Abstract

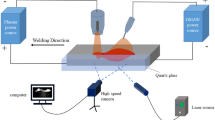

In this research, AA 5083 aluminum alloy was proposed to be joined by the bypass-current plasma-GMAW hybrid arc welding with pulse current mode. During this hybrid process, three kinds of current work synergistically, including the main current from the welding wire, the bypass current into the copper nozzle, and the welding current into the base metal. Moreover, they have the same waveform due to the same system controlling them. For a deep understanding of the coupled effects of multiple pulse currents on metal droplets, a comprehensive study combining the experiment and the simulation was executed to compare the heat and mass transfer behaviors when the current mode changes. The results show that when the wire feed speed is maintained at 6 m/min, the droplets have a projected transfer mode no matter with which kind of current mode. However, the transfer frequency is increased by approximately double when the pulse waveform is employed. Furthermore, the transfer stability is further enhanced due to the force state getting regulated by the various hybrid electromagnetic fields stimulated by the pulse currents. This investigation offers a deeper understanding and continuous optimization of precise control of metal droplet behaviors in aluminum alloy welding.

Similar content being viewed by others

Data availability

Not applicable.

References

Xu SX, Chen JX, Shen W, Hou RJ, Wu YG (2022) Fatigue strength evaluation of 5059 aluminum alloy welded joints considering welding deformation and residual stress. Int J Fatigue 162. https://doi.org/10.1016/j.ijfatigue.2022.106988

Xia HB, Li LQ, Tan CW, Yang J, Li HY, Song W, Zhang KP, Wang Q, Ma NS (2022) In situ SEM study on tensile fractured behavior of Al/steel laser welding- brazing interface. Mater Design 224. https://doi.org/10.1016/j.matdes.2022.111320

Luo J, Li SX, Chen W, Xiang JF, Wang H (2015) Simulation of aluminum alloy flowing in friction stir welding with a multiphysics field model. Int J Adv Manuf Technol 81(1-4):349–360. https://doi.org/10.1007/s00170-015-7228-6

Luo Y, Zhu Y, Xie XJ, Wan R (2016) Study on the transient impact energy of metal droplet transfer in P-MIG welding based on acoustic emission signals analysis. Mater Design 90:22–28. https://doi.org/10.1016/j.matdes.2015.10.112

Li YW, Zou WF, Lee BY, Babkin A, Chang YL (2020) Research progress of aluminum alloy welding technology. Int J Adv Manuf Technol 109(5-6):1207–1218. https://doi.org/10.1007/s00170-020-05606-1

Li YW, Dong ZH, Liu HF, Babkin A, Lee B, Chang YL (2022) Research progress on transition behavior control of welding droplets. Int J Adv Manuf Technol 120(3-4):1571–1582. https://doi.org/10.1007/s00170-022-08928-4

Liu AH, Tang XH, Lu FG (2013) Study on welding process and prosperities of AA5754 Al-alloy welded by double pulsed gas metal arc welding. Mater Design 50:149–155. https://doi.org/10.1016/j.matdes.2013.02.087

Chen C, Fan CL, Lin SB, Cai XY, Zhou L, Ye SF, Yang CL (2018) Effect of ultrasonic pattern on weld appearance and droplet transfer in ultrasonic assisted MIG welding process. J Manuf Process 35:368–372. https://doi.org/10.1016/j.jmapro.2018.08.019

Li KH, Zhang YM (2010) Interval model control of consumable double-electrode gas metal arc welding process. IEEE Trans Autom Sci Eng 7(4):826–839. https://doi.org/10.1109/tase.2009.2032156

Shi Y, Zhang G, Huang Y, Lu L, Huang J, Shao Y (2014) Pulsed double-electrode GMAW-brazing for joining of aluminum to steel. Weld J 93(6):216S–224S

