Abstract

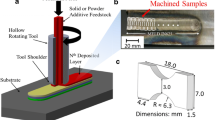

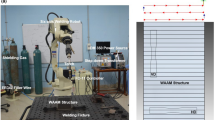

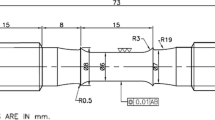

This work focuses on high-cycle fatigue and quasi-static tensile performance of additively manufactured and wrought 17–4 stainless steel. Test specimens were manufactured using a Markforged Metal X printer via the atomic diffusion additive manufacturing process or machined from commercial stock. High-cycle fatigue testing showed that wrought specimens could sustain higher loads at 106 cycles (565 MPa) as compared to additively manufactured specimens with solid infill (216 MPa) and triangular infill (136 MPa). The mass-normalized fatigue responses of the additively manufactured specimens were similar when comparing in-fill type while wrought specimens performed roughly 50% better across the range from 104 to 3.5 × 107 cycles.

Similar content being viewed by others

Data availability

The data referenced in our manuscript will not be deposited.

Code availability

Any code referenced in our manuscript will not be deposited.

References

Beretta S, Romano S (2017) A comparison of fatigue strength sensitivity to defects for materials manufactured by AM or traditional processes. Int J Fatigue 94:178–191

Flodberg G, Pettersson H, Yang L (2018) Pore analysis and mechanical performance of selective laser sintered objects. Addit Manuf 24:307–315

Gatto A, Bassoli E, Denti L (2018) Repercussions of powder contamination on the fatigue life of additive manufactured maraging steel. Addit Manuf 24:13–19

Shamsaei N, Yadollahi A, Bian L, Thompson SN (2015) An overview of direct laser deposition for additive manufacturing; part II: mechanical behavior, process parameter optimization and control. Addit Manuf 8:12–35

Haghdadi N, Laleh M, Moyle M, Primig S (2021) Additive manufacturing of steels: a review of achievements and challenges. J Mater Sci 56:64–107

Mahmoudi M, Elwany A, Yadollahi A, Thompson SM, Bian L, Shamsaei N (2017) Mechanical properties and microcharacterization of selective laser melted 17–4PH stainless steel. Rapid Prototyp J 23(2):280–294

Agrawal P, Haridas RS, Thapliyal S, Yadav S, Mishra RS, McWilliams VA, Cho KC (2021) Metastable high entropy alloys: an excellent defect tolerant material for additive manufacturing. Mater Sci Eng A 826:142005

Shu Y, Galles D, Tertuiliano OA, McWilliams BA, Yang N, Cai W, Lew AJ (2021) A critical look at the prediction of the temperature field around a laser-induced melt pool on metallic substrates. Sci Rep 11(1):1–11

Vandresse N, Richter A, Nuno N, Bocher P (2018) Measurement of deformation heterogeneities in additively manufactured lattice materials by digital image correlation: strain maps analysis and reliability assessment. J Mech Behav Biomed Mater 86:397–408

Takezawa A, Koizumi Y, Kobashi M (2017) High-stiffness and strength porous maraging steel via topology optimization and selective laser melting. Addit Manuf 18:194–202

Hedayati R, Hosseini-Toudeshky H, Sadighi M, Mohammadi-Aghdam M, Zadpoor AA (2016) Computational prediction of the fatigue behavior of additively manufactured porous metallic biomaterials. Int J Fatigue 84:67–79

Walker KF, Liu Q, Brandt M (2017) Evaluation of fatigue crack propagation behavior in Ti-6Al-4V manufactured by selective laser melting. Int J Fatigue 104:302–308

Hedayati R, Hosseini-Toudeshky H, Sadighi M, Mohammadi-Aghdam M, Zadpoor AA (2018) Multiscale modeling of fatigue crack propagation in additively manufactured porous biomaterials. Int J Fatigue 113:416–427

Henry TC, Phillips FR, Cole DP, Garboczi E, Haynes RA, Johnson T (2020) In situ fatigue monitoring investigation of additively manufactured maraging steel. Int J Adv Manuf Technol 107:3499–3510

Kirka MM, Greely DA, Hawkins C, Dehoff RR (2017) Effect of anisotropy and texture on the low cycle fatigue behavior of Inconel 718 processed via electron beam melting. Int J Fatigue 105:235–243

Lawrence BD, Coatney MD, Phillips F et al (2022) Evaluation of the mechanical properties and performance cost of additively manufactured continuous glass and carbon fiber composites. Int J Adv Manuf Technol 120:1135–1147. https://doi.org/10.1007/s00170-022-08879-w

Jones R, Kovarik O, Bagherifard S, Cizek J, Lang J (2021) Damage tolerance assessment of AM 304L and cold spray fabricated 316L steels and its implications for attritable aircraft. Eng Fract Mech 254:107916

Croccolo D, De Agostinis M, Fini S, Olmi G, Robusto F, Kostic SC, Vranic A, Bogojevic N (2018) Fatigue response of as-built DMLS maraging steel and effects of aging, machining, and peening treatments. Metals 8:505–526

Suryawanshi J, Parshanth KG, Ramamurty U (2017) Tensile, fracture, and fatigue crack growth properties of a 3D printed maraging steel through selective laser melting. J Alloy Compd 725:355–364

