Abstract

Optimization of industrial processes is a constant concern and a main task for many companies in several industry sectors. Based on optimized solutions, the company can decrease manufacturing costs, lead times or, more generally, increase benefit. However, when developing a new process, you must be sure that the new solution will add more value to the initial solution. This, among many others, is one of the main reasons why companies opt, in addition to experimentation, for the use of tools that allow for the virtual prototyping, simulation, and integration of complex and sophisticated processes. Experimentation requires approximation testing, searching for the ideal values of quantity, temperature, etc.; simulation provides industrial processes with test support ranging from flows to robotic systems such as the intelligent software. This simulation software allows to develop programs, add Computer Aided Design (CAD) layouts, and simulate the cycle times of the different tasks to be performed. In this paper, an experimental approach is presented with atomization and fan spray pressure as the study basis and a simulation of the robot-based handling solution used in a tyre production line. The result is an improvement of the painting process, optimisation of the amount of fluid deposited on the tyre, of the processed product, as well as of the running times of the robot.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Tyre manufacturing is distributed around the world, and around 450 factories have the capacity to produce more than two billion tyres annually [1, 2]. However, although the construction of a tyre is a complex combination of components made from various ingredients that starts in the rubber tree and ends on the road, every year, 600,000 tons of used tyres are removed from the marketed, and it is replaced by the same number of new tyres [3]. The worldwide tyre market is predicted to reach 2268 million units in 2021, and with the expected exponential growth in the coming years, 2665 million units will be reached in 2027, which will correspond to a Compound Annual Growth Rate (CAGR) close to 2.8% in the period 2022–2027 [2,3,4]. This makes the tyre industry one of the largest consumers, with over 70% of the 30 million tons produced each year, of global natural rubber [2,3,4,5,6,7]. Due to these numbers, tyres deposited in dumps, in the open air and rivers, becomes an environmental problem that goes beyond the unpleasant point of view, becoming capable of causing many other complications [2, 5, 8] like diseases caused by the release of rubber microparticles. So, based on these numbers, it is easy to understand that tyre recycling is essential (~ 87.5% of all forms of tyre recycling according to the European Tyre and Rubber Manufacturers’ Association (ETRMA) is done by shredding) [9] integrating it into a Circular Economy (CE) cycle, reusing it in a new product [10, 11]; however, the use and recycling of tyres only make sense after their production, i.e., there is no use and no recycling process if tyres are not produced.

Thus, from the above, the importance is clear that this industry assumes on the world scene not only by the number of units produced (2665 million units reached in 2027) but also by the quantities of raw materials consumed. In this sense, any reduction or change that occurs in the consumption of products used in production [12] will result in a reduction of costs and an improvement in industrial sustainability [13]. So, these reductions will have a high impact on the production of modern tyres as it is a complex process that combines ingredients (rubber, steel, and textiles) starting from the rubber tree and ending on the road [2]. Then, tyre production is a multi-stage process made up of five essential tyre manufacturing stage (see Fig. 1).

Essential stage of tyre production process flowchart, adapted from [14]

It is at the production stage 3 “Building the tyre” that the study of this case will focus, starting with the analysis of the amount of product deposited on the painting stage (study of the gas–liquid ratio of the nozzle spraying), preparation for vulcanization, ending with the robotic feeding system and its programming whether it is carried out online or offline.

The use of robotic handling systems in industry is notorious and is becoming increasingly important and popular in modern industry [15], not only for its greater production efficiency but mainly for its long working capacity to work alongside humans in a hybrid automation [16]. However, programming robotic systems has long been considered a challenging task as it requires specific engineering knowledge [17]. To meet this challenge, two programming modes (online and offline) were developed so that programming mode, in manual and automatic, can be implemented in the majority robotic systems today. Without requiring advanced knowledge, online programming mode is currently the easiest method of programming technicians to teach the robot [18, 19]. It is a time-consuming method, since the robot will be guided by an operator who will guide it to perform the necessary movements [19]. However, considering all the development of robot teaching–playback technology [20], this programming mode does not make it the most suitable for the industry, as the various pieces of work can lead to critical losses of programming efficiency. Due to these facts, offline programming (OLP) has been developed in recent years with the aim of overcoming these shortcomings.

Offline programming aims to generate programming automatically, without resorting to operations performed in real robotic systems. This programming mode reduces the robots’ downtime required for system programming, resulting in significant savings in labour costs [21]. This approach to robot programming has taken on such importance that, in the recent few decades, several offline programming methods have been developed that have revolutionized the manufacturing industry. This OLP software, classified based on the development method, allows the transition, directly, to the commercial software [22,23,24], of the system to be modelled and, automatically, generate the robotic programme to be implemented. Software such as Roboguide™, Robostudio™, Robocad™, Delmia Robotics™, and RobotDK™, and others are proprietary and, for so, expensive commercial applications that, by the process to automating (by three-dimensional CAD packages), generate high precision robotic programs, supported by their own robots [25] or by a generic way like RobotDK™ and vision-based offline programming approach [19, 20, 26].

