Abstract

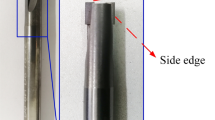

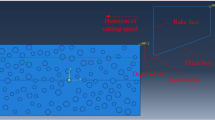

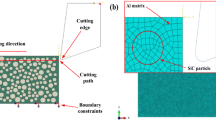

Directing at the hard machinability of high volume fraction 70% SiCp/Al composites, a longitudinal and torsional ultrasonic-assisted milling (LTUAM) method is proposed to improve the edge quality and machining efficiency. By observing the metallographic structure of the material, a three-dimensional (3D) finite element model of random distribution of spherical, elliptical and polygonal SiC particles is established and analyzed by ABAQUS simulation software. The formation mechanism of edge defects, stress distribution, defect characteristics and the effect of machining parameters on milling forces are investigated during ultrasonic-assisted milling. The results show that the edge defects appear at the inlet, outlet and middle edge position, especially is more serious at the outlet position. The SiC particles failure modes mainly include particle pullout, particle shearing, and crushing, moreover, the edge defects mainly include matrix tearing, edge breakage, burrs, bulges and pits. Ultrasonic-assisted milling (UAM) with a certain range of ultrasonic amplitude could effectively reduce the surface fragmentation rate and milling force, and it not only could slow down the expansion of cracks, but also increase the plastic flow of material, and obtain better edge quality compared with the traditional machining method. Comparing the results of finite element analysis and experimental tests, it shows that the simulation results are in good agreement with that of tests.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Chawla N, Shen Y-L (2001) Mechanical behavior of particle reinforced metal matrix composites. Adv Eng Mater 3(6):357–370

Basak A, Pramanik A, Prakash C (2019) Deformation and strengthening of SiC reinforced Al-MMCs during in-situ micro-pillar compression. Mater Sci Eng A 763:138141

Lu SJ, Zhang JJ, Li ZQ, Zhang JG, Wang XH, Hartmaier A, Xu JF, Yan YD, Sun T (2021) Cutting path-dependent machinability of SiCp/Al composite under multi-step ultra-precision diamond cutting. Chin J Aeronaut 34:241–252

Zhao GL, Mao PC, Li L, Iqbal A, He N (2020) Micro-milling of 65 vol% SiCp/Al composites with a novel laser-assisted hybrid process. Ceram Int 46:26121–26128

Zhou L, Cui C, Zhang P, Ma Z (2017) Finite element and experimental analysis of machinability during machining of high-volume fraction SiCp/Al composites. Int J Adv Manuf Technol 91:1935–1944

Kadivar MA, Akbari J, Yousefi R, Rahi A, Nick MG (2014) Investigating the effects of vibration method on ultrasonic-assisted drilling of Al/SiCp metal matrix composites. Robot Cim-Int Manuf 30(3):344–350

Aurich JC, Dornfeld D, Arrazola PJ (2009) Burrs—Analysis, control and removal. CIRP Ann 58(2):519–542

Yang B, Shen X, Lei S (2009) Mechanisms of edge chipping in laser-assisted milling of silicon nitride ceramics Int. J Mach Tool Manufact 49:344–350

Woo WS, Lee CM (2018) A study on the edge chipping according to spindle speed and inclination angle of workpiece in laser-assisted milling of silicon nitride. Opt Laser Technol 99:351–362

Chen J, An Q, Ming W, Chen M (2020) Investigation on machined surface quality in ultrasonic-assisted grinding of Cf/SiC composites based on fracture mechanism of carbon fibers. Int J Adv Manuf Technol 109:1583–1599

Chen J, Ming W, An Q, Chen M (2020) Mechanism and feasibility of ultrasonic-assisted milling to improve the machined surface quality of 2D Cf/SiC composites. Ceram Int 46(10):15122–15136

Wang J, Zha H, Feng P, Zhang J (2016) On the mechanism of edge chipping reduction in rotary ultrasonic drilling: A novel experimental method. Precis Eng 44:231–235

Juri AZ, Zhang YZ, Kotousov A, Ling Y (2021) Zirconia responses to edge chipping damage induced in conventional and ultrasonic vibration-assisted diamond machining. J Mater Res Technol 13:573–589

Fang B, Yuan Z, Li D, Gao L (2021) Effect of ultrasonic vibration on finished quality in ultrasonic vibration assisted micromilling of Inconel718. Chin J Aeronaut 34(6):209–219

Yadav AK, Bajpai V, Singh NK, Singh RK (2017) FE modeling of burr size in high- speed micro-milling of Ti6Al4V. Precis Eng 49:287–292

Yu W, Chen J, Ming W, An Q, Chen M (2021) Experimental and FEM study of cutting mechanism and damage behavior of ceramic particles in orthogonal cutting SiCp/Al composites. Ceram Int 47:7183–7194

Zhou L, Wang Y, Ma ZY, Yu XL (2014) Finite element and experimental studies of the formation mechanism of edge defects during machining of SiCp/Al composites. Int J Mach Tool Manufact 84:9–16

Niu Q, Jing L, Li C et al (2021) Study on effects of tool nose radius on the formation mechanism of edge defects during milling SiCp /Al composites. Int J Adv Manuf Technol 114:2261–2269

Nasr MNA, Ghandehariun A, Kishawy HA (2017) A physics-based model for metal matrix composites deformation during machining: a modified constitutive equation. J Eng Mater Technol 139(1):011003

Ghandehariun A, Kishawy HA, Umer U, Hussein HM (2016) Ontool–workpiece interactions during machining metal matrix composites: investigation of the effect of cutting speed. Int J Adv Manuf Technol 84:2423–2435

Wu J, Yu G, Gao Y, Wang L (2018) Mechatronics modeling and vibration analysis of a 2-DOF parallel manipulator in a 5-DOF hybrid machine tool. Mech Mach Theory 121:430–445

Wu J, Wang J, Lp W, Li T, Zheng Y (2009) Study on the stiffness of a 5-DOF hybrid machine tool with actuation redundancy. Mech Mach Theory 44(2):289–305

Wu J, Wang J, Li T, Wang LP (2007) Dynamic analysis of the 2-DOF planar parallel manipulator of a heavy duty hybrid machine tool

Funding

We are very grateful to the National Natural Science Foundation of China (No. 5197052714) for their strong support.

Author information

Authors and Affiliations

Contributions

Peicheng Peng: Methodology, Investigation, Formal analysis, Writing-review & editing. Daohui Xiang: Project administration, Formal analysis, Writing—review & editing. Xiaofei Lei: Data curation, Investigation. Zhanli Shi: Data curation, Investigation. Bo Li: Data curation, Investigation. Gaofeng Liu: Data curation, Investigation. Bo Zhao: Writing—review & editing. Guofu Gao: Writing—review & editing.

Corresponding author

Ethics declarations

Ethical approval

I would like to declare on behalf of my co-authors that the work described was an application that has not been published previously, and not under consideration for publication elsewhere, in whole or in part.

Consent to participate

All authors know and agree to be co-authors.

Consent to publish

All authors agreed to be published.

Conflict of interest

The authors have declared that there are no conflicts of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection: New Intelligent Manufacturing Technologies through the Integration of Industry 4.0 and Advanced Manufacturing

Rights and permissions

About this article

Cite this article

Peng, P., Xiang, D., Lei, X. et al. Study on the edge defects of high volume fraction 70% SiCp/Al composites in ultrasonic-assisted milling. Int J Adv Manuf Technol 122, 485–498 (2022). https://doi.org/10.1007/s00170-021-08586-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08586-y