Huang JK, He XY, Guo YN, Zhang ZP, Shi Y, Fan D (2017) Joining of aluminum alloys to galvanized mild steel by the pulsed DE-GMAW with the alternation of droplet transfer. J Manuf Process 25:16–25. https://doi.org/10.1016/j.jmapro.2016.10.003

Zhao WY, Jin HX, Du XW, Chen JC, Wei YH (2022) A 3D arc-droplet-molten pool integrated model of Al alloy GMAW process: heat transfer, fluid flow and the effect of external magnetic field. Vacuum 202. https://doi.org/10.1016/j.vacuum.2022.111129

Essers WG (1976) New process combines plasma with GMA welding. Weld J 55(5):394–400

Bai Y, Gao HM, Qiu L (2010) Droplet transition for plasma-MIG welding on aluminium alloys. T Nonferr Metal Soc 20(12):2234–2239. https://doi.org/10.1016/S1003-6326(10)60634-6

Miao YG, Wang ZR, Wang L, Ma XB, Deng QW, Zhang BS (2022) Effects of bypass-current and out plasma current on droplet transfer behaviours during plasma-MIG hybrid arc welding. Sci Technol Weld Joint. https://doi.org/10.1080/13621718.2022.2153998

Hertel M, Fussel U, Schnick M (2014) Numerical simulation of the plasma-MIG process-interactions of the arcs, droplet detachment and weld pool formation. Weld World 58(1):85–92. https://doi.org/10.1007/s40194-013-0095-6

Xu J, Ma YM, Wang L, Zhang YR, Lu X (2022) Numerical investigation on the influence of current waveform on droplet transfer in pulsed gas metal arc welding. Vacuum 203. https://doi.org/10.1016/j.vacuum.2022.111230

Miao YG, Wang ZR, Liu J, Wu YF, Zhao YY, Li CW (2022) Effects of bypass-current and outer plasma current on the arc stability and melt pool behaviors during plasma-MIG hybrid arc welding. J Manuf Process 82:415–424. https://doi.org/10.1016/j.jmapro.2022.08.017

Murphy AB (2011) A self-consistent three-dimensional model of the arc, electrode and weld pool in gas-metal arc welding. J Phys D Appl Phys 44(19). https://doi.org/10.1088/0022-3727/44/19/194009

Wu DS, Hua XM, Li F, Huang LJ (2017) Understanding of spatter formation in fiber laser welding of 5083 aluminum alloy. Int J Heat Mass Transf 113:730–740. https://doi.org/10.1016/j.ijheatmasstransfer.2017.05.125

Chen X, Jiang N, Jiang M, Du Y, Ma SC, Chen Y, Tan CW, Lei ZL, Zhao SC, Chen YB (2022) Numerical investigation of asymmetric weld fusion geometry in laser welding of aluminium alloy with beam oscillation. Science and Technology of Welding and Joining:1–11. https://doi.org/10.1080/13621718.2022.2091343

Tanaka M, Lowke JJ (2007) Predictions of weld pool profiles using plasma physics. J Phys D Appl Phys 40(1):R1–R23. https://doi.org/10.1088/0022-3727/40/1/r01

Hirt CW, Nichols BD (1981) Volume of fluid (VOF) method for the dynamics of free boundaries. J Comput Phys 39(1):201–225. https://doi.org/10.1016/0021-9991(81)90145-5

Jian XX, Wu CS (2015) Numerical analysis of the coupled arc-weld pool-keyhole behaviors in stationary plasma arc welding. Int J Heat Mass Transf 84:839–847. https://doi.org/10.1016/j.ijheatmasstransfer.2015.01.069

Li Y, Zhao YQ, Zhou XD, Zhan XC (2022) Effect of droplet transition on the dynamic behavior of the keyhole during 6061 aluminum alloy laser-MIG hybrid welding. Int J Adv Manuf Technol 119(1-2):897–909. https://doi.org/10.1007/s00170-021-08270-1

Zargari HH, Ito K, Kumar M, Sharma A (2020) Visualizing the vibration effect on the tandem-pulsed gas metal arc welding in the presence of surface tension active elements. Int J Heat and Mass Transf 161. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120310

Zhu C, Cheon J, Tang X, Na SJ, Cui H (2018) Molten pool behaviors and their influences on welding defects in narrow gap GMAW of 5083 Al-alloy. Int J Heat Mass Transf 126(PT. A):1206-1221. https://doi.org/10.1016/j.ijheatmasstransfer.2018.05.132.

