Abstract

In this paper, a preventive maintenance scheme for a rotary ultrasonic vibration-assisted EDM machine is investigated. A preventive maintenance cost optimization model for machine tools was developed under the constraint of reliability. The model is simple and efficient and can be applied to rotary ultrasonic vibration-assisted EDM machine tool. The mathematical model is based on particle swarm optimization, which is solved by MATLAB to compare the differences in optimization results under different iterations, and the optimal preventive maintenance interval for the machine tool is 417 h according to the constraints, corresponding to a minimum maintenance cost, which effectively reduces the downtime loss and maintenance cost caused by the failure of machine tools, and provides a theoretical basis for the preventive maintenance plan of machine tools.

Similar content being viewed by others

Data availability

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

Prakash V, Kumar P, Singh PK et al (2019) Micro-electrical discharge machining of difficult-to-machine materials: a review. Proc Inst Mech Eng, Part B: J Eng Manuf 233(2):339–370. https://doi.org/10.1177/0954405417718591

Endo T, Tsujimoto T, Mitsui K (2008) Study of vibration-assisted micro-EDM—the effect of vibration on machining time and stability of discharge. Precis Eng 32(4):269–277. https://doi.org/10.1016/j.precisioneng.2007.09.003

Ghoreishi M, Atkinson J (2002) A comparative experimental study of machining characteristics in vibratory, rotary and vibro-rotary electro-discharge machining. J Mater Process Technol 120(1–3):374–384. https://doi.org/10.1016/S0924-0136(01)01160-8

Hsue AWJ, Hao TJ (2016) Comparison on gas bubble and pulse trains of deep-cavity electrical discharge machining with/without rotary ultrasonic assistance. Int J Adv Manuf Technol 87(5):2153–2164. https://doi.org/10.1007/s00170-016-8557-9

Goiogana M, Sarasua JA, Ramos JM et al (2016) Pulsed ultrasonic assisted electrical discharge machining for finishing operations. Int J Mach Tools Manuf 109:87–93. https://doi.org/10.1016/j.ijmacht-ools.2016.07.005

Lin YC, Chuang FP, Wang A et al (2014) Machining characteristics of hybrid EDM with ultrasonic vibration and assisted magnetic force. Int J Precis Eng Manuf 15(6):1143–1149. https://doi.org/10.1007/s12541-014-0449-z

Dong Y, Liu J, Li G et al (2022) Thermodynamic simulation modeling analysis and experimental research of vertical ultrasonic vibration assisted EDM. Int J Adv Manuf Technol 119(7):5303–5314. https://doi.org/10.1007/s00170-021-08604-z

Kremer D, Lhiaubet C, Moisan A (1991) A study of the effect of synchronizing ultrasonic vibrations with pulses in EDM. CIRP Ann 40(1):211–214. https://doi.org/10.1016/S0007-8506(07)61970-2

Chen Y, Feng X, Xin G (2021) Experimental study on ultrasonic vibration-assisted WECDM of glass microstructures with a high aspect ratio. Micromachines 12(2):125. https://doi.org/10.3390/mi12020125

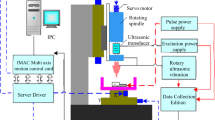

Yinghuai D, Jianbao S, Guangyan L et al (2021) Research on non-contact ultrasonic vibration assisted rotating electrical discharge machining (EDM) mach-ine tool. Int J Nanomanuf 17(1):1–12. https://doi.org/10.1504/IJNM.2021.10035737

Kaiyue LI, Zhang Y, Yang G et al (2014) Investigation on using combination process of ultrasonic vibration assisted grinding with EDM for machining particle reinforced metal matrix composite(PRMMCs). Hot Work Technol 43(16):123–127

Jiang Y, Zhao W, Xi X et al (2012) Vibration assisted EDM of small-holeusing voice coil motor. Procedia CIRP 1:645–650. https://doi.org/10.1016/j.proci-r.2012.05.014

Tong H, Li Y, Wang Y (2008) Experimental research on vibration assisted EDM of micro-structures with non-circular cross-section. J Mater Process Technol 208(1–3):289–298. https://doi.org/10.1016/j.jmatprotec.2007.12.126

Xu, M et al (2021) Reliability allocation of rotary ultrasonic vibration-assisted EDM machine tool based on maximum entropy ordered weighted average and constraint under the index of overall cost. Int J Adv Manuf Technol 1–10. https://doi.org/10.1007/s00170-021-07420-9

Dui H, Si S, Yam RCM (2017) A cost-based integrated importance measure of system components for preventive maintenance. Reliab Eng Syst Saf 168:98–104. https://doi.org/10.1016/j.ress.2017.05.025

Gong YJ, Li J, Zhou Y et al (2015) Genetic learning particle swarm optimization. IEEE trans cybern 46(10):2277–2290. https://doi.org/10.1109/TCYB.2015.2475174

