germany). The Quillaja extract had a saponin content of 62.5% and 3.38% citric acid as additive. Crystalline β-carotene was provided by DSM Nutritional Products Ltd. (Basel, Switzerland). Sodium azide was purchased from Carl Roth GmbH & Co. KG (Karlsruhe, Germany). Sodium dihydrogen phosphate and disodium hydrogen phosphate were obtained from Sigma Aldrich Co. (Steinheim, Germany). Bidistilled, deionized water was used throughout the study.

Preparation of emulsifier solution

Aqueous emulsifier solutions (3% w/w) containing 2% (w/w) Quillaja saponin extract and 1% (w/w) high- or low-melting lecithin were prepared by dissolving them in a 10 mM sodium phosphate buffer (pH 7) containing 0.02% (w/v) sodium azide as a bacteriostatic agent.

Preparation of SLN

The SLN preparation was carried out by applying a hot high-pressure homogenization method. First, the lipid phase (10% w/w) comprising of different ratios r (% w/w) of tristearin and cocoa butter (10:0, 7.5:2.5, 5.0:5.0, 2.5:7.5, 0:10) was melted (at 90 °C) and then mixed with the hot (90 °C) emulsifier solution (90% w/w). In part of the experiments, 0.1% (w/w) β-carotene was added into the lipid phase, which resulted in a concentration of 0.01% (w/w) in the final SLN. Second, a course pre-emulsion was generated by using an Ultra-turrax (Labworld, Staufen, Germany) at 24,000 min−1 for 2 min. Third, a fine emulsion was formed by passing the pre-emulsion through a microfluidizer (Microfluidizer Processor M-110EH-30) equipped with a ceramic H10Z interaction chamber (diameter: 100 μm) (Microfluidics Corporation, Newton, MA, USA) four times at 500 bar. The microfluidizer was heated up prior to homogenization by cycling hot water (90 °C) through the machine to prevent crystallization during the procedure. Finally, the hot emulsion was cooled down in an ice bath and stored at 2 °C.

Dynamic light scattering

The hydrodynamic particle diameter (dH) and polydispersity index (PDI) measurements were carried out using a dynamic light scattering device (Nano Zetasizer, Malvern Instruments, Malvern, UK) at 2 °C. The samples were diluted 1:100 with 10 mM sodium phosphate buffer (pH 7) to prevent multiple scattering of the particles.

Differential scanning calorimetry (DSC)

The thermal behavior of the samples was assessed using a differential scanning calorimeter (Perkin Elmer Life and Analytical Sciences, Shelton, CT, USA). About 7–10 mg of the sample was placed in an aluminum pan covered with an aluminum lid and hermetically sealed. An empty pan was used as a reference. The measurements were carried at the following temperature program: Heating from 10 to 85 °C, and cooling down to − 10 °C at a rate of 20 °C/min.

Statistical analysis

All measurements were carried out for triplicate samples. Results are shown as average and standard deviations.

Results and discussion

Physical stability

The purpose of these experiments was to evaluate the physical stability of SLN (10% lipid phase, 2% Quillaja saponins, 1% high- or low-melting lecithin, pH 7) with or without encapsulated β-carotene during a 21-day storage at 2 °C.

