Abstract

In order to discuss the problems involved in the joining of fiber-reinforced thermoplastic composite materials with aluminum alloys that is required for the production of several parts in aerospace, automotive, and other engineering applications, a comprehensive review of the research status of this dissimilar joint alloys both in China and abroad is made. The overview mainly includes adhesive bonding, mechanical fastening, welding, and new joining techniques, as well as residual stress and corrosion performance of the joints. The current problems, development prospects, and future research direction of different joining technologies used in this field have been discussed. It is believed that the numerical simulation combined with the welding test can be used to further study the joining process of friction stir welding between carbon fiber-reinforced thermoplastic composite materials and aluminum alloys and the hybrid joining method of friction stir welding and adhesion.

Similar content being viewed by others

References

Sinn G, Singer G, Jocher L, Unteriass MM (2019) Mechanical and fracture mechanical properties of matrix-reinforced carbon fiber composites with carbon nanotubes. Key Eng Mater 809:615–619

Wang B, Ma S, Yan S, Zhu J (2019) Readily recyclable carbon fiber reinforced composites based on degradable thermosets: a review. Green Chem:21

Huang YX, Meng XC, Xie YM, Wan L, Lv ZL, Cao J, Feng JC (2018) Friction stir welding/processing of polymers and polymer matrix composites. Compos Part A-Appl S 105:235–257

Mitschang P, Blinzler M, Wöginger A (2003) Processing technologies for continuous fibre reinforced thermoplastics with novel polymer blends. Compos Sci Technol 63(14):2099–2110

Zhang T (2013) Applications of high performance thermoplastic composites for commercial airplane structural component. Aeron Manuf Technol 15:32–35

Liu FC, Liao J, Nakata K (2014) Joining of metal to plastic using friction lap welding. Mater Design 54:236–244

Moshwan R, Rahmat SM, Yusof F, Hassan MA, Hamdi M, Fadzil M (2015) Dissimilar friction stir welding between polycarbonate and AA7075 aluminum alloy. Int J Mater Res 106(3):258–266

Pramanik A, Basak AK, Dong Y, Sarker PK, Uddin MS, Littlefair G, Dixit AR, Chattopadhyaya S (2017) Joining of carbon fibre reinforced polymer (CFRP) composites and aluminium alloys—a review. Compos Part A-Appl S 101:1–29

Rhee KY, Choi NS, Park SJ (2002) Effect of plasma treatment of aluminum on the bonding characteristics of aluminum-CFRP composite joints. J Adhes Sci Technol 16(11):1487–1500

Rhee KY, Lee SG, Choi NS, Park SJ (2003) Treatment of CFRP by IAR method and its effect on the fracture behavior of adhesive bonded CFRP/aluminum composites. Mater Sci Eng A 357(1–2):270–276

Rhee KY, Yang JH (2003) A study on the peel and shear strength of aluminum/CFRP composites surface-treated by plasma and ion assisted reaction method. Compos Sci Technol 63(1):33–40

Gomathi N, Sureshkumar A, Neogi S (2008) RF plasma-treated polymers for biomedical applications. Curr Sci India 94(11):1478–1486

Chung HJ, Rhee KY, Lee BC, Lee JH (2009) Effect of oxygen plasma treatment on the bonding strength of CFRP/aluminum foam composite. J Alloys Compd 481(1–2):214–219

Lee CJ, Lee JM, Ryu HY, Lee KH, Kim BM, Ko DC (2014) Design of hole-clinching process for joining of dissimilar materials-Al6061-T4 alloy with DP780 steel, hot-pressed 22MnB5 steel, and carbon fiber reinforced plastic. J Mater Process Technol 214(10):2169–2178

Lee CJ, Lee SH, Lee JM, Kim BH, Kim BM, Ko DC (2014) Design of hole-clinching process for joining CFRP and aluminum alloy sheet. Int J Precis Eng Manuf 15(6):1151–1157

Pleines IW (1938) Riveting methods and rivet equipments used in the German light metal aeroplane construction. Aeronaut J 42(333):761–815

Liu P, Zhang KF, Li Y (2013) Experiment study on interference amount of rivet joining for CFRP/Al components. Appl Mech Mater 421:127–131

Aman F, Cheraghi SH, Krishnan KK, Lankarani H (2013) Study of the impact of riveting sequence, rivet pitch, and gap between sheets on the quality of riveted lap joints using finite element method. Int J Adv Manuf Technol 67(1–4):545–562

