Abstract

The AISI 316L stainless steel (316L SS) is commonly used in the orthopedic prosthesis field due to its mechanical properties, biocompatibility, and corrosion resistance. However, due to its high density and low wear resistance during sliding-contact operations, it may cause an allergic reaction due to the release of toxic ions and wear particles liberated during the sliding-contact operations. The modification of this class of metallic implants’ surface characteristics represents the most common solution to change the surface’s properties of the metal substrate, especially to improve the surface’s mechanical and tribological behavior. DC magnetron sputtering (DCMS) is a suitable technique to deposit a layer with special characteristics due to its high control of deposition parameters, improving the film quality control. On the other hand, the binary (MN) and ternary (MXN) transition nitride coatings have shown promising results, especially the titanium (Ti), tantalum (Ta), and zirconium (Zr) nitride films, showing a high wear and corrosion resistance in mono- and multilayer arrangement. This technique can control the deposition time and temperature, working pressure, substrate rotation, the flux of gases, and the distance between the substrate and targets that modify the coating characteristics. This work presents the tribological analysis of the tantalum-zirconium-nitride/tantalum-zirconium (TaZrN/TaZr) multilayer coatings sliding-contact operations. Films with 7 and 11 layers were produced using DCMS, controlling the number and thickness of the layers’ coating (LC) with the nitrogen injection to the work chamber. The films presented similar structures and chemical compositions. Similarly, the elastic modulus of both films was similar, but the 7LC coating exhibited a high harness (20 ± 0.6) than the 11LC film (17.2 ± 0.4). The variation of mechanical properties was reflected in the plastic deformation resistance (H3/E*2) and the elastic strain to the failure (H/E) ratios. Reciprocating sliding-contact tests carried out the tribological tests at applied loads of 0.5, 1, and 2N at dry conditions, employing an alumina (Al2O3) ball as a counter-body. The 7LC coating presented a higher coefficient of friction (CoF) and wear rate than 11LC film at 0.5N and 1N, but at 2N, the 11CL film was detached from the surface, increasing the wear rate value. On both films, the wear tracks presented a high material transference that produces a protected layer of tantalum oxide (Ta2O5), as was observed in the Raman spectra.

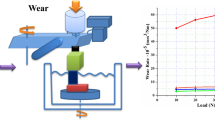

Graphical abstract

Similar content being viewed by others

Data availability

The data and material are in “Mendeley Data.”

Code availability

The code availability is not applicable in this work.

References

Ingham E, Fisher J (2000) "Biological reactions to wear debris in total joint replacement," Proceedings of the Institution of Mechanical Engineers. J Eng Med 214(1):21–37

Bitar D, Parvizi J (2015) Biological response to prosthetic debris. World J Orthop 6(2):172–189

Ratner BD, Hoffman AS, Schoen FJ, Lemons JE (2004) Biomaterials science: an introduction to materials in medicine. Elsevier Science

Nasr A, Gawad SA, Fekry AM (2020) A sensor for monitoring the corrosion behavior of orthopedic drug calcium hydrogen phosphate on a surgical 316L stainless steel alloy as implant. J Bio-Tibo-Corros 6(2):36

Li W, Ming-hui D, Hong-sen Z, Bin Z (2018) Study on HfCxN1-x coatings deposited on biomedical AISI 316L by radio-frequency magnetron sputtering. J Alloys Compd 730:219–227

T, H, Sampath Kumar TS, Perumal G, Doble M, Ramakrishna S (2018) Electrospun PCL/HA coated friction stir processed AZ31/HA composites for degradable implant applications. J Mater Process Technol 252:398–406

Gnanavel S, Ponnusamy S, Mohan L, Muthamizhchelvan C (2017) In vitro corrosion behaviour of Ti–6Al–4V and 316L stainless steel alloys for biomedical implant applications. J Bio-Tibo-Corros 4(1):1

Mattox DM (2010) Handbook of physical vapor deposition (PVD) processing, Elsevier Science.

