Abstract

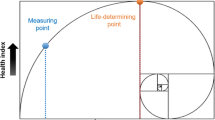

It is well known that cable plays a paramount role for transmission and distribution networks in ship power system. This paper tries to propose a two-factor lifetime prediction model for ship ethylene propylene rubber (EPR) cable under the influence of temperature and oil mist concentration. To achieve this goal, particle swarm optimization (PSO) is used to determine the optimal time temperature translation factor. Subsequently, the relationship between retention rate of hardness (RRH) and retention rate of elongation at break (EAB) is constructed by main curve fitting. Based on 50% of EAB, 15.1714% of RRH is considered as the end of life (EOL). On the basis, a two-factor prediction model based on RRH is established. Finally, the model is applied to assess the lifetime of ship EPR cable. The proposed two-factor model can realize rapid online detection of cable life, and ensure the prediction results are more in line with the real-life operation condition. The prediction results can provide theoretical guidance for the replacement and maintenance of ship cable, and ensure the safety of ship navigation. Note that the method discussed in this paper can also achieve remaining useful life (RUL) prediction and be extended to other different types of ship cables.

Similar content being viewed by others

References

Men RJ, Lei ZP, Song JC, Li YY, Lin LY, Tian MQ, Fabiani D, Xu XX (2019) Effect of thermal ageing on space charge in ethylene propylene rubber at DC voltage. IEEE Trans Dielectr Electr Insul 26(3):792–800

Lei ZP, Song JC, Geng PL, Tian MQ, Lin LY, Xu CY, Feng C, Zeng JX, Li ZY (2015) Influence of temperature on dielectric properties of EPR and partial discharge behavior of spherical cavity in EPR insulation. IEEE Trans Dielectr Electr Insul 22(6):3488–3497

Lin LY, Lin C, Geng PL, Lei ZP, Song JC, Tian MQ (2020) Ageing life evaluation of coal mining flexible EPR cables under multi-stresses. IEEE Access 8:53539–53546

Men RJ, Lei ZP, Han T, Fabiani D, Li CY, Suraci SV, Wang J (2019) Effect of long-term fluorination on surface electrical performance of ethylene propylene rubber. High voltage 4(4):339–344

Lei ZP, Song JC, Tian MQ, Cui XH, Li CY, Wen MM (2014) Partial discharges of cavities in ethylene propylene rubber insulation. IEEE Trans Dielectr Electr Insul 21(4):1647–1659

MengXK (2017) “Study on nondestructive lifetime prediction method of EPR insulation material in shipboard power cables,” Ph.D. dissertation, Dalian Univ. of Technology, Dalian, China

WeiY (2012) “Theoretical and experimental study on residual life prediction of shipboard low voltage cable,” Ph.D. dissertation, Dalian Maritime Univ., Dalian, China

Wang HX (2014) “Study of the rule of ship cable insulation ageing and rapid detection methods,” Ph.D. dissertation, Dalian Maritime Univ

Nobrega AM, Martinez MLB, de Queiroz AAA (2013) Investigation and analysis of electrical ageing of XLPE insulation for medium voltage covered conductors manufactured in Brazil. IEEE Trans Dielectr Electr Insul 20(2):628–640

Li Z, Moon KS, Yao YG, Hansen K, Watkins K, Morato L, Wong CP (2013) Carbon nanotube/polymer nanocomposites: Sensing the thermal ageing conditions of electrical insulation components. Carbon 65:71–79

Muniz PR, Teixeira JL, Santos NQ, Magioni PLQ, Cani SPN, Fardin JF (2017) Prospects of life estimation of low voltage electrical cables insulated by PVC by emissivity measurement. IEEE Trans Dielectr Electr Insul 24(6):3951

Donguk J, Seonghee P (2017) Evaluation of electrical tree degradation in cross-linked polyethylene cable using Weibull process of propagation time. Energies 10(11):1759

Cheng L, Mei H, Wang L, Guan Z, Zhang F (2017) Research on ageing evaluation and remaining lifespan prediction of composite insulators in high temperature and humidity regions. IEEE Trans Dielectr Electr Insul 23(5):2850–57

Neier T, Knauel J, Bawart M, Antipov D, Kim S (2019) A statistical method for statistical appraisal of the power cable conditions based on the TD and PD diagnostics result. In: Proceedings of ISTCSES, Kazan, Russia

Santhosh TV, Gopika V, Ghosh AK, Fernandes BG, Dubey KA (2016) Reliability prediction of I&C cable insulation materials by DSC and Weibull theory for probabilistic safety assessment of NPPs. Nucl Eng Des 296:51–61

