Abstract

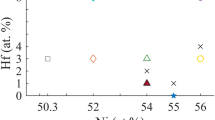

Development of hard materials for structural and bearing applications is a challenging task due to complexities in materials processing. Nickel-based intermetallics are a choice for the wear resistance applications. In this study, in order to examine the effects of Ni and Cr addition on the wear performance of Ni-rich alloys, 60Ni, 55Ni-5Cr, 50Ni-5Cr, and 50Ni-10Cr (at.%) alloys were developed through arc melting technique. The aim was to conduct a microstructural and phase analysis study and their effects on hardness and wear behavior. Samples were solution treated at 900 °C for 5 h under vacuum followed by equilibrium cooling. Microstructural and phase analysis revealed the presence of B2 cubic NiTi austenite along with Ni-rich hexagonal Ni3Ti and Cr-rich tetragonal Cr3Ni2 phases throughout the microstructure of alloys. The Cr developed phase was not present in binary composition because of Cr absence. Ternary compositions possessed higher hardness and wear resistance than the binary alloy. Hardness and wear resistance of 50Ni-5Cr and 50Ni-10Cr were comparable with tool steels and conventional 440C martensitic stainless steel bearing material; this high hardness and wear resistance was attributed to the strong solid solution strengthening and precipitation hardening effects of Cr along with the combined effect of Ni-rich Ni3Ti and NiTi austenite phases. Improvement in hardness and wear resistance were correlated with the Cr addition in the developed alloys.

Similar content being viewed by others

References

DellaCorte C, Noebe R, Stanford M, Padula S (2011) Resilient and corrosion-proof rolling element bearings made from superelastic Ni-Ti alloys for aerospace mechanism applications. Rolling element bearings symposium; Anaheim, CA; United Stataes

DellaCorte C, Moore LE III, Clifton JS (2012) Static indentation load capacity of the superelastic 60NiTi for rolling element bearings. NASA/TM-2012-216016

DellaCorte C, Moore LE III, Clifton JS (2013) The effect of pre-stressing on the static indentation load capacity of the superelastic 60NiTi. NASA/TM-2013-216479

Della Corte C, Moore LE III (2010) Launch load resistant spacecraft mechanism bearings made from NiTi superelastic intermetallic materials, in: Proceedings of the 40th Aerospace Mechanisms Symposium; Cocoa Beach, FL; United States

Della Corte C, Howard A, Thomas F, Stanford M (2017) Microstructural and material quality effects on rolling contact fatigue of highly elastic intermetallic NiTi ball Bearings. NASA/TM-2017-219466

Della Corte C (2014) Novel super-elastic materials for advanced bearing applications. Adv Sci Technol 89:1–9

Stanford MK, Thomas F, DellaCorte C (2012) Processing issues for preliminary melts of the intermetallic compound 60-NiTiNOL. NASA/TM-2012-216044

Hornbuckle BC (2014) Investigations in phase stability and mechanical attributes in nickel-rich Nitinol with and without hafnium additions, PhD Thesis, University of Alabama Libraries

DellaCorte C, Noebe RD, Stanford MK, Padula SA (n.d.) Resilient and corrosion-proof rolling element bearings made from superelastic Ni-Ti alloys for aerospace mechanism applications, NASA/TM—2011-217105

Zeng QF, Dong GN (2014) Superlubricity behaviors of Nitinol 60 alloy under oil lubrication. Trans Nonferrous Metals Soc China 24:354–359

Zeng QF, Dong GN, Martin JM (2016) Green superlubricity of Nitinol 60 alloy against steel in presence of castor oil. Sci Rep 6:29992

Qin Q, Wen Y, Wang G, Zhang L (2016) Effects of solution and aging treatments on corrosion resistance of as-cast 60NiTi alloy. J Mater Eng Perform 25:5167–5172

Khanlari K, Ramezani M, Kelly P (n.d.) 60NiTi: a review of recent research findings, potential for structural and mechanical applications, and areas of continued investigations, Trans. Indian Inst. Met., 1-19

Ingole S (2013) 60NiTi alloy for tribological and biomedical surface engineering applications. JOM 65(6):792–798

Stanford MK (2016) Hardness and microstructure of binary and ternary nitinol compounds. NASA/TM-2016-218946

DellaCorte C, Wozniak WA (2012) Design and manufacturing considerations for shockproof and corrosion-immune superelastic nickel-titanium bearings for a space station application. NASA/TM-2012-216015

Hornbuckle BC, Xiao XY, Noebe RD, Martens