Abstract

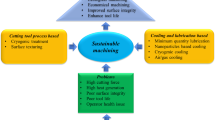

Superalloys are vastly used in the aerospace industry due to their alluring properties such as maintaining their strength at high-temperature applications. Nevertheless, manufacturing these raw materials to the desired geometrical shapes is one of the main challenges of the subtractive manufacturing industry and they are categorized as hard-to-machine materials. Several approaches such as high-speed machining (HSM), cryogenic cooling, minimum quantity lubrication (MQL), and heat-assisted machining (HAM) are introduced to tackle this matter.

HAM is a technique that introduces external heat sources to the workpiece (pre-heating or real-time heating methods) to increase the ductility of the superalloy and therefore reduce the yield and shear strength of the workpiece. By this means, the machining parameters demonstrate an improvement compared to conventional machining.

This review article focuses on the research approaches conducted to evaluate the effect of the various heat source applications (gas flame, induction, laser, and plasma) on the material properties and the machinability of the superalloys. Additionally, the heating methodology and heat assistance impact on cutting parameters (forces, tool life, surface integrity, and chip morphology) are outlined. Finally, a comparison of the heat source efficiency and the economics of the various heat applications is performed.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

Abbreviations

- \(\alpha\) :

-

Beam divergence

- \(\Delta t\) :

-

Pulse duration

- \(\varepsilon\) :

-

Electrical permittivity

- \(\eta\) :

-

Thermal efficiency

- \(\mu\) :

-

Magnetic Permeability

- \(\rho\) :

-

Electrical Resistivity

- \({\rho }_{t}\) :

-

Density

- \(\sigma\) :

-

Electrical Conductivity

- \(b\) :

-

Width of Cut

- \(C\) :

-

Specific heat

- \({d}_{s}\) :

-

Laser spot diameter

- \(D\) :

-

Diameter

- \(\overline{D }\) :

-

Electric flux density

- \({f}_{r}\) :

-

Feed per revolution

- \({F}_{f}\) :

-

Feed Force

- \({F}_{l}\) :

-

Focal length of the lens

- \({F}_{r}\) :

-

Radial Force

- \({F}_{t}\) :

-

Tangential Force

- \(h\) :

-

Depth of Cut

- \({T}_{s}\) :

-

Surface thermal

- \(V\) :

-

Voltage

- \(\overline{H }\) :

-

Magnetic field intensity

- \(i\) :

-

Inclination angle

- \(I\) :

-

Current

- \(\overline{J }\) :

-

Current Density

- \(k\) :

-

Thermal conductivity

- \({K}_{fc}\) :

-

Feed Cutting Constant

- \({K}_{fe}\) :

-

Feed Edge Constant

- \({K}_{rc}\) :

-

Radial Cutting Constant

- \({K}_{re}\) :

-

Radial Edge Constant

- \({K}_{tc}\) :

-

Tangential Cutting Constant

- \({K}_{te}\) :

-

Tangential Edge Constant

- \({L}_{p}\) :

-

Laser power

- \({P}_{d}\) :

-

Power density

- \(q\) :

-

Heat generation rate

- \(Q\) :

-

Input power

- \(r\) :

-

Radius

- \(t\) :

-

Time

- \(T\) :

-

Temperature

- \({T}_{0}\) :

-

Initial thermal

- \({V}_{c}\) :

-

Cutting speed/Velocity

- \(x\) :

-

Length in cutting direction

References

Popli D, Gupta M (2017) Experimental study and optimization of cutting parameters in machining of super alloy with hybrid ultrasonic method. Adv Manuf 5:199–216. https://doi.org/10.1007/s40436-017-0185-6

Shen Y, Liu Y, Dong H et al (2017) Surface integrity of Inconel 718 in high-speed electrical discharge machining milling using air dielectric. Int J Adv Manuf Technol 90:691–698. https://doi.org/10.1007/s00170-016-9332-7

Fang N, Pai PS, Edwards N (2013) A comparative study of high-speed machining of Ti-6Al-4V and Inconel 718 - Part I: Effect of dynamic tool edge wear on cutting forces. Int J Adv Manuf Technol 68:1839–1849. https://doi.org/10.1007/s00170-013-4981-2