Stueber M, Holleck H, Leiste H, Seemann K, Ulrich S, Ziebert C (2009) Concepts for the design of advanced nanoscale PVD multilayer protective thin films. J Alloys Compd 483(1):321–333

Kim SK, Cha BC (2005) Deposition of tantalum nitride thin films by D.C. magnetron sputtering. Thin Solid Films 475(1–2):202–207

Aouadi SM, Maeruf T, Twesten RD, Mihut DM, Rohde SL (2006) Physical and mechanical properties of chromium zirconium nitride thin films. Surf Coat Technol 200(11):3411–3417

Stavrev M, Fischer D, Wenzel C, Drescher K, Mattern N (1997) Crystallographic and morphological characterization of reactively sputtered Ta, TaN and TaNO thin films. Thin Solid Films 307(1):79–88

Liu K-Y, Lee J-W, Wu F-B Fabrication and tribological behavior of sputtering TaN coatings. Surf Coat Technol 259(Part B):123–128

Roman D, Bernardi J, Amorim CLG d, de Souza FS, Spinelli A, Giacomelli C, Figueroa CA, Baumvol IJR, Basso RLO (2011) Effect of deposition temperature on microstructure and corrosion resistance of ZrN thin films deposited by DC reactive magnetron sputtering. Mater Chem Phys 130(1):147–153

Pilz M, Staats K, Tobudic S, Assadian O, Presterl E, Windhager R, Holinka J (2019) Zirconium nitride coating reduced staphylococcus epidermidis biofilm formation on orthopaedic implant surfaces: an in vitro study. Clin Orthop Relat Res 477(2):461–466

Radhakrishnan K, Geok Ing N, Gopalakrishnan R (1999) Reactive sputter deposition and characterization of tantalum nitride thin films. Mater Sci Eng B 57(3):224–227

Aryasomayajula A, Valleti K, Aryasomayajula S, Bhat DG (2006) Pulsed DC magnetron sputtered tantalum nitride hard coatings for tribological applications. Surf Coat Technol 201(7):4401–4405

Tan P, Fu L, Teng J, Zhu J, Yang W, Li D, Zhou L (2019) Effect of texture on wear resistance of tantalum nitride film. Tribol Int 133:126–135

Aouadi SM (2006) Structural and mechanical properties of TaZrN films: experimental and ab initio studies. J Appl Phys 99(5):053507

Aouadi SM, Filip P, Debessai M (2004) Characterization of tantalum zirconium nitride sputter-deposited nanocrystalline coatings. Surf Coat Technol 187(2):177–184

Teoh SH (2000) Fatigue of biomaterials: a review. Int J Fatigue 22(10):825–837

Inspektor A, Salvador PA (2014) Architecture of PVD coatings for metal cutting applications: a review. Surf Coat Technol 257(Supplement C):138–153

Ali R, Sebastiani M, Bemporad E (2015) Influence of Ti–TiN multilayer PVD-coatings design on residual stresses and adhesion. Mater Des 75:47–56

Imbeni V, Martini C, Lanzoni E, Poli G, Hutchings IM (2001) Tribological behaviour of multi-layered PVD nitride coatings. Wear 251(1–12):997–1002

Kang Y, Lee C, Lee J (2000) Effects of processing variables on the mechanical properties of Ta/TaN multilayer coatings. Mater Sci Eng B 75(1):17–23

Hernández-Navarro C, Rivera LP, Flores-Martínez M, Camps E, Muhl S, García E (2019) Tribological study of a mono and multilayer coating of TaZrN/TaZr produced by magnetron sputtering on AISI-316L stainless steel. Tribol Int 131:288–298

Arif M, Eisenmenger-Sittner C (2017) In situ assessment of target poisoning evolution in magnetron sputtering. Surf Coat Technol 324:345–352

Khadem M, Penkov OV, Yang H-K, Kim D-E (2017) Tribology of multilayer coatings for wear reduction: A review. Friction 5(3):248–262

García E, Flores M, Rodríguez E, Rivera LP, Camps E, Muhl S (2018) Tribological, tribocorrosion and wear mechanism studies of TaZrN coatings deposited by magnetron sputtering on TiAlV alloy. Coatings 8(9):295