In this paper, the improvement of manufacturing capacity and the reduction of production costs of the painting station and its robotic arm of the tyre painting station are presented. The tyre painting programme developed based on a virtual reality representation, in 3D CAD, is presented, which will allow to overcome the limitations of the real application of tyre painting. The rest of the paper is organized as follows. Section 2 introduces the problem and the proposed analysis of the efficiency of the painting system and offline programming methodologies. In Sect. 3, its effectiveness in controlling the amount of special fluid is demonstrated, as well as the programming method and its integration into a robotic tyre manipulation system in the vulcanization stage. The discussion of the obtained results and the implementation of the proposed programming method are provided in Sect. 4, and the conclusions are presented in Sect. 5.

2 Industrial problem

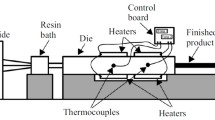

The process to be optimized is a tyre painting station, placing a lubricating film on the inner surface. As can be seen in Fig. 2, the station is built with a painting station (PS), two conveyors, a cleaning place, and a robot manipulator. The gripper is the most sophisticated and important element in the entire system. With eight fingers, each with touch sensors, it allows gripping tyres with different diameters and heights. The process starts when the first conveyor delivers the tyre to the picking place. When the sensor detects the correct position, the programmable logical controller (PLC) sends the signal to the handler to pick up the tyre. After the picking step, the handler takes the tyre to the PS machine. At all stages of the process, the PLC is the decision unit, including the amount of fluid to be sprayed and the pressure required. Therefore, when painting is finished, the PLC orders the handler to remove the tyre and place it on the second conveyor belt “place conveyor.” When the sensor detects that the tyre is in place and no longer stuck, the belt takes the tyre to a new manufacturing station and vulcanization, and the process is complete.

The process is very efficient, since the cycle time of the manipulation is just 12 s, but the company [27] would like to evolve to a system with double grippers that allows moving two tyres at the same time and improve the efficiency of the painting process and the amount of fluid sprayed. The improvement at the manipulator means that still only one tyre can be painted at the same time, but the new gripper will pick up and place two tyres at the same moment. Therefore, the main objective of the project is to create the new programme with a new gripper for the existing solution, optimize spray flow considering different pressures, and simulate the entire process to see if this solution can reduce cycle time and be more efficient.

3 Problem analysis

The production of a tyre is a complex combination of several components and several steps. In the five steps mentioned above (see Fig. 1), the various components are agglomerated along the production chain, starting with the manufacture of the components with the incorporation of the steel cord in one or more layers of rubber. In a second step, the malleable rubber, obtained in the mixer, is incorporated into the tread, and sent to the extruder. After extrusion and according to the weight per metre ratio, the tread is cooled and cut according to the size of the tyre. Textile threads are added by embedding them in a thin layer of rubber. The core of the tyre bead is formed from several ring-shaped steel wires that will be joined to the sidewall section cut to the specific size of the tyre.

It is in step 3 of the process (see Fig. 1) that the tyre begins to be formed. In this phase, the various semi-finished products obtained in the previous steps are assembled in the manufacturing machine, originating the so-called “green tyre,” which is subsequently sprayed with a special fluid to prepare the vulcanization process and move on to the next steps. Although the subsequent stages are equally important in the production process, it is in the “Building tyre” that study focused, concentrating essentially on the painting process and its feeding.

3.1 Atomization process

The painting process, also called tyre lubrication, is an atomization process that consists of the discharge of a liquid at high speed in a slow stream of fluid [28]. In other words, atomisation can be regarded as the transformation of a continuous volume of liquid into a large number of small droplets, i.e., the formation of clouds of liquid droplets, as described in Fig. 3.

Influence of atomization on the jet [29]

A variety of spray nozzles can be found on the market. Developed according to the application and flow, they can generate the desired droplet size and velocity distribution. These can be categorized based on mass flow rate, angle (typically between 20 and 60°), impact, droplet size, and area (flat fan, full cone, and hollow cone) [30]. Thus, for the same nozzle, the variation in the flow rate leads to the variation in the size of the drops, so the application will determine the adequate flow rate for the nozzle depending on the amount of fluid required and operational objectives. On the other hand, it is known that this process is closely dependent on the disintegration of the fluid into droplets. This disintegration results from the action of internal and external forces, exerted on the drops, which separate them in greater numbers and in significantly smaller drops. Thus, and based on this distinction, we will be dealing with cohesive and destructive forces that cause disturbances and oscillations in a liquid film, causing its disintegration into small drops, primary atomization. In turn, the larger diameter droplets will again be disintegrated into smaller droplets in the designed secondary atomization. These two stages promote the development of the spray which, through the injection pressure of the liquid, increased from zero, passes to the following five rupture regimes [31]: (i) liquid dribbles from the orifice (Rayleigh regime); (ii) liquid leaves as a thin distorted pencil; (iii) a cone forms at the orifice, but is contracted by surface tension forces into a closed bubble; (iv) the bubble opens into a hollow tulip shape terminating in a ragged edge, where the liquid disintegrates into fairly large droplets; and (v) the curved surface straightens to form a conical sheet. As the sheet of fluid expands, its thickness decreases, and it soon becomes unstable and disintegrates into ligaments and then falls in the form of a cone spray. These five stages of spray development are shown in Fig. 4.

