Abstract

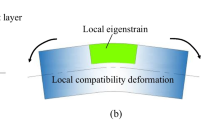

Origami-based sheet metal (OSM) bending is a promising new die-free folding technique for sheet metal. OSM bending principle is based on deforming the material along a pre-defined fold line, which is determined using material discontinuity (MD) produced by laser or waterjet cutting. The objective of this work is to study and evaluate the fracture in OSM bending under the influence of various MD types, kerf-to-thickness (k/t) ratios, and sheet thicknesses. The research goal is to provide information on selecting an optimized k/t ratio and type of MD that allows for fracture-free bending. Four different ductile fracture criteria (DFC) are used and calibrated from experimental data to forecast fracture. The DFC calibration is used to produce a set of critical damage values (CDV) for assessing the possibility of fracture in the OSM bending. In addition, the study provides fracture evaluation using finite element analysis (FEA) integrated with experimental cases for a broader range of OSM bending parameters and MDs. The results demonstrated that an MD with a higher k/t ratio is less likely to fracture during the OSM bending, whereas a higher sheet thickness increases the possibility of fracture. Furthermore, the study identifies the k/t ratio limit that ensures successful bending without fracture and categorizes MD types into two groups based on fracture likelihood. The fracture in the first group is dependent on the limiting k/t ratio, whereas the possibility of fracture in the second group is independent of the k/t ratio due to its topology.

Similar content being viewed by others

Abbreviations

- 2-D:

-

Two-dimensional

- 3-D:

-

Three-dimensional

- CDV:

-

Critical damage value

- D i (i = CL, B, A, RT):

-

Damage values corresponding to each of these DFC

- DFC:

-

Ductile fracture criteria

- DV:

-

Damage value

- ε̅ p :

-

Equivalent plastic strain

- \({\overline{\varepsilon }}_{p}^{f}\) :

-

Equivalent plastic strain at fracture

- ϵ:

-

True strain

- \({\upepsilon }_{u}\) :

-

Ultimate true strain

- FFLD:

-

Fracture forming limit diagram

- FEA:

-

Finite element analysis

- FLD:

-

Forming limit diagrams

- g :

-

Punch placement

- k/t ratio:

-

Kerf-to-thickness ratio

- MD:

-

Material discontinuity

- OSM:

-

Origami-based sheet metal

- R p :

-

Punch radius

- s :

-

Offset distance

- SSE:

-

Error sum of squares

- σ :

-

True stress

- σ i (i = 1,2,3):

-

Principal stresses

- σ eq :

-

Equivalent stress

- σ h :

-

Hydrostatic stress

- σ u :

-

Ultimate true stress

- W :

-

Weight factor

References

Turner N, Goodwine B, Sen M (2015) A review of origami and its applications in mechanical engineering. J Mech Eng Sci 1–18. https://doi.org/10.1177/0954406215597713

Lang RJ, Tolman K, Crampton E et al (2018) Accommodating thickness in origami-inspired engineered systems. Appl Mech Rev 70:1–20. https://doi.org/10.1115/1.4039314

Edmondson BJ, Lang RJ, Howell LL (2014) An offset panel technique for thick rigidly foldable origami. In ASME 2014 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, IDETC/CIE 2014. New York, USA, pp 1–8

Crampton EB, Magleby SP, Howell LL (2017) Realizing origami mechanism from metal sheets. The ASME 2017 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference IDETC/CIE 2017. Cleveland, USA, pp 1–10

Wu W, You Z (2011) A solution for folding rigid tall shopping bags. Proc R Soc A Math Phys Eng Sci 467:2561–2574. https://doi.org/10.1098/rspa.2011.0120

Durney MW, Pendley AD, Rappaport IS (2006) Techniques for designing and manufacturing precision-folded, high strength, fatigue-resistant structures and sheet therefor 1–64

Ablat MA, Qattawi A (2018) Finite element analysis of origami-based sheet metal folding process. J Eng Mater Technol 140:031008. https://doi.org/10.1115/1.4039505

Ablat MA, Qattawi A (2019) Investigating the design and process parameters of folded perforated sheet metal. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-018-3149-5