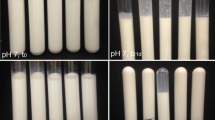

The dynamic light scattering data showed that all SLN containing different ratios of tristearin and cocoa butter with or without encapsulated β-carotene formed nanosized particles (< 200 nm) independent of the used lecithin type (Table 1). The low PDI-values (< 0.2) indicated that the particles had very narrow particle size distributions. After 21 days of storage at 2 °C, the particle diameter hardly changed for any samples. An exception was tristearin SLN (r = 10:0) stabilized with low-melting lecithin that showed a slight increase in their particle size, but also in the PDI (Table 1). This increase in PDI indicated that some bigger particles were also present in the lipid dispersions. This agrees with previous literature that demonstrated that SLN stabilized with 2% Quillaja saponins in combination with low-melting lecithin are less stable than SLN stabilized with Quillaja saponins and high-melting lecithin [4]. Nevertheless, no visual aggregation or gelling was observed in the tristearin SLN (r = 10:0) emulsified with low-melting lecithin. Overall, the particle size results (Table 1) indicated that the addition of cocoa butter into the tristearin matrix led to improved physical stability of the SLN even when emulsified with Quillaja saponins and low-melting lecithin. Moreover, our data showed that incorporation of β-carotene into the SLN did not influence the physical stability (Table 1).

Previous studies demonstrate that the stabilization of SLN containing cocoa butter is not so straightforward. A study by Kim et al. [22] investigated cocoa butter SLN (0.05–5% lipid) stabilized by curdlan (a high-molecular weight linear polymer comprising β-1,3-linked glucose residues, 0.05%) and Tween 80 (0.05%). Their research showed that formation of small cocoa butter SLN (dH = 140–200 nm, PDI = 0.4) was only possible up to 0.5% lipid concentration. The authors stated that the particles were unimodally distributed. Nevertheless, a PDI-value of 0.4 indicates a polydisperse distribution. On the other hand, using a higher lipid concentration (> 1%) led to aggregation of the cocoa butter SLN [22]. Another study demonstrated that a 1:1 mixture of cocoa butter and goat fat SLN (5% lipid) stabilized by two surfactants—lecithin product Phospholipon 90G (30%) and Tween 80 (0.01–1%)—showed the formation of small lipid particles after homogenization [23]. The mean particle sizes (d90%) of the SLN showed only slight increases during 1 week of storage, whereas after 1 month the mean particle sizes increased substantially. Surprisingly, the SLN made of only cocoa butter had a better physical stability than those of the two mixed lipids (cocoa butter and goat fat), and showed increased mean particle sizes only after 3 months of storage time [23]. It should be noted that the authors revealed no information of the particle size distributions, but acknowledged that the higher values of d90% point to the presence of µm-sized particles. In a study by Qian et al. [24] the authors investigated the influence of a mixed lipid composition on the physical stability of SLN. They reported that Tween 80-stabilized SLN composed of cocoa butter and hydrogenated palm oil (10% lipid, r = 1:1) with encapsulated β-carotene were physically unstable. Moreover, the SLN prepared with only hydrogenated palm oil gelled, and no particle size data was given for SLN comprising only cocoa butter [24]. This instability of SLN was shown to be due to the inability of the surfactant Tween 80 to prevent polymorphic transition from α- to β-subcell crystals [24].

In contrast to the previous literature, Ribeiro et al. [25] reported a successful formation of nanosized cocoa butter—sesame oil nanostructured lipid carriers (NLC) stabilized with Pluronic 68—a nonionic triblock copolymer composed of polyoxypropylene linked to polyoxyethylene chains. The authors showed that the mean particles sizes of the NLC (9% lipid with cocoa butter—sesame oil r = 7:3 or 4:1) stabilized with 5% Pluronic 68 were somewhat smaller (dH = ~ 190 nm, PDI 0.14–0.16) compared to NLC (7% lipid, r = 3:1) stabilized with 3% surfactant (dH = ~ 230 nm, PDI 0.18–0.2). The former NLC formulation (9% lipid, r = 7:3, 5% Pluronic 68) with and without inclusion of a hydrophobic drug molecule lidocaine was subjected to a 12-month storage test at 25 °C, and the results showed that the NLC remained stable (dH = < 250 nm, PDI < 0.2) [25].

Phase transition behavior of SLN

This series of investigations was carried out to assess the thermal behavior and the crystal morphology of SLN (10% lipid phase, 2% Quillaja saponins, 1% high- or low-melting lecithin, pH 7) with or without encapsulated β-carotene during a 21-day storage at 2 °C.