Stages in spray development with increase in liquid injection pressure [31]

On the other hand, in addition to the influence of pressure on the formation of the lubricant film, viscosity also plays an important role in the rupture of the film, leading to the formation of droplets with a larger average size. This increase in viscosity results in a closed sheet without any atomization caused by the damping of surface waves which reduce the lateral spread of the fluid [32]. However, not only the previously mentioned factors that influence the geometry of the film and the amount deposited also the nozzle becomes relevant [30]. Summarizing the above, it can be said that droplet size depends on the type of nozzle used, the flow rate, the feed pressure, and the spray pattern.

3.2 Selection of nozzles

According to the market research, it was decided to carry out two painting tests with the AVX Airmix 15AG 2468 and with the Airpray A25 LP atomizing nozzles [33], and respective pumps. These nozzles combine the atomizing air pressure, the fan pressure, and the lubricating liquid flow according to the diagram shown in Fig. 5 (left).

Pneumatic atomizing nozzle (left). Nozzles Airmix and Airspray (right) [33]

The aqueous emulsion used, with a dynamic viscosity between 830 and 1550 mPa.s, was applied on the inner surface of the tyre ensuring that it was completely, but not excessively, covered. It should be noted, however, that the robotic feeding system, namely, the gripper, like the one Fig. 6, when developing its rotation movement around the spraying nozzle, accumulates lubricant which will have to be removed from time to time.

Robotic rotary gripper and internal tyre spraying [34]

In this case, perfect control of the parameters associated with each tyre is essential, which are a function of tyre size, fan pressure, and atomization pressure. So, the operator assumes a preponderant role in the correct parameterization of the equipment (definition of setpoints) and, as such, becomes an agent of process optimization. In this sense, the correct selection of the optimized pressures and the fan are fundamental for the correct coating of the inner surface of the tyre and to avoid the wasting of the lubricating fluid that will partially accumulate in the gripper jaws. Then, these residues will have to be removed from the gripper, so both in the simulation and in the physical action, a routine cleaning of the robot must be considered. An action has been integrated into a maintenance situation to be carried out by the machine operator or pre-programmed, in a cyclical manner.

3.2.1 Experimental study of the nozzles

In studies of two-phase gas–liquid jet flows of atomization and spray processes, computational fluid dynamics (CFD) based on Reynolds-averaged Navier–Stokes (RANS) approach is essential for the calculation of the two-phase flow [35]. These computational models of the cavity flow of the fan nozzle make it possible to effectively simulate the atomization characteristics with regard to, for example, the analysis of the impact of the Weber critical number on the diameter of the atomized particles and the speed of movement [36] as well, as the perception of coalescence phenomena and the problem of droplet formation using the numerical method smoothed particle hydrodynamics (SPH) or the Van der Waals equation of state [37]. Experimentation and modelling are tools that complement each other, acting as validation agents for simulation models. In this approach, the study was limited to carrying out experimental tests with the two nozzles based on an atomization pressure between 0 and 6 bar, on a tyre with a diameter of 596 mm, varying the atomization and fan pressure. Thus, and to compare the results obtained with the two nozzles and the atomization pressures, three test of pressures (0, 3, and 6 bar), four fan pressures (0, 2, 4, and 6 bar), and a pump operating pressure of 2.5 bar were defined. The results were obtained on a flat surface to measure the dispersion of the jet and the amplitude of the fan, keeping the nozzle at an average distance equivalent to half the diameter of the tyre. Although this is a simple approach, it allows a quick knowledge of the results obtained and the definition of empirical parameterisation tables, which nevertheless follow a rational methodology and are easily implemented by maintenance, which are important for the set-points to be defined in the commissioning phase. A scientific approach can always be carried out at a later stage by refining the parameters obtained. So, the influence of atomization pressure on fan amplitude obtained in tests with the Airmix nozzle is shown in Table 1. As expected, it appears that the largest amplitude occurs for an atomization pressure of 6 bar and for a fan pressure of 0 bar. Likewise, the smallest amplitude is verified for an atomization pressure of 0 bar and a fan pressure of 6 bar.

Similar to the test carried out for the Airmix nozzle, the amplitude of the lubricant jet fan, for the Airspray nozzle, was studied, with the variation of atomization and fan pressure. The results obtained were very interesting and clearly different from those obtained in the first test.

Taking into consideration the values obtained in the previous test (increase of the amplitude with the decrease of the fan pressure and increase of the atomization pressure, see Table 1), the atomization pressure was established in 2.5 bar, recommendation of the nozzle manufacturer. The experiment focused on the variation of the fan pressure (0 to 6 bar) obtaining the amplitude-diameter ratios according to Table 2.

From the analysis of Table 2, it is possible to conclude that with the increase tyre diameter, the fan pressure range must be reduced. The lubrication cone has grown with reduced fan pressures and larger tyre diameters creating a greater atomizing effect with a better finish. Otherwise, for a fan pressure of 6 bar, there was a concentration in the central zone of the jet and a dispersion of the fluid droplets in the external parts of the cone, i.e., their vaporization.

