Abstract

Due to its exceptional electrical, optical, chemical and magnetic properties, tin oxide (SnO and SnO2), which is a functional material, has gained enormous attention for use in a variety of applications. Films of SnOX have a direct band gap between the ranges of 2.2 and 3.6 eV, with these films finding usefulness in various functions such as solar cells, transparent conducting oxides for gas sensors, lithium-ion batteries and microelectronics, and use in the optoelectronics industries. In order to satisfy the needs of a broad range of these applications, thin films with an extensive properties span defined by film composition, thickness, structural properties and morphology are required. This article explains the theory and research status of the various manufacturing processes of tin oxide. The purpose is to analyze the effects of the thin films through distinct forms of deposition. The general finding summarized in this research on SnOX showed that various researchers studied specific characteristics of tin oxide properties restricted by experimental conditions.

Similar content being viewed by others

References

Epifani M, Francioso L, Siciliano P, Helwig A, Mueller G, Díaz R, Arbiol J, Morante JR (2007) SnO2 thin films from metalorganic precursors: Synthesis, characterization, microelectronic processing and gas-sensing properties. Sensors Actuators B Chem 124(1):217–226. https://doi.org/10.1016/j.snb.2006.12.029

Göpel W, Schierbaum KD (1995) SnO2 sensors: current status and future prospects. Sensors Actuators B Chem 26(1-3):1–12. https://doi.org/10.1016/0925-4005(94)01546-t

Aswathy BR, Vinay K, Arjun M, Manoj PK. (2019) Deposition of tin oxide thin film by sol-gel dip coating technique and its characterization. Proceedings of the international conference on advanced materials: ICAM 2019 [Internet]. AIP Publishing; 2019; Available from: https://doi.org/10.1063/1.5130344

McAleer JF, Moseley PT, Norris JOW, Williams DE, Taylor P, Tofield BC (1997) Tin oxide based gas sensors. Mater Chem Phys 17(6):577–583. https://doi.org/10.1016/0254-0584(87)90017-4

Zhitomirsky VN, David T, Boxman RL, Goldsmith S, Verdyan A, Soifer YM, Rapoport L (2005) Properties of SnO2 coatings fabricated on polymer substrates using filtered vacuum arc deposition. Thin Solid Films 492(1-2):187–194. https://doi.org/10.1016/j.tsf.2005.06.061

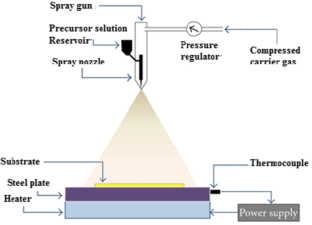

Albin D, Risbud S (1997) Spray pyrolysis processing of optoelectronic materials. Adv Ceram Mater(USA) 2(3A). https://doi.org/10.1111/j.1551-2916.1987.tb00089.x

Manifacier J, Fillard J, Bind J (1991) Deposition of In2O3 SnO2 layers on glass substrates using a spraying method. Thin Solid Films 77(1-3):67–80. https://doi.org/10.1016/0040-6090(81)90361-8

Chopra K, Major S, Pandya D (1993) Transparent conductors—a status review. Thin Solid Films 102(1):1–46. https://doi.org/10.1016/0040-6090(83)90256-0

Bel Hadj Tahar R, Ban T, Ohya Y, Takahashi Y (1998) Tin doped indium oxide thin films: Electrical properties. J Appl Phys 83(5):2631–2645. https://doi.org/10.1063/1.367025

Studenikin S, Golego N, Cocivera M (1998) Optical and electrical properties of undoped ZnO films grown by spray pyrolysis of zinc nitrate solution. J Appl Phys 83(4):2104–2111. https://doi.org/10.1063/1.366944

Coutts TJ, Wu X, Mulligan WP, Webb JM (1996) High-performance, transparent conducting oxides based on cadmium stannate. J Electron Mater 25(6):935–943. https://doi.org/10.1007/bf02666727

Omura K, Veluchamy P, Tsuji M, Nishio T, Murozono M (1999) A pyrosol technique to deposit highly transparent, low-resistance SnO2: F Thin films from dimethyltin dichloride. J Electrochem Soc 146(6):2113. https://doi.org/10.1002/chin.199939215

Kar A, Kundu S, Patra A (2011) Surface defect-related luminescence properties of SnO2 nanorods and nanoparticles. J Phys Chem C 115(1):118–124. https://doi.org/10.1021/jp110313b

Vijayarangamuthu K, Rath S (2014) Nanoparticle size, oxidation state, and sensing response of tin oxide nanopowders using Raman spectroscopy. J Alloys Compd 610:706–712. https://doi.org/10.1016/j.jallcom.2014.04.187

Calestani D, Zha M, Zappettini A, Lazzarini L, Salviati G, Zanotti L, Sberveglieri G (2005) Structural and optical study of SnO2 nanobelts and nanowires. Mater Sci Eng C 25(5-8):625–630. https://doi.org/10.1016/j.msec.2005.07.014

Nemade KR, Waghuley SA (2014) Comparative study of carbon dioxide sensing by Sn-doped TiO2 nanoparticles synthesized by microwave-assisted and solid-state diffusion route. Appl Nanosci 5(4):419–424. https://doi.org/10.1007/s13204-014-0333-2

Kinumoto T, Nagano K, Yamamoto Y, Tsumura T, Toyoda M (2014) Anticorrosion properties of tin oxide coatings for carbonaceous bipolar plates of proton exchange membrane fuel cells. J Power Sources 249:503–508. https://doi.org/10.1016/j.jpowsour.2013.10.065

Tosun BS, Feist RK, Gunawan A, Mkhoyan KA, Campbell SA, Aydil ES (2012) Sputter deposition of semicrystalline tin dioxide films. Thin Solid Films 520(7):2554–2561. https://doi.org/10.1016/j.tsf.2011.10.169

Behrendt A, Friedenberger C, Gahlmann T, Trost S, Becker T, Zilberberg K, Polywka A, Görrn P, Riedl T (2015) Highly robust transparent and conductive gas diffusion barriers based on tin oxide. Adv Mater 27(39):5961–5967. https://doi.org/10.1002/adma.201502973