De Matos PFP, McEvily AJ, Moreira PMGP, De Castro PMST (2007) Analysis of the effect of cold-working of rivet holes on the fatigue life of an aluminum alloy. Int J Fatigue 29(3):575–586

Atre A, Johnson WS (2007) Analysis of the effects of interference and sealant on riveted lap joints. J Aircr 44(2):353–364

Franco GD, Fratini L, Pasta A, Ruisi AF (2010) On the self-piercing riveting of aluminium blanks and carbon fibre composite panels. Int J Mater Form 3:1035–1038

Franco GD, Fratini L, Pasta A (2012) Influence of the distance between rivets in self-piercing riveting bonded joints made of carbon fiber panels and AA2024 blanks. Mater Design 35:342–349

Settineri L, Atzeni E, Ippolito R (2010) Self piercing riveting for metal-polymer joints. Int J Mater Form 3:995–998

Franco GD, Fratini L, Pasta A (2013) Analysis of the mechanical performance of hybrid (SPR/bonded) single-lap joints between CFRP panels and aluminum blanks. Int J Adhes Adhes 41:24–32

Kweon JH, Jung JW, Kim TH, Choi JH, Kim DH (2006) Failure of carbon composite-to-aluminum joints with combined mechanical fastening and adhesive bonding. Compos Struct 75(1):192–198

Benatar A, Gutowski TG (1989) Ultrasonic welding of PEEK graphite APC-2 composites. Polym Eng Sci 29:1705–1721

Balle F, Eifler D (2012) Statistical test planning for ultrasonic welding of dissimilar materials using the example of aluminum-carbon fiber reinforced polymers (CFRP) joints. Mater Werkst 43(4):286–292

Balle F, Wagner G, Eifler D (2007) Ultrasonic spot welding of aluminum sheet/carbon fiber reinforced polymer-joints. Mater Werkst 38(11):934–938

Huxhold S, Balle F, Wagner G, Eifler D (2011) Ultrasonic welding of hybrid aluminum/CFRP-joints: monotonic properties, fatigue behavior and microstructure of the joining zone. Supplemental Proceedings: Materials Processing and Energy Materials 1:743–748

Balle F, Wagner G, Eifler D (2009) Ultrasonic metal welding of aluminium sheets to carbon fibre reinforced thermoplastic composites. Adv Eng Mater 11(1–2):35–39

Yu G, Zhao SS, Zhang YJ, He XL, Pang M (2009) Research on key issues of laser welding of dissimilar metal. Chin J Las 36(2):261–268

Katayama S, Kawahito Y, Mizutani M (2013) Latest progress in performance and understanding of laser welding. Phys Procedia 39:8–16

Jung KW, Kawahito Y, Takahashi M, Katayama S (2013) Laser direct joining of carbon fiber reinforced plastic to aluminum alloy. J Laser Appl 25(3):530–533

Jung KW, Kawahito Y, Katayama S (2011) Laser direct joining of carbon fibre reinforced plastic to stainless steel. Sci Technol Weld Join 16(8):676–680

Jung KW, Kawahito Y, Takahashi M, Katayama S (2013) Laser direct joining of carbon fiber reinforced plastic to zinc-coated steel. Mater Design 47:179–188

Çam G, Koçak M (1998) Progress in joining of advanced materials—part I: solid state joining, fusion joining, and joining of intermetallics. Sci Technol Weld Join 3(3):105–126

Çam G, Koçak M (1998) Progress in joining of advanced materials. Int Mater Rev 43(1):1–44

Kashaev N, Ventzke V, Çam G (2018) Prospects of laser beam welding and friction stir welding processes for aluminum airframe structural applications. J Manuf Process 36:571–600

Zhang Z, Shan JG, Tan XH, Zhang J (2016) Effect of anodizing pretreatment on laser joining CFRP to aluminum alloy A6061. Int J Adhes Adhes 70:142–151

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78

Von Strombeck A, Çam G, dos Santos JF, Ventzke V, Koçak M (2001) A comparison between microstructure, properties, and toughness behavior of power beam and friction stir welds in Al-alloys. In: Das SK, Kaufman JG, Lienert TJ (eds) Proc. of the TMS 2001 Annual Meeting Aluminum, Automotive and Joining (New Orleans, Louisiana, USA, February 12–14, 2001). TMS, Warrendale, PA, USA, pp 249–264