Ma J-W, Wang F-J, Jia Z-Y et al (2014) Study of machining parameter optimization in high speed milling of Inconel 718 curved surface based on cutting force. Int J Adv Manuf Technol 75:269–277. https://doi.org/10.1007/s00170-014-6115-x

Yazid MZA, Ibrahim GA, Said AYM et al (2011) Surface integrity of Inconel 718 when finish turning with PVD coated carbide tool under MQL. Procedia Eng 19:396–401. https://doi.org/10.1016/j.proeng.2011.11.131

Akca E, Gürsel A (2015) A Review on Superalloys and IN718 Nickel-Based INCONEL Superalloy. Period Eng Nat Sci 3. https://doi.org/10.21533/pen.v3i1.43

Pramanik A (2014) Problems and solutions in machining of titanium alloys. Int J Adv Manuf Technol 70:919–928. https://doi.org/10.1007/s00170-013-5326-x

Ax M, Manohar M, Madhukar PM, Jeyapandiarajan P (2017) Experimental investigation of work hardening, residual stress and microstructure during machining Inconel 718. J Mech Sci Technol 31:4789–4794. https://doi.org/10.1007/s12206-017-0926-2

Qi Z, Li B, Xiong L (2014) The formation mechanism and the influence factor of residual stress in machining. Front Mech Eng 9:265–269. https://doi.org/10.1007/s11465-014-0311-0

Cai X, Qin S, Li J et al (2014) Experimental investigation on surface integrity of end milling nickel-based alloy-inconel 718. Mach Sci Technol 18:31–46. https://doi.org/10.1080/10910344.2014.863627

Jin D, Liu Z (2012) Effect of cutting speed on surface integrity and chip morphology in high-speed machining of PM nickel-based superalloy FGH95. Int J Adv Manuf Technol 60:893–899. https://doi.org/10.1007/s00170-011-3679-6

Ezugwu EO (2004) High Speed Machining of Aero-Engine Alloys. J Brazilian Soc Mech Sci Eng 26:1–11. https://doi.org/10.1590/S1678-58782004000100001

Kuzu AT, Bijanzad A, Bakkal M (2015) Experimental Investigations of Machinability in the Turning of Compacted Graphite Iron using Minimum Quantity Lubrication. Mach Sci Technol 19:559–576. https://doi.org/10.1080/10910344.2015.1085313

Singh GR, Gupta MK, Mia M, Sharma VS (2018) Modeling and optimization of tool wear in MQL-assisted milling of Inconel 718 superalloy using evolutionary techniques. Int J Adv Manuf Technol 97:481–494. https://doi.org/10.1007/s00170-018-1911-3

Kaynak Y (2014) Evaluation of machining performance in cryogenic machining of Inconel 718 and comparison with dry and MQL machining. Int J Adv Manuf Technol 72:919–933. https://doi.org/10.1007/s00170-014-5683-0

Nandy AK, Gowrishankar MC, Paul S (2009) Some studies on high-pressure cooling in turning of Ti-6Al-4V. Int J Mach Tools Manuf 49:182–198. https://doi.org/10.1016/j.ijmachtools.2008.08.008

Dudzinski D, Devillez A, Moufki A et al (2004) A review of developments towards dry and high speed machining of Inconel 718 alloy. Int J Mach Tools Manuf 44:439–456. https://doi.org/10.1016/S0890-6955(03)00159-7

Umbrello D (2013) Investigation of surface integrity in dry machining of Inconel 718. Int J Adv Manuf Technol 69:2183–2190. https://doi.org/10.1007/s00170-013-5198-0

Zhou J, Bushlya V, Avdovic P, Ståhl JE (2012) Study of surface quality in high speed turning of Inconel 718 with uncoated and coated CBN tools. Int J Adv Manuf Technol 58:141–151. https://doi.org/10.1007/s00170-011-3374-7

Hao ZP, Fan YH, Lin JQ, Yu ZX (2015) Wear characteristics and wear control method of PVD-coated carbide tool in turning Inconel 718. Int J Adv Manuf Technol 78:1329–1336. https://doi.org/10.1007/s00170-014-6752-0