Wang CH, Lin TW (2011) Improved particle swarm optimization to minimize periodic preventive maintenance cost for series-parallel systems. Expert Syst Appl 38(7):8963–8969. https://doi.org/10.1016/j.eswa.2011.01.113

Loganathan MK, Gandhi OP (2016) Maintenance cost minimization of manufacturing systems using PSO under reliability constraint. Int J Syst Assur Eng Manag 7(1):47–61. https://doi.org/10.1007/s13198-015-0374-2

Kumarappan N, Suresh K (2018) Particle swarm optimization based approach to maintenance scheduling using levelized risk method. 2008 Joint International Conference on Power System Technology and IEEE Power India Conference. IEEE 1–6. https://doi.org/10.1109/ICPST.2008.4745384

Yare Y, Venayagamoorthy GK (2010) Optimal maintenance scheduling of generators using multiple swarms-MDPSO framework. Eng Appl Artif Intell 23(6):895–910. https://doi.org/10.1016/j.engappai.2010.05.006

Li Hui (2016) Study on optimization of preventive maintenance period for gas pipeline based on particle swarm optimization. Dissertation, Xi’an University of Architecture and Technology

Jagtap HP, Bewoor AK, Kumar R et al (2020) Performance analysis and availability optimization to improve maintenance schedule for the turbo-generator subsystem of a thermal power plant using particle swarm optimization. Reliab Eng Syst Saf 204:107130. https://doi.org/10.1016/j.ress.2020.107130

Khalili-Damghani K, Abtahi AR, Tavana M (2013) A new multi-objective particle swarm optimization method for solving reliability redundancy allocation problems. Reliab Eng Syst Saf 111:58–75. https://doi.org/10.1016/j.ress.2012.10.009

Chou JS, Le TS (2011) Reliability-based performance simulation for optimized pavement maintenance. Reliab Eng Syst Saf 96(10):1402–1410. https://doi.org/10.1016/j.ress.2011.05.005

Lin D, Jin B, Chang D (2020) A PSO approach for the integrated maintenance model. Reliab Eng Syst Saf 193:106625. https://doi.org/10.1016/j.ress.2019.106625

Marseguerra M (2013) A MC-PSO approach to the failure probability evaluation of risky plant components: the maintenance design. Reliab Eng Syst Saf 111:1–8. https://doi.org/10.1016/j.ress.2012.09.009

Acitas S, Aladag CH (2019) Senoglu B (2019) A new approach for estimating the parameters of Weibull distribution via particle swarm optimization: an application to the strengths of glass fibre data. Reliab Eng Syst Saf 183:116–127. https://doi.org/10.1016/j.ress.2018.07.024

Li S, Chi X, Yu B (2022) An improved particle swarm optimization algorithm for the reliability redundancy allocation problem with global reliability. Reliab Eng Syst Saf 108604. https://doi.org/10.1016/j.ress.2022.108604

Li J, Chen J (2019) Solving time-variant reliability-based design optimization by PSO-t-IRS: a methodology incorporating a particle swarm optimization algorithm and an enhanced instantaneous response surface. Reliab Eng Syst Saf 191:106580. https://doi.org/10.1016/j.ress.2019.106580

Sibalija TV (2019) Particle swarm optimisation in designing parameters of manufacturing processes: a review (2008–2018). Appl Soft Comput 84:105743. https://doi.org/10.1016/j.asoc.2019.105743

Wang D, Tan D, Liu L (2018) Particle swarm optimization algorithm: an overview. Soft Comput 22(2):387–408. https://doi.org/10.1007/s00500-016-2474-6

Eriksen S, Utne IB, Lützen M (2021) An RCM approach for assessing reliability challenges and maintenance needs of unmanned cargo ships. Reliab Eng Syst Saf 210:107550. https://doi.org/10.1016/j.ress.2021.107550

Zheng R (2015) Parameter estimation of three-parameter Weibull distributio-n and its application in reliability analysis. J Vib Shock 34(5):78–81

Funding

The study is supported by the National Natural Science Foundation of China (51205505).

Author information

Authors and Affiliations

Contributions

Minggang Xu and Zhe Wang: validation, analysis, investigation, writing of the original draft.

Hao Fu and Mingyue Ma: Data calculation, analysis, investigation, writing review.

Wang Tian: investigation, analysis, writing review.

Corresponding author

Ethics declarations

Ethics approval

This paper is our original unpublished work, and it has not been submitted to any other journal for reviews.

Consent to participate

All authors were fully involved in the study and preparation of the manuscript; each of the authors has read and concurs with the content in the final manuscript.

Consent for publication

All authors consent to publish the content in the final manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, M., Wang, Z., Fu, H. et al. A preventive maintenance scheme for rotary ultrasonic vibration EDM machine tool based on PSO under reliability constraints. Int J Adv Manuf Technol 124, 4603–4613 (2023). https://doi.org/10.1007/s00170-022-10612-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10612-6