Maccioni L, Fraccaroli L, Borgianni Y, Concli F (2021) High-cycle-fatigue characterization of an additive manufacturing 17–4 PH stainless steel. Key Eng Mater 877:49–54. https://doi.org/10.4028/www.scientific.net/KEM.877.49

Henry TC, Morales MA, Cole DP, Shumeyko CM, Riddick JC (2021) Mechanical behavior of 17–4 PH stainless steel processed by atomic diffusion additive manufacturing. Int J Adv Manuf Technol 114(7):2103–2114

Lewandowski JL, Mohsen S (2016) Metal additive manufacturing: a review of mechanical properties. Annu Rev Mater Res 46:151–186

Gao X, Tao C, Wu S, Chen B, Wu S (2022) X-ray imaging of defect population and the effect on high cycle fatigue life of laser additive manufactured Ti6Al4V alloys. Int J Fatigue 162:106979

Edwards P, Ramulu M (2014) Fatigue performance evaluation of selective laser melted Ti-6Al-4V. Mater Sci Eng A 598:327–337

Carneiro L, Jalalahmadi B, Ashtekar A, Jiang Y (2019) Cyclic deformation and fatigue behavior of additively manufactured 17–4 PH stainless steel. Int J Fatigue 123:22–30

Lee S, Pegues JW, Shamsaei N (2020) Fatigue behavior and modeling for additive manufacturing 304L stainless steel: the effect of surface roughness. Int J Fatigue 141:105856

Nezhadfar PD, Burford E, Anderson-Wedge K, Zhang B, Shao S, Daniewicz SR, Shamsaei N (2019) Fatigue crack growth behavior of additively manufactured 17–4 PH stainless steel: effects of build orientation and microstructure. Int J Fatigue 123:168–179

Gonzalez-Gutierrez J, Cano S, Schuschnigg S, Kukla C, Sapkota J, Holzer C (2018) Additive Manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: a review and future perspectives. Materials 11(840):1–36

Wu G, Langrana NA, Rangarajan S, McCuiston R, Sadanji R, Danforth S (2002) Solid freeform fabrication of metal components using fused deposition of metals. Mater Des 23(1):775–782

Galati M, Minetola P (2019) Analysis of density, roughness, and accuracy of the atomic diffusion additive manufacturing (ADAM) process for metal parts. Materials 12(24):1–15

Iacopo B, Valerio DP, Tommaso M, Massimiliano P, Alessio V (2022) Environmental impacts assessment of bound metal deposition 3D printing process for stainless steel. Procedia CIRP 150:386–391

Kedziora S, Decker T, Museyibov E, Morbach J, Hohmann S, Huwer A, Wahl M (2022) Strength properties of 316L and 17–4 PH stainless steel produced with additive manufacturing. Materials 15:1–26

Watson A, Belding J, Ellis B. Characterization of 17-4 PH processed via bound metal deposition (BMD).TMS 2020 149th Annual Meeting & Exhibition. Springer, Cham. https://doi.org/10.1007/978-3-030-36296-6_19

Suwanpreecha C, Manonukul A (2022) On the build orientation effect in as-printed and as-sintered bending properties of 17–4 PH alloy fabricated by metal fused filament fabrication. Rapid Prototyp J 28(6):1076–1085

Bjørheim F, La Torraca Lopez IM (2021) Tension testing of additively manufactured specimens of 17–4 PH processed by Bound Metal Deposition. IOP Conf Ser Mater Sci Eng 1201(1):012037

Yadollahi A, Shamsaei N, Thompson SM, Elwany A, Bian L (2017) Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17–4 PH stainless steel. Int J Fatigue 94:218–235

Yadollahi A, Shamsaei N (2017) Additive manufacturing of fatigue resistant materials: Challenges and opportunities. Int J Fatigue 98:14–31

Singh G, Missiaen JM, Bouvard D, Chaix JM (2021) Additive manufacturing of 17–4 PH steel using metal injection molding feedstock: analysis of 3D extrusion printing, debinding and sintering. Addit Manuf 47:102287

Pellegrini A, Palmieri ME, Guerra MG (2022) Evaluation of anisotropic mechanical behavior of 316L parts realized by metal fused filament fabrication using digital image correlation. Int J Adv Manuf Technol 120(12):7951–7965

Author information

Authors and Affiliations

Contributions

Bradley D. Lawrence: investigation, formal analysis, visualization, writing—original draft.

Todd C. Henry: conceptualization, visualization, formal analysis, resources, supervision, writing—original draft.

Francis Phillips: visualization, formal analysis, writing—original draft.

Andelle Kudzal: investigation, visualization, writing—original draft.

Jaret Riddick: Conceptualization, resources, supervision, writing—original draft.

Corresponding author

Ethics declarations

Ethics approval

The authors have no ethics approval statements to provide.

Consent to participate

The authors give their consent for participation in this journal.

Consent for publication

The authors give their consent for publication in this journal.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lawrence, B.D., Henry, T.C., Phillips, F. et al. High-cycle tension-tension fatigue performance of additively manufactured 17–4 PH stainless steel. Int J Adv Manuf Technol 126, 777–786 (2023). https://doi.org/10.1007/s00170-023-11146-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11146-1