Beneking C, Rech B, Wieder S, Kluth O, Wagner H, Frammelsberger W, Geyer R, Lechner P, Rübel H, Schade H (1999) Recent developments of silicon thin film solar cells on glass substrates. Thin Solid Films 351(1-2):241–246. https://doi.org/10.1016/s0040-6090(98)01793-3

Rosental A, Tarre A, Gerst A, Uustare T, Sammelselg V (2001) Atomic-layer chemical vapor deposition of SnO2 for gas-sensing applications. Sensors Actuators B Chem 77(1-2):297–300. https://doi.org/10.1016/s0925-4005(01)00746-8

Jin C, Yamazaki T, Ito K, Kikuta T, Nakatani N (2006) H2S sensing property of porous SnO2 sputtered films coated with various doping films. Vacuum 80(7):723–725. https://doi.org/10.1016/j.vacuum.2005.11.002

Yang H, Zhang X, Tang A (2006) Mechanosynthesis and gas-sensing properties of In2O3/SnO2 nanocomposites. Nanotechnology 17(12):2860. https://doi.org/10.1088/0957-4484/17/12/006

Hagemeyer A, Hogan Z, Schlichter M, Smaka B, Streukens G, Turner H, Volpe Jr A, Weinberg H, Yaccato K (2007) High surface area tin oxide. Appl Catal A Gen 317(2):139–148. https://doi.org/10.1016/j.apcata.2006.09.040

Hosono H, Ohta H, Orita M, Ueda K, Hirano M (2002) Frontier of transparent conductive oxide thin films. Vacuum 66(3-4):419–425. https://doi.org/10.1016/s0042-207x(02)00165-3

Wang GF, Tao XM, Huang HM (2005) Light-emitting devices for wearable flexible displays. Color Technol 121(3):132–138. https://doi.org/10.1111/j.1478-4408.2005.tb00263.x

Vergöhl M, Malkomes N, Matthee T, Bräuer G, Richter U, Nickol FW, Bruch J (2001) In situ monitoring of optical coatings on architectural glass and comparison of the accuracy of the layer thickness attainable with ellipsometry and photometry. Thin Solid Films 392(2):258–264. https://doi.org/10.1016/s0040-6090(01)01040-9

Chen JS, Lou XW (2013) SnO2-based nanomaterials: synthesis and application in lithium-ion batteries. Small 9(11):1877–1893. https://doi.org/10.1002/smll.201202601

Nazarov DV, Maximov MY, Novikov PA, Popovich AA, Silin AO, Smirnov VM et al (2017) Atomic layer deposition of tin oxide using tetraethyltin to produce high-capacity Li-ion batteries. J Vac Sci Technol A 35(1):01B137. https://doi.org/10.1116/1.4972554

Roy P, S.K. (2015) Srivastava, Nanostructured anode materials for lithium ion batteries. J Mater Chem A 3(6):2454–2484. https://doi.org/10.1039/c4ta04980b

Reddy M, Subba Rao G, B. (2013) Chowdari, Metal oxides and oxysalts as anode materials for Li ion batteries. Chem Rev 113(7):5364–5457. https://doi.org/10.1021/cr3001884

Shrotriya V, Li G, Yao Y, Chu CW, Yang Y (2006) Transition metal oxides as the buffer layer for polymer photovoltaic cells. Appl Phys Lett 88(7):073508. https://doi.org/10.1063/1.2174093

Betz U, Olsson MK, Marthy J, Escolá MF, Atamny F (2006) Thin films engineering of indium tin oxide: large area flat panel displays application. Surf Coat Technol 200(20-21):5751–5759. https://doi.org/10.1016/j.surfcoat.2005.08.144

Adnane M, Cachet H, Folcher G, Hamzaoui S (2005) Beneficial effects of hydrogen peroxide on growth, structural and electrical properties of sprayed fluorine-doped SnO2 films. Thin Solid Films 492(1-2):240–247. https://doi.org/10.1016/j.tsf.2005.06.085

Viirola H, Niinistö L (1994) Controlled growth of antimony-doped tin dioxide thin films by atomic layer epitaxy. Thin Solid Films 251(2):127–135. https://doi.org/10.1016/0040-6090(94)90677-7

Aguir K, Bernardini S, Lawson B, Fiorido T (2020) Trends in metal oxide thin films: Synthesis and applications of tin oxide. Tin Oxide Mater:219–246. https://doi.org/10.1016/b978-0-12-815924-8.00008

Benhaoua A, Rahal A, Benhaoua B, Jlassi M (2014) Effect of fluorine doping on the structural, optical and electrical properties of SnO2 thin films prepared by spray ultrasonic. Superlattice Microst 70:61–69. https://doi.org/10.1016/j.spmi.2014.02.005

Mishra S, Ghanshyam C, Ram N, Singh S, Bajpai RP, Bedi RK (2002) Alcohol sensing of tin oxide thin film prepared by sol-gel process. Bull Mater Sci 25(3):231–234. https://doi.org/10.1007/bf02711159

Batzill M, Diebold U (2005) The surface and materials science of tin oxide. Prog Surf Sci 79(2-4):47–154. https://doi.org/10.1016/j.progsurf.2005.09.002

Das S, Jayaraman V (2014) SnO2: A comprehensive review on structures and gas sensors. Prog Mater Sci 66:112–255. https://doi.org/10.1016/j.pmatsci.2014.06.003

Krivetskiy VV, Rumyantseva MN, Gaskov AM (2013) Chemical modification of nanocrystalline tin dioxide for selective gas sensors. Russ Chem Rev 82(10):917. https://doi.org/10.1070/rc2013v082n10abeh004366

Arafat MM, Dinan B, Akbar SA, Haseeb ASMA (2012) Gas sensors based on one dimensional nanostructured metal-oxides: a review. Sensors 12(6):7207–7258. https://doi.org/10.3390/s120607207

Choi G, Satyanarayana L, Park J (2006) Effect of process parameters on surface morphology and characterization of PE-ALD SnO2 thin films for gas sensing. Appl Surf Sci 252(22):7878–7883. https://doi.org/10.1016/j.apsusc.2005.09.069