Riekkinen T, Molarius J, Laurila T, Nurmela A, Suni I, Kivilahti JK (2002) Reactive sputter deposition and properties of TaxN thin films. Microelectron Eng 64(1–4):289–297

Alishahi M, Mahboubi F, Mousavi Khoie SM, Aparicio M, Lopez-Elvira E, Mendez J, Gago R (2016) Structural properties and corrosion resistance of tantalum nitride coatings produced by reactive DC magnetron sputtering. RSC Adv 6(92):89061–89072

Constable CP, Yarwood J, Münz WD (1999) Raman microscopic studies of PVD hard coatings. Surf Coat Technol 116–119:155–159

Stoehr M, Shin C-S, Petrov I, Greene JE (2007) Raman scattering from epitaxial TaNx(0.94≤x≤1.37) layers grown on MgO(001). J Appl Phys 101(12):123509

Pilloud D, Dehlinger AS, Pierson JF, Roman A, Pichon L (2003) Reactively sputtered zirconium nitride coatings: structural, mechanical, optical and electrical characteristics. Surf Coat Technol 174-175(Supplement C):338–344

Leyland A, Matthews A (2000) On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear 246(1–2):1–11

Musil J, Kunc F, Zeman H, Poláková H (2002) Relationships between hardness, Young's modulus and elastic recovery in hard nanocomposite coatings. Surf Coat Technol 154(2):304–313

Mo JL, Zhu MH (2009) Tribological oxidation behaviour of PVD hard coatings. Tribol Int 42(11–12):1758–1764

Guo C, Hu Y, Qian H, Ning J, Xu S (2011) Magnetite (Fe3O4) tetrakaidecahedral microcrystals: synthesis, characterization, and micro-Raman study. Mater Charact 62(1):148–151

Ferrari AC, Robertson J (1824) 2004, "Raman spectroscopy of amorphous, nanostructured, diamond–like carbon, and nanodiamond," Philosophical Transactions of the Royal Society of London. Series A: Mathematical, Physical and Engineering Sciences 362:2477–2512

Fondell M, Johansson F, Gorgoi M, von Fieandt L, Boman M, Lindblad A (2015) Phase control of iron oxides grown in nano-scale structures on FTO and Si(100): Hematite, maghemite and magnetite. Vacuum 117:85–90

Pilloud D, Dehlinger AS, Pierson JF, Roman A, Pichon L (2003) Reactively sputtered zirconium nitride coatings: structural, mechanical, optical and electrical characteristics. Surf Coat Technol 174-175:338–344

Constable CP, Lewis DB, Yarwood J, Münz WD (2004) Raman microscopic studies of residual and applied stress in PVD hard ceramic coatings and correlation with X-ray diffraction (XRD) measurements. Surf Coat Technol 184(2–3):291–297

Acknowledgements

C Hernández-Navarro wants to thank the University of Guadalajara for the research stay at the University Center for Exact Sciences and Engineering (CUCEI). E García wants to thank the Cátedras-CONACyT program, México. The authors thank Eng. Sergio Oliva for his help with the SEM images. Martín Flores-Martinez thanks to CONACyT Frontier Science Project 1103.

Author information

Authors and Affiliations

Contributions

C Hernández-Navarro: Investigation, formal analysis, writing—original draft and editing. M Flores-Martínez: Resources. E Camps: Resources. L. Rivera: Writing—review and editing. E García: Conceptualization, formal analysis, writing—original draft and editing.

Corresponding author

Ethics declarations

Ethics approval

This work did not apply ethics approval.

Consent to participate

This work did not apply the consent to participate.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Navarro, C.H., Martínez, M.F., Carvajal, E.E.C. et al. Analysis of the wear behavior of multilayer coatings of TaZrN/TaZr produced by magnetron sputtering on AISI-316L stainless steel. Int J Adv Manuf Technol 117, 1565–1573 (2021). https://doi.org/10.1007/s00170-021-07655-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07655-6