Phase transition temperatures

The DSC heating thermographs of tristearin SLN (r = 10:0) stabilized with high-melting lecithin showed only one endothermic event at ~ 57 °C (Fig. 1a), whereas tristearin SLN stabilized with low-melting lecithin showed also a second endothermic peak at ~ 70 °C (Fig. 1b). This describes the typical melting behavior of the α- and β-subcell crystals of tristearin at ~ 57 and ~ 70 °C, respectively [14, 26]. Increasing the ratio of cocoa butter in the tristearin matrix showed that the melting temperature (Tm) of the α- and β-subcell crystals of tristearin in the SLN decreased (Figs. 1, 2a). For example, SLN made with the equal ratios of tristearin and cocoa butter (r = 5:0:5:0) showed a Tm(peak) at ~ 48–50 °C and ~ 66 °C (Fig. 1). The results also showed that there were no differences between the onset melting temperatures (Tm(onset)) of SLN stabilized with either high- or low-melting lecithin or whether β-carotene was present or not (Fig. 2a). A previous study reported that SLN made of cocoa butter and hydrogenated palm oil (1:1) showed a lower Tm of 41.2 °C, which can be explained by the lower Tm of hydrogenated palm oil (Tm = 49.7 °C) [24] compared to that of tristearin (Tm = 58.2 °C) [14, 27].

The SLN made of pure cocoa butter (r = 0:10) had the lowest Tm(onset) at ~ 16 °C (Fig. 2a) and Tm(peak) at ~ 22–23 °C. This corresponds to the melting of the α-subcell crystals (polymorph II) of cocoa butter (Tm = 23.3 °C) [28]. The melting behavior is also similar with previous studies on cocoa butter SLN reporting a Tm at 19.3 °C [24] most likely corresponding to melting of cocoa butter polymorphs I (Tm = 17.3 °C), and II [28]. In contrast, another study reported a higher Tm(peak) at 31–32 °C for cocoa butter SLN stabilized with lecithin and Tween 80 after 3 months of storage [23]. This is likely due to that the cocoa butter in the SLN had polymorphed to a more stable β-polymorph over time, which the authors actually verified by wide angle X-ray diffraction measurements showing the presence of β-crystals (d = 4.6 Å). Cocoa butter in the β-crystal configurations, i.e. as polymorph IV and V (d = 4.6 Å) have a Tm of 33.8 and 36.3 °C, respectively [28].

The DSC cooling thermographs revealed one exothermic event corresponding to the crystallization of the SLN particles (Fig. 3). Tristearin SLN (r = 10:0) stabilized with high-melting lecithin began to crystallize at ~ 39–40 °C (Fig. 2a, 3a), whereas tristearin SLN emulsified with low-melting lecithin crystallized at ~ 31 °C (Figs. 2b, 3b). This is in accordance with earlier research [4]. Similar influence of the lecithin type was also observed for SLN with mixed ratios of tristearin and cocoa butter where SLN with high-melting lecithin crystallized at a higher temperature compared to the low-melting lecithin (Fig. 3b). The differences in crystallization onset temperature TC(onset) between the SLN stabilized with high-melting and low-melting lecithin illustrates that the high-melting lecithin (Tm = 52 °C) crystallizes at a higher temperature upon cooling (Fig. 2b) and initiates crystallization of the saturated carrier lipids via heterogenous nucleation around 7–9 °C higher than low-melting lecithin. The low-melting lecithin, however, remains liquid due to its unsaturated fatty acid tail (Tm < 0 °C), and therefore cannot induce crystallization of the lipid matrix. This phenomenon has been explained in previous studies [4, 13, 14].

