Abstract

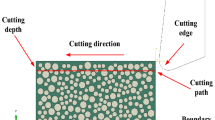

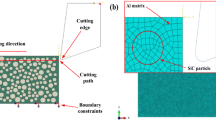

During milling, brittle fracture occurs in SiCp/Al composites due to extrusion, while plastic deformation occurs in the aluminum matrix. The damage of particles and the matrix is different. In order to observe the brittle fracture process of particles more accurately, a single particle milling model was established to analyze the damage and deformation of particles when cutting along different positions. In the study of the influence of cutting speed on particle failure, a two-dimensional simulation model with multi-particle random distribution was established. Keeping the cutting depth the same, only the cutting speed was varied to study its effect on the surface quality. Detailed analysis of the orthogonal test results shows that the influence on surface quality is from feed rate, milling speed, and milling depth in descending order. The optimal cutting conditions are milling speed of 47.10 m/min, feed speed of 10 mm/min, and cutting depth of 80 μm. Through the analysis of sub-surface morphology, the main causes of cracks, pits, and other defects on machined surfaces can be explained, and the experimental results are proved to be the same as the simulation results.

Similar content being viewed by others

Availability of data and material

The data used to support the findings of this study are available from the corresponding author upon request.

Abbreviations

- σ:

-

Flow stress

- \(\varepsilon\) :

-

Strain

- A:

-

Initial yield stress

- B:

-

Material strain hardening modulus

- C:

-

Strain rate strengthening index

- n:

-

Material hardening index

- \(\dot{\varepsilon }\) :

-

Effective plastic strain rate

- \(\dot{{\varepsilon }_{0}}\) :

-

Reference plastic strain rate

- T:

-

Deformation temperature

- \({T}_{r}\) :

-

Reference temperature

- \({T}_{m}\) :

-

Melting temperature

- m:

-

Temperature sensitivity constant

- \({\upvarepsilon }_{\mathrm{f}}\) :

-

Failure strain

- \(\mathrm{\Delta \varepsilon }\) :

-

Effective plastic strain increment in the state of increasing load units.

- \({\varepsilon }_{f}\) :

-

Plastic strain of the material

- \({D}_{1}\) to \({D}_{5}\) :

-

Material failure model coefficients

- \(p\) :

-

Main principal stress

- \(q\) :

-

Flow stress

- \({\upsigma }_{1},{\upsigma }_{2},{\upsigma }_{3}\) :

-

Principal stress components

- \({\sigma }_{0}\) :

-

Tensile stress of the material

- \({\mathrm{G}}_{\mathrm{f}}^{1}\) :

-

Type I fracture energy

- \({\upsigma }_{\mathrm{tu}}^{\mathrm{I}}\) :

-

Failure stress at the time of crack formation

- G:

-

Shear modulus of material failure

- \({\mathrm{e}}_{\mathrm{nn}}^{\mathrm{ck}}\) :

-

Crack extension strain

References

Wu Q, Si Y, Wang GS, Wang L (2016) Machinability of a silicon carbide particle-reinforced metal matrix composite. RSC Adv 6(26):21765–21775

Wang YF, Liao WH, Tang D, Yang K, Jang QF, Li L (2018) Research on cutting forces of ultra-precision cutting of Sicp/Al composites. IOP Conference 394

Lu SJ, Li ZQ, Zhang JJ, Zhang JG, Wang XH, Yan YD, Sun T (2020) Finite element investigation of the influence of SiC particle distribution on diamond cutting of SiCp/Al composites. Nanomanufac Metrol 3:251–259

Mabrouki T, Courbon C, Zhang YC, Rech J, Nélias D, Asad M, Hamdi H, Belhadi S, Salvatore F (2016) Some insights on the modelling of chip formation and its morphology during metal cutting operations. CR MECANIQUE 344(4–5):335–354

Shui XJ, Zhang YD, Wu Q (2014) Mesoscopic model for SiCP/Al composites and simulation on the cutting process. Appl Mech Mater 487:189–194

Teng XY, Chen WQ, Huo DH, Shyha I, Lin C (2018) Comparison of cutting mechanism when machining micro and nano particles reinforced SiC/Al metal matrix composites. COMPOS STRUCT 203:636–647

