Abstract

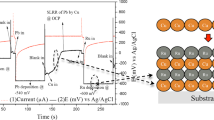

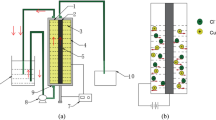

Electrodeposition is a novel and benign fabrication method which excellently combines electrochemical deposition mechanism and additive manufacturing to realize the processing of metal-based structures layer-upon-layer. Herein, an unusual additive manufacturing (AM) method is proposed based on electrochemical deposition. Notably, three-dimensional forming of metal by local conductive samples (PLA-CNTs7wt%) as cathode through selective electrochemical deposition was realized. Moreover, the effect of the deposition time on the surface morphology and quality of the sample were explored. Besides, the method of preparing metal parts in array type solves the problem of slow electrochemical additive manufacturing (ECAM) and provides a new approach to achieve mass production for industry. Then, the prepared copper-nickel multilayer metal samples realized the ECAM of multi-metals. Finally, the 4D printing effect of copper-nickel bimetallic samples was preliminarily explored, and the feasibility of preparing energy storage elements by selective electrochemical deposition was further proved.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Gao W, Pumera M (2021) 3D printed nanocar-bon frameworks for Li-ion battery cathodes. Adv Funct Mater 31(11):2007285. https://doi.org/10.1002/adfm.202007285

Horn T J, Harrysson O L (2012) Overview of current additive manufacturing technologies and selected applications. Science Progress, 95(3): 255–282. https://doi.org/10.3184/003685012X13420984463047

Behroozfar A, Daryadel S, Morsali SR, Mor-eno S, Baniasadi M, Bernal RA, Minary-Jolanda-n M (2018) Microscale 3D printing of nanotwin-ned copper. Adv Mater 30(4):1705107. https://doi.org/10.1002/adma.201705107

Tofail SAM, Koumoulos EP, Bandyopadhyay A, Bose OS, L, Charitidis C, (2018) Additive manufacturing: scientific and technological challenges, market uptake and opportunities. Mater Today 21(1):22–37. https://doi.org/10.1016/j.mattod.2017.07.001

Yao B, Chandrasekaran S, Zhang H, Ma A, Kang J, Zhang L, Lu X, Qian F, Zhu C, Duoss EB, Spadaccini CM, Worsley MA, Li Y (2020) 3D-printed structure boosts the kinetics and intrinsic capacitance of pseudocapacitive graphene aerogels. Adv Mater 32(8):e1906652. https://doi.org/10.1002/adma.201906652

Kuang X, Chen K, Dunn CK, Wu J, Li VCF, Qi HJ (2018) 3D printing of highly stretchable, shape-memory, and self-healing elastomer toward novel 4D printing. ACS Appl Mater Interfaces 10(8):7381–7388. https://doi.org/10.1021/acsami.7b18265

Seol SK, Kim D, Lee S, Kim JH, Chang WS, Kim JT (2015) Electrodeposition-based 3D printing of metallic microarchitectures with controlled internal structures. Small 11(32):3896–3902. https://doi.org/10.1002/smll.201500177

Gomes MC, dos Santos AG, de Oliveira D, Figueiredo GV, Ribeiro KSB, De Los RGAB, da Silva MB, Coelho RT, Hung WNP (2021) Micro-machining of additively manufactured metals: a review. Int J Adv Manuf Technol 118(7–8):2059–2078. https://doi.org/10.1007/s00170-021-08112-0

Hirt L, Ihle S, Pan Z, Dorwling-Carter L, Reiser A, Wheeler JM, Spolenak R, Vörös J, Zambelli Alain Reiser T (2016) Template-free 3D microprinting of metals using a force-controlled nanopipette for layer-by-layer electrodeposition. Adv Mater 28(12):2311–2315. https://doi.org/10.1002/adma.201504967

Schaffer TB, Sercombe GB (2003) Rapid manufacturing of aluminum components. Science 301(5637):1225–1227. https://doi.org/10.1126/science.1086989