As you can see in Table 3, in this test, there is a wide range of values, varying between 75 and 480 mm, which allowed some conclusions to be draw regarding this technology and the use of this nozzle. Airspray technology gives a better finish and created a greater atomization effect than Airmix, so the results shown are within expectations. However, in the process of painting a tyre, Airspray may not be the most suitable technology due to the amount of lubricant that is wasted.

The values shown in Table 4 are obtained according to the procedure described above (pressure 2.5 bar) and the fan pressure variation (0 to 6 bar) using the Airspray nozzle with different geometries. The results were also obtained on the same flat surface by measuring the fan amplitude, keeping the nozzle at an average distance equal to half the tyre diameter.

From the analysis of Table 4, it was also possible to conclude that with increasing tyre diameter, the pressure range of the fan should be reduced. This happened due to the high atomization generated by the nozzle, which tends to over-nebulize the jet and with increasing distance, the jet was completely dissipated, and the drop diameter decreases with increasing gas-to-liquid proportionality [38], i.e., the complete vaporization of the fluid drops. This situation can be explained by the fact that the air supply pressure increases, the gas-fluid flow rate also increases, and consequently, the collision intensity of the gas phase with the liquid phase increases the jet atomization at the nozzle exit [30, 39]. On the other hand, when the air supply pressure was exceeded, it leads to disruption of the gas-fluid mass flow balance, transforming the spray mainly into air, a complete dissipation of the jet [29]. This is the main reason why the cells in Table 3 and Table 4 are empty, no fluid deposition has occurred due to total vaporization of the droplets.

From the amplitude measurement data recorded in Table 2, with a constant atomization pressure equal to 2.5 bar, as the fan pressure increases, the fan amplitude gradually decreases (Fig. 7).

Table 2 also shows that as tyre diameters increase, the spray fan angle decreases, maintaining the spray range. The experimental data presented above fit perfectly into a second-degree polynomial equation that establishes the relationship between tyre diameters and fan pressures in the Airmix nozzle, as shown in Fig. 7.

From the amplitude measurement data recorded in Table 4, maintaining the atomization pressure, as the fan pressure increases, the fan amplitude gradually increases. Table 4 also shows that as tyre diameters increase, the spray fan angle increases to the point where it becomes a single jet of air. The experimental data presented above fit neatly into a third-degree polynomial equation that establishes the relationship between tyre diameters and fan pressures at the Airspray nozzle, as shown in Fig. 8.

Therefore, it becomes unequivocal that the formation of the spray fan, its amplitude, and length are intimately linked to the constructive type of the nozzle. This influence is perceptible in the case of the Airspray nozzle, which, with the increase in fan pressure, leads to total disaggregation of the jet. On the other hand, and considering the manufacturer’s recommendations, atomization pressures between 0 and 3 bar, it can be established that the fan pressures, both for the Airmix and Airspray nozzles, should vary between 0 and 2 bar. This range presents very interesting results in the range of tests carried out and a very significant reduction in the waste of lubricating fluid as well as in the reduction of the number of robot stops to clean the gripper. However, the Arispray nozzle already has complete jet dissipation at 2 bar fan pressure, which further limits its use.

3.3 Changes robot implementation

As can be seen from the layout shown in Fig. 2 the improvement of the painting process would involve increasing the robot-assisted working speed, with all the inconveniences that could arise from this, or increasing the load on the gripper. Another possibility to optimize the painting would be to expand it by doubling the robot-assistance, individually, an additional robot for spraying and handling the tyres. This solution, one of those proposed by [34], would imply duplicating the entire painting unit, PS, and the robot, or simply placing a second robot operating in parallel and in an opposite cycle to the first one. Each of the previous solutions would involve spending large sums of money and a high time for implementation, programming development and, mainly, robot coordination and conflict management (Fig. 9).

Robot-assisted systems with spray booth, adapted from [34]

On the other hand, as the final objective is optimization, duplicating the painting station would optimize the line, increasing production capacity, without effectively increasing the productivity of the equipment. In this sense and considering the maximum reduction in the investment to be made, it was decided, as already mentioned, to evolve to a handling system with double clamps that allows handling two tyres simultaneously. This is the significant change from the conventional painting processes used. This change to the gripper is based on the duplication of the gripping system; this results in an innovative approach and a smaller and more efficient investment from a production and energy point of view. The creation of this new gripper will lead to the restructuring of the robot’s code, which will initially go through a simulation process that will be explained in the following chapters.

