Abstract

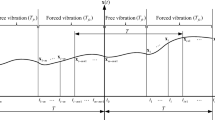

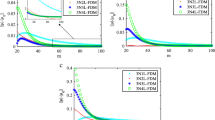

Chatter has been one of the major limiting factors leading to poor productivity and surface finish. The prediction of the stable cutting zones of cutting parameters is thus vital in machining. On the basis of piecewise polynomial interpolations, two efficient and accurate methods are developed in this paper for calculating the stability lobes. Firstly, the dynamic milling process with regenerative effect is modeled by delay differential equations (DDEs) with time-periodic coefficients. The principal period of system is easily separated based on the existence of any non-zero elements of coefficient matrix, and the forced vibration phase is equally discretized into a series of subintervals. Piecewise polynomial interpolations are adopted in two contiguous subintervals to estimate all parts of the DDEs. Secondly, the state transition matrix is formed to search for the borderline of stable cutting region based on Floquet theory. Thirdly, the convergence rates of the two proposed methods are analyzed through comparison with four existing algorithms. The results validate that the two proposed approaches achieve higher convergence rate, accuracy, and efficiency than the others within the same time intervals. Finally, the operability of the two proposed methods is verified by cutting tests, which indicate that the two proposed methods are of effectiveness and practicability.

Similar content being viewed by others

References

Tao JF, Qin CJ, Xiao DY, Shi HT, Liu CL (2019) A pre-generated matrix-based method for real-time robotic drilling chatter monitoring. Chinese J Aeronaut 32(12):2755–2764. https://doi.org/10.1016/j.cja.2019.09.001

Tao JF, Qin CJ, Xiao DY, Shi HT, Ling X, Li BC, Liu CL (2020) Timely chatter identification for robotic drilling using a local maximum synchrosqueezing-based method. J Intell Manuf 31:1243–1255. https://doi.org/10.1007/s10845-019-01509-5

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann 53(2):619–642

Qin CJ, Tao JF, Liu CL (2018) A predictor-corrector-based holistic-discretization method for accurate and efficient milling stability analysis. Int J Adv Manuf Technol 96(5–8):2043–2054

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann 44(1):357–362

Merdol SD, Altintas Y (2004) Multi frequency solution of chatter stability for low immersion milling. J Manuf Sci Eng 126(3):459–466

Bachrathy D, Stepan G (2013) Improved prediction of stability lobes with extended multi frequency solution. CIRP Ann Manuf Technol 62:411–414

Butcher EA, Bobrenkov OA, Bueler E, Nindujarla P (2009) Analysis of milling stability by the Chebyshev collocation method: algorithm and optimal stable immersion levels. J Comput Nonlin Dyn 4:031003

Yan Z, Liu Z, Wang X, Liu B, Luo Z, Wang D (2016) Stability prediction of thin-walled workpiece made of Al7075 in milling based on shifted Chebyshev polynomials. Int J Adv Manuf Technol 87(1–4):115–124

Insperger T, Stépán G (2004) Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int J Numer Methods Biomed Eng 61(1):117–141

Insperger T, Stépán G, Turi J (2008) On the higher-order semi-discretizations for periodic delayed systems. J Sound Vib 313(1–2):334–341

Insperger T (2010) Full-discretization and semi-discretization for milling stability prediction: some comments. Int J Mach Tools Manuf 50(7):658–662

Long XH, Balachandran B (2007) Stability analysis for milling process. Nonlinear Dynam 49(3):349–359

Long XH, Balachandran B, Mann BP (2007) Dynamics of milling processes with variable time delays. Nonlinear Dyn 49(1–3):49–63

Wan M, Zhang W, Dang J, Yang Y (2010) A unified stability prediction method for milling process with multiple delays. Int J Mach Tools Manuf 50(1):29–41

Jin G, Zhang Q, Hao S, Xie Q (2013) Stability prediction of milling process with variable pitch cutter. Math Prob Eng 2013:1–11. https://doi.org/10.1155/2013/932013

Wang Y, Wang T, Yu Z, Zhang Y, Wang Y (2015) Liu H, (2015) chatter prediction for variable pitch and variable helix milling. Shock Vib

Jiang SL, Sun YW, Yuan XL, Liu WR (2017) A second-order semi-discretization method for the efficient and accurate stability prediction of milling process. Int J Adv Manuf Technol 92(1–4):583–595

