Abstract

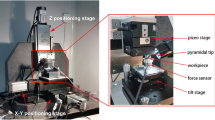

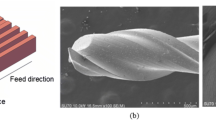

Silicon, glass, and other hard and brittle materials exhibit strong inertness and chemical stability and are ideal substrates for preparing macrochannels. To prepare microchannels with hard and brittle material through high-precision and high-efficiency machining, the author innovatively proposed a new technology called template-based electrophoretically assisted micro-ultrasonic machining (TBEPAMUSM). The microchannel shape punch-pin was transferred to a workpiece by micro-ultrasonic machining (MUSM). Due to the electrophoretic characteristics of ultrafine abrasive particles, applying a DC field can ensure that ultrafine abrasive particles are present in the machining area. Four process parameter (average particle size, particle concentration, ultrasonic power, and electrophoretic DC voltage) single-factor experiments and orthogonal experiments were carried out for TBEPAMUSM. The single-factor experimental study indicated that (1) an increase in the average particle size and ultrasonic power can effectively improve the material removal rate (MRR), but the surface roughness (SR) also decreases. (2) An increase in the abrasive concentration reduces the SR, but a suitable concentration can maximize the MRR. (3) When a suitable DC voltage is introduced, the MRR and SR can be effectively improved. The orthogonal experiment results show that the average particle size exerts the greatest effect on the SR and MRR. Considering the balance between machining quality and machining efficiency, the optimal parameters were as follows: ultrasonic power 70%, average abrasive particle size 18 μm, abrasive concentration 18%, and DC voltage 40 V.

Similar content being viewed by others

Data availability

Not applicable.

References

Wei ZY, Wang SQ, Hirvonen J, Santos HA, Wei L (2022) Microfluidics fabrication of micrometer-sized hydrogels with precisely controlled geometries for biomedical applications. Adv Healthc Mater 11(16):2200846. https://doi.org/10.1002/adhm.202200846. Accessed 20 Nov 2022

Bendre A, Bhat MP, Lee KH, Altalhi T, Alruqi MA, Kurkuri M (2022) Recent developments in microfluidic technology for synthesis and toxicity-efficiency studies of biomedical nanomaterials. Mater Today Adv 13:100205. https://doi.org/10.1016/j.mtadv.2022.100205. Accessed 20 Dec 2022

Amirifar L, Besanjideh M, Nasiri R, Shamloo A, Nasrollahi F, Barros NR, Davoodi E, Erdem A, Mahmoodi M, Hosseini V, Montazerian H, Jahangiry J, Darabi MA, Haghniaz R, Dokmeci MR, Annabi N, Ahadian S, Khademhosseini A (2021) Droplet-based microfluidics in biomedical applications. Biofabrication 14(2):022001. https://doi.org/10.1088/1758-5090/ac39a9. Accessed 3 Dec 2022

An ZG, Zhang CJ, Gao ZY, Luo YS, Dong Y (2022) Heat dissipation performance of hybrid lithium battery thermal management system using bionic nephrolepis micro-channel. Appl Therm Eng 217:119127. https://doi.org/10.1016/j.applthermaleng.2022.119127. Accessed 6 Mar 2023

Ren YT, Qi H, Chen Q, Li Y, Ruan LM (2019) Optofluidic control using light illuminated plasmonic nanostructure as microvalve. Int J Heat Mass Transf 133:1019–1025. https://doi.org/10.1016/j.ijheatmasstransfer.2019.01.021. Accessed 12 May 2021

Peng J, Fang CF, Ren S, Pan JJ, Jia YD, Shu ZQ, Gao DY (2019) Development of a microfluidic device with precise on-chip temperature control by integrated cooling and heating components for single cell-based analysis. Int J Heat Mass Transf 130:660–667. https://doi.org/10.1016/j.ijheatmasstransfer.2018.10.135. Accessed 18 Jul 2021