4 Description of the solution

4.1 Choice of the lubrification nozzle

Regarding the use of the spray nozzle, the equipment that presented the most stable results and within the expected values was adopted. The Airmix nozzle was therefore chosen. According to the evolution of the amplitudes presented for the fan pressures (Fig. 10), the amplitudes of the lubrication fans evolve in the opposite direction; for the Airmix, the fan decreases with pressure increase, while for Airspray, it increases. In Fig. 10, the comparison is made between the average fan width of the two nozzles according to a fan pressure variation between 0 and 3 bar. Then, and considering the values shown in Table 2 and Table 4, we can verify, in Fig. 10a, the centrality of the averages for each of the values obtained for the two nozzles under study. Thus, starting from a fan pressure of 0 bar, it is verified that the centrality of the amplitude averages for both nozzles. However, the Airmix nozzle (1) (Table 2) has a considerably high amplitude, leading to high fluid losses, contrary to the Airspray nozzle (2) (Table 4), which in this case leads to insufficient deposition. In turn, Fig. 10b shows the inversion of the centralization of the averages of the amplitude of the two nozzles. For this pressure, there is a balance between the two, pressure of 1 bar, with very close values. It should be noted that spraying tyres with the highest diameter is already close to the fluid deposition limit. This situation can be seen in the amplitude graph associated with nozzle 2, fan amplitude at 400 mm and tyre diameter 778 mm.

It should be noted, however, that the performance of the nozzle 2 completely dissipates the jet at 2 bar of fan pressure and with the greatest distance (848 mm tyre diameter), Fig. 10c. In this situation, the lubricant film is completely broken, and the droplets of fluid disintegrate and complete vaporization, without any particles being deposited on the tyre surface. Finally, in Fig. 10d, and for the 3 bar pressure, nozzle 1 keeps and practically unchanged the amplifier range; however, nozzle 2 shows a complete breakdown of the fan range for diameters greater than 647 mm.

On the other hand, and knowing that the operation of the Airspray, nozzle 2, completely dissipates the jet at 2 bar of fan pressure, greater lubrication distance (tyre diameter equal to or greater than 848 mm), the operation, in addition to the use of the Airmix, nozzle 1, must be carried out at a pressure of ± 1 bar. The adoption of these assumptions leads to less fluid waste and a more uniform deposition, as well as a reduction in the number of robots stops to clean the gripper. However, the best result will always be obtained with nozzle 1 at a fan pressure of 2 bar, more uniform distribution. This is an important step towards commissioning the machine and reducing fluid losses for more sustainable production.

4.2 Increase robotic efficiency

The first step to improve the robotics system efficiency was to modulate all the equipment’s used in this production unit. Using a CAD tool, all the equipment’s that make up the system were reproduced, respecting the positioning of each one. With the integration of the model in the simulation tool, it was possible to test (offline) all the trajectories, verify collisions and safety conditions, and create all the different equipment frames. The code resulting from the simulation was refined online considering the real operating conditions and the operators’ indications. So, the proposed solution to increase the efficiency of the robotic operation involves the use of five different user frames that can be related to each of the machines. In this case, if there is a need to change the implementation of a machine, devices will be in different position referred to manipulator, it will only be necessary to change the origin of the frames, which are found at the beginning of the conveyors and in the centre of the cleaning and PS machine. Another possibility that was considered is the definition of all points in a single coordinate table. However, this possibility did not present itself as a good solution in terms of efficiency, because after any small change in the system, we will have to define new coordinates for all points.

The programming was implemented, as well as the simulation, based on the five frames used to define the initial position, execution of the return routine, the initialization phase of the program, as well as the positioning of the robot at the beginning of the process. This initial state was considered a very important procedure since the robot is returned to the initial position, even if the previous programme has been interrupted, or is stopped in any position. This relocation guarantees compliance with the robot’s route, eliminating possible collisions or inappropriate operations, that is, the correct functioning of the system. Other essential issue for the correct functioning of the painting station must also be considered in these tables. These points concern the maintenance and cleaning processes since they are in space, therefore not interconnected to any of the devices. The maintenance position is the point where people can enter to the cell and check the paint or the gripper condition. At the cleaning station, the gripper cleans the fingers that can sometimes be dirty with the lubricant used in the paint machine. Both processes are carried out very rarely compared to the receiving, painting, and placing processes. Due to this fact, each of these main tasks has a separate point as well as a reference frame whose numbers correspond to each other and can be used in register-based loops. In Fig. 11, the proposed layout for increase the painting process is presented. The first user frame (reference frames in Roboguide) is the world coordinate frame and originates from the base of the robot.

Each point in the system has its own safety point which is always above the corresponding one and defined as an offset function. From the starting position, the robot goes to the safety of the collection point. After pick the tyre, move again, and the tyres go to the painting process that can only be done for one of them at the same time. Each of the points has an offset that is covered first. Therefore, after painting the first tyre, the gripper rises and rotates 180° around the centre of the tool. Therefore, since this case study involves optimizing the painting process, another coordinate frame has been added with the second painting point, in the same position as the first, but with the opposite orientation. This simple approach aims to save the time corresponding to the positioning and collection trajectories of a new tyre. Using a gripper with a double load makes it possible to eliminate these two movements and save around 6 s, even with a painting time that is twice as long. After painting the second tyre, the manipulator brings the tyres to the second conveyor belt, finishing the process. At this point, the programme should ask the user, or at least check the PLC information, if it is necessary to clean the gripper fingers or go to the maintenance position. Otherwise, the process continues, and the manipulator shifts to the pickup position and repeats the procedure.

