Abstract

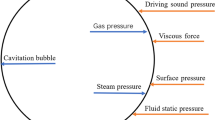

Fundamental observation of bubbles and debris in deep-cavity electrical discharge machining (EDM) with an ultrasonic spindle aimed at achieving higher machining efficiency is proposed and compared. Various discharge pulse trains for EDM, rotary EDM (R-EDM), ultrasonic vibration-assisted EDM (UA-EDM), and rotary ultrasonic EDM (RU-EDM) are investigated. Their effects on the removal efficiency, machining stability, and the tool wear rate are studied as well. It is found that EDM in deep cavity is actually discharged in the gas bubble most of the time except the short period at the very beginning stage. The main bubble at EDM tool jumping is maintained with a constant volume. And, the volume results in the boundary height of the bubble at the next EDM stroke. In which, ultrasonic vibration of sufficient strength was found to split main bubble quickly and improve the material removal rate at about 49 % through much higher frequency of pulse trains. Appended with rotation, the rotary ultrasonic vibration EDM can improve the tool wear rate but reduces the MRR in compared with conventional EDM.

Similar content being viewed by others

References

Ghoreishi M, Atkinson J (2002) A comparative experimental study of machining characteristics in vibratory, rotary and vibro-rotary EDM. J Mater Processing Tech 120(1–3):374–384

Kunieda M, Yoshida M (1997) Electrical discharge machining in Gas. CIRP Ann 46–1:143–146

Zhang QH, Zhang JH, Deng JX, Qin Y, Niu ZW (2002) Ultrasonic vibration electrical discharge machining in gas. J Mater Process Tech 129(1–3):135–138

Shervani Tabar MT, Shabgard MR (2010) Numerical study on the effect of the frequency and amplitude of the tool on the material removal rate in ultrasonic assisted electrical discharge machining. Proc IMechE Part B: J Eng Manuf 225:408–413

Prihandana GS, Muslim M, Hamdi M, Mitsui K (2011) Effect of low-frequency vibration on workpiece in EDM processes. J Mech Sci Tech 25(5):1231–1234

Cetin S, Okada A, Uno Y (2004) Effect of debris distribution on wall concavity in deep-hole EDM. Int J Series C of Japan Soc Mech Eng 47–2:553–558

Y.S. Liao, P.S. Wu, F.Y. Liang (2013) Study of debris exclusion effect in linear motor equipped die-sinking EDM process. Procedia CIRP 6:123–128

Hsue AW-J, Yan M-T, Chung C-H (2013) Effective pulses discriminator and control strategy for high speed direct-drive electrical discharge machining. J Chinese Soc Mech Eng 34(2):167–176

Wang J, Han F, Cheng G, Zhao F (2012) Debris and bubble movements during electrical discharge machining. Int J Mach Tool Manuf 58:11–18

Wang J, Han F (2014) Simulation model of debris and bubble movement in consecutive-pulse discharge of electrical discharge machining. Int J Mach Tool Manuf 77:56–65

Kitamura T, Kunieda M, Abe K (2014) Observation of relationship between bubbles and discharge locations in EDM using transparent electrodes. Prec Eng 40:26–32

Ji R, Liu Y, Zhang Y, Cai B, Ma J, Li X (2012) Influence of dielectric and machining parameters on the process performance for electric discharge milling of SiC ceramic. Int J Adv Manuf Technol 59(1–4):127–136

Ji R, Liu Y, Zhang Y, Cai B, Li H, Ma J (2010) Optimizing machining parameters of silicon carbide ceramics with ED milling and mechanical grinding combined process. Int J Adv Manuf Tech 51(1–4):195–204

Shervani-Tabar MT, Mobadersany N (2013) Numerical study of the dielectric liquid around an electrical discharge generated vapor bubble in ultrasonic assisted EDM. Ultrasonics 53:943–955

Koyano T, Hosokawa A, Suzuki S, Ueda T (2015) Influence of external hydrostatic pressure on machining characteristics of electrical discharge machining. Ann CIRP Manuf Tech 64:229–232

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declaration

1. This manuscript has not been published elsewhere nor has it been submitted for publication at the other journal.

2. Grammatical errors and writing style in the original version have been corrected by our colleague who is a native English speaker.

Conflict of interest

The authors declare that they have no conflicts of interest.

Electronic supplementary materials

Below is the link to the electronic supplementary material.

(WMV 17793 kb)

(WMV 18658 kb)

(WMV 19773 kb)

(WMV 17664 kb)

Rights and permissions

About this article

Cite this article

Hsue, A.WJ., Hao, TJ. Comparison on gas bubble and pulse trains of deep-cavity electrical discharge machining with/without rotary ultrasonic assistance. Int J Adv Manuf Technol 87, 2153–2164 (2016). https://doi.org/10.1007/s00170-016-8557-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8557-9