Ablat MA, Qattawi A, Jaman MS et al (2020) An experimental and analytical model for force prediction in sheet metal forming process using perforated sheet and origami principles. Procedia Manuf 48:407–418. https://doi.org/10.1016/j.promfg.2020.05.063

Kuo CC, Li MR (2016) A cost-effective method for rapid manufacturing sheet metal forming dies. Int J Adv Manuf Technol 85:2651–2656. https://doi.org/10.1007/s00170-015-8139-2

Qattawi A (2012) Extending origami technique to fold forming of sheet metal. PhD Dissertation, Clemson University

Qattawi A, Mayyas A, Thiruvengadam H et al (2014) Design considerations of flat patterns analysis techniques when applied for folding 3-D sheet metal geometries. J Intell Manuf 25:109–128. https://doi.org/10.1007/s10845-012-0679-9

Qattawi A, Abdelhamid M, Mayyas A, Omar M (2014) Design analysis for origami-based folded sheet metal parts. SAE Int J Mater Manuf 7:488–498. https://doi.org/10.4271/2014-01-9098

Venhovens P, Bell K, Marathe P et al (2013) Application of a novel metal folding technology for automotive BiW design. SAE Int J Passeng Cars - Mech Syst 6:584–600. https://doi.org/10.4271/2013-01-0373

Shi Q, Shi X, Gattas JM, Kitipornchai S (2017) Folded assembly methods for thin-walled steel structures. J Constr Steel Res 138:235–245. https://doi.org/10.1016/j.jcsr.2017.07.010

Shi Q, Heitzmann MT, Gattas JM (2020) Nonlinear rotational stiffness and clash prevention in perforated steel fold lines. Eng Struct 209:110218

Nikhare CP (2019) Bending and springback analysis on sheet metal material discontinuity. In ASME 2019 14th International Manufacturing Science and Engineering Conference, MSEC 2019, pp 1–7

Emmens WC (2011) Formability: a review of parameters and processes that control, limit or enhance the formability of sheet metal. Springer, Heidelberg Dordrecht London New York

Hajian M, Assempour A (2014) Experimental and numerical determination of forming limit diagram for 1010 steel sheet: a crystal plasticity approach. Int J Adv Manuf Technol 76:1757–1767. https://doi.org/10.1007/s00170-014-6339-9

Zhang R, Shao Z, Shi Z et al (2021) Effect of cruciform specimen design on strain paths and fracture location in equi-biaxial tension. J Mater Process Technol 289. https://doi.org/10.1016/j.jmatprotec.2020.116932

Zhang R, Shi Z, Shao Z et al (2021) Biaxial test method for determination of FLCs and FFLCs for sheet metals: validation against standard Nakajima method. Int J Mech Sci 209:106694. https://doi.org/10.1016/j.ijmecsci.2021.106694

Lou Y, Huh H, Lim S, Pack K (2012) New ductile fracture criterion for prediction of fracture forming limit diagrams of sheet metals. Int J Solids Struct 49:3605–3615. https://doi.org/10.1016/j.ijsolstr.2012.02.016

Alipour M, Torabi MA, Sareban M et al (2020) Finite element and experimental method for analyzing the effects of martensite morphologies on the formability of DP steels. Mech Based Des Struct Mach 48:525–541

He J, Cedric Xia Z, Zeng D, Li S (2013) Forming limits of a sheet metal after continuous-bending-under-tension loading. J Eng Mater Technol 135:031009. https://doi.org/10.1115/1.4023676

Isik K, Silva MB, Tekkaya AE, Martins PAF (2014) Formability limits by fracture in sheet metal forming. J Mater Process Technol 214:1557–1565. https://doi.org/10.1016/j.jmatprotec.2014.02.026

Güler B, Efe M (2017) Large strain cruciform biaxial testing for FLC detection. AIP Conf Proc 1896. https://doi.org/10.1063/1.5007975

Banabic D, Barlat F, Cazacu O, Kuwabara T (2020) Advances in anisotropy of plastic behaviour and formability of sheet metals. Int J Mater Form 13:749–787

Jeswiet J, Micari F, Hirt G et al (2005) Asymmetric single point incremental forming of sheet metal. CIRP Ann - Manuf Technol 54:88–114. https://doi.org/10.1016/S0007-8506(07)60021-3