The approach to the problem defined for this case study involves the use of a control programme using a single Tool Centre Point (TCP), calibrated at the centre of the tool’s symmetry and the rectangular coordinate system [40]. Therefore, the choice point and location must be set exactly in the centre between two tyres. After the simulation starts, the robot performs the procedure, and from its automation mode, the system will repeat it until the user forces it to stop. A problem that arises here is the orientation of the choice point is opposite to that of the place point. Therefore, using the MOD function that calculates the modulus of 2 and every second cycle, the orientation is changed to the opposite approach that must also be applied to the painting points. In addition, the programme operates with the digital inputs of signals 1 and 2 that are sent from the PLC, requesting the robot to move to the maintenance position or to the cleaning process. The disadvantage of this solution is that we cannot continuously control the position of the grippers. The fingers only have a sensor that detects whether the object is stuck or not, but we would not be able to say anything about its position during movements between stations. The path of the centralized TCP during one of the pick-and-place process simulations with the cleaning procedure is shown in Fig. 12.

4.3 Manual control for the robot-assistant

The purpose of the manual control project version is to create a programme that allows you to know in detail the project content, as well as the movement between points previously saved in the robot’s memory. This module allowed us to check or change the coordinates that are already registered in the robot, because in automation mode, everything is done very quickly by the manipulator, and therefore, its location is not so obvious. Thus, after the homing procedure, the software asks the user which point he would like to go. In this case, the operator can choose predefined points from 1 to 9 or from 22, 33,…, 99 which are the displacement points, previously defined. In addition to the group of inputs that allow converting the numbers received from the PLC into digital inputs and requesting the robot to move to the requested point, the programme also allows changing the TCP. If the change is applied, which can only be done at the “highest points,” the system asks us again about the destination.

On the other hand, security regulations and restrictions are important in all versions and operational steps; however, when it comes to the automatic version, they are usually programmed and simulated offline. In case of manual mode, it will be mainly used in real and real-time robot; therefore, the safety conditions must be applied very carefully. Due to this fact, if the robot is in one of the positions 2 to 9, the only movement it can make is to go to the displacement point, respectively, e.g., 3 to 33. All other points are blocked, and the user will be asked again to provide the correct choice, as any other movement can cause massive damage to the hardware. Although the robot is in the home position or any other offset point, this can move between them freely. To know what position the robot is in, and what position it reaches, the additional register with conditions was added. If the point is not achievable another register saves the choice, but the position register is still the same and the user is asked again to provide the correct point.

The main version consists of the possibility to control by the user the mode he wants to activate. Based on two digital inputs, automatic or manual versions can be called up. Both options can be considered since they consist of an entry that can be activated whenever the user wants to go back to the main menu.

5 Conclusions and future work

The main objective of this study focused on optimizing the tyre painting process, the amount of deposited fluid, and the spray fan opening, as well as the robotic feeding system of the painting system. For this purpose, several fluid atomization pressure tests and the fan pressure necessary for the correct coating of the inner surface of the tyre were carried out. It has been found that the working pressure for the atomisation and the fan should be between 2.5 and 2 bar, so that the adoption of the Airmix nozzle is the best option even with large tyres. The fan pressure to diameter ratio presents a good compromise and therefore a comprehensive deposition of the whole internal surface of the tyre. From the point of view of the robot-assistant feeding system, the control software capable of controlling the Fanuc industrial robot has been developed, which can, from the point of view of feeding, contribute to the optimization process of tyre painting. The gripper’s experimentation confirmed the gains obtained by the simulation made in Roboguide which showed that it will save some cycle time, about 6 s.

The objective of the study was reached, but there are some considerations that can be used in future works. First, the pressure control of the atomization system must be controlled using several proportional pressure valves responding to predefined analogue signals, adjustable according to the size of the tyres. The process will respond according to the specific characteristics of each tyre and the manual action of the operator, identification of the tyre model to be sprayed. Second, code segmentation can be very useful in case additional functionality is created. Also, changes that can simplify the code can be made within the user framework organization. On the other hand, many of the user frames connected to the devices will play a key role in case the station's design and layout change. The gripper control programme should run in the background while continuously sending the TCP coordinates, verifying that they are consistent with the given coordinates. In short, the software is created in such a way that it is controlled by the PLC to control and synchronize the process with the conveyors belt. In the future, vision or another system to control positioning may be added. As so, this study certainly is one of the many steps to develop the tyre painting process.

As an additional improvement to the work carried out, the authors propose the integration of a PROFINET or ETHERNET-IP industrial communication network between the Robot and the PLC, which will allow significant improvements in work cycles, more efficient maintenance, and the integration of the concept of industry 4.0. For this, there would be a Cloud platform with data collection and the real-time monitoring of the process with the creation of Dashboards. Also, a system of remote access to the robot would be useful in processes related to the maintenance of the same.

Data availability

Not applicable.

Code availability

Not applicable.