In general, TC(onset) decreased with increasing ratios of cocoa butter (Figs. 2b, 3). The data also showed that the encapsulation of β-carotene into the SLN did not impact the crystallization behavior (Fig. 2). For example, SLN at r = 5.0–5.0 showed a crystallization event (TC(peak)) at ~ 29–30 °C (high-melting lecithin) and at ~ 21–22 °C (low-melting lecithin) (Figs. 2b, 3b). The TC-value detected for the low-melting lecithin -stabilized SLN (r = 5.0–5.0) (Fig. 2b) is similar to that of Tween 20 -stabilized SLN prepared with 50% cocoa butter and 50% hydrogenated palm oil (TC = 20.5 °C) [24]. This can be explained by the fact that Tweens—surfactant family of polysorbates—also do not crystallize on the SLN surface upon cooling [13].

The cocoa butter SLN (r = 0:10) showed the lowest crystallization temperature (Fig. 2b) which can be explained by the fatty acid composition of the cocoa butter: The presence of saturated fatty acids such as palmitic acid (C16:0; ~ 25–27%) in addition to stearic acid (C18:0; ~ 33–38%), and arachidic acid (C20:0; ~ 1%) as well as unsaturated fatty acids such as oleic acid (C18:1; ~ 33–36%) and linoleic acid (C18:2; ~ 2–4%) in the cocoa butter [29] lower the melting and crystallization temperatures compared to saturated tristearin. Furthermore, the lecithin type showed a less pronounced impact on the crystallization temperature in cocoa butter SLN (r = 0:10): The SLN stabilized by high-melting lecithin started to crystallize around 1–5 °C higher than the ones stabilized with low-melting lecithin (Fig. 2b). The less distinct effect of high-melting lecithin on the TC(onset) in the cocoa butter SLN is rather interesting. This indicates that the interactions between the saturated lipid tails of the high-melting phospholipids and the lipids in the cocoa butter matrix upon crystallization are rather low, and comparable to low-melting lecithin. In other words, the saturated fatty acid chains of the high-melting lecithin protruding into the lipid particle are less effective in initiating nucleation in the cocoa butter lipids because they may be partially solubilized in the unsaturated fatty acids present in the cocoa butter. This in turn interferes with the heterogenous nucleation process because the saturated lipid tails cannot act as nucleation templates anymore, at least not to the extent observed when more saturated lipids are present in the lipid particles. Consequently, the overall crystallization temperature of the cocoa butter SLN irrespective of the lecithin type was very similar (TC(peak) = 4.8–5.6 °C) (Fig. 3). This is similar to an earlier reported TC-values for cocoa butter SLN at 5.3 °C [24].

Phase transition enthalpies

In order to gain insights into the polymorphic stability of the SLN, the DSC results were plotted as a ratio between the melting enthalpy change of α-subcell crystals and crystallization enthalpy change (ΔHm(α)/ΔHC). A high ΔHm(α)/ΔHC-ratio indicates that α-subcell crystals are dominating, whereas a low enthalpy ratio demonstrates that more β-subcell crystals are present. The rate of polymorphic transition is illustrated only for SLN with encapsulated β-carotene (Fig. 4). The enthalpy ratios for SLN without β-carotene are not shown as no major differences were found between the samples with and without β-carotene.

Tristearin SLN (r = 10:0) stabilized with Quillaja saponins and high-melting lecithin retained fully their α-subcell crystals over the studied storage period (Fig. 4a). Interestingly, the polymorphic stability of tristearin SLN stabilized with Quillaja saponins and low-melting lecithin decreased only slightly from a ΔHm(α)/ΔHC-ratio of 0.97 ± 0.01 to 0.92 ± 0.11 (Fig. 4b). This polymorphic change agrees with the slightly increased particle size and PDI data (Table 1), indicating that a small amount of the tristearin SLN polymorphed from spherically shaped α-subcell crystals to platelet shaped β-subcell crystals. This result is contradictory to a previous study that reported that the α-subcell crystals of tristearin SLN stabilized with 2% Quillaja saponins and 1% low-melting lecithin rapidly polymorphed to β-subcell crystals (ΔHm(α)/ΔHC = ~ 0.5) during 22 days of storage [4]. The reason for this difference is that in the previous study the samples were stored at 25 °C, whereas in the current study the SLN were stored at 2 °C. This demonstrates that the polymorphic transition is much slower when the storage temperature is kept low.

