Abstract

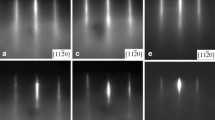

In this study, a radio-frequency plasma-assisted chemical beam epitaxy (RF-PACBE) system with low growing temperatures was used to grow high-quality indium nitride (InN) thin films. The prepared InN thin films were annealed through a line-shaped CO2 laser beam irradiation in an atmospheric environment at room temperature. The structural and electrical properties of InN thin films annealed with different CO2 laser annealing parameters were measured and analyzed. The crystalline grains turned into large and granular morphologies after the InN thin films were annealed under various feeding speeds of a motorized X-axis positioning stage. According to the measured XRD patterns and rocking curves, the InN (0 0 2) peak intensities of laser-annealed thin films were higher than those of as-grown InN thin films. All surface roughnesses and sheet resistances of laser-annealed InN thin films were higher and less than those of as-grown InN thin films. At the set feeding speed of 7.5 mm/s, the laser-annealed InN thin film had the largest grain size of 69.4 nm and the lowest sheet resistance of 20.21 ± 0.27 Ω/sq. The experimental results revealed that the proper annealing conditions could decrease grain boundaries and release internal stresses to enhance the electrical properties through adjusting feeding speeds.

Similar content being viewed by others

References

Sparvoli M, Gazziro M, Mansano R, Chubaci J, Jorge F, Onmori R (2018)Study of InN thin film for pulse oximeter application. Latin America Optics and Photonics Conference, pp Tu4A–41

Wu GG, Li WC, Shen CS, Gao FB, Liang HW, Wang H, Song LJ, Du GT (2012) Near infrared electroluminescence from n-InN/p-GaN light-emitting diodes. Appl Phys Lett 100:103504

Chowdhury FI, Alnuaimi A, Alkis S, Ortaç B, Aktürk S, Alevli M, Dietz N, Okyay AK, Nayfeh A (2016) Enhancement in c-Si solar cells using 16 nm InN nanoparticles. Mater Res Express 3:079502

Alizadeh M, Goh BT, Qadir KW, Yousefi H, Mehmood MS, Rasuli R (2019) Improvement of polycrystalline InN thin films properties by localized ion source under low RF plasma ambient. J Mater Sci: Mater Electron 30 :15534–15543

Lye KS, Kobayashi A, Ueno K, Ohta J, Fujioka H (2016) InN thin-film transistors fabricated on polymer sheets using pulsed sputtering deposition at room temperature.Appl Phys Lett 109:032106

Basilio AM, Hsu YK, Chang CC, Wei PC, Ganguly A, Shih HC, Chen YT, Chen LC, Chen KH (2010) Electrochemical characterization of InN thin films for biosensing applications. J New Mat Electrochem Syst 13(4):337–343

Rai SK, Kao KW, Agarwal A, Gwo SJ, Kumar A, Yeh JA (2018) Platinum coating on an ultrathin InN epilayer as a dual gas sensor for selective sensing of ammonia and acetone by temperature modulation for liver malfunction and diabetes applications. ECS J Solid State Sci Technol 7(7):Q3221–Q3229

Chen X, Liu H, Li Q, Chen H, Peng R, Chu S, Cheng B (2015) Terahertz detectors arrays based on orderly aligned InN nanowires. Sci Rep 5:13199

Zhang Z, Xiang G, Zhang J, Zhang J, Liu Y, Peng W, Zhou Y, Li R, Mei M, Zhao Y, Deng G, Wang H (2021) Preparation of InN films at different substrate temperatures and the effect of operating temperatures on the carrier transmission characteristics of p-NiO/n-InN heterojunction. Vacuum 194:110583

Li H, Zhang H, Wu H, Hao J, Liu C (2020) Tree-like structures of InN nanoparticles on agminated anodic aluminum oxide by plasma-assisted reactive evaporation. Appl Surf Sci 503:144309

Peng H, Feng X, Gong J, Wang W, Liu H, Quan Z, Pan S, Wang L (2018) Low temperature growth of polycrystalline InN films on non-crystalline substrates by plasma-enhanced atomic layer deposition. Appl Surf Sci 459:830–834

Chen WC, Chen HP, Lin YW, Liu DR (2019) Growth of narrow substrate temperature window on the crystalline quality of InN epilayers on AlN/Si(1 1 1) substrates using RF-MOMBE. J Cryst Growth 522:204–209

Mickevičius J, Dobrovolskas D, Steponavičius T, Malinauskas T, Kolenda M, Kadys A, Tamulaitis G (2018) Engineering of InN epilayers by repeated deposition of ultrathin layers in pulsed MOCVD growth. Appl Surf Sci 427:1027–1032

Liu G, Zhao S, Henderson RDE, Leonenko Z, Abdel-Rahman E, Mi Z, Ban D (2016) Nanogenerators based on vertically aligned InN nanowires. Nanoscale 8:2097–2106

Chang SP, Chen KJ, Kuo PJ, Chiou YZ (2012) Effects of surface treatment and annealing on properties of InN layers grown using metal organic chemical vapor deposition. Appl Mech Mater 271–272:190–196

Parr AA, Gill K, Gardiner DJ, Hoyland JD, Sands D, Brunson K, Carline RT (2002) A comparison of laser- and furnace-annealed polysilicon structure. Semicond Sci Technol 17:47–54

Maruyama T, Yorozu K, Noguchi T, Seki Y, Saito Y, Araki T, Nanishi Y (2003) Surface treatment of GaN and InN using (NH4)2Sx,. Phys Status Solidi C 0:2031–2034