Li H, Liu HX, Zou ZP (2020) Experimental study and performance analysis of high-performance micro-channel heat exchanger for hypersonic precooled aero-engine. Appl Therm Eng 182:116108. https://doi.org/10.1016/j.applthermaleng.2020.116108. Accessed 7 Mar 2022

Alahmari AM, Darwish S, Ahmed N (2016) Laser beam micro-milling (LBMM) of selected aerospace alloys. Int J Adv Manuf Technol 86(9-12):2411-2431. https://doi.org/10.1007/s00170-015-8318-1. Accessed 9 Dec 2019

Song ZY, Ji J, Zhang YZ, Cai JY, Li ZM (2022) Experimental and numerical investigation on a photovoltaic heat pump with two condensers: A micro-channel heat pipe/thermoelectric generator condenser and a submerged coil condenser. Energy 242:122525. https://doi.org/10.1016/j.energy.2021.122525. Accessed 15 Oct 2022

Tan MY, Huang L, Cao JY, Zhang H, Zhao SQ, Liu MZ, Jia ZQ, Zhai RZ, Liu H (2022) Microflow multi-layer diffraction optical element processed by hybrid manufacturing technology. Opt Express 30(14):24689–24702. https://doi.org/10.1364/OE.464192. Accessed 21 Mar 2023

Ahmed T, Haider F, Aoni RA, Ahmed R (2021) Highly sensitive U-shaped micro-channel photonic crystal fiber–based plasmonic biosensor. Plasmonics 16(6):2215–2223. https://doi.org/10.1007/s11468-021-01477-8. Accessed 29 Sept 2022

Manz A, Graber N, Widmer HM (1990) Miniaturized total chemical analysis systems: A novel concept for chemical sensing. Sens Actuators B Chem 1(1–6):244–248. https://doi.org/10.1016/0925-4005(90)80209-I. Accessed 11 Feb 2021

Lin CH, Lee GB, Lin YH, Chang GL (2001) A fast prototyping process for fabrication of microfluidic systems on soda-lime glass. J Micromech Microeng 11(6):726–732. https://doi.org/10.1088/0960-1317/11/6/316. Accessed 3 Apr 2022

Peng Y, Jiang SL, Xia L, Yin XL, Yu BJ, Qian LM (2020) Direct ink writing combined with metal-assisted chemical etching of microchannels for the microfluidic system applications. Sens Actuator A Phys 315:1–9. https://doi.org/10.1016/j.sna.2020.112320. Accessed 7 Oct 2021

Daniel LF, Vincent MD, Dale EI (1983) Basic chemistry and mechanisms of plasma etching. J Vac Sci Technol B Microelectron Process Phenom 1(1):23–30. https://doi.org/10.1116/1.582536. Accessed 12 Jun 2022

Kazou N (2015) Dry etching technology for semiconductors. Cham. Accessed 28 May 2021

Huang CY, Kuo CH, Hsiao WT, Huang KC, Tseng SF, Chou CP (2012) Glass biochip fabrication by laser micromachining and glass-molding process. J Mater Process Technol 212(3):633–639. https://doi.org/10.1016/j.jmatprotec.2011.10.013. Accessed 24 Jul 2021

Mahmoud AAG, Abdulaziz NA, Abdullah NA, Zeyad AA, Hamad AA (2020) Femtosecond laser microfabrication of micro-channels on (1 0 0) silicon surfaces. Mater Today Proc 33:1–5. https://doi.org/10.1016/j.matpr.2020.05.395. Accessed 25 Aug 2021

Fu LM, Ju WJ, Yang RJ, Wang YN (2013) Rapid prototyping of glass-based microfluidic chips utilizing two-pass defocused CO2 laser beam method. Microfluid Nanofluidics 14(3):479–487. https://doi.org/10.1007/s10404-012-1066-8. Accessed 27 Jun 2022