Addition of cocoa butter into the tristearin SLN revealed that the ΔHm(α)/ΔHC =-ratio decreased with increasing ratios of cocoa butter (Fig. 4). This can be explained by the increasing amounts of unsaturated fatty acids present in the SLN that cannot pack as densely as saturated lipids. Furthermore, the presence of different types of saturated fatty acids disrupts the crystallized lipid matrix more than one type of saturated lipid chain [21]. Consequently, this heterogenous lipid matrix allows more freedom of movement which leads to polymorphic transition [12, 14, 30]. Increased polymorphism has been observed in cocoa butter-sesame oil NLC [25].

The rate of polymorphic transition in the SLN containing cocoa butter depended on the type of lecithin and the concentration of cocoa butter used (Fig. 4). In general, the SLN stabilized with high-melting lecithin showed higher ΔHm(α)/ΔHC-ratios during storage than SLN stabilized with low-melting lecithin. In SLN containing the lowest ratio of cocoa butter (r = 7.5:2.5), the ΔHm(α)/ΔHC-ratio only decreased from 0.94 ± 0.80 on day 0 to 0.8 ± 0.06 on day 1 when high-melting lecithin was applied (Fig. 4a). On the other hand, when low-melting lecithin was used, the ΔHm(α)/ΔHC-ratio decreased faster from 0.80 ± 0.04 on day 0 to 0.67 ± 0.08 on day 1 (Fig. 4b). After 7 days of storage, however, the ΔHm(α)/ΔHC-ratios in the SLN at r = 7.5:2.5 were very similar regardless of the type of lecithin used (Fig. 4).

At r = 5.0:5:0, SLN stabilized with high-melting lecithin retained the majority of the α-subcell crystals of tristearin on day 1 (ΔHm(α)/ΔHC = 0.71 ± 0.01) (Fig. 4a), whereas the SLN with low-melting lecithin contained already mostly β-subcell crystals (Fig. 4b). In the high-melting lecithin -stabilized SLN at r = 5.0:5:0, the ΔHm(α)/ΔHC-ratio continued to slowly decrease over time and reached a similar ratio of α- and β-subcell crystals on day 21 as the SLN emulsified with low-melting lecithin (Fig. 4). On the other hand, SLN at r = 2.5:7.5 showed a rapid polymorphic transition already shortly after preparation, and the enthalpy ratio remained at ~ 0.25 after day 1 for SLN stabilized by either high- or low-melting lecithin (Fig. 4).

In comparison, the investigation of Attama et al. [23] reported that 1:1 mixture of cocoa butter and goat fat SLN stabilized by two surfactants—Phospholipon 90G and Tween 80—showed a lower crystallinity compared to SLN consisting of only cocoa butter as carrier lipid. The lower crystallinity that is formed by the mixed lipids is required to increase the loading capacity for bioactive components. Consequently, they suggested that by mixing lipids it is possible to overcome the problem of bioactive compound expulsion [23].

Key insights

Our results showed that heterogenous lipids used in this study, namely cocoa butter and tristearin, as well as the two emulsifier combinations, namely Quillaja saponins and high-or low-melting lecithin, selected for the stabilization of the SLN influenced the physical stability and thermal behavior of the formed SLN. The key insights of our study are summarized as follows:

All SLN with different ratios of tristearin and cocoa butter generated particles < 200 nm irrespective of the emulsifier type used after homogenization.

Tristearin SLN stabilized with Quillaja saponins and high-melting lecithins remained physically and polymorphically stable during storage.