Zhang Z, Assala PDS, Wu LH (2018) Residual life assessment of 110 kV XLPE cable. Electr Pow Syst Res 163:572–580

Fan WN, Huang YG, Zhang YR, Xiong J, Wang Y, You J, Zhu B, Jia ZD (2016) Study on diagnostic method of ageing 10kV XLPE cable. In: Proceedings of the CICED, Xi’an, China

Chen JQ, Wang ST (2000) Method of estimating the remaining life of the 10 kV XLPE cable operated 10 years. In: Proceedings of ICPADM, Xi’an, China, pp 204–208

Meng XK, Wang ZQ, Li GF (2017) Life assessment of marine ethylene propylene rubber power cables based on retention rate of hardness. Archi Electr Eng 66(3):475–484

Koga Y, Arao Y, Kubouchi M (2020) Application of small punch test to lifetime prediction of plasticized polyvinyl chloride wire. Polym Degradat Stab 171:109013. https://doi.org/10.1016/j.polymdegradstab.2019.109013

Hahn P, Polansky R (2015) “Estimation of the service lifetime of cable sheath materials designed for working in harsh operating environment”, in Proc. Kouty nad Desnou, Czech Republic, ISCEPE, pp 307–310

Aras F, Alekperov V, Can N, Kirkici H (2007) Aging of 154 kV underground power cable insulation under combined thermal and electrical stresses. IEEE Electr Insulat Mag 23(5):25–33. https://doi.org/10.1109/MEI.2007.4318272

Kim J, Yoon JS, Choi SW (2016) Lifetime assessment method using multiple-stress acceleration ageing for flexible cable of portable electric machines. J Electr Eng Technol 11(5):1377–1382

Wang ZQ, Zhou CL, Li GF, Wang NH (2012) Thermal lifetime estimation of ethylene propylene rubber insulated shipboard power cable using artificial neural network. J Comput Inform Syst 8(7):2999–3006

Son KL, Fouladirad M, Barros A, Levrat E, Lung B (2013) Remaining useful life estimation based on stochastic deterioration models: A comparative study. Reliab Eng Syst Safe 112:165–175

Fink O, Zio E, Weidmann U (2014) Predicting component reliability and level of degradation with complex-valued neural networks. Reliab Eng Sys Safe 121:198–206

Tang XP, Liu KL, Wang X, Gao FR, Macro J, Widanage WD (2020) Model migration neural network for predicting battery ageing trajectories. IEEE T Transp Electr 6(2):363–374

Vahidi B, Ranjbar AH, Omranpour H, Akbari M (2008) Application of artificial neural network in cable life time estimation and its failure rate per 100 km. In: Proceedings of MPS, Johor Baharu, Malaysia, pp 22–25

Santhosh TV, Gopika V, Ghosh AK, Fernandes BG (2018) An approach for reliability prediction of instrumentation & control cables by artificial neural networks and Weibull theory for probabilistic safety assessment of NPPs. Reliab Eng Syst Safe 170:31–44

Lakhdar B, Larbi B, Djillali M, Boubakeur A (2017) Lifetime estimation and diagnosis of XLPE used in HV insulation cables under thermal ageing: arithmetic sequences optimised by genetic algorithms approach. IET Gener Transm Dis 11(10):2429–2437

Alwis K, Burgoyne C (2006) Time-temperature superposition to determine the stress-rupture of aramid fibres. Appl Compos Mater 13(4):249–264

Zbiciak A, Michalczyk R, Brzeziski K (2019) Time-temperature superposition for viscoelastic materials with application to asphalt-aggregate mixes. Int J Environ Sci Te 16(9):5059–5064

Cai L, Lin JD, Liao XY (2020) Residual life prediction of marine EPR cable under discontinuous operation. IET Gener Transm Distrib 14(1):6306–6311

Liu L, Wang QR, Wang JZ, Liu M (2016) A rolling grey model optimized by particle swarm optimization in economic prediction. Comput Intell 32(3):391–419

Ashitha PN, Ganga S (2017) Remaining life estimation of an overhead composite insulator using particle swarm optimization technique. In: 2017 International conference on power and embedded drive control (ICPEDC), Chennai, India, pp 137-141

Liu M (2017) Study on ageing state and life analysis of marine low voltage insulated cables. M.S. thesis, Dalian University of Technology, Dalian, China

Acknowledgements

The authors declare that there is no funding support for this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cai, L., Yan, G. & Lin, J. Lifetime prediction of ship EPR cable under two factors based on retention rate of hardness. Electr Eng 105, 1839–1848 (2023). https://doi.org/10.1007/s00202-023-01748-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00202-023-01748-z