Wang Y, Tsai HL (2001) Impingement of filler droplets and weld pool dynamics during gas metal are welding process. Int J Heat and Mass Transf 44(11):2067–2080. https://doi.org/10.1016/s0017-9310(00)00252-0

Brackbill JU, Kothe DB, Zemach C (1992) A continuum method for modeling surface tension. J Comput Phys 100(2):335–354. https://doi.org/10.1016/0021-9991(92)90240-y

Voller VR, Prakash C (1987) A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int J Heat Mass Transf 30(8):1709–1719. https://doi.org/10.1016/0017-9310(87)90317-6

Li LQ, Gong JF, Xia HB, Peng GC, Hao Y, Meng SB, Wang JM (2021) Influence of scan paths on flow dynamics and weld formations during oscillating laser welding of 5A06 aluminum alloy. J Mater Res Technol 11:19–32. https://doi.org/10.1016/j.jmrt.2020.12.102

Zhao WY, Cao XY, Du XW, Wei Y, Liu R, Chen J (2022) Numerical simulation of heat and mass transfer in CMT-based additive manufacturing. J MechEng 58(01):267–276. https://doi.org/10.3901/JME.2022.01.267

Kim WH, Na SJ (1998) Heat and fluid flow in pulsed current GTA weld pool. Int J Heat Mass Transf 41(21):3213–3227. https://doi.org/10.1016/s0017-9310(98)00052-0

Gonalves CV, Vilarinho LO, Scotti A (2006) Estimation of heat source and thermal efficiency in GTAW process by using inverse techniques. J Mater Process Technol 172(1):42–51. https://doi.org/10.1016/j.jmatprotec.2005.08.010

Liu JW, Rao ZH, Liao SM, Tsai HL (2015) Numerical investigation of weld poor behaviors and ripple formation for a moving GTA welding under pulsed currents. Int J Heat and Mass Trans 91:990–1000. https://doi.org/10.1016/j.ijheatmasstransfer.2015.08.046

Padmanabham G, Pandey S, Schaper M (2005) Pulsed gas metal arc welding of Al-Cu-Li alloy. Science and Technology of Welding and Joining 10(1):67–75. https://doi.org/10.1179/174329305x19358

Ogino Y, Hirata Y, Murphy AB (2016) Numerical simulation of GMAW process using Ar and an Ar-CO2 gas mixture. Weld World 60(2):1–9. https://doi.org/10.1007/s40194-015-0287-3

Wang L, Chen J, Wu CS, Luan SC (2020) Numerical analysis of arc and droplet behaviors in gas metal arc welding with external compound magnetic field. J Mater Process Technol 282. https://doi.org/10.1016/j.jmatprotec.2020.116638

Funding

This research was supported by the National Natural Science Foundation of China (No. 51975138), High-Tech Ship Scientific Research Project from the Ministry of Industry and Information Technology ([2019]360), and High-Tech Ship Scientific Research Project from the Ministry of Industry and Information Technology (No. CJ05N20).

Author information

Authors and Affiliations

Contributions

ZW and YM conceived the idea. ZW wrote the initial draft of the paper. All authors discussed the results and finalized this paper.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Z., Miao, Y., Liu, J. et al. Numerical and experimental investigation of metal droplet transfer during pulsed bypass-current plasma-GMAW hybrid arc welding. Int J Adv Manuf Technol 129, 2747–2762 (2023). https://doi.org/10.1007/s00170-023-12487-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12487-7