Abstract

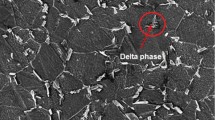

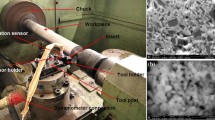

Nanofluid minimum quantity lubrication (NFMQL) has been gaining popularity as a means of improving superalloy machinability and resolving health-related and environmental issues caused by conventional cutting fluids. In this study, Inconel 718 was machined with vegetable oil-based MQL containing varying weights of Al2O3 (aluminum oxide) nanoparticles. Tool wear, cutting forces, chip morphology, and average surface roughness were investigated in relation to the feed rate, the cutting speed, and the machining environment. The outcome indicates that surface roughness and cutting forces are improved by approximately 30% and 25%, respectively, when using 4 weight percentage (wt% ) nanoparticles in MQL compared to the pure MQL (0 wt%). The present study also investigated various factors associated with chip morphology, such as peak, pitch, and valleys, which affect machining performance. It was found that 4 wt% NFMQL resulted in significant improvements in chip morphology. Furthermore, the chip morphology and tool wear were examined under various cutting conditions in this study, and nanoparticles at 4 wt% showed optimal results.

Similar content being viewed by others

Data availability

Data can be requested from the corresponding author.

References

Khanafer K, Eltaggaz A, Deiab I, Agarwal H, Abdul-Latif A (2020) Toward sustainable micro-drilling of Inconel 718 superalloy using MQL-Nanofluid. Int J Adv Manuf Technol 107:1–11. https://doi.org/10.1007/s00170-020-05112-4

H. S. C. Ltd, “Inconel 718 for aerospace engine applications.”

Huffman BT, Sutton M (2019) The effects of heat generation on cutting tool and machined workpiece The Effects of Heat Generation on Cutting Tool and Machined Workpiece. https://doi.org/10.1088/1742-6596/1378/2/022012

Eltaggaz A, Said Z, Deiab I (2020) An integrated numerical study for using minimum quantity lubrication (MQL) when machining austempered ductile iron (ADI). Int J Interact Des Manuf 14(3):747–758. https://doi.org/10.1007/s12008-020-00662-z

Ali S, Pervaiz S, Kannan S (2021) Current research trends in variants of minimum quantity lubrication (MQL): a review. https://doi.org/10.1115/IMECE2021-73656

Pervaiz S, Rashid A, Deiab I, Nicolescu M (2014) Influence of tool materials on machinability of titanium- and nickel-based alloys: a review. Mater Manuf Process 29(3):219–252. https://doi.org/10.1080/10426914.2014.880460

ul Haq MA et al (2021) Evaluating the effects of nano-fluids based MQL milling of IN718 associated to sustainable productions. J Clean Prod 310:127463. https://doi.org/10.1016/j.jclepro.2021.127463

Eltaggaz A, Deiab I (2018) The effect of nanoparticle concentration on mql performance when machining Ti-6Al-4V titanium alloy, pp 1–4. https://doi.org/10.25071/10315/35211

Yin Q et al (2018) Effects of the physicochemical properties of different nanoparticles on lubrication performance and experimental evaluation in the NMQL milling of Ti–6Al–4V. Int J Adv Manuf Technol 99(9):3091–3109. https://doi.org/10.1007/s00170-018-2611-8

Pereira O, Martín-Alfonso JE, Rodríguez A, Calleja A, Fernández-Valdivielso A, López de Lacalle LN (2017) Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J Clean Prod 164:1419–1429. https://doi.org/10.1016/j.jclepro.2017.07.078

Sen B, Mia M, Gupta MK, Rahman MA, Mandal UK, Mondal SP (2019) Influence of Al2O3 and palm oil–mixed nano-fluid on machining performances of Inconel-690: IF-THEN rules–based FIS model in eco-benign milling. Int J Adv Manuf Technol 103(9):3389–3403. https://doi.org/10.1007/s00170-019-03814-y

Günan F, Kıvak T, Yıldırım ÇV, Sarıkaya M (2020) Performance evaluation of MQL with AL2O3 mixed nanofluids prepared at different concentrations in milling of Hastelloy C276 alloy. J Mater Res Technol 9(5):10386–10400. https://doi.org/10.1016/j.jmrt.2020.07.018

Pal A, Chatha SS, Sidhu HS (2020) Experimental investigation on the performance of MQL drilling of AISI 321 stainless steel using nano-graphene enhanced vegetable-oil-based cutting fluid. Tribol Int 151:106508. https://doi.org/10.1016/j.triboint.2020.106508

Yıldırım ÇV (2020) Investigation of hard turning performance of eco-friendly cooling strategies: cryogenic cooling and nanofluid based MQL. Tribol Int 144. https://doi.org/10.1016/j.triboint.2019.106127

Bai X, Li C, Dong L, Yin Q (2019) Experimental evaluation of the lubrication performances of different nanofluids for minimum quantity lubrication (MQL) in milling Ti-6Al-4V. Int J Adv Manuf Technol 101(9):2621–2632. https://doi.org/10.1007/s00170-018-3100-9

Wang Y et al (2018) Processing characteristics of vegetable oil-based nanofluid mql for grinding different workpiece materials. Int J Precis Eng Manuf Technol 5(2):327–339. https://doi.org/10.1007/s40684-018-0035-4

Şirin Ş, Sarıkaya M, Yıldırım ÇV, Kıvak T (2021) Machinability performance of nickel alloy X-750 with SiAlON ceramic cutting tool under dry, MQL and hBN mixed nanofluid-MQL. Tribol Int 153. https://doi.org/10.1016/j.triboint.2020.106673