Ding Y, Zhu LM, Zhang XJ, Ding H (2010a) A full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 50(5):502–509

Ding Y, Zhu LM, Zhang XJ, Ding H (2010b) Second-order full discretization method for milling stability prediction. Int J Mach Tools Manuf 50(10):926–932

Quo Q, Sun YW, Jiang Y (2012) On the accurate calculation of milling stability limits using third-order full-discretization method. Int J Mach Tools Manuf 62:61–66

Guo Q, Sun YW, Jiang Y, Guo DM (2014) Prediction of stability limit for multi-regenerative chatter in high performance milling. Int J Dyn Control 2(1):35–45

Ozoegwu CG, Omenyi SN, Ofochebe SM (2015) Hyper-third order full-discretization methods in milling stability prediction. Int J Mach Tools Manuf 92:1–9

Liu YL, Zhang DH, Wu BH (2012) An efficient full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 63:44–48

Ji YJ, Wang XB, Liu ZB, Wang HJ, Yan ZH (2018) An updated full-discretization milling stability prediction method based on the higher order Hermite-Newton interpolation polynomial. Int J Adv Manuf Technol 95(5–8):2227–2242

Zhou K, Feng PF, Xu C, Zhang JF, Wu ZJ (2017) High-order fulldiscretization methods for milling stability prediction by interpolating the delay term of time-delayed differential equations. Int J Adv Manuf Technol 93(5–8):2201–2214

Li MZ, Zhang GJ, Huang Y (2013) Complete discretization scheme for milling stability prediction. Nonlinear Dyn 71:187–199

Xie QZ (2016) Milling stability prediction using an improved complete discretization method. Int J Adv Manuf Technol 83(5–8):815–821

Li ZQ, Yang ZK, Peng YR, Zhu F, Ming XZ (2016) Prediction of chatter stability for milling process using Runge-Kutta-based complete discretization method. Int J Adv Manuf Technol 86(1–4):943–952

Niu JB, Ding Y, Zhu LM, Ding H (2014) Runge–Kutta methods for a semi-analytical prediction of milling stability. Nonlinear Dyn 76(1):289–304

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Numerical integration method for prediction of milling stability. J Manuf Sci Eng 133(3):031005

Dai Y, Li H, Xing X, Hao B (2018) Prediction of chatter stability for milling process using precise integration method. Precis Eng 52:152–157

Zhang Z, Li HG, Meng G, Liu C (2015) A novel approach for the prediction of the milling stability based on the Simpson method. Int J Mach Tools Manuf 99:43–47

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Milling stability analysis using the spectral method. Sci China Technol Sci 54(12):3130–3136

Lehotzky D, Insperger T, Khasawneh F, Stepan G (2017) Spectral element method for stability analysis of milling processes with discontinuous time-periodicity. Int J Adv Manuf Technol 89(9–12):2503–2514

Qin CJ, Tao JF, Xiao DY, Shi HT, Li BC, Liu CL (2020) A novel Chebyshev-wavelet-based approach for accurate and fast prediction of milling stability. Precis Eng 62:244–255

Tang X, Peng F, Yan R, Gong Y, Li Y, Jiang L (2017) Accurate and efficient prediction of milling stability with updated full discretization method. Int J Adv Manuf Technol 88(9–12):2357–2368

Yan Z, Wang X, Liu Z, Wang D, Jiao L, Ji Y (2017) Third-order updated full-discretization method for milling stability prediction. Int J Adv Manuf Technol 92(5–8):2299–2309

Qin CJ, Tao JF, Liu CL (2019) A novel stability prediction method for milling operations using the holistic-interpolation scheme. Proc Inst Mech Eng C J Mech Eng Sci 233(13):4463–4475

Funding

This work was partially supported by the alliance research of Hunan province and Hengyang city through grant number (Grant No. 2018JJ4031), aid program for science and technology innovative research team in higher educational institutions of Hunan province and Hengyang science and technology guidance project grant number (Grant No. 2017KJ161), and scientific research projects of Hunan Education Department (Grant No. 18B466).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, A., Wu, Y., Deng, B. et al. Two novel prediction methods for milling stability analysis based on piecewise polynomial interpolations. Int J Adv Manuf Technol 109, 2113–2132 (2020). https://doi.org/10.1007/s00170-020-05692-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05692-1