Zhang P, Yue X, Zhang Q, Zong C, Fang Y (2021) Investigation on the influence of SiC particle parameters on the machinability of SiCp/Al composite. Vacuum 191(5–8):110340

Yin WD, Duan CZ, Li YJ, Miao KQ (2021) Dynamic cutting force model for cutting SiCp/Al composites considering particle characteristics stochastic models. Ceram Int 47(24):35234–35247

Chen YF, Zhang X (2021) Study on the cutting mechanism of SiCp/Al considering particle size and distribution. INT J Adv Manuf Technol 115(4):1211–1225

Laghari RA, Li JG, Wu Y (2020) Study of machining process of SiCp/Al particle reinforced metal matrix composite using finite element analysis and experimental verification. Materials 13(23):5524

Yu WW, Chen J, Ming WW, An QL, Chen M (2020) Experimental and FEM study of cutting mechanism and damage behavior of ceramic particles in orthogonal cutting SiCp/Al composites. Ceram Int 47(5):7183–7194

Liu JW, Kai C, Ding H, Chen SJ, Zhao L (2018) An investigation of the influence of phases’ removal ways on surface quality in micro milling SiCp/Al composites. Procedia CIRP 71:59–64

Hou N, Zhou L, Huang ST, Xu LF (2021) finite element and experimental analysis of edge defects formation during orthogonal cutting of SiCp/Al composites.Adv Mater Res 500:146–151.

Dabade UA, Joshi SS (2009) Analysis of chip formation mechanism in machining of Al/SiCp metal matrix composites. J Mater Process Tech 209(10):4704–4710

Ghandehariun A, Kishawy HA, Umer U, Hussein HM (2015) Analysis of tool-particle interactions during cutting process of metal matrix composites. Int J Adv Manuf Technol 82(1–4):143–152

Liu C, Gao L, Jiang XG, Xu WW, Liu SN, Yang T (2020) Analytical modeling of subsurface damage depth in machining of SiCp/Al composites. INT J MECH SCI 185:105874

Funding

This work was supported by the National Natural Science Foundation of China (No. 51905083) and the Doctoral Start-up and Youth Project Fund of Liaoning Province (2019-BS-123).

Author information

Authors and Affiliations

Contributions

Zhang did all the milling experiments and wrote the papers. Gao guided Zhang to revise the paper. Wang made a parameter measurement of the material used in this experiment. Chen, Cui, and Yin helped with the experimental process. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval

This research project has been approved by the Ethics Committee of Liaoning University of Technology. The authors state that the research was conducted according to ethical standard.

Consent to participate

I solemnly declare that the paper “Study on the Milling Surface Quality of 20% Volume Fraction SiCp/Al Composites” presented by us is the result of our research. This paper does not contain any work published or written by any other individual or group, except for the content specifically noted and cited in the paper. I fully realize that the legal consequences of this statement shall be borne by me.

Consent for publication

That the work described has not been published before; that it is not under consideration for publication elsewhere; that its publication has been approved by all coauthors, if any; and that its publication has been approved by the responsible authorities at the institution where the work is carried out.

The author agrees to publication in the Journal indicated below and also to publication of the article in English by Springer in Springer’s corresponding English-language journal. The copyright to the English-language article is transferred to Springer effective if and when the article is accepted for publication. The author warrants that his/her contribution is original and that he/she has full power to make this grant. The author signs for and accepts responsibility for releasing this material on behalf of any and all coauthors. The copyright transfer covers the exclusive right to reproduce and distribute the article, including reprints, translations, photographic reproductions, microform, electronic form, or any other reproductions of similar nature. After submission of the agreement signed by the corresponding author, changes of authorship or in the order of the authors listed will not be accepted by Springer. Journal: The International Journal of Advanced Manufacturing Technology, chemical samples. Names of all contributing authors: Ke Zhang, Qi Gao, Quanzhao Wang, Ye Chen, Tianyang Cui, and Xunyu Yin.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, K., Gao, Q., Wang, Q. et al. Study on the milling surface quality of 20% volume fraction SiCp/Al composites. Int J Adv Manuf Technol 122, 1555–1566 (2022). https://doi.org/10.1007/s00170-022-09949-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09949-9