Dutaive M, Lalauze R, Pijolat C (1995) Sintering, catalytic effects and defect chemistry in polycrystalline tin oxide. Sensors Actuators B 26:26–27. https://doi.org/10.1016/0925-4005(94)01552-s

Ray SC, Karanjai MK, DasGupta D (1998) Tin dioxide based transparent semiconducting films deposited by the dip-coating technique. Surf Coat Technol 102(1-2):73–80. https://doi.org/10.1016/s0257-8972(97)00561-6

Rahal A, Benhaoua A, Jlassi M, Benhaoua B (2015) Structural, optical and electrical properties studies of ultrasonically deposited tin oxide (SnO2) thin films with different substrate temperatures. Superlattice Microst 86:403–411. https://doi.org/10.1016/j.spmi.2015.08.003

Ichimura M, Shibayama K, Masui K (2004) Fabrication of SnO2 thin films by a photochemical deposition method. Thin Solid Films 466(1-2):34–36. https://doi.org/10.1016/j.tsf.2004.01.117

Abdul-Hamead AA (2018) Properties of SnO2 thin films deposited by chemical spray pyrolysis using different precursor solutions. https://doi.org/10.1063/1.5039204

Park JJ, Kim KK, Roy M, Song JK, Park SM (2015) Characterization of SnO2thin films grown by pulsed laser deposition under transverse magnetic field. Rapid Commun Photosci 4(3):50–53. https://doi.org/10.5857/rcp.2015.4.3.50

Shamala K, Murthy L, Rao KN (2004) Studies on tin oxide films prepared by electron beam evaporation and spray pyrolysis methods. Bull Mater Sci 27(3):295–301. https://doi.org/10.1007/bf02708520

Monteiro OC, Mendonca MHM, Pereira MIS, Nogueira JMF (2006) Preparation of lead and tin oxide thin films by spin coating and their application on the electrodegradation of organic pollutants. J Solid-State Electrochem 10(1):41–47. https://doi.org/10.1007/s10008-005-0652-z

Van Mol AMB, Chae Y, McDaniel AH, Allendorf MD (2006) Chemical vapor deposition of tin oxide: fundamentals and applications. Thin Solid Films 502(1-2):72–78. https://doi.org/10.1016/j.tsf.2005.07.247

Ponraj JS, Attolini G, Bosi M (2013) Review on atomic layer deposition and applications of oxide thin films. Critic Rev Solid State Mater Sci 38(3):203–233. https://doi.org/10.1080/10408436.2012.736886

Akl AA (2004) Microstructure and electrical properties of iron oxide thin films deposited by spray pyrolysis. Appl Surf Sci 221(1-4):319–329. https://doi.org/10.1016/s0169-4332(03)00951-6

Murthy L, Rao KK (1999) Thickness dependent electrical properties of CdO thin films prepared by spray pyrolysis method. Bull Mater Sci 22(6):953–957. https://doi.org/10.1007/bf02745685

Blunden SJ, Cusack PA, Hill R (1995) The industrial uses of tin chemicals. Vol. 337. Royal Society of Chemistry, London. https://doi.org/10.1002/ange.19860981142

Pengyi L, Junfang C, Wangdian S (2004) Sheet resistance and gas-sensing properties of tin oxide thin films by Plasma enhanced chemical vapor deposition. Plasma Sci Technol 6(2):2259. https://doi.org/10.1088/1009-0630/6/2/015

Brinzari V, Korotcenkov G, Golovanov V, Schwank J, Lantto V, Saukko S (2002) Morphological rank of nano-scale tin dioxide films deposited by spray pyrolysis from SnCl4·5H2O water solution. Thin Solid Films 408(1-2):51–58. https://doi.org/10.1016/s0040-6090(02)00086-x

Saadie J (2014) Influence of thickness on electrical and optical properties of tellurium thin films deposited by chemical spray pyrolysis. Int J Appl Math Electron Comput 3, 96(2):–101. https://doi.org/10.18100/ijamec.27133

Akl AA (2004) Optical properties of crystalline and non-crystalline iron oxide thin films deposited by spray pyrolysis. Appl Surf Sci 233(1-4):307–319. https://doi.org/10.1016/j.apsusc.2004.03.263

Yadav AA (2015) SnO2 thin film electrodes deposited by spray pyrolysis for electrochemical supercapacitor applications. J Mater Sci Mater Electron 27(2):1866–1872. https://doi.org/10.1007/s10854-015-3965-4

Patil GE, Kajale DD, Gaikwad VB, Jain GH (2012) Spray pyrolysis deposition of nanostructured tin oxide thin films. ISRN Nanotechnol 2012:2012–2015. https://doi.org/10.5402/2012/275872

Sears W, Gee MA (1998) Mechanics of film formation during the spray pyrolysis of tin oxide. Thin Solid Films 165(1):265–277. https://doi.org/10.1016/0040-6090(88)90698-0

Thiagarajan S, Sanmugam A, Vikraman D (2017) Facile methodology of sol-gel synthesis for metal oxide nanostructures. Recent Applications in Sol-Gel Synthesis, p. 1-17. https://doi.org/10.5772/intechopen.68708

Levy D, Zayat M (Eds.). (2015). The Sol-Gel Handbook. https://doi.org/10.1002/9783527670819

López TM, Avnir D, Aegerter MA (2013) Emerging fields in sol-gel science and technology: Springer Science & Business Media. doi https://doi.org/10.1007/978-1-4615-0449-8

Lee SC, Lee JH, Oh TS, Kim YH (2003) Fabrication of tin oxide film by sol–gel method for photovoltaic solar cell system. Sol Energy Mater Sol Cells 75(3-4):481–487. https://doi.org/10.1016/s0927-0248(02)00201-5

Korotcenkov G, Brinzari V, Ivanov M, Cerneavschi A, Rodriguez J, Cirera A, Morante J (2005) Structural stability of indium oxide films deposited by spray pyrolysis during thermal annealing. Thin Solid Films 479(1-2):38–51. https://doi.org/10.1016/j.tsf.2004.11.107

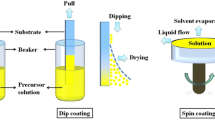

Dislich H, Hussmann E (1991) Amorphous and crystalline dip coatings obtained from organometallic solutions: procedures, chemical processes and products. Thin Solid Films 77(1-3):129–140. https://doi.org/10.1016/0040-6090(81)90369-2