Çam G, İpekoğlu G (2017) Recent developments in joining of aluminium alloys. Int J Adv Manuf Technol 91(5–8):1851–1866

Çam G (2011) Friction stir welded structural materials: beyond Al-alloys. Int Mater Rev 56(1):1–48

Çam G, Mıstıkoğlu S (2014) Recent developments in friction stir welding of Al-alloys. J Mat Eng Perform 23:1936–1953

Çam G, İpekoğlu G, Küçükömeroğlu T, Aktarer SM (2017) Applicability of friction stir welding to steels. J Achieve Mat Manufac Eng 80(2):65–85

Threadgill PL, Leonard AJ, Shercliff HR, Withers PJ (2009) Friction stir welding of aluminum alloys. Int Mater Rev 54:49–93

Goushegir SM, dos Santos JF, Amancio-Filho ST (2014) Friction spot joining of aluminum AA2024/carbon-fiber reinforced poly (phenylene sulfide) composite single lap joints: microstructure and mechanical performance. Mater Design 54:196–206

Goushegir SM, dos Santos JF, Amancio-Filho ST (2015) Influence of process parameters on mechanical performance and bonding area of AA2024/carbon-fiber-reinforced poly (phenylene sulfide) friction spot single lap joints. Mater Design 83:431–442

André NM, Goushegir SM, dos Santos JF, Leonardo B, Sergio T, Amancio-Filho (2016) Friction spot joining of aluminum alloy 2024-T3 and carbon-fiber-reinforced poly (phenylene sulfide) laminate with additional PPS film interlayer: microstructure, mechanical strength and failure mechanisms. Compos Part B-Eng 94:197–208

André NM, Goushegir SM, dos Santos JF, Canto LB, Amancio-Filho ST (2017) Influence of the interlayer film thickness on the mechanical performance of AA2024-T3/CF-PPS hybrid joints produced by friction spot joining. Weld Int 32:1–10

Esteves JV, Goushegir SM, dos Santos JF, Canto LB, Hage E Jr, Amancio-Filho ST (2015) Friction spot joining of aluminum AA6181-T4 and carbon fiber-reinforced poly (phenylene sulfide): effects of process parameters on the microstructure and mechanical strength. Mater Design 66:437–445

Amancio-Filho ST, Bueno C, dos Santos JF, Huber N, Hage E Jr (2011) On the feasibility of friction spot joining in magnesium/fiber-reinforced polymer composite hybrid structures. Mater Sci Eng A 528(10–11):3841–3848

Pabandi HK, Movahedi M, Kokabi AH (2017) A new refill friction spot welding process for aluminum/polymer composite hybrid structures. Compos Struct 174:59–69

Nagatsuka K, Yoshida S, Tsuchiya A, Nakata K (2015) Direct joining of carbon-fiber-reinforced plastic to an aluminum alloy using friction lap joining. Compos Part B-Eng 73:82–88

Ratanathavorn W, Melander A (2015) Dissimilar joining between aluminium alloy (AA 6111) and thermoplastics using friction stir welding. Sci Technol Weld Join 20(3):222–228

Huang YX, Meng XC, Wang YH, Xie YM, Zhou L (2018) Joining of aluminum alloy and polymer via friction stir lap welding. J Mater Process Technol 257:146–154

Shahmiri H, Movahedi M, Kokabi AH (2016) Friction stir lap joining of aluminium alloy to polypropylene sheets. Sci Technol Weld Join 22:120–126

Khodabakhshi F, Haghshenas M, Chen J, Amirkhiz BS, Li J, Gerlich AP (2017) Bonding mechanism and interface characterisation during dissimilar friction stir welding of an aluminium/polymer bi-material joint. Sci Technol Weld Join 22(3):182–190

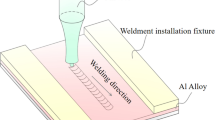

Huang YX, Meng XC, Xie YM, Li JC, Wan L (2018) Joining of carbon fiber reinforced thermoplastic and metal via friction stir welding with co-controlling shape and performance. Compos Part A 112:328–336

Xie Y, Zhang JH, Zhou T (2019) Large-area mechanical interlocking via nanopores: ultra-high-strength direct bonding of polymer and metal materials. Appl Surf Sci 492:558–570