Tristearin SLN stabilized with Quillaja saponins and low-melting lecithins showed slightly increased particle sizes due to polymorphic transition during storage.

Tristearin—cocoa butter SLN and cocoa butter SLN independent of used emulsifier type remained physically stable during storage. This indicated that the heterogenous lipid matrix overcame the stability issues encountered especially in low-melting lecithin—stabilized SLN composed of purely saturated triacylglycerides.

Increasing the ratio of cocoa butter in the SLN led to decreased Tm and TC-values, which was expected due to the lower Tm of cocoa butter containing a mixture of saturated and unsaturated fatty acids.

SLN emulsified with Quillaja saponins and high-melting lecithin had a 7–9 °C higher crystallization temperature than SLN stabilized with Quillaja saponins and low-melting lecithin. This indicated that the saturated lipid tails of the high-melting lecithin solidified first and induced crystallization of the carrier lipids via heterogenous nucleation.

The SLN stabilized with Quillaja saponins and low-melting lecithin stayed liquid upon cooling due to the low Tm (< 0 °C) of the unsaturated fatty acid chains of the low-melting lecithin. The carrier lipids usually crystallize when the supercooled lipid dispersion reaches a low enough temperature, which is usually around 20 °C lower than the bulk lipid [4, 14, 31].

Polymorphic transition was generally higher in SLN composed of heterogenous lipids, however, applying Quillaja saponins and high-melting lecithin as emulsifier slowed down this transition more than when Quillaja saponins and low-melting lecithin was used.

The minor differences in TC(onset) detected between the different lecithin types in cocoa butter SLN indicate that the high-melting lecithin co-crystallizes only to a very low extent with the lipids in the cocoa butter matrix similarly to the low-melting lecithin. This indicates that the behavior of the emulsifiers is also influenced by the lipid types used.

Conclusions

This study highlighted the application of heterogenous carrier lipids which enable structuring of more disordered lipid crystals lattices in solid lipid dispersions that also allow the inclusion of bioactive ingredients. More importantly, the choice of appropriate surfactants that can stabilize the crystallized lipid matrices against polymorphic transition over time is of crucial importance. Interestingly, the use of mixed lipids may also partially overcome the stability issues encountered when applying surfactants that otherwise would not be able to stabilize the crystallized lipid particles. The current study showed the successful formation of stable food-grade SLN comprised of cocoa butter-tristearin lipid matrix with and without encapsulated β-carotene upon applying Quillaja saponins and high- or low-melting lecithins as surfactants. In particular, Quillaja saponins and high-melting lecithin were more effective in slowing down the polymorphic transition of the SLN than when low-melting lecithin was used. Nevertheless, the mixed lipids facilitated the formation of physically stable SLN even when Quillaja saponins and low-melting lecithin was used, even though they are not able to stabilize SLN with saturated triacylglycerides (such as tristearin) very well. In general, these findings are promising for inclusion of bioactive ingredients in foods, but also for variety of products in pharmaceutical, cosmetics, and personal care industries that use cocoa butter or any heterogenous lipids as ingredients. In addition, further research is needed about how the heterogenous lipid matrix impacts the oxidative stability of the incorporated bioactive ingredients, and what kind of role does the internal structure of these lipid particles play in their physical and chemical stability.

References

Beg MS, Ahmad S, Jan K, Bashir K (2017) Status, supply chain and processing of cocoa—a review. Trends Food Sci Technol 66:108–116. https://doi.org/10.1016/j.tifs.2017.06.007

Żyżelewicz D, Krysiak W, Budryn G, Oracz J, Nebesny E (2014) Tocopherols in cocoa butter obtained from cocoa bean roasted in different forms and under various process parameters. Food Res Int 63:390–399. https://doi.org/10.1016/j.foodres.2014.03.027

Combs Jr GF (2012) Chapter 5—vitamin A. In: The vitamins. 4th edn. Academic Press, San Diego. https://doi.org/10.1016/B978-0-12-381980-2.00005-0

