Abstract

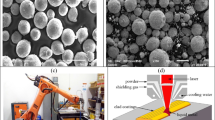

In the present paper, experimental and statistical studies of wear behavior of two HVOF sprayed coatings (NiCr-WC10Co4Cr (Coat1) and WC10Co4Cr (Coat2)) deposited on 304L austenitic stainless steel have been investigated. Applied load, sliding velocity, and distance are the most important parameters that directly affect the wear volume of a given coating. In order to quantify the influence of each parameter on the wear rate of both coatings, two different loads (5 and 15 N), velocities (5 and 20 cm/s), and distances (500 and 1500 m) are selected to perform the experimental study. The microstructural study conducted on both coatings using scanning electron microscopy (SEM) and X-ray diffraction (XRD) technique reveals a dissolution of WC particles into the NiCr matrix with the formation of W2C eutectic phase that affects the coatings during tribology tests. The wear mechanism appears to be abrasive for Coat2 and combined mechanism of adhesive and abrasive wears in the case of Coat1. Based on the mathematical model developed using response surface methodology (RSM), the results show that both coatings yield the same response in terms of RSM individual output. In addition, RSM reveals that the normal load is the most significant individual parameter affecting wear volume with t-ratio of 46.11 and 32.00 of Coat1 and Coat2, respectively. However, the interaction of parameters is different regarding the nature of the coating. Normal load-sliding velocity interaction is the most influencing in Coat1, while Coat2 wear behavior is more influenced by sliding distance-normal load interaction.

Similar content being viewed by others

References

Fauchais PL, Heberlein JV, Boulos MI (2014) Industrial applications of thermal spraying technology. In: Thermal spray fundamentals (pp 1401-1566). Springer, Boston, MA.

Davis JR (ed) (2004) Handbook of Thermal Spray Technology. TTS ASM Thermal Spray Society, ASM International, USA

Meng Y, Xu J, Jin Z, Prakash B, Hu Y (2020) A review of recent advances in tribology. Friction 8(2):221–300

Thakur L, Arora N (2013) Sliding and abrasive wear behavior of WC-CoCr coatings with different carbide sizes. J Mater Eng Perform 22(2):574–583

Dearnley PA, Aldrich-Smith G (2004) Corrosion–wear mechanisms of hard coated austenitic 316L stainless steels. Wear 256(5):491–499

Peat T, Galloway A, Toumpis A, Harvey D, Yang W-H (2016) Performance evaluation of HVOF deposited cermet coatings under dry and slurry erosion. Surf Coat Technol 300:118–127

Sidhu HS, Sidhu BS, Prakash S (2006) Mechanical and microstructural properties of HVOF sprayed WC–Co and Cr3C2–NiCr coatings on the boiler tube steels using LPG as the fuel gas. J Mater Process Technol 171(1):77–82

Fauchais PL, Heberlein JV, Boulos MI (2014) Thermal spray fundamentals: from powder to part. Springer Science & Business Media, NY, USA

Vicenzi J, Marques C, Bergmann C (2008) Hot and cold erosive wear of thermal sprayed NiCr-based coatings: influence of porosity and oxidation. Surf Coat Technol 202(15):3688–3697

Zhou W, Zhou K, Li Y, Deng C, Zeng K (2017) High temperature wear performance of HVOF-sprayed Cr3C2-WC-NiCoCrMo and Cr3C2-NiCr hardmetal coatings. Appl Surf Sci 416:33–44

Karaoglanli AC, Oge M, Doleker KM, Hotamis M (2017) Comparison of tribological properties of HVOF sprayed coatings with different composition. Surf Coat Technol 318:299–308

Azizpour MJ, Tolouei-Rad M (2019) The effect of spraying temperature on the corrosion and wear behavior of HVOF thermal sprayed WC-Co coatings. Ceram Int 45(11):13934–13941

Wickramarachchi CT, Rogers TJ, Leahy W, Cross EJ (2021) Predicting tool wear using linear response surface methodology and Gaussian process regression. Topics in Modal Analysis & Testing, vol 8. Springer, Boston, MA, pp 283–286

Kumar A, Kumar P, Singh B (2021) Optimizing the effect of wear test parameters on the specific wear rate of AZ91D magnesium alloy. Mater Today: Proc

Khuri AI, Mukhopadhyay S (2010) Response surface methodology. Wiley Interdiscip Rev Comput Stat 2(2):128–149

Huiping L, Guoqun Z, Shanting N, Yiguo L (2007) Technologic parameter optimization of gas quenching process using response surface method. Comput Mater Sci 38(4):561–570

Velmanirajan K, Thaheer ASA, Narayanasamy R, Basha CA (2012) Numerical modelling of aluminium sheets formability using response surface methodology. Mater Des 41:239–254

Saravanan I, Perumal AE, Vettivel S, Selvakumar N, Baradeswaran A (2015) Optimizing wear behavior of TiN coated SS 316L against Ti alloy using response surface methodology. Mater Des 67:469–482

Baradeswaran A, Vettivel S, Perumal AE, Selvakumar N, Issac RF (2014) Experimental investigation on mechanical behaviour, modelling and optimization of wear parameters of B4C and graphite reinforced aluminium hybrid composites. Mater Des 63:620–632