Chatelon JP, Terrier C, Bernstein E, Berjoan R, Roger JA (1994) Morphology of SnO2 thin films obtaibed by the sol-gel technique. Thin Solid Films 247(2):162–168. https://doi.org/10.1016/0040-6090(94)90794-3

Kumar A, Nanda D (2019) Methods and fabrication techniques of superhydrophobic surfaces, in Superhydrophobic Polymer Coatings. Elsevier. p. 43-75. doi https://doi.org/10.1016/b978-0-12-816671-0.00004-7

Neacşu IA, Nicoară AI, Vasile OR, Vasile BŞ (2016) Inorganic micro- and nanostructured implants for tissue engineering. Nanobiomater Hard Tissue Eng 4:271–295. https://doi.org/10.1016/b978-0-323-42862-0.00009-2

Karanjai MK, Dasgupta D (1997) Preparation and study of sulphide thin films deposited by the dip technique. Thin Solid Films 155(2):309–315. https://doi.org/10.1016/0040-6090(87)90075-7

Zhao J, Huo LH, Gao S, Zhao H, Zhao JG (2006) Alcohols and acetone sensing properties of SnO2 thin films deposited by dip-coating. Sensors Actuators B Chem 115(1):460–464. https://doi.org/10.1016/j.snb.2005.10.024

Dominguez M, Luna-Lopez JA, Flores FJ (2017) Semiconductor materials by ultrasonic spray pyrolysis and their application in electronic devices. Pyrolysis, p. 251. doi https://doi.org/10.5772/67548

Alarcon-Flores G, Aguilar-Frutis MIGUEL, García-Hipolito MANUEL, Guzman-Mendoza J, Canseco MA, Falcony C (2008) Optical and structural characteristics of Y 2 O 3 thin films synthesized from yttrium acetylacetonate. J Mater Sci 43(10):3582–3588. https://doi.org/10.1007/s10853-008-2566-5

Sánchez-García MA, Maldonado A, Castañeda L, Silva-González R, de la Luz Olvera M (2012) Characteristics of SnO2: F thin films deposited by ultrasonic spray pyrolysis: effect of water content in solution and substrate temperature. Mater Sci Appl 3(10):690–696. https://doi.org/10.4236/msa.2012.310101

Jadsadapattarakul D, Euvananont C, Thanachayanont C, Nukeaw J, Sooknoi T (2008) Tin oxide thin films deposited by ultrasonic spray pyrolysis. Ceram Int 34(4):1051–1054. https://doi.org/10.1016/j.ceramint.2007.09.096

Park H-H, Park H-H, Hill RH (2004) Stacking effect on the ferroelectric properties of PZT/PLZT multilayer thin films formed by photochemical metal-organic deposition. Appl Surf Sci 237(1-4):427–432. https://doi.org/10.1016/j.apsusc.2004.06.103

Gao M, Hill RH (1998) High efficiency photoresist-free lithography of UO 3 patterns from amorphous films of uranyl complexes. J Mater Res 13(5):1379–1389. https://doi.org/10.1557/jmr.1998.0196

Park H-H, Kim WS, Yang J-K, Park H-H, Hill RH (2004) Characterization of PLZT thin film prepared by photochemical deposition using photosensitive metal-organic precursors. Microelectron Eng 71(2):215–220. https://doi.org/10.1016/j.mee.2003.11.004

Park H-H, Park H-H, Hill RH (2006) Direct-patterning of SnO2 thin film by photochemical metal-organic deposition. Sensors Actuators A Phys 132(2):429–433. https://doi.org/10.1016/j.sna.2006.02.030

Ichimura M, Goto F, Arai E (1999) Photochemical deposition of CdS from aqueous solutions. J Electrochem Soc 146(3):1028. https://doi.org/10.1149/1.1391716

Ichimura M, Takeuchi K, Nakamura A, Arai E (2001) Photochemical deposition of Se and CdSe films from aqueous solutions. Thin Solid Films 384(2):157–159. https://doi.org/10.1016/s0040-6090(00)01826-5

Sasaki H, Shibayama K, Ichimura M, Masui K (2002) Preparation of (Bi, Sb) 2S3 semiconductor films by photochemical deposition method. J Cryst Growth 237:2125–2129. https://doi.org/10.1016/s0022-0248(01)02280-1

Bravo-Vasquez JP, Hill RH (2000) Photolithographic deposition of conducting gold films from thin amorphous films of AuPR3X (X = NO3, RCO2) on silicon surfaces. Polyhedron. 19(3):343–349. https://doi.org/10.1016/s0277-5387(99)00364-2

Avey AA, Hill RH (1996) Solid state photochemistry of Cu2 (OH2)2 (O2C (CH2) 4CH3)4 in thin films: The photochemical formation of high-quality films of copper and copper (I) oxide. Demonstration of a novel lithographic technique for the patterning of copper. J Am Chem Soc 118(1):237–238. https://doi.org/10.1021/ja952937j

Park HH, Yoon S, Park HH, Hill RH (2004) Electrical properties of PZT thin films by photochemical deposition. Thin Solid Films 447:669–673. https://doi.org/10.1016/j.tsf.2003.09.005

Law W, Hill RH (2000) Photolithographic deposition of insulating Al2O3 films from thin amorphous films of aluminum complexes on silicon surfaces. Thin Solid Films 375(1-2):42–45. https://doi.org/10.1016/s0040-6090(00)01177-9

Ando M, Suto S, Suzuki T, Tsuchida T, Nakayama C, Miura N, Yamazoe N (1994) H2S-sensitive thin film fabricated from hydrothermally synthesized SnO2 sol. J Mater Chem 4(4):631. https://doi.org/10.1039/jm9940400631

Baik NS, Sakai G, Miura N, Yamazoe N (2000) Hydrothermally treated sol solution of tin oxide for thin-film gas sensor. Sensors Actuators B Chem 63(1-2):74–79. https://doi.org/10.1016/s0925-4005(99)00513-4

Ren X, Pang L, Zhang Y, Ren X, Fan H, Liu SF (2015) One-step hydrothermal synthesis of monolayer MoS2 quantum dots for highly efficient electrocatalytic hydrogen evolution. J Mater Chem A 3(20):10693–10697. https://doi.org/10.1039/c5ta02198g