Fernández-Pradas JM, Serrano D, Serra P, Morenza JL (2009) Laser fabricated microchannels inside photostructurable glass-ceramic. Appl Surf Sci 255(10):5499–5502. https://doi.org/10.1016/j.apsusc.2008.08.099. Accessed 9 Mar 2023

He QH, Chen S, Su Y, Fang Q, Chen HW (2008) Fabrication of 1D nanofluidic channels on glass substrate by wet etching and room-temperature bonding. Analytica Chimica Acta 628(1):1–8. https://doi.org/10.1016/j.aca.2008.08.040. Accessed 7 Mar 2023

Sergeev MM, Veiko VP, Tiguntseva EY, Olekhnovich RO (2016) Picosecond laser fabrication of microchannels inside Foturan glass at CO2 laser irradiation and following etching. Opt Quantum Electron 48(11):1–10. https://doi.org/10.1007/s11082-016-0752-2. Accessed 16 Oct 2022

Lee KB, Lin LW (2004) Surface micromachined glass and polysilicon microchannels using MUMPs for BioMEMS applications. Sens Actuator A Phys, 111(1):44-50. https://doi.org/10.1016/j.sna.2003.10.027. Accessed 12 Sept 2021

D'Arrigo G, Spinella C, Arena G, Lorenti S (2003) Fabrication of miniaturised Si-based electrocatalytic membranes. Mater Sci Eng C 23(1):13–18. https://doi.org/10.1016/S0928-4931(02)00228-X. Accessed 11 Aug 2021

Hung VN, Abe T, Minh PN, Esashi M (2003) High-frequency one-chip multichannel quartz crystal microbalance fabricated by deep RIE. Sens Actuator A Phys 108(1):91–96. https://doi.org/10.1016/S0924-4247(03)00260-7. Accessed 11 Aug 2021

Tseng SF, Chen MF, Hsiao WT, Huang CY, Yang CH, Chen YS (2014) Laser micromilling of convex microfluidic channels onto glassy carbon for glass molding dies. Opt Lasers Eng 57:58–63. https://doi.org/10.1016/j.optlaseng.2013.11.011. Accessed 3 Apr 2021

Ju J, Lim S, Seok J, Kim S (2015) A method to fabricate low-cost and large area vitreous carbon mold for glass molded microstructures. Int J Precis Eng Manuf 16(2): 287-291. https://doi.org/10.1007/s12541-015-0038-9. Accessed 3 Apr 2021

Ju WJ, Hong TF, Yang RJ, Fu LM, Lee CY (2012) Rapid fabrication of glass-based microfluidic chips utilizing a femtosecond laser. Adv Sci Lett 8(1):416–420. https://doi.org/10.1166/asl.2012.2376. Accessed 24 Mar 2020

Li Y, Qu SL (2011) Femtosecond laser-induced breakdown in distilled water for fabricating the helical microchannels array. Optics letters 36(21):4236-4238. https://doi.org/10.1364/OL.36.004236. Accessed 21 Feb 2021

Brokmann U, Milde T, Rädlein E, Liefeith K (2019) Fabrication of 3D microchannels for tissue engineering in photosensitive glass using NIR femtosecond laser radiation. Biomed Glass 5(1):34–45. https://doi.org/10.1515/bglass-2019-0003. Accessed 27 Dec 2021

Arif M, Rahman M, San WY (2011) Ultraprecision ductile mode machining of glass by micromilling process. J Manuf Process 13(1):50–59. https://doi.org/10.1016/j.jmapro.2010.10.004. Accessed 16 Nov 2022

Ku XY, Zhang ZW, Liu XL, Chen L, Li G (2018) Low-cost rapid prototyping of glass microfluidic devices using a micromilling technique. Microfluid Nanofluidics 22(8):82–90. https://doi.org/10.1007/s10404-018-2104-y. Accessed 12 Dec 2021

Liu XL, Dong ZY, Zhao Q, Li G (2020) Optimization of micromilled channels for microfluidic applications using gas-blowing-assisted PDMS coating. Microfluid Nanofluidics 24(1):11–19. https://doi.org/10.1007/s10404-019-2315-x. Accessed 17 Feb 2022

