Abstract

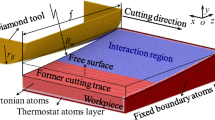

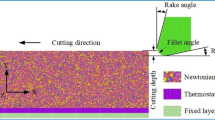

The nano-cutting process of metallic glass (Zr52Cu20Ni16Ni12) processed at room temperature was studied by molecular dynamics simulation in this paper. At different cutting speeds, the microstructure of metallic glass, cutting force, strain morphology of cutting zone, temperature change of cutting zone and its influence on the quality of machined surface were analyzed. The simulation results show that the cutting speed has little effect on the content of Voronoi polyhedron in the cutting area of metallic glass. The cutting force increases significantly with the increase of cutting speed. The shape of strain deformation in the cutting zone of metallic glass material is significantly affected by the cutting speed, and the influence depth of strain is deepened with the increase of cutting speed. The increase of cutting speed has a significant effect on the temperature of the cutting zone of metallic glass, and the temperature of atoms in the cutting zone increases rapidly. The cutting speed has a significant impact on the surface quality of metal glass cutting. The surface quality of metal glass cutting becomes worse with the increase of cutting speed. In particular, the initial stage of plastic deformation in metal glass cutting process is simulated and analyzed, and the formation and evolution of its shear band and free volume are simulated and studied.

Similar content being viewed by others

References

Schuh CA, Hufnagel TC, Ramamurty U (2007) Mechanical behavior of amorphous alloys. Acta Mater 55(12):4067–4109

Rapaport DC (2004) The art of molecular dynamics simulation. Cambridge University Press, Cambridge

Luo XC, Liang YC, Dong S (1999) Application of molecular dynamics in nanomachining technology. Chin Mech Eng 6:100–104

Shimizu F, Ogata S, Li J (2007) Theory of shear banding in metallic glasses and molecular dynamics calculations. Mater Trans 48:2923–2927

Shimizu F, Ogata S, Li J (2006) Yield point of metallic glass. Acta Mater 54:4293–4298

Sheng HW, Lou WK, Alamgir FM et al (2006) Atomic packing and short-to-medium-range order in metallic glass. Nature 439:419

Cheng YQ, Sheng HW, Ma E (2008) Relationship between structure, dynamics, and mechanical properties in metallic glass-forming alloys. Phys Rev B 78:014207

Cheng YQ, Cao AJ, Ma E (2009) Correlation between the elastic modulus and intrinsic plastic behavior of metallic glasses: the roles of atomic configuration and alloy composition. Acta Mater 57:3253–3267

Zhao D (2020) Research on nanoindentation response of metallic glasses via molecular dynamics simulations. Jilin University

Wang YC, Wu CY, Chu JP et al (2010) Indentation behavior of Zr-based metallic glass films via molecular-dynamics simulations. Metall Mater Trans A 41(11):3010–3017

Huang SQ, Gao S, Huang CZ, Huang H (2022) Nanoscale removal mechanisms in abrasive machining of brittle solids. Diamond & Abrasives Eng 42(3):257–267

Wang XS, Yang GL, Dong ZG, Kang RK (2022) Research progress on exit burr in drilling assembly hole of aerospace aluminum alloy components. Diamond & Abrasives Eng 42(4):385–409

Branka AC, Wojciechowshi KW (2000) Generalization of Nose and Nose-Hoover isothermal dynamics. Phys Rev E 62(3):3281–3292

Rateitschak K, Klages R, Hoover WG (2000) The Nose-Hoover thermostated Lorentz gas. J Stat Phys 101(1-2):61–77

Pieprzyk S, Heyes DM, Mackowlak S et al (2015) Galilean-invariant Nose-Hoover-type thermostats. Phys Rev E 91(3):033312

Beckedahl D, Obage EO, Uken DA et al (2016) On the configurational temperature Nose-Hoover thermostat. Phys A: Stat Mech Appl 461:19–35

Fukuda I (2016) Coupled Nose-Hoover lattice: a set of the Nose-Hoover equations with different temperatures. Phys Lett A 380(33):2465–2474

Zhu ZX (2017) Study on mechanism and influencing factors of surface and chip generation in nanometric machining of single crystal nickel. Northeast University

Mendelev MI, Sordelet DL, Kramer MJ (2007) Using atomistic computer simulations to analyze X-ray diffraction data from metallic glasses. J Appl Phys 102:043501

Duan LJ, Liu YC (2020) Relationships between elastic constants and EAM/FS potential functions for cubic crystals. Acta Metall Sin 56(01):112–118

Liu YX, Sun JJ, Gao Y, Gu H et al (2008) Several fitting methods for parameters of Lennard-Jones potential functions. J Liaoning Univ (Nat Sci) 03:206–209

Gong ZL, Zhou CB, Peng YZ (2015) Dynamics of stick-slip on interfacial friction based on the Lennard-Jones potential theory. Surf Technol 44(09):36–42

Tersoff J (1989) Modeling solid-state chemistry: interatomic potentials for multicomponent systems. Phys Rev B Condens Matter 39(39):5566–5568

Brostow W, Castano VM (1999) Voronoi polyhedral as a tool for dealing with spatial structures of amorphous solids. J Mater Educ 21(5/6):297–304

Boudreaux DS, Frost HJ (1981) Short-range order in theoretical models of binary metallic glass alloys. Phys Rev B 23(4):1506

Fan HY (2021) Structural heterogeneity and its correlations with properties in Zr-Cu-based metallic glasses. Univ Sci Tech Beijing 12:20

Funding

This research was supported by National Natural Science Foundation of China (Grant No. 52005346, 52005347, 52275455, and U1908230), Natural Science Foundation of Liaoning Province (Grant No. 2021-BS-149), Scientific Research Funding Project of Liaoning Provincial Department of Education (Grant No. LQGD2020017), General Project of Basic Scientific Research Projects for Higher Education Institutions of Liaoning Provincial Department of Education (Grant No. LJKMZ20220459), Project of Liaoning Province Applied Basic Research Program (Grant No. 2022JH2/101300214), and Special Fund for Tackling Key Scientific and Technological Problems in Liaoning Province (Grant No. 2021JH1/10400077).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Yin Liu, Xiaoqing Cui, Xingwei Sun, Fei Pan, and Hongxun Zhao. The first draft of the manuscript was written by Xiaoqing Cui, Yin Liu, and Yadong Gong. Experimental tests were carried out by Heran Yang, Zewei Yuan, Zhixu Dong, and Weijun Liu. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

The authors consent to publish this article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Y., Cui, X., Sun, X. et al. Investigations into the effect of cutting speed on nano-cutting of metallic glass by using molecular dynamics simulation analysis. Int J Adv Manuf Technol 127, 5253–5263 (2023). https://doi.org/10.1007/s00170-023-11884-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11884-2