Sun S, Brandt M, Dargusch MS (2010) International Journal of Machine Tools & Manufacture Thermally enhanced machining of hard-to-machine materials — A review. Int J Mach Tools Manuf 50:663–680. https://doi.org/10.1016/j.ijmachtools.2010.04.008

Ravi AM, Murigendrappa SM, Mukunda PG (2014) Experimental investigation on thermally enhanced machining of high-chrome white cast iron and to study its machinability characteristics using Taguchi method and artificial neural network. Int J Adv Manuf Technol 72:1439–1454. https://doi.org/10.1007/s00170-014-5752-4

Anderson M, Patwa R, Shin YC (2006) Laser-assisted machining of Inconel 718 with an economic analysis. Int J Mach Tools Manuf 46:1879–1891. https://doi.org/10.1016/j.ijmachtools.2005.11.005

Bermingham MJ, Schaffarzyk P, Palanisamy S, Dargusch MS (2014) Laser-assisted milling strategies with different cutting tool paths. Int J Adv Manuf Technol 74:1487–1494. https://doi.org/10.1007/s00170-014-6093-z

Kumar A, Maity K (2018) Engineering Science and Technology, an International Journal Experimental investigation on tool life and chip morphology in hot machining of Monel-400. Eng Sci Technol an Int J 21:371–379. https://doi.org/10.1016/j.jestch.2018.04.003

Kumar A, Maity K (2019) Numerical and experimental analysis of specific cutting energy in hot turning of Inconel 718. Measurement 133:361–369. https://doi.org/10.1016/j.measurement.2018.10.033

Lei S, Pfefferkorn F (2007) A review of thermally assisted machining. Proc ASME Int Manuf Sci Eng Conf 2007(MSEC2007):325–336. https://doi.org/10.1115/MSEC2007-31096

Machinability T, Baili M, Wagner V, Dessein G (2011) An Experimental Investigation of Hot Machining with Induction to Improve An experimental investigation of hot machining with induction to improve Ti-5553 machinability. 2018–2022. https://doi.org/10.4028/www.scientific.net/AMM.62.67

Kim EJ, Lee CM (2019) A study on the optimal machining parameters of the induction assisted milling with Inconel 718. Materials (Basel) 12:233. https://doi.org/10.3390/ma12020233

Kibria G, Doloi B, Bhattacharyya B (2013) Investigation and analysis on pulsed Nd:YAG laser micro-turning process of aluminium oxide (Al2O3) ceramic at various laser defocusing conditions. Int J Adv Manuf Technol 76:17–27. https://doi.org/10.1007/s00170-013-5254-9

Meijer J (2004) Laser beam machining (LBM), state of the art and new opportunities. J Mater Process Technol 149:2–17. https://doi.org/10.1016/j.jmatprotec.2004.02.003

Dubey AK, Yadava V (2008) Laser beam machining-A review. Int J Mach Tools Manuf 48:609–628. https://doi.org/10.1016/j.ijmachtools.2007.10.017

Azhdari Tadavani S, Shoja Razavi R, Vafaei R (2017) Pulsed laser-assisted machining of Inconel 718 superalloy. Opt Laser Technol 87:72–78. https://doi.org/10.1016/j.optlastec.2016.07.020

Ahmed N, Darwish S, Alahmari AM, Shar MA (2016) Micro-channels by Nd:YAG laser beam machining: fabrication, microstructures, and micro-hardness profiles. Int J Adv Manuf Technol 85:1955–1968. https://doi.org/10.1007/s00170-015-7257-1

Kim DH, Lee CM (2014) A study of cutting force and preheating-temperature prediction for laser-assisted milling of Inconel 718 and AISI 1045 steel. Int J Heat Mass Transf 71:264–274. https://doi.org/10.1016/j.ijheatmasstransfer.2013.12.021

Lee CM, Kim DH, Baek JT, Kim EJ (2016) Laser-assisted milling device: A review. Int J Precis Eng Manuf - Green Technol 3:199–208. https://doi.org/10.1007/s40684-016-0027-1