Chen Q, Qian Y, Chen Z, Zhou G, Zhang Y (1995) Fabrication of ultrafine SnO2 thin films by the hydrothermal method. Thin Solid Films 264(1):25–27. https://doi.org/10.1016/0040-6090(95)06586-5

Baik, Seok N, Sakai G, Miura N, Yamazoe N (2000) Preparation of stabilized nanosized tin oxide particles by hydrothermal treatment. J Am Ceram Soc 83(12):2983–2987. https://doi.org/10.1111/j.1151-2916.2000.tb01670.x

Jackson T, Palmer S (1994) Oxide superconductor and magnetic metal thin film deposition by pulsed laser ablation: a review. J Phys D Appl Phys 27(8):1581. https://doi.org/10.1088/0022-3727/27/8/001

Torrisi L, Margarone D (2006) Investigations on pulsed laser ablation of Sn at 1064 nm wavelength. Plasma Sources Sci Technol 15(4):635. https://doi.org/10.1088/0963-0252/15/4/007

Handbook of Physical Vapor Deposition (PVD) Processing. (2010) https://doi.org/10.1016/c2009-0-18800-1

Koinkar V, Ogale S (1991) Pulsed excimer laser processing of optical thin films. Thin Solid Films 206(1-2):259–263. https://doi.org/10.1016/0040-6090(91)90432-w

Dawar AL, Kumar A, Sharma S, Tripathi KN, Mathur PC (1993) Effect of laser irradiation on structural, electrical and optical properties of SnO2 films. J Mater Sci 28(3):639–644. https://doi.org/10.1007/bf01151238

Galindo H, Vincent AB, Sánchez-R JC, Laude LD (1993) Excimer laser processing for surface improvement of tin oxide thin films. J Appl Phys 74(1):645–648. https://doi.org/10.1063/1.355226

Kunz R, Rothschild M, Ehrlich D (1998) Selective—area laser photodeposition of transparent conductive SnO2 films. MRS Online Proceedings Library Archive. 129. doi https://doi.org/10.1557/proc-129-447

Treece RE, Horwitz JS, Claassen JH, Chrisey DB (1994) Pulsed laser deposition of high-quality NbN thin films. Appl Phys Lett 65(22):2860–2862. https://doi.org/10.1063/1.112516

Kim H, Gilmore AC, Pique A, Horwitz JS, Mattoussi H, Murata H, ..., Chrisey DB (1999) Electrical, optical, and structural properties of indium–tin–oxide thin films for organic light-emitting devices. J Appl Phys 86(11):6451-6461. doi https://doi.org/10.1063/1.371708

Kim H, Horwitz JS, Kushto GP, Kafafi ZH, Chrisey DB (2001) Indium tin oxide thin films grown on flexible plastic substrates by pulsed-laser deposition for organic light-emitting diodes. Appl Phys Lett 79(3):284–286. https://doi.org/10.1063/1.1383568

Phillips HM, Li Y, Bi Z, Zhang B (1996) Reactive pulsed laser deposition and laser induced crystallization of SnO2 transparent conducting thin films. Appl Phys A 63(4):347–351. https://doi.org/10.1007/s003390050397

Dolbec R, El Khakani MA, Serventi AM, Trudeau M, Saint-Jacques RG (2002) Microstructure and physical properties of nanostructured tin oxide thin films grown by means of pulsed laser deposition. Thin Solid Films 419(1-2):230–236. https://doi.org/10.1016/s0040-6090(02)00769-1

Xu NS, Huq SE (2005) Novel cold cathode materials and applications. Mater Sci Eng R Rep 48(2-5):47–189. https://doi.org/10.1016/j.mser.2004.12.001

Electron Beam Physical Vapor Deposition (EBPVD). (2019) Encyclopedia of Nanotechnology, 1057–1057. doi https://doi.org/10.1007/978-94-017-9780-1_100290

George J, Menon C (2000) Electrical and optical properties of electron beam evaporated ITO thin films. Surf Coat Technol 132(1):45–48. https://doi.org/10.1016/s0257-8972(00)00726-x

Kachouane A, Addou M, Bougrine A, Messoussi R, Regragui M, Bérnede JC (2001) Preparation and characterisation of tin-doped indium oxide films. Mater Chem Phys 70(3):285–289. https://doi.org/10.1016/s0254-0584(00)00492-2

Park YC, Kim YS, Seo HK, Ansari SG, Shin HS (2002) ITO thin films deposited at different oxygen flow rates on Si (100) using the PEMOCVD method. Surf Coat Technol 161(1):62–69. https://doi.org/10.1016/s0257-8972(02)00476-0

Wang CP, Do KB, Beasley MR, Geballe TH, Hammond RH (1997) Deposition of in-plane textured MgO on amorphous Si3N4 substrates by ion-beam-assisted deposition and comparisons with ion-beam-assisted deposited yttria-stabilized-zirconia. Appl Phys Lett 71(20):2955–2957. https://doi.org/10.1063/1.120227

Ektessabi A, Sato S, Kitamura H, Masaki Y (1993) Simulation of ion beam assisted deposition—a comparison with experimental results. Vacuum 44(3-4):213–217. https://doi.org/10.1016/0042-207x(93)90156-5

Ektessabi AM, Kimura H (1995) Characterization of the surface of bio-ceramic thin films. Thin Solid Films 270(1-2):335–340. https://doi.org/10.1016/0040-6090(95)06714-0

Fursey G (1996) Early field emission studies of semiconductors. Appl Surf Sci 94-95:44–59. https://doi.org/10.1016/0169-4332(95)00518-8

Hossain MF, Naka S, Okada H (2018) Annealing effect of E-beam evaporated TiO2 films and their performance in perovskite solar cells. J Photochem Photobiol A Chem 360:109–116. https://doi.org/10.1016/j.jphotochem.2018.04.025

Pan XQ, Fu L, Dominguez JE (2001) Structure–property relationship of nanocrystalline tin dioxide thin films grown on (1̄012) sapphire. J Appl Phys 89(11):6056–6061. https://doi.org/10.1063/1.1368866