References

Shanbag A, Manjare S (2020) Life cycle assessment of tyre manufacturing process. J Sustain Dev Energy Water Environ Syst 8(1):22–34. https://doi.org/10.13044/j.sdewes.d7.0260

Katarzyna P, Izabela P, Patrycja B-W, Weronika K, Andrzej T (2020) LCA as a tool for the environmental management of car tyre manufacturing. Appl Sci 10:7015. https://doi.org/10.3390/app10207015

Silke Krömer, Eckhard Kreipe, Diethelm Reichenbach, Rainer Stark (1999) Life cycle assessment of a car tyre. Continental AG. http://163.172.57.238/sites/default/files/Continental%20LCA.pdf. Accessed 15 February 2023

Raj CP (2022) Tyre market: the global tyre industry analysis. OEM News. https://oem.news/industry/rubber/tyre/tyre-market-the-global-tyre-industry-analysis/. Accessed 15 February 2023

Inkonkoy F (2021) Sustainability in the natural rubber supply chain: getting the basics right. SPOTT. London: Zoological Society of London. https://www.spott.org/news/sustainability-in-the-naturalrubber-supply-chain/. Accessed 20 Mar 2023

Rubber, Natural (2022) Chemical economics handbook. S&P Global Commodity insights. https://www.ihs.com/products/naturalrubber-chemical-economics-handbook.html. Accessed 15 Mar 2023

Millard E (2019) Recent experiences from the natural rubber industry and its movement towards sustainability. In: Schmidt, M., Giovannucci, D., Palekhov, D., Hansmann, B. (eds) Sustainable global value chains. Natural resource management in transition. Springer, Cham 2:499–520. https://doi.org/10.1007/978-3-319-14877-9_27

Czajczyńska D, Czajka K, Krzyżyńska R, Jouhara H (2020) Waste tyre pyrolysis – impact of the process and its products on the environment. Therm Sci Eng Prog 20:100690. https://doi.org/10.1016/j.tsep.2020.100690

Formela K (2021) Sustainable development of waste tyres recycling technologies – recent advances, challenges and future trends. Adv Ind Eng Polym Res 4(3):209–222. https://doi.org/10.1016/j.aiepr.2021.06.004

Araujo-Morera J, Verdejo R, López-Manchado MA, Santana MH (2021) Sustainable mobility: the route of tyres through the circular economy model. Waste Manage 126:309–322. https://doi.org/10.1016/j.waman.2021.03.025

Colom X, Cañavate J, Carrillo-Navarrete F (2022) Towards circular economy by the valorization of different waste subproducts through their incorporation in composite materials: ground tyre rubber and chicken feathers. Polymers 14(6):1090. https://doi.org/10.3390/polym14061090

Bera A, Ganguly D, Ghorai SK, Rath JP, Ramakrishnan S, Job Kuriakose SKP, Amarnath SC (2022) Treatment of natural rubber with bio-based components: a green endeavor to diminish the silica agglomeration for tyre tread application. Chem Eng J Adv 11:100349. https://doi.org/10.1016/j.ceja.2022.100349

Lolage M, Parida P, Chaskar M, Gupta A, Rautaray D (2020) Green silica: industrially scalable & sustainable approach towards achieving improved “nano filler – Elastomer” interaction and reinforcement in tire tread compounds. Sustain Mater Technol 26:e00232. https://doi.org/10.1016/j.susmat.2020.e00232

Tyre production (2023) Wow a tire is made. Continental AG. https://www.continental-tyres.com/car/tyre-knowledge/tyre-basics/tyre-production. Accessed 15 Mar 2023

Lai YL (2023) A fast task planning system for 6R articulated robots based on inverse kinematics. Int J Adv Manuf Technol 125:3989–5013. https://doi.org/10.1007/s00170-023-11002-2

Barravecchia F, Mastrogiacomo L, Franceschini F (2023) A general cost model to assess the implementation of collaborative robots in assembly processes. Int J Adv Manuf Technol 125:5247–5266. https://doi.org/10.1007/s00170-023-10942-z

Chen H, Sheng W (2011) Transformative CAD based industrial robot program generation. Robot Comput-Integr Manuf 27:942–948. https://doi.org/10.1016/j.rcim.2011.03.006

Lin HI (2020) Design of an intelligent robotic precise assembly system for rapid teaching and admittance control. Rob Comput Integr Manuf 64:101946. https://doi.org/10.1016/j.rcim.2020.101946

Zheng C, An Y, Wang Z, Haoyu Wu, Qin X, Eynard B, Zhang Y (2022) Hybrid offline programming method for robotic welding systems. Robot Comput-Integr Manuf 73:102238. https://doi.org/10.1016/j.rcim.2021.102238

Du G, Chen M, Liu C, Zhang B, Zhang P (2018) Online robot teaching with natural human–robot interaction. IEEE Trans Ind Electron 65(12):9571–9581. https://ieeexplore.ieee.org/document/8331855

Pérez L, Diez E, Usamentiaga R, García DF (2019) Industrial robot control and operator training using virtual reality interfaces. Comput Ind 109:114–120. https://doi.org/10.1016/j.compind.2019.05.001

ABB RobotStudio® Suite (2021). https://new.abb.com/products/robotics/robotstudio. Accessed 28 March 2023