Lee Y, Lee C (2019) A Study on Optimal Machining Conditions and Energy Efficiency in Plasma Assisted Machining of Ti-6Al-4V. Materials 12:2590

Moon SH, Lee CM (2018) A study on the machining characteristics using plasma-assisted machining of AISI 1045 steel and Inconel 718. Int J Mech Sci 142–143:595–602. https://doi.org/10.1016/j.ijmecsci.2018.05.020

Chen SH, Tsai KT (2017) The study of plasma-assisted machining to Inconel-718. Adv Mech Eng 9:1–7. https://doi.org/10.1177/1687814017735789

Hadzley ABM, Hafiz SM, Azahar W et al (2015) Heat-assisted machining for material removal improvement. IOP Conf Ser Mater Sci Eng 88:12052. https://doi.org/10.1088/1757-899X/88/1/012052

Shams OA, Pramanik A, Chandratilleke TT (2017). Thermal-Assisted Machining of Titanium Alloys. https://doi.org/10.1007/978-3-319-56099-1

López De Lacalle LN, Sánchez JA, Lamikiz A, Celaya A (2004) Plasma assisted milling of heat-resistant superalloys. J Manuf Sci Eng Trans ASME 126:274–285. https://doi.org/10.1115/1.1644548

Prasad Rambabu N, Eswara Prasad VVK, Wanhill RJH (2017) Aerospace Materials and Material Technologies, Volume 1: Aerospace Material Technologies. Aerosp Mater Mater Technol Aerosp Mater 1:586. https://doi.org/10.1007/978-981-10-2134-3

Davis JR (2001) ASM specialty handbook: nickel, cobalt, and their alloys. ASM International

Zielińska M, Yavorska M, Poreba M, Sieniawski J (2010) Thermal properties of cast nickel based superalloys. Arch Mater Sci Eng 44:35–38

Youssef HA (2015) Machining of stainless steels and super alloys: Traditional and nontraditional techniques. John Wiley & Sons, New York. https://doi.org/10.1002/9781118919514

Lee JA (2012) Hydrogen embrittlement of nickel, cobalt, and iron-based superalloys. Gaseous HydrogEmbrittlement Mater Energy Technol Probl its Characterisation Eff Part Alloy Classes 624–667.https://doi.org/10.1533/9780857093899.3.624

Ducki KJ (2015) Analysis of the Precipitation and Growth Processes of the Intermetallic Phases in a Fe-Ni Superalloy. Superalloys. https://doi.org/10.5772/61159

Kitaguchi H (2012) Microstructure-Property Relationship in Advanced Ni-Based Superalloys. Metall - Adv Mater Process. https://doi.org/10.5772/52011

Graybill B, Li M, Malawey D, et al (2018) Additive manufacturing of nickel-based superalloys. ASME 2018 13th Int Manuf Sci Eng Conf MSEC 2018 1: https://doi.org/10.1115/MSEC2018-6666

Heilmaier M, Reppich B (1996) Creep lifetime prediction of oxide-dispersion-strengthened nickel-base superalloys: A micro mechanically based approach. Metall Mater Trans A Phys Metall Mater Sci 27:3861–3870. https://doi.org/10.1007/bf02595635

Zhang Z, Liu D, Yang Y et al (2019) Microstructure evolution of nickel-based superalloy with periodic thermal parameters during rotary tube piercing process. Int J Adv Manuf Technol 104:3991–4006. https://doi.org/10.1007/s00170-019-04126-x

Razumovskiy VI, Scheiber D, Razumovskii IM et al (2018) New Cr-Ni-base alloy for high-temperature applications designed on the basis of first-principles calculations. Adv Condens Matter Phys 2018:9383981. https://doi.org/10.1155/2018/9383981

Tsai YC, Hsieh JM (2005) An analysis of cutting-edge curves and machining performance in the Inconel 718 machining process. Int J Adv Manuf Technol 25:248–261. https://doi.org/10.1007/s00170-003-1869-6

Machining Nickel Alloys, Nickel Development Institute Reference Book, (1995). Series No 11008