Nam SC, Kim YH, Cho WI, Cho BW, Chun HS, Yun KS (1998) Charge-discharge performance of electron-beam-deposited tin oxide thin-film electrodes. Electrochem Solid-State Lett 2(1):9. https://doi.org/10.1149/1.1390717

Vuong DD, Sakai G, Shimanoe K, Yamazoe N (2004) Preparation of grain size-controlled tin oxide sols by hydrothermal treatment for thin film sensor application. Sensors Actuators B Chem 103(1-2):386–391. https://doi.org/10.1016/j.snb.2004.04.122

Adedokun O, Odebunmi BM, Sanusi YK (2018) Effect of fluorine doping on the structural, optical and electrical properties of spin coated tin oxide thin films for solar cells application. (2019). Sci Focus J. https://doi.org/10.36293/sfj.2019.0002

Yilbas BS, Al-Sharafi A, Ali H (2019) Surfaces for self-cleaning. Self-Cleaning Surf Water Droplet Mobil 45–98. doi https://doi.org/10.1016/b978-0-12-814776-4.00003-3

Boudrioua A, Chakaroun M, Fischer A (2017) Introduction. Org Lasers, Elsiver. https://doi.org/10.1016/b978-1-78548-158-1.50009-2

Senez V, Thomy V, Dufour R (2014) Nanotechnologies for synthetic super non-wetting surfaces. Nanotechnol Synth Super Non-Wetting Surf:1–12. https://doi.org/10.1002/9781119015093.ch1

Cavicchi RE, Walton RM, Aquino-Class M, Allen JD, Panchapakesan B (2001) Spin-on nanoparticle tin oxide for microhotplate gas sensors. Sensors Actuators B Chem 77(1-2):145–154. https://doi.org/10.1016/s0925-4005(01)00686-4

Gu F, Wang SF, Lü MK, Cheng XF, Liu SW, Zhou GJ, Xu D, Yuan DR (2004) Luminescence of SnO2 thin films prepared by spin-coating method. J Cryst Growth 262(1-4):182–185. https://doi.org/10.1016/j.jcrysgro.2003.10.028

Kääriäinen T, Cameron D, Kääriäinen M-L, Sherman A (2013) Atomic layer deposition: principles, characteristics, and nanotechnology applications. doi https://doi.org/10.1002/9781118747407

Babu Krishna Moorthy S (Ed.) (2015) Thin Film Structures in Energy Applications. doi https://doi.org/10.1007/978-3-319-14774-1

Morosanu CE (1990) Thin film structure. Thin Films by Chemical Vapour Deposition 177–200. doi https://doi.org/10.1016/b978-0-444-98801-0.50013-6

Seshan K, Schepis D (2018) Handbook of thin film deposition, 103. William Andrew. doi https://doi.org/10.1016/b978-0-12-812311-9.00030-x

Manawi Y, Ihsanullah, Samara A, Al-Ansari T, Atieh M (2018) A Review of carbon nanomaterials’ synthesis via the chemical vapor deposition (CVD) method. Materials 11(5):822. https://doi.org/10.3390/ma11050822

Pierson HO (1999) Fundamentals of chemical vapor deposition. Handbook of Chemical Vapor Deposition (CVD), 36–67. doi https://doi.org/10.1016/b978-081551432-9.50005-x

Ho P (1998) Chemical Vapor Deposition for microelectronics: principles, technology and applications. Arthur Sherman (Noyes Publications, 1987). MRS Bull 13(11):78–78. https://doi.org/10.1557/s0883769400064046

George SM, Park BK, Kim CG, Chung T-M (2014) Heteroleptic group 2 metal precursors for metal oxide thin films. Eur J Inorg Chem 2014(11):2002–2010. https://doi.org/10.1002/ejic.201301296

Giunta CJ, Strickler DA, Gordon RG (1993) Kinetic modeling of the chemical vapor deposition of tin oxide from dimethyltin dichloride and oxygen. J Phys Chem 97(10):2275–2283. https://doi.org/10.1021/j100112a032

Yadava Y, Denicoló G, Arias A, Roman L, Hümmelgen I (1997) Preparation and characterization of transparent conducting tin oxide thin film electrodes by chemical vapour deposition from reactive thermal evaporation of SnCl2. Mater Chem Phys 48(3):263–267. https://doi.org/10.1016/s0254-0584(96)01899-8

Buchanan JL, McKown C (1997) Off-line sheet glass coating system. J Non-Cryst Solids 218:179–184. https://doi.org/10.1016/s0022-3093(97)00292-5

Gordon R (1997) Chemical vapor deposition of coatings on glass. J Non-Cryst Solids 218:81–91. https://doi.org/10.1016/s0022-3093(97)00198-1

McCurdy RJ (1999) Successful implementation methods of atmospheric CVD on a glass manufacturing line. Thin Solid Films 351(1-2):66–72. https://doi.org/10.1016/s0040-6090(99)00199-6

Choy K (2003) Chemical vapour deposition of coatings. Prog Mater Sci 48(2):57–170. https://doi.org/10.1016/s0079-6425(01)00009-3

Yusta FJ, Hitchman ML, Shamlian SH (1997) CVD preparation and characterization of tin dioxide films for electrochemical applications. J Mater Chem 7(8):1421–1427. https://doi.org/10.1039/a608525c

Melsheimer J, Ziegler D (1993) Thin tin oxide films of low conductivity prepared by chemical vapour deposition. Thin Solid Films 109(1):71–83. https://doi.org/10.1016/0040-6090(83)90032-9

Houssa M (Ed.) (2004) High k Gate Dielectrics. https://doi.org/10.1201/9781420034141

Heil SBS, van Hemmen JL, Hodson CJ, Singh N, Klootwijk JH, Roozeboom F, … Kessels WMM (2007) Deposition of TiN and HfO[sub 2] in a commercial 200 mm remote plasma atomic layer deposition reactor. J Vacuum Sci Technol A: Vacuum Surf Films 25(5):1357. https://doi.org/10.1116/1.2753846

Ritala M, Leskelä M (2002) Atomic layer deposition. Handbook of Thin Films, 103–159. doi https://doi.org/10.1016/b978-012512908-4/50005-9