Huang YX, Meng XC, Xie YM, Li JC, Wan L (2018) New technique of friction-based filling stacking joining for metal and polymer. Compos Part B 163:216–223

Meng XC, Huang YX, Xie YM, Li JC, Guan M, Wan L (2019) Friction self-riveting welding between polymer matrix composites and metals. Composites Part A 127:105–624

Moshwan R, Rahmat SM, Yosof F, Hassan MA, Hamdi M, Fadzil M (2015) Dissimilar friction stir welding between polycarbonate and AA7075 aluminum alloy. Int J Mater Res 106(3):258–266

Rout A, Pandey P, Oliveira EF, Autreto P, Gumaste A, Singh AK, Galvao DS, Arora A, Tiwary CS (2019) Atomically locked interfaces of metal (aluminum) and polymer (polypropylene) using mechanical friction. Polymer 169:148–153

Lambiase F, Paoletti A, Grossi V, Genna S (2017) Improving energy efficiency in friction assisted joining of metals and polymers. J Mater Process Technol 250:379–389

Yusof F, Muhamad M, Moshwan R, Jamaludin M, Miyashita Y (2016) Effect of surface states on joining mechanisms and mechanical properties of aluminum alloy (A5052) and polyethylene terephthalate (PET) by dissimilar friction spot welding. Metals 6(5):101

Yusof F, Miyashita Y, Seo N, Mutoh Y, Moshwan R (2012) Utilising friction spot joining for dissimilar joint between aluminum alloy (A5052) and polyethylene terephthalate. Sci Technol Weld Join 17(7):544–549

Huang BS, Chen Q, Zhao X, Zhang RF, Zhu Y (2018) Microstructure, properties and corrosion characterization of welded joint for composite pipe using a novel welding process. Trans Indian Inst Metals 71(12):2933–2944

Chen Q, Yang J, Liu XH, Tang JL, Huang BS (2019) Effect of the groove type when considering a thermometallurgical-mechanical model of the welding residual stress and deformation in an S355JR-316L dissimilar welded joint. J Manuf Process 45:290–303

Xie YJ, Zhuang J, Huang BS, Chen Q, Li GW (2020) Effect of different welding parameters on residual stress and deformation of 20/0Cr18Ni9 dissimilar metal arc-welding joint. J Adhes Sci Technol 6:1–25

Bauer A, Grundmeier G, Steger H, Weitl J (2017) Corrosive delamination processed of CFRP-aluminum alloy hybrid components. Mater Corros:1–8

Li SG, Khan HA, Hihara LH, Cong HB, Li JJ (2018) Corrosion behavior of friction stir blind riveted Al/CFRP and Mg/CFRP joints exposed to a marine environment. Corros Sci 132:300–309

Mandel M, Krüger L (2013) Determination of pitting sensitivity of the aluminum alloy EN AW-6060-T6 in a carbon-fibre reinforced plastic/aluminum rivet joint by finite element simulation of the galvanic corrosion process. Corros Sci 73:172–180

Marannano G, Zuccarello B (2015) Numerical experimental analysis of hybrid double lap aluminum-CFRP joints. Compos Part B 71(15):28–39

Manes A, Giglio M, Viganò F (2011) Effect of riveting process parameters on the local stress field of a T-joint. Int J Mech Sci 53(12):1039–1049

Chen Q, Fei F, Yu SD, Liu CJ, Tang JH, Yang X (2020) Numerical simulation of temperature field and residual stresses in stainless steel T-joint. Trans Indian Inst Metals 73:751–761

Huang BS, Liu JQ, Zhang SS, Chen Q, Chen LZ (2020) Effect of post-weld heat treatment on the residual stress and deformation of 20/0Cr18Ni9 dissimilar metal welded joint by experiments and simulations. J Mater Res Technol 9(3):6186–6200

Acknowledgments

This work was supported by the Youth Talent Innovation Project in Guangdong Province (fund number: 2019KQNCX228) and the School-Level Key Projects (fund number: GKY-2016KYZD-6).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, B., Chen, Q. & Yang, J. Advances in joining technology of carbon fiber-reinforced thermoplastic composite materials and aluminum alloys. Int J Adv Manuf Technol 110, 2631–2649 (2020). https://doi.org/10.1007/s00170-020-06021-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06021-2