Salminen H, Gömmel C, Leuenberger BH, Weiss J (2016) Influence of encapsulated functional lipids on crystal structure and chemical stability in solid lipid nanoparticles: towards bioactive-based design of delivery systems. Food Chem 190:928–937. https://doi.org/10.1016/j.foodchem.2015.06.054

Weiss J, Decker EA, McClements DJ, Kristbergsson K, Helgason T, Awad T (2008) Solid lipid nanoparticles as delivery systems for bioactive food components. Food Biophys 3(2):146–154. https://doi.org/10.1007/s11483-008-9065-8

McClements DJ, Decker EA, Weiss J (2007) Emulsion-based delivery systems for lipophilic bioactive components. J Food Sci 72(8):R109–R124. https://doi.org/10.1111/j.1750-3841.2007.00507.x

Sato K, Garti N (1988) Crystallization and polymorphism of fats and fatty acids. Marcel Dekker, New York

Sato K, Ueno S (2011) Crystallization, transformation and microstructures of polymorphic fats in colloidal dispersion states. Curr Opin Colloid Interface Sci 16(5):384–390. https://doi.org/10.1016/j.cocis.2011.06.004

Bunjes H, Steiniger F, Richter W (2007) Visualizing the structure of triglyceride nanoparticles in different crystal modifications. Langmuir 23(7):4005–4011. https://doi.org/10.1021/la062904p

Helgason T, Awad TS, Kristbergsson K, McClements DJ, Weiss J (2008) Influence of polymorphic transformations on gelation of tripalmitin solid lipid nanoparticle suspensions. J Am Oil Chem Soc 85(6):501–511. https://doi.org/10.1007/s11746-008-1219-9

Müller RH, Mäder K, Gohla S (2000) Solid lipid nanoparticles (SLN) for controlled drug delivery—a review of the state of the art. Eur J Pharm Biopharm 50(1):161–177. https://doi.org/10.1016/S0939-6411(00)00087-4

Salminen H, Aulbach S, Leuenberger BH, Tedeschi C, Weiss J (2014) Influence of surfactant composition on physical and oxidative stability of Quillaja saponin-stabilized lipid particles with encapsulated ω-3 fish oil. Coll Surf B Biointerfaces 122:46–55. https://doi.org/10.1016/j.colsurfb.2014.06.045

Salminen H, Helgason T, Aulbach S, Kristinsson B, Kristbergsson K, Weiss J (2014) Influence of co-surfactants on crystallization and stability of solid lipid nanoparticles. J Colloid Interface Sci 426:256–263. https://doi.org/10.1016/j.jcis.2014.04.009

Salminen H, Helgason T, Kristinsson B, Kristbergsson K, Weiss J (2013) Formation of solid shell nanoparticles with liquid ω-3 fatty acid core. Food Chem 141(3):2934–2943. https://doi.org/10.1016/j.foodchem.2013.05.120

Guo S, Kenne L (2000) Structural studies of triterpenoid saponins with new acyl components from Quillaja saponaria Molina. Phytochem 55(5):419–428. https://doi.org/10.1016/S0031-9422(00)00340-X

Güçlü-Üstündağ Ö, Mazza G (2007) Saponins: Properties, applications and processing. Crit Rev Food Sci Nutr 47(3):231–258. https://doi.org/10.1080/10408390600698197

Yang Y, Leser ME, Sher AA, McClements DJ (2013) Formation and stability of emulsions using a natural small molecule surfactant: Quillaja saponin (Q-Naturale®). Food Hydrocoll 30:589–596. https://doi.org/10.1016/j.foodhyd.2012.08.008

Ralla T, Salminen H, Edelmann M, Dawid C, Hofmann T, Weiss J (2017) Sugar beet extract (Beta vulgaris L.) as a new natural emulsifier: emulsion formation. J Agric Food Chem 65(20):4153–4160. https://doi.org/10.1021/acs.jafc.7b00441