Gerritsen E, Emonet N, Caillat C, Jourdan N, Piazza M, Fraboulet D, Boeck B, Berthelot A, Smith S, Mazoyer P (2005) Evolution of materials technology for stacked-capacitors in 65 nm embedded-DRAM. Solid State Electron 49(11):1767–1775. https://doi.org/10.1016/j.sse.2005.10.024

Jakschik S, Schroeder U, Hecht T, Dollinger G, Bergmaier A, Bartha J (2004) Physical properties of ALD-Al2O3 in a DRAM-capacitor equivalent structure comparing interfaces and oxygen precursors. Mater Sci Eng B 107(3):251–254. https://doi.org/10.1016/j.mseb.2003.09.044

Suk Yang W, Kwan Kim Y, Yang S-Y, Hwak Choi J, Soo Park H, In Lee S, Yoo J-B (2000) Effect of SiO2 intermediate layer on Al2O3/SiO2/n + -poly Si interface deposited using atomic layer deposition (ALD) for deep submicron device applications. Surf Coat Technol 131(1-3):79–83. https://doi.org/10.1016/s0257-8972(00)00763-5

Suntola T (1999) Atomic layer epitaxy. Mater Sci Rep 4(5):261–312. https://doi.org/10.1016/s0920-2307(89)80006-4

Kim H (2003) Atomic layer deposition of metal and nitride thin films: Current research efforts and applications for semiconductor device processing. J Vacuum Sci Technol B: Microelectron Nanometer Struct 21(6):2231. https://doi.org/10.1116/1.1622676

Leskelä M, Ritala M (2003) Atomic layer deposition chemistry: recent developments and future challenges. Angew Chem Int Ed 42(45):5548–5554. https://doi.org/10.1002/anie.200301652

Ghosh AP, Gerenser LJ, Jarman CM, Fornalik JE (2005) Thin-film encapsulation of organic light-emitting devices. Appl Phys Lett 86(22):223503. https://doi.org/10.1063/1.1929867

Groner MD, George SM, McLean RS, Carcia PF (2006) Gas diffusion barriers on polymers using Al2O3 atomic layer deposition. Appl Phys Lett 88(5):051907. https://doi.org/10.1063/1.2168489

Agostinelli G, Delabie A, Vitanov P, Alexieva Z, Dekkers HFW, De Wolf S, Beaucarne G (2006) Very low surface recombination velocities on p-type silicon wafers passivated with a dielectric with fixed negative charge. Sol Energy Mater Sol Cells 90(18-19):3438–3443. https://doi.org/10.1016/j.solmat.2006.04.014

Reijnen L, Meester B, Goossens A, Schoonman J (2003) Atomic Layer Deposition of CuxS for Solar Energy Conversion. Chem Vap Depos 9(1):15–20. https://doi.org/10.1002/cvde.200290001

Van TT, Chang JP (2005) Controlled erbium incorporation and photoluminescence of Er-doped Y2O3. Appl Phys Lett 87(1):011907. https://doi.org/10.1063/1.1984082

King JS, Neff CW, Summers CJ, Park W, Blomquist S, Forsythe E, Morton D (2003) High-filling-fraction inverted ZnS opals fabricated by atomic layer deposition. Appl Phys Lett 83(13):2566–2568.10.1063/1 1609240

Mayer TM, Elam JW, George SM, Kotula PG, Goeke RS (2003) Atomic-layer deposition of wear-resistant coatings for microelectromechanical devices. Appl Phys Lett 82(17):2883–2885. https://doi.org/10.1063/1.1570926

Scharf T, Prasad S, Dugger M, Kotula P, Goeke R, Grubbs R (2006) Growth, structure, and tribological behavior of atomic layer-deposited tungsten disulphide solid lubricant coatings with applications to MEMS. Acta Mater 54(18):4731–4743. https://doi.org/10.1016/j.actamat.2006.06.009

Johnson RW, Hultqvist A, Bent SF (2014) A brief review of atomic layer deposition: from fundamentals to applications. Mater Today 17(5):236–246. https://doi.org/10.1016/j.mattod.2014.04.026

George SM (2010) Atomic layer deposition: an overview. Chem Rev 110(1):111–131. https://doi.org/10.1021/cr900056b

Knez M, Nielsch K, Niinistö L (2007) Synthesis and surface engineering of complex nanostructures by atomic layer deposition. Adv Mater 19(21):3425–3438. https://doi.org/10.1002/adma.200700079

Sundqvist J, Lu J, Ottosson M, Hårsta A (2006) Growth of SnO2 thin films by atomic layer deposition and chemical vapour deposition: A comparative study. Thin Solid Films 514(1-2):63–68. https://doi.org/10.1016/j.tsf.2006.02.031

Choi W-S (2009) The fabrication of tin oxide films by atomic layer deposition using tetrakis(ethylmethylamino) tin precursor. Trans Electr Electron Mater 10(6):200–202. https://doi.org/10.4313/teem.2009.10.6.200

Tiznado H, Zaera F (2006) Surface chemistry in the atomic layer deposition of tin films from TiCl4and ammonia. J Phys Chem B 110(27):13491–13498. https://doi.org/10.1021/jp062019f

Aaltonen T, Ritala M, Sajavaara T, Keinonen J, Leskelä M (2003) Atomic layer deposition of platinum thin films. Chem Mater 15(9):1924–1928. https://doi.org/10.1021/cm021333t

Pan D, Guan D, Jen T-C, Yuan C (2016) Atomic layer deposition process modeling and experimental investigation for sustainable manufacturing of nano thin films. J Manuf Sci Eng 138(10). https://doi.org/10.1115/1.4034475

Bachmann J (Ed.) (2017) Atomic layer deposition in energy conversion applications. doi https://doi.org/10.1002/9783527694822

Shaeri MR, Jen T-C, Yuan CY (2015) Reactor scale simulation of an atomic layer deposition process. Chem Eng Res Des 94:584–593. https://doi.org/10.1016/j.cherd.2014.09.019

Marquardt AE, Breitung EM, Drayman-Weisser T, Gates G, Phaneuf RJ (2015) Protecting silver cultural heritage objects with atomic layer deposited corrosion barriers. Herit Sci 3(1):37. https://doi.org/10.1186/s40494-015-0066-x