Yıldırım ÇV, Sarıkaya M, Kıvak T, Şirin Ş (2019) The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol Int 134:443–456. https://doi.org/10.1016/j.triboint.2019.02.027

Nouzil I, Eltaggaz A, Pervaiz S (2022) Toxicity analysis of nano-minimum quantity lubrication machining — a review, pp 1–21

Khanafer K, Eltaggaz A, Deiab I (2020) Numerical study of flow and heat transfer of minimum quantity lubrication based nanofluid in a turning process using Inconel alloy. Int J Adv Manuf Technol 108(1):475–483. https://doi.org/10.1007/s00170-020-05430-7

Ali S, Pervaiz S (2023) Machinability analysis of AZ31 magnesium alloys using the Taguchi gray relational analysis. Int J Adv Manuf Technol (0123456789). https://doi.org/10.1007/s00170-023-11354-9

Halim NHA, Haron CHC, Ghani JA, Azhar MF (2019) Tool wear and chip morphology in high-speed milling of hardened Inconel 718 under dry and cryogenic CO2 conditions. Wear 426–427:1683–1690. https://doi.org/10.1016/j.wear.2019.01.095

Danish M, Gupta MK, Rubaiee S, Ahmed A, Sarikaya M (2021) Influence of graphene reinforced sunflower oil on thermo-physical, tribological and machining characteristics of inconel 718. J Mater Res Technol 15:135–150. https://doi.org/10.1016/j.jmrt.2021.07.161

Arul K, Mohanavel V, Raj Kumar S, Maridurai T, Magesh Kumar K, Ravichandran M (2022) Investigation of machining attributes on machining of alloys under nano fluid MQL environment: a review. Mater Today Proc 59:1312–1318. https://doi.org/10.1016/j.matpr.2021.11.525

Yıldırım ÇV, Kıvak T, Sarıkaya M, Şirin Ş (2020) Evaluation of tool wear, surface roughness/topography and chip morphology when machining of Ni-based alloy 625 under MQL, cryogenic cooling and CryoMQL. J Mater Res Technol 9(2):2079–2092. https://doi.org/10.1016/j.jmrt.2019.12.069

Jaffery SHI, Mativenga PT (2012) Wear mechanisms analysis for turning Ti-6Al-4V-towards the development of suitable tool coatings. Int J Adv Manuf Technol 58(5–8):479–493. https://doi.org/10.1007/s00170-011-3427-y

ISO, “ISO 8688-2:1989(en) Tool life testing in milling — part 2: end milling.” https://www.iso.org/obp/ui/#iso:std:iso:8688:-2:ed-1:v1:en

Davim JP (2010) Surface integrity in machining. https://doi.org/10.1007/978-1-84882-874-2

Jamil M et al (2020) Milling of Ti–6Al–4V under hybrid Al2O3-MWCNT nanofluids considering energy consumption, surface quality, and tool wear: a sustainable machining. Int J Adv Manuf Technol 107(9):4141–4157. https://doi.org/10.1007/s00170-020-05296-9

An Q, Cai C, Zou F, Liang X, Chen M (2020) Tool wear and machined surface characteristics in side milling Ti6Al4V under dry and supercritical CO2 with MQL conditions. Tribol Int 151:106511. https://doi.org/10.1016/j.triboint.2020.106511

Deng Y, Xiu S, Shi X, Sun C, Wang Y (2017) Study on the effect mechanisms of pre-stress on residual stress and surface roughness in PSHG. Int J Adv Manuf Technol 88(9):3243–3256. https://doi.org/10.1007/s00170-016-9033-2

Thakur DG, Ramamoorthy B, Vijayaraghavan L (2009) Machinability investigation of Inconel 718 in high-speed turning. Int J Adv Manuf Technol 45(5):421–429. https://doi.org/10.1007/s00170-009-1987-x

Singh G, Gupta MK, Mia M, Sharma VS (2018) Modeling and optimization of tool wear in MQL-assisted milling of Inconel 718 superalloy using evolutionary techniques. Int J Adv Manuf Technol 97(1):481–494. https://doi.org/10.1007/s00170-018-1911-3

Luo T (2014) Tribological properties of Al2O3 nanoparticles as lubricating oil additive. Ceram Int 40(5):7143–7149

Funding

Authors would like to acknowledge the financial support from the Natural Science and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Contributions

Conceptualization, Ibrahim Deiab; methodology, Abdelkrem Eltaggaz, Shafahat Ali, and Kashish Badwal; validation, Abdelkrem Eltaggaz; formal analysis, Shafahat Ali; investigation, Abdelkrem Eltaggaz, Kashish Badwal, and Shafahat Ali; resources, Ibrahim Deiab; data curation, Kashish Badwal; writing—original draft preparation, Shafahat Ali, Kashish Badwal, and Abdelkrem Eltaggaz; writing—review and editing, Ibrahim Deiab and Abdelkrem Eltaggaz; supervision, Ibrahim Deiab; project administration, Ibrahim Deiab and Abdelkrem Eltaggaz; funding acquisition; Ibrahim Deiab

Corresponding author

Ethics declarations

Consent for publication

All authors have read and agreed to the published version of the manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Eltaggaz, A., Ali, S., Badwal, K. et al. Influence of nanoparticle concentration in nanofluid MQL on cutting forces, tool wear, chip morphology when milling of Inconel 718. Int J Adv Manuf Technol 129, 1787–1800 (2023). https://doi.org/10.1007/s00170-023-12393-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12393-y