Stoughton TB, Yoon JW (2011) A new approach for failure criterion for sheet metals. Int J Plast 27:440–459. https://doi.org/10.1016/j.ijplas.2010.07.004

Hu Q, Zhang F, Li X, Chen J (2018) Overview on the prediction models for sheet metal forming failure: necking and ductile fracture. Acta Mech Solida Sin 31:259–289. https://doi.org/10.1007/s10338-018-0026-6

Wierzbicki T, Bao Y, Lee YW, Bai Y (2005) Calibration and evaluation of seven fracture models. Int J Mech Sci 47:719–743. https://doi.org/10.1016/j.ijmecsci.2005.03.003

Cockcroft MG, Latham DJ (1968) Ductility and the workability of metals. J Inst Met 96:33–39

Talebi-Ghadikolaee H, Naeini HM, Mirnia MJ et al (2020) Ductile fracture prediction of AA6061-T6 in roll forming process. Mech Mater 148:103498. https://doi.org/10.1016/j.mechmat.2020.103498

Brozzo P, Deluca B, Rendina D (1972) A new method for the prediction of formability limits in metal sheets. In Sheet Metal Forming and Formability: Proceedings of the 7th biennial Conference of the International Deep Drawing Research Group

Mahalle G, Kotkunde N, Gupta AK, Singh SK (2020) Comparative assessment of failure strain predictions using ductile damage criteria for warm stretch forming of IN718 alloy. Int J Mater Form. https://doi.org/10.1007/s12289-020-01588-3

Ayada M (1987) Central bursting in extrusion of inhomogeneous materials. In: Proceedings of 2nd International Conference on Technology for Plasticity. Stuttgart, Germany, pp 553–558

Talebi-Ghadikolaee H, Naeini HM, Mirnia MJ et al (2020) Fracture analysis on U-bending of AA6061 aluminum alloy sheet using phenomenological ductile fracture criteria. Thin-Walled Struct 148:106566. https://doi.org/10.1016/j.tws.2019.106566

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields. J Mech Phys Solids 17:201–217. https://doi.org/10.1016/0022-5096(69)90033-7

Hu XH, Choi KS, Sun X, Golovashchenko SF (2014) Edge fracture prediction of traditional and advanced trimming processes for AA6111-T4 sheets. J Manuf Sci Eng 136:021016. https://doi.org/10.1115/1.4026273

Fu Z, Chen W, Tian X, Hu B (2014) Modeling and simulation for multiple-step incremental air-bending forming of sheet metal. Int J Adv Manuf Technol 72:561–570. https://doi.org/10.1007/s00170-014-5708-8

ASTM International (2009) ASTM E8/E8M-13 standard test methods for tension testing of metallic materials. West Conshohocken, PA

Ling Y (2004) Uniaxial true stress-strain after necking. AMP J Technol 5:37–48

Hyun HC, Kim M, Bang S, Lee H (2014) On acquiring true stress-strain curves for sheet specimens using tensile test and FE analysis based on a local necking criterion. J Mater Res 29:695–707. https://doi.org/10.1557/jmr.2014.24

Yang SY, Tong W (2009) A finite element analysis of a tapered flat sheet tensile specimen. Exp Mech 49:317–330. https://doi.org/10.1007/s11340-009-9241-x

Wang L, Tong W (2015) Identification of post-necking strain hardening behavior of thin sheet metals from image-based surface strain data in uniaxial tension tests. Int J Solids Struct 75–76:12–31. https://doi.org/10.1016/j.ijsolstr.2015.04.038

Arola D, Ramulu M (1997) Material removal in abrasive waterjet machining of metals a residual stress analysis. Wear 211:302–310. https://doi.org/10.1016/S0043-1648(97)00131-2

Funding

This work was partially supported by Hellman Fellow Fund.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ablat, M.A., Alafaghani, A., Sun, JQ. et al. Investigating fracture failure in origami-based sheet metal bending. Int J Adv Manuf Technol 119, 5335–5363 (2022). https://doi.org/10.1007/s00170-021-08576-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08576-0