Farmer DB, Gordon RG (2005) ALD of high-κ dielectrics on suspended functionalized SWNTs. Electrochem Solid-State Lett 8(4):G89. https://doi.org/10.1149/1.1862474

Nwanna EC, Coetzee RAM, Jen T-C (2019) Investigating the purge flow rate in a reactor scale simulation of an atomic layer deposition process. Volume 2B: Advanced Manufacturing. doi https://doi.org/10.1115/imece2019-10692

Lim BS, Rahtu A, Gordon RG (2003) Atomic layer deposition of transition metals. Nat Mater 2(11):749–754. https://doi.org/10.1038/nmat1000

Aaltonen T, Ritala M, Sammelselg V, Leskelä M (2004) Atomic layer deposition of iridium thin films. J Electrochem Soc 151(8):G489. https://doi.org/10.1149/1.1761011

Wang X, Tabakman SM, Dai H (2008) Atomic layer deposition of metal oxides on pristine and functionalized graphene. J Am Chem Soc 130(26):8152–8153. https://doi.org/10.1021/ja8023059

Frank MM, Wilk GD, Starodub D, Gustafsson T, Garfunkel E, Chabal YJ, Muller DA (2005) HfO2 and Al2O3 gate dielectrics on GaAs grown by atomic layer deposition. Appl Phys Lett 86(15):152904. https://doi.org/10.1063/1.1899745

Ritala M, Kaupo K, Antti R, Räisänen PI, Markku L, Timo S, Juhani K (2000) Atomic layer deposition of oxide thin films with metal alkoxides as oxygen sources. Science 288(5464):319–321. https://doi.org/10.1126/science.288.5464.319

Kim JY, George SM (2010) Tin monosulfide thin films grown by atomic layer deposition using tin 2,4-pentanedionate and hydrogen sulfide. J Phys Chem C 114(41):17597–17603. https://doi.org/10.1021/jp9120244

Yousfi E, Weinberger B, Donsanti F, Cowache P, Lincot D (2001) Atomic layer deposition of zinc oxide and indium sulfide layers for Cu(In,Ga)Se2 thin-film solar cells. Thin Solid Films 387(1-2):29–32. https://doi.org/10.1016/s0040-6090(00)01838-1

Zaera F (2008) The surface chemistry of thin film atomic layer deposition (ALD) processes for electronic device manufacturing. J Mater Chem 18(30):3521. https://doi.org/10.1039/b803832e

Pellin MJ, Stair PC, Xiong G, Elam JW, Birrell J, Curtiss L, Wang H-H (2005) Mesoporous catalytic membranes: synthetic control of pore size and wall composition. Catal Lett 102(3-4):127–130. https://doi.org/10.1007/s10562-005-5843-9

Elam JW, Routkevitch D, Mardilovich PP, George SM (2003) Conformal coating on ultrahigh-aspect-ratio nanopores of anodic alumina by atomic layer deposition. Chem Mater 15(18):3507–3517. https://doi.org/10.1021/cm0303080

Wei Z, Hai Z, Akbari MK, Qi D, Xing K, Zhao Q, Verpoort F, Hu J, Hyde L, Zhuiykov S (2018) Atomic layer deposition-developed two-dimensional α-MoO3 windows excellent hydrogen peroxide electrochemical sensing capabilities. Sensors Actuators B Chem 262:334–344. https://doi.org/10.1016/j.snb.2018.01.243

Bakke JR, Pickrahn KL, Brennan TP, Bent SF (2011) Nanoengineering and interfacial engineering of photovoltaics by atomic layer deposition. Nanoscale 3(9):3482. https://doi.org/10.1039/c1nr10349k

Van Delft JA, Garcia-Alonso D, Kessels WMM (2012) Atomic layer deposition for photovoltaics: applications and prospects for solar cell manufacturing. Semicond Sci Technol 27(7):074002. https://doi.org/10.1088/0268-1242/27/7/074002

Hatanpää T, Ritala M, Leskelä M (2013) Precursors as enablers of ALD technology: contributions from University of Helsinki. Coord Chem Rev 257(23-24):3297–3322. https://doi.org/10.1016/j.ccr.2013.07.002

Miikkulainen V, Leskelä M, Ritala M, Puurunen RL (2013) Crystallinity of inorganic films grown by atomic layer deposition: overview and general trends. J Appl Phys 113(2):021301. https://doi.org/10.1063/1.4757907

Warner EJ, Johnson F, Campbell SA, Gladfelter WL (2015) Atomic layer deposition of tin oxide and zinc tin oxide using tetraethyltin and ozone. J Vac Sci Technol A 33(2):021517. https://doi.org/10.1116/1.4907562

Heo J, Hock AS, Gordon RG (2010) Low temperature atomic layer deposition of tin oxide. Chem Mater 22(17):4964–4973. https://doi.org/10.1021/cm1011108

Mullings MN, Hägglund C, Bent SF (2013) Tin oxide atomic layer deposition from tetrakis(dimethylamino)tin and water. J Vac Sci Technol A 31(6):061503. https://doi.org/10.1116/1.4812717

Li AD, Liu WC (2010) Optical properties of ferroelectric nanocrystal/polymer composites. In Physical Properties and Applications of Polymer Nanocomposites (pp. 108-158). Woodhead Publishing. doi https://doi.org/10.1533/9780857090249.1.108

Sōmiya S, Roy R (2000) Hydrothermal synthesis of fine oxide powders. Bull Mater Sci 23(6):453–460. https://doi.org/10.1007/bf02903883

Du X, George SM (2008) Thickness dependence of sensor response for CO gas sensing by tin oxide films grown using atomic layer deposition. Sensors Actuators B Chem 135(1):152–160. https://doi.org/10.1016/j.snb.2008.08.015

Acknowledgements

The authors hereby devote acknowledgement to the University Research Commission (URC), the Global Excellence Stature (GES) as well as the National Research Foundation (NRF) South Africa for being supportive financially.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nwanna, E.C., Imoisili, P.E. & Jen, TC. Fabrication and synthesis of SnOX thin films: a review. Int J Adv Manuf Technol 111, 2809–2831 (2020). https://doi.org/10.1007/s00170-020-06223-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06223-8