B. Geddes, H. Leon, X. Huang, (2009) Superalloys: Alloying and Performance, ASTM International,

Sarikaya M, Gullu A (2015) Examining of Tool Wear in Cryogenic Machining of Cobalt-Based Haynes 25 Superalloy. Int J Mater Metallurg Eng 9(8):751–755

Tian X, Zhao J, Zhao J et al (2013) Effect of cutting speed on cutting forces and wear mechanisms in high-speed face milling of Inconel 718 with Sialon ceramic tools. Int J Adv Manuf Technol 69:2669–2678. https://doi.org/10.1007/s00170-013-5206-4

Montazeri S, Aramesh M, Veldhuis SC (2019) An investigation of the effect of a new tool treatment technique on the machinability of Inconel 718 during the turning process. Int J Adv Manuf Technol 100:37–54. https://doi.org/10.1007/s00170-018-2669-3

Stephenson D, Agapiou J (2016) Metal Cutting Theory and Practise. CRC Press

Altintas Y (2012) Manufacturing Automation, 2nd edn. Cambridge University Press, Cambridge. https://doi.org/10.1017/CBO9780511843723

Filho JMC (2012) Prediction of cutting forces in mill turning through process simulation using a five-axis machining center. Int J Adv Manuf Technol 58:71–80. https://doi.org/10.1007/s00170-011-3391-6

Krystof J (1939) Berichte uber Betriebswissenschaftliche Arbeiten, VDI Verlag. Bd., 12,

Shaffer BW, Lee EH (1951) Theory of plasticity applied to the problem of machining. J Appl Mech 18:405–413

Merchant ME (1945) Mechanics of the metal cutting process. J Appl Phys 16:267–279

Kumar A, Maity K (2018) Engineering Science and Technology, an International Journal Comparison the machinability of Inconel 718, Inconel 625 and Monel 400 in hot turning operation. Eng Sci Technol an Int J 21:364–370. https://doi.org/10.1016/j.jestch.2018.03.018

Choi YH, Lee CM (2018) A study on the machining characteristics of AISI 1045 steel and Inconel 718 with circular cone shape in induction assisted machining. J Manuf Process 34:463–476. https://doi.org/10.1016/j.jmapro.2018.06.023

Baek JT, Woo WS, Lee CM (2018) A study on the machining characteristics of induction and laser-induction assisted machining of AISI 1045 steel and Inconel 718. J Manuf Process 34:513–522. https://doi.org/10.1016/j.jmapro.2018.06.030

Ha JH, Lee CM (2019) A study on the thermal effect by multi heat sources and machining characteristics of laser and induction assisted milling. Materials (Basel) 12:1032. https://doi.org/10.3390/ma12071032

Kim TW, Lee CM (2015) A study on the development of milling process for silicon nitride using ball end-mill tools by laser-assisted machining. Int J Adv Manuf Technol 77:1205–1211. https://doi.org/10.1007/s00170-014-6525-9

Hwang SJ, Oh WJ, Lee CM (2016) A study of preheating characteristics according to various preheating methods for laser-assisted machining. Int J Adv Manuf Technol 86:3015–3024. https://doi.org/10.1007/s00170-016-8387-9

Kong X, Yang L, Zhang H et al (2015) Cutting performance and coated tool wear mechanisms in laser-assisted milling K24 nickel-based superalloy. Int J Adv Manuf Technol 77:2151–2163. https://doi.org/10.1007/s00170-014-6606-9

Ding H, Shin YC (2013) Improvement of machinability of Waspaloy via laser-assisted machining. Int J Adv Manuf Technol 64:475–486. https://doi.org/10.1007/s00170-012-4012-8

Venkatesan K, Ramanujam R, Kuppan P (2017) Investigation of machinability characteristics and chip morphology study in laser-assisted machining of Inconel 718. Int J Adv Manuf Technol 91:3807–3821. https://doi.org/10.1007/s00170-017-9987-8

Wu X, Chen J (2018) The temperature process analysis and control on laser-assisted milling of nickel-based superalloy. Int J Adv Manuf Technol 98:223–235. https://doi.org/10.1007/s00170-018-1809-0