Fanuc (2021). https://www.fanucamerica.com/products/robots/robot-simulation-software-FANUC-ROBOGUIDE. Accessed 28 March 2023

Kuka software (2023). https://www.kuka.com/en-de/products/robot-systems/software. Accessed 28 March 2023

Bedaka AK, Lin CY (2020) CAD-based offline programming platform for welding applications using 6-DOF and 2-DOF robots. In: 2020 International Conference on Advanced Robotics and Intelligent Systems(ARIS), pp 1–4. https://ieeexplore.ieee.org/document/9205784

Bedaka AK, Vidal J, Lin CY (2019) Automatic robot path integration using three-dimensional vision and offline programming. Int J Adv Manuf Technol 102:1935–1950. https://doi.org/10.1007/s00170-018-03282-w

Gislotica, Mechanical Solutions (2023). http://www.gislotica.pt/en/about_us.4.html. Accessed 28 March 2023

Lefebvre AH, McDonell VG (2017) Atomizers. Atomization and sprays, 2nd edn. CRC Press, Taylor & Francis Group, pp 72–103

Couto SH (2007). Curso Atomização e Sprays. Escola de Combustão, Florianópolis. http://ftp.demec.ufpr.br/foguete/bibliografia/CURSO%20%20DE%20ATOMIZA%C3%87%C3%83O%20%20&%20%20SPRAYS.pdf. Accessed 30 March 2023

Omer K, Ashgriz N (2011) Spray nozzles. In: Ashgriz N (ed) Handbook of atomization and sprays, theory and applications. Springer, Boston, MA, pp 497–579. https://doi.org/10.1007/978-1-4419-7264-4_24

Lefebvre AH, McDonell VG (2017) Atomizers, in Atomization and sprays, 2nd edn. CRC Press Taylor & Francis Group, NW, pp 71–103. https://doi.org/10.1201/9781315120911

Sarchami A, Ashgriz N (2011) Splash plate atomizers. In: Ashgriz N (ed) Handbook of atomization and sprays, theory and applications. Springer, Boston, MA, pp 709–726. https://doi.org/10.1007/978-1-4419-7264-4_31

Sames Kremlin (2023) Da pistola à bomba até às instalações completas de acabamento. https://www.sames.com/portugal/pt/home.html. Accessed 27 March 2023

Ilmberger (2023) Green tyre spraying systems. https://www.ilmberger.de/en/coating-technology/green-tyre-spraying-systems/. Accessed 28 March 2023

Jiang X, Siamas GA, Jagus K, Karayiannis TG (2010) Physical modelling and advanced simulations of gas–liquid two-phase jet flows in atomization and sprays. Prog Energy Combust Sci 36(2):131–167. https://doi.org/10.1016/j.pecs.2009.09.002

Yi Z, Mi S, Tong T, Li K, Feng B, Li B, Lin Y (2022) Simulation analysis on the jet flow field of a single nozzle spraying for a large ship outer panel coating robot. Coatings 12(3):369. https://doi.org/10.3390/coatings12030369

Silva GR, Torres MD, Souto HP (2018) Influência do número de Weber e do parâmetro de impacto no fenômeno de coalescência binária de gotas de fluidos de van der Waals via o método Smoothed Particle Hydrodynamics. X Congresso Nacional de Engenharia Mecânica (CONEM), Salvador, Brasil. https://doi.org/10.26678/ABCM.CONEM2018.CON18-0031

Thiebes AL, Klein S, Zingsheim J, Möller GH, Gürzing S, Reddemann MA, Behbahani M, Jockenhoevel S, Cornelissen CG (2022) Effervescent atomizer as novel cell spray technology to decrease the gas-to-liquid ratio. Pharmaceutics 14:2421. https://doi.org/10.3390/pharmaceutics14112421

Wang P, Zhang K, Liu R (2019) Influence of air supply pressure on atomization characteristics and dust-suppression efficiency of internal-mixing air-assisted atomizing nozzle. Powder Technol 355:393–407. https://doi.org/10.1016/j.powtec.2019.07.040

Krakhmalev ON, Petreshin DI, Krakhmalev GN (2018) Methods of calibrating the orientation of the industrial robot tool. In: 2018 International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon). Vladivostok, pp 1–5. https://doi.org/10.1109/FarEastCon.2018.8602519

Funding

Open access funding provided by FCT|FCCN (b-on). We acknowledge the financial support of CIDEM, R&D unit, funded by the FCT – Portuguese Foundation for the Development of Science and Technology, Ministry of Science, Technology and Higher Education, under the Project UID/EMS/0615/2019, and INEGI and LAETA, under project UIDB/50022/2020, and CIETI—funded by national funds through the FCT/MCTES (PIDDAC), Portugal.

Author information

Authors and Affiliations

Contributions

A.A.S: writing—original draft, investigation, and validation; F.P: writing, investigation, formal analysis, and validation; C.F.: writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Santos, A.A., Pereira, F. & Felgueiras, C. Optimization and improving of the production capacity of a flexible tyre painting cell. Int J Adv Manuf Technol (2024). https://doi.org/10.1007/s00170-024-13208-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00170-024-13208-4