Sun XQ, Masuzawa T, Fujino M (1996) Micro ultrasonic machining and self-aligned multilayer machining/assembly technologies for 3D micromachines. In: Proceedings of ninth international workshop on micro electromechanical systems, San Diego, pp 312–317. https://doi.org/10.1109/MEMSYS.1996.494000. Accessed 12 Jun 2022

Yan BH, Wang AC, Huang CY, Huang FY (2002) Study of precision micro-holes in borosilicate glass using micro EDM combined with micro ultrasonic vibration machining. Int J Mach Tools Manuf 42(10):1105–1112. https://doi.org/10.1016/S0890-6955(02)00061-5. Accessed 3 Mar 2023

Ranko T, Yasuhiro K, Tojiro A, Hitoshi O, Seiji H (2012) Ultrasonic vibration and cavitation-aided micromachining of hard and brittle materials. Procedia CIRP 2012:1342–1346. https://doi.org/10.1016/j.procir.2012.04.061. Accessed 12 Jun 2022

Wang AC (2003) Study of high precision compound technology of micro-holes and micro-slits and machining characteristic research. Dissertation. National Central University. http://ir.lib.ncu.edu.tw:88/thesis/view_etd.asp?URN=87343007. Accessed 16 Nov 2021

Kai E, Ryokei K, Ryohei O, Keishi Y, Minoru O (2014) Drilling of microholes down to 10μm in diameter using ultrasonic grinding. Precis Eng 38(3):605–610. https://doi.org/10.1016/j.precisioneng.2014.02.010. Accessed 6 Dec 2022

Li T, Visvanathan K, Gianchandani YB (2014) A batch-mode micromachining process for spherical structures. J Micromech Microeng 24(2):1–8. https://doi.org/10.1088/0960-1317/24/2/025002. Accessed 27 Feb 2023

Basem MAA, Saqib A, Abdualziz ET (2019) Machinability study of biolox forte ceramic by milling microchannels using rotary ultrasonic machining. J Manuf Process 43:175–191. https://doi.org/10.1016/j.jmapro.2019.05.031. Accessed 24 Oct 2022

Jain A, Singh G, Jain V, Gupta D (2020) Feasibility analysis for machining serpentine microchannels on glass using rotary ultrasonic milling. Measurement 160:107844. https://doi.org/10.1016/j.measurement.2020.107844. Accessed 6 Jun 2022

Tateishi T, Nobuhito Y, Wang YJ, Kuriyagawa T (2009) Fabrication of high-aspect ratio micro holes on hard brittle materials-study on electrorheological fluid-assisted micro ultrasonic machining. Key Eng Mater 389:264–270. https://doi.org/10.4028/www.scientific.net/KEM.389-390.264. Accessed 3 Mar 2016

Funding

This work was supported by the National Science Foundation of Guangdong Province (Project # 2020A1515011164, #2022A1515110691), characteristic innovation projects of universities in Guangdong Province (Project # 2021KTSCX068), the Science and Technology Program of Guangzhou (Project # 202201011219), and the Science and Technology Planning Project of Zhanjiang (Project # 2021A05232).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Conception and design were performed by Haishan Lian, Zhongning Guo. Material preparation and data collection were performed by Haishan Lian, Cuiyuan Deng, Yuandong Mo. Data analysis was performed by Cuiyuan Deng, Linpeng Zhang, and Junfeng He. The first draft of the manuscript was written by Haishan Lian and Linpeng Zhang.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication.

All authors have read and agreed to the published version of the manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lian, H., Deng, C., Zhang, L. et al. Fabrication of microchannels through template-based electrophoretically assisted micro-ultrasonic machining. Int J Adv Manuf Technol 129, 5287–5302 (2023). https://doi.org/10.1007/s00170-023-12605-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12605-5