Prepelita P, Craciun V, Garoi F, Staicu A (2015) Effect of annealing treatment on the structural and optical properties of AZO samples. Appl Surf Sci 352:23–27

Shih HI, Kim KH, Kim TW, Kim HK (2016) Fiber laser annealing of brush-painted ITO nanoparticles for use as transparent anode for organic solar cells. Ceram Int 42:13983–13989

Lin HK, Huang YJ, Shih WC, Chen YC, Chang WT (2019) Crystalline characteristics of annealed AlN films by pulsed laser treatment for solidly mounted resonator applications. BMC Chem 13:30

Tseng SF, Hsiao WT, Huang KC, Chiang D, Chou CP (2011) Mechanical and optoelectric properties of post-annealed fluorine-doped tin oxide films by ultraviolet laser irradiation. Appl Surf Sci 257:7204–7209

Li BJ, Wang YY, Huang LJ, Cao HD, Wang Q, Ren NF, Ding H (2018) Ultrasonic-vibration-assisted laser annealing of fluorine-doped tin oxide thin films for improving optical and electrical properties: Overlapping rate optimization. Ceram Int 44:2225–2234

Kang J, Koh JH (2020) The effect of Ga doping on ZnO thin films subjected to CO2 laser annealing. Ceram Int 46(8):10603–10609

Ding CF, Hsiao WT, Yong HT (2019) Evaluation of structural properties of AZO conductive films modification using low-temperature ultraviolet laser annealing. Ceram Int 45:16387–16398

Chung CK, Chuang KP, Cheng SY, Lin SL, Hsie KY (2013) Effect of solution contents on the evolution of microstructure and photoluminescence of laser-annealed rutile TiO2 thin films. J Alloys Compd 574:83–87

Chen MF, Lin K, Ho YS (2012) Laser annealing process of ITO thin films using beam shaping technology. Opt Lasers Eng 50:491–495

El Hamali SO, Cranton WM, Kalfagiannis N, Hou X, Ranson R, Koutsogeorgis DC (2016) Enhanced electrical and optical properties of room temperature deposited aluminium doped Zinc Oxide (AZO) thin films by excimer laser annealing. Opt Lasers Eng 80:45–51

Look DC, Lu H, Schaff WJ, Jasinski J, Liliental-Weber Z (2002) Donor and acceptor concentrations in degenerate InN. Appl Phys Lett 80:258–260

Bhuiyan AG, Hashimoto A, Yamamoto A (2003) Indium nitride (InN): a review on growth, characterization, and properties. J Appl Phys 94:2779–2808

Ratke L, Voorhees PW (2002) Growth and coarsening: Ostwald ripening in material processing, 1st edn. Springer, Berlin

Huang LJ, Li BJ, Ren NF (2016) Enhancing optical and electrical properties of Al-doped ZnO coated polyethylene terephthalate substrates by laser annealing using overlap rate controlling strategy. Ceram Int 42:7246–7252

Li BJ, Huang LJ, Ren NF, Kong X, Cai YL, Zhang JL (2015) Improving the performance of nickel-coated fluorine-doped tin oxide thin films by magnetic-field-assisted laser annealing. Appl Surf Sci 351:113–118

Alizadeh M, Goh BT, Pandey AK, Dee CF, Rahman SA (2017) Low-RF-power growth of InN thin films by plasma-assisted reactive evaporation with a localized ion source. Mater Chem Phys 199:408–415

Metzger T, Höpler R, Born E, Ambacher O, Stutzmann M, Stömmer R, Schuster M, Göbel H, Christiansen S, Albrecht M, Strunk HP (1998) Defect structure of epitaxial GaN films determined by transmission electron microscopy and triple-axis X-ray diffractometry. Philos Mag A 77:1013

Tseng SF (2018) Investigation of post-annealing aluminum-doped zinc oxide (AZO) thin films by a graphene-based heater. Appl Surf Sci 448:163–167

Asemi M, Ahmadi M, Ghanaatshoar M (2018) Preparation of highly conducting Al-doped ZnO target by vacuum heat-treatment for thin film solar cell applications. Ceram Int 44:12862–12868

Li BJ, Yang GY, Huang LJ, Zu W, Ren NF (2020) Performance optimization of SnO2:F thin films under quasi-vacuum laser annealing with covering a transparent PET sheet: a study using processing map. Appl Surf Sci 509:145334

Li BJ, Huang LJ, Zhou M, Ren NF, Wu B (2014) Surface morphology and photoelectric properties of fluorine-doped tin oxide thin films irradiated with 532 nm nanosecond laser. Ceram Int 40:1627–1633

Zamkovskaya A, Maksimova E, Nauhatsky I, Shapoval M (2017) X-ray diffraction investigations of the thermal expansion of iron borate FeBO3 crystals. J Phys: Conf Ser 929:012030

Ali AH, Hassan Z, Shuhaimi A (2018) Enhancement of optical transmittance and electrical resistivity of post-annealed ITO thin films RF sputtered on Si. Appl Surf Sci 443:544–547

Funding

This research is financially supported by the Ministry of Science and Technology (MOST), Taiwan under grant nos. MOST 110-2221-E-027-076 and MOST 110-2622-E-027-032.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflicts of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tseng, SF., Wang, CJ. & Chen, WC. Investigation of line-shaped CO2 laser annealing on InN/AlN/sapphire substrates. Int J Adv Manuf Technol 120, 5687–5696 (2022). https://doi.org/10.1007/s00170-022-09130-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09130-2