McClements DJ (2016) Food emulsions: principles, practices, and techniques, 3rd edn. CRC Press, Boca Raton

Üner M (2006) Preparation, characterization and physico-chemical properties of solid lipid nanoparticles (SLN) and nanostructured lipid carriers (NLC): their benefits as colloidal drug carrier systems. Die Pharm Int J Pharm Sci 61(5):375–386

Müller RH, Radtke M, Wissing SA (2002) Solid lipid nanoparticles (SLN) and nanostructured lipid carriers (NLC) in cosmetic and dermatological preparations. Adv Drug Deliv Rev 54(1):S131–S155. https://doi.org/10.1016/S0169-409X(02)00118-7

Kim B-D, Na K, Choi H-K (2005) Preparation and characterization of solid lipid nanoparticles (SLN) made of cacao butter and curdlan. Eur J Pharm Sci 24(2):199–205. https://doi.org/10.1016/j.ejps.2004.10.008

Attama AA, Schicke BC, Paepenmuller T, Müller-Goymann CC (2007) Solid lipid nanodispersions containing mixed lipid core and a polar heterolipid: characterization. Eur J Pharm Biopharm 67(1):48–57. https://doi.org/10.1016/j.ejpb.2006.12.004

Qian C, Decker EA, Xiao H, McClements DJ (2013) Impact of lipid nanoparticle physical state on particle aggregation and β-carotene degradation: potential limitations of solid lipid nanoparticles. Food Res Int 52(1):342–349. https://doi.org/10.1016/j.foodres.2013.03.035

Ribeiro LNM, Breitkreitz MC, Guilherme VA, da Silva GHR, Couto VM, Castro SR, de Paula BO, Machado D, de Paula E (2017) Natural lipids-based NLC containing lidocaine: from pre-formulation to in vivo studies. Eur J Pharm Sci 106:102–112. https://doi.org/10.1016/j.ejps.2017.05.060

Hagemann J, Rothfus J (1983) Polymorphism and transformation energetics of saturated monoacid triglycerides from differential scanning calorimetry and theoretical modeling. J Am Oil Chem Soc 60(6):1123–1131. https://doi.org/10.1007/bf02671340

Bunjes H, Koch MHJ (2005) Saturated phospholipids promote crystallization but slow down polymorphic transitions in triglyceride nanoparticles. J Controll Release 107(2):229–243. https://doi.org/10.1016/j.jconrel.2005.06.004

Sato K, Koyano T (2001) Crystallization properties of cocoa butter. In: Garti N, Sato K (eds) Crystallization processes in fats and lipid systems. Marcel Dekker Inc., New York

Foubert I, Vanrolleghem PA, Thas O, Dewettinck K (2004) Influence of chemical composition on the isothermal cocoa butter crystallization. J Food Sci 69(9):E478–E487. https://doi.org/10.1111/j.1365-2621.2004.tb09933.x

Awad TS, Helgason T, Weiss J, Decker EA, McClements DJ (2009) Effect of omega-3 fatty acids on crystallization, polymorphic transformation and stability of tripalmitin solid lipid nanoparticle suspensions. Cryst Growth Des 9(8):3405–3411. https://doi.org/10.1021/cg8011684

Bunjes H, Westesen K, Koch MHJ (1996) Crystallization tendency and polymorphic transitions in triglyceride nanoparticles. Int J Pharm 129(1–2):159–173. https://doi.org/10.1016/0378-5173(95)04286-5

Acknowledgements

Open Access funding provided by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with animal or human subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Salminen, H., Stübler, AS. & Weiss, J. Preparation, characterization, and physical stability of cocoa butter and tristearin nanoparticles containing β-carotene. Eur Food Res Technol 246, 599–608 (2020). https://doi.org/10.1007/s00217-020-03431-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-020-03431-0