Collins PC, Brice DA, Samimi P, Ghamarian I, Fraser HL (2016) Microstructural control of additively manufactured metallic materials. Annu Rev Mater Res 46(1):63–91. https://doi.org/10.1146/annurev-matsci-070115-031816

Kamaraj AB, Sundaram M (2019) A mathematical model of the deposition rate and layer height during electrochemical additive manufacturing. Int J Adv Manuf Technol 102(5–8):2367–2374. https://doi.org/10.1007/s00170-019-03292-2

Nydegger M, Pruska A, Galinski H, Zenobi R, Reiser A, Spolenak R (2022) Additive manufacturing of Zn with submicron resolution and its conversion into Zn/ZnO core-shell structures. Nanoscale 14(46):17418–17427. https://doi.org/10.1039/d2nr04549d

Hengsteler J, Mandal B, Van Nisselroy C, Lau GPS, Schlotter T, Zambelli T, Momotenko D (2021) Bringing electrochemical three-dimensional printing to the nanoscale. Nano Lett 21(21):9093–9101. https://doi.org/10.1021/acs.nanolett.1c02847

Rolandi M, Okawa D, Backer SA, Zettl A, Fréchet JMJ (2007) Fabrication of magnetic force microscopy probes via localized electrochemical deposition of cobalt. J Vacuum Sci Technol B: Microelectron Nanometer Struct 25(5):L39–L42. https://doi.org/10.1116/1.2766935

Pellicer E, Pané S, Panagiotopoulou VC, Fusco S, Sivaraman KM, Suriñach S, Baró MD, Nelson BJ, Sort J & F́ısica D (2012) Localized electrochemical deposition of porous Cu-Ni microcolumns: insights into the growth mechanisms and the mechanical performance. Int J Electrochem Sci 7(5):4014–4029. https://doi.org/10.3103/S1068375512030143

Aydemir N, Parcell J, Laslau C, Nieuwoudt M, Williams DE, Travas-Sejdic J (2013) Direct writing of conducting polymers. Macromol Rapid Commun 34(16):1296–1300. https://doi.org/10.1002/marc.201300386

Roach DJ, Hamel CM, Dunn CK, Johnson MV, Kuang X, Qi HJ (2019) The m4 3D printer: a multi-material multi-method additive manufacturing platform for future 3D printed structures. Addit Manuf 29:100819. https://doi.org/10.1016/j.addma.2019.100819

Kuang X, Qi HJ (2020) Modular 4D printing assisted by dynamic chemical bonds. Matter 2(5):1080–1082. https://doi.org/10.1016/j.matt.2020.04.014

Vaezi M, Chianrabutra S, Mellor B, Yang S (2013) Multiple material additive manufacturing-Part 1: a review. Virtual Phys Prototyp 8(1):19–50. https://doi.org/10.1080/17452759.2013.778175

Xu J, Ren W, Lian Z, Yu P, Yu H (2020) A review: development of the maskless localized electrochemical deposition technology. Int J Adv Manuf Technol 110(7–8):1731–1757. https://doi.org/10.1007/s00170-020-05799-5

Funding

This research was supported by National Natural Science Foundation of China (No.52075219) and National Key R&D Program of China (No. 2022YFB4600202).

Author information

Authors and Affiliations

Contributions

Chenghan Zhao and Jing Wang played guiding roles in this paper and contributed equally to the article as co-first authors. Wenzheng Wu contributed to the conceptualization, methodology, and resources. Tianyu Liu and Jinyu Guo contributed to experimental investigation and prepared the original draft. Chenghan Zhao and Jing Wang contributed to the data curation, validation, reviewing and editing. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Chenghan Zhao and Jing Wang as co-first authors.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, C., Wang, J., Liu, T. et al. Additive manufacturing of Cu/Ni by selective electrochemical deposition on local conductive substrate. Int J Adv Manuf Technol 126, 5081–5087 (2023). https://doi.org/10.1007/s00170-023-11426-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11426-w