Amin AKMN, Hossain MI, Patwari AU (2012) Enhancement of machinability of Inconel 718 in end milling through online induction heating of workpiece. Adv Mater Res 415–417:420–423. https://doi.org/10.4028/scientific.net/AMR.415-417.420

Brecher C, Emonts M, Rosen C, Hermani J (2011) Laser-assisted Milling of. Adv Mater 12:599–606. https://doi.org/10.1016/j.phpro.2011.03.076

Leshock CE, Kim JN, Shin YC (2001) Plasma enhanced machining of Inconel 718: Modeling of workpiece temperature with plasma heating and experimental results. Int J Mach Tools Manuf 41:877–897. https://doi.org/10.1016/S0890-6955(00)00106-1

Novak JW, Shin YC, Incropera FP (1994) Assessment of plasma-enhanced machining for improved machinability of Inconel 718. Am Soc Mech Eng Prod Eng Div PED 68–1:443–451

Ezilarasan C, Senthil Kumar VS, Velayudham A (2013) Effect of machining parameters on surface integrity in machining nimonic C-263 superalloy using whisker-reinforced ceramic insert. J Mater Eng Perform 22:1619–1628. https://doi.org/10.1007/s11665-012-0439-1

Li X, Wang Y, Xu R et al (2019) Influence of surface integrity on fatigue behavior of Inconel 718 and Ti6Al4V workpieces with CBN electroplated wheel. Int J Adv Manuf Technol 102:2345–2356. https://doi.org/10.1007/s00170-019-03345-6

Jafarian F, Amirabadi H, Fattahi M (2014) Improving surface integrity in finish machining of Inconel 718 alloy using intelligent systems. Int J Adv Manuf Technol 71:817–827. https://doi.org/10.1007/s00170-013-5528-2

Qiang L, Ya-dong G, Ming C, Ming-jun L (2017) Research on surface integrity in milling Inconel718 superalloy. Int J Adv Manuf Technol 92:1449–1463. https://doi.org/10.1007/s00170-017-0080-0

de Paula OG, Cindra Fonseca M, Araujo AC (2017) Analysis of residual stress and cutting force in end milling of Inconel 718 using conventional flood cooling and minimum quantity lubrication. Int J Adv Manuf Technol 92:3265–3272. https://doi.org/10.1007/s00170-017-0381-3

Hua Y, Liu Z (2018) Effects of cutting parameters and tool nose radius on surface roughness and work hardening during dry turning Inconel 718. Int J Adv Manuf Technol 96:2421–2430. https://doi.org/10.1007/s00170-018-1721-7

Ren X, Liu Z (2019) A simulation model for predicting surface integrity coupled thermal-mechanical effect in turning of Inconel 718 superalloy. Int J Adv Manuf Technol 100:1825–1837. https://doi.org/10.1007/s00170-018-2704-4

Kasim MS, Hafiz MSA, Ghani JA et al (2019) Chip morphology in ball nose end milling process of nickel-based alloy material under MQL condition. Int J Adv Manuf Technol 103:4621–4625. https://doi.org/10.1007/s00170-019-03948-z

Pacella M (2019) A new low-feed chip breaking tool and its effect on the chip morphology. Int J Adv Manuf Technol 104:1145–1157. https://doi.org/10.1007/s00170-019-03961-2

Behera GC, Thrinadh J, Datta S (2020) Influence of cutting insert (uncoated and coated carbide) on cutting force, tool-tip temperature, and chip morphology during dry machining of Inconel 825. Mater Today Proc 6:2664–2670. https://doi.org/10.1016/j.matpr.2020.08.332

Venkatesan K, Manivannan K, Devendiran S et al (2019) Study of forces, surface finish and chip morphology on machining of Inconel 825. Procedia Manuf 30:611–618. https://doi.org/10.1016/j.promfg.2019.02.086

Germain G, Lebrun JL, Braham-Bouchnak T et al (2008) Laser-assisted machining of Inconel 718 with carbide and ceramic inserts. Int J Mater Form 1:523–526. https://doi.org/10.1007/s12289-008-0213-y

Leshock CE, Kim J, Shin YC (2001) Plasma enhanced machining of Inconel 718: modeling of workpiece temperature with plasma heating and experimental results. Int J Mach Tool Manuf 41:877–897