Sail K, Aouici H, Hassani S, Fnides B, Belaadi A, Naitbouda A, Abdi S (2017) Influence of tribological parameters on S335 steel filing Ti–W–N in dry sliding wear: prediction model and sliding condition optimization. Int J Adv Manuf Technol 92(9-12):4057–4071

Sharma S (2012) Wear study of Ni–WC composite coating modified with CeO 2. Int J Adv Manuf Technol 61(9-12):889–900

Derringer G, Suich R (1980) Simultaneous optimization of several response variables. J Qual Technol 12(4):214–219

Spliid H (2002) Design and analysis af experiments with k factors having p levels. Technical University of Denmark, Denmark

Goupy J, Creighton L (2007) Introduction to design of experiments with JMP examples. SAS publishing

Toma D, Brandl W, Marginean G (2001) Wear and corrosion behaviour of thermally sprayed cermet coatings. Surf Coat Technol 138(2-3):149–158

Berger L-M, Saaro S, Naumann T, Wiener M, Weihnacht V, Thiele S, Suchánek J (2008) Microstructure and properties of HVOF-sprayed chromium alloyed WC–Co and WC–Ni coatings. Surf Coat Technol 202(18):4417–4421

Murthy J, Bysakh S, Gopinath K, Venkataraman B (2007) Microstructure dependent erosion in Cr3C2–20 (NiCr) coating deposited by a detonation gun. Surf Coat Technol 202(1):1–12

Xiang D, Cheng X-d, Xiang Y, Chao L, C-q Y, Z-x D (2018) Structure and cavitation erosion behavior of HVOF sprayed multi-dimensional WC–10Co4Cr coating. Trans Nonferrous Metals Soc China 28(3):487–494

Mi P, Wang T, Ye F (2017) Influences of the compositions and mechanical properties of HVOF sprayed bimodal WC-Co coating on its high temperature wear performance. Int J Refract Met Hard Mater 69:158–163

Mazouzi A, Djerdjare B, Triaa S, Rezzoug A, Cheniti B, Aouadi SM (2020) Effect of annealing temperature on the microstructure evolution, mechanical and wear behavior of NiCr–WC–Co HVOF-sprayed coatings. J Mater Res 35(20):2798–2807

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7(6):1564–1583

Zhang Y, Epshteyn Y, Chromik RR (2018) Dry sliding wear behaviour of cold-sprayed Cu-MoS2 and Cu-MoS2-WC composite coatings: the influence of WC. Tribol Int 123:296–306

Stott F, Wood G (1978) The influence of oxides on the friction and wear of alloys. Tribol Int 11(4):211–218

Miguel J, Guilemany J, Vizcaino S (2003) Tribological study of NiCrBSi coating obtained by different processes. Tribol Int 36(3):181–187

Cowan R, Winer W. ASM Handbook: Vol. 18 Friction, Lubrication and Wear Technology. ASM International, OH

Cheniti B, Miroud D, Hvizdoš P, Balko J, Sedlák R, Csanádi T, Belkessa B, Fides M (2018) Investigation of WC decarburization effect on the microstructure and wear behavior of WC-Ni hardfacing under dry and alkaline wet conditions. Mater Chem Phys 208:237–247

Mahmud TAB, Atieh AM, Khan TI (2017) The wear behavior of HVOF sprayed near-nanostructured WC-17% Ni (80/20) Cr coatings in dry and slurry wear conditions. J Mater Eng Perform 26(7):3507–3515

Jarrah NA (2009) Studying the influence of process parameters on the catalytic carbon nanofibers formation using factorial design. Chem Eng J 151(1-3):367–371

Gujarati DN (2004) Econométrie, Traduction de la 4ième édition américaine par Bernard Bernier. De Boeck, Bruxelles

Acknowledgements

The authors thank ETS Boudjellal metallizing for the preparation of the HVOF coatings and CRTI team for characterization help (Fabrication and Characterization Workshop).

Availability of data and material

The authors confirm that the data supporting the findings of this study are available within the article. The raw data that support the findings of this study are available upon a reasonable request.

Code availability

Not applicable (jmp 13 design of experiments “free version”)

Author information

Authors and Affiliations

Contributions

Azzeddine Mazouzi: conceptualization, experimental work, data curation, and writing (original draft preparation). Amine Rezzoug: investigation, experimental work, reviewing, and editing. Billel Cheniti: methodology, reviewing and editing (final draft), review, and editing. Seif El Islam Lebouachera: software and analysis of all the obtained raw data of response surface methodology. Djamel Miroud: supervision and project administration. Aniss-Rabah Boukantar: validation. Nadjib Drouiche: methodology, validation, and involved in the discussion. Boubekeur Djerdjare: project administration.

Corresponding author

Ethics declarations

Ethics approval

This study complies with the ethical standards set out by Springer. All the authors read and approved the final manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mazouzi, A., Rezzoug, A., Cheniti, B. et al. Impact of wear parameters on NiCr-WC10Co4Cr and WC10Co4Cr HVOF sprayed composite coatings using response surface methodology. Int J Adv Manuf Technol 114, 525–539 (2021). https://doi.org/10.1007/s00170-021-06877-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06877-y