Zhuang K, Zhang X, Zhu D, Ding H (2015) Employing preheating- and cooling-assisted technologies in the machining of Inconel 718 with ceramic cutting tools: towards reducing tool wear and improving surface integrity. Int J Adv Manuf Technol 80:1815–1822. https://doi.org/10.1007/s00170-015-7153-8

U.S. Department of Energy. Technical Support Documents for Residential cooking Products, Vol. 2: Potential Impact of Alternative Efficiency Levels for Residential Cooking

Valery Rudnev, Don Loveless, Raymond Cook MB (2003) Handbook of Induction Heating

Istardi D, Triwinarko A (2011) Induction Heating Process Design Using COMSOL ® Multiphysics Software Induction Heating Process Design Using COMSOL ® Multiphysics Software. https://doi.org/10.12928/telkomnika.v9i2.704

Pastras G, Fysikopoulos A, Stavropoulos P, Chryssolouris G (2014) An approach to modeling evaporation pulsed laser drilling and its energy efficiency. Int J Adv Manuf Technol 72:1227–1241. https://doi.org/10.1007/s00170-014-5668-z

Bergström D (2008) The Absorption of Laser Light by Rough Metal Surfaces, ISSN:14021544

Kügler H (2019) Effects of Short-Term Laser Beam Heating on the Absorptivity of Steel Sheets. J Manuf Mater Process 3:41. https://doi.org/10.3390/jmmp3020041

Daub R, Wiedenmann R, Mahrle A, et al (2018) Influence on the efficiency of the heat conduction mode laser beam welding process regarding different laser spot geometries INFLUENCE ON THE EFFICIENCY OF THE HEAT CONDUCTION MODE LASER BEAM. 200:. https://doi.org/10.2351/1.5062026

Woo W, Lee C (2019) Innovative use of multi-heat sources for the improvement of tool life in thermally assisted machining of high-strength material. J Manuf Process 38:30–37. https://doi.org/10.1016/j.jmapro.2018.12.031

Amin AKMN, Ginta TL (2014) Heat-Assisted Machining. Elsevier

Bogaerts A, Neyts EC (2018) Plasma Technology : An Emerging Technology for Energy Storage. ACS Energy Lett 3:1013–1027. https://doi.org/10.1021/acsenergylett.8b00184

Hinds BK, De Almeida SM (1981) Plasma arc heating for hot machining. Int J Mach Tool Des Res 21:143–152. https://doi.org/10.1016/0020-7357(81)90005-6

Pashatskii NV, Prokhorov AV (2002) Analytical model of heating a component by plasma-assisted machining. Weld Int 16:405–407. https://doi.org/10.1080/09507110209549550

Siebner HR, Limmer C, Peinemann A et al (2018) Introduction to Mechanical Engineering. Springer International Publishing, Berlin

Revuru RS, Posinasetti NR, Vsn VR, Amrita M (2017) Application of cutting fluids in the machining of titanium alloys—a review. Int J Adv Manuf Technol 91:2477–2498. https://doi.org/10.1007/s00170-016-9883-7

Hubbard KM, Callahan RN, Strong SD (2008) A standardized model for the evaluation of machining coolant/lubricant costs. Int J Adv Manuf Technol 36:1–10. https://doi.org/10.1007/s00170-006-0806-x

Ganta V, Chakradhar D (2014) An Experimental Investigation of Hot Machining Performance Parameters using Oxy-Acetylene gas setup. 1–6

Kong X, Yang L, Zhang H et al (2017) Optimization of surface roughness in laser-assisted machining of metal matrix composites using Taguchi method. Int J Adv Manuf Technol 89:529–542. https://doi.org/10.1007/s00170-016-9115-1

Author information

Authors and Affiliations

Contributions

All the above-mentioned authors contributed to the manuscript equally.

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bijanzad, A., Munir, T. & Abdulhamid, F. Heat-assisted machining of superalloys: a review. Int J Adv Manuf Technol 118, 3531–3557 (2022). https://doi.org/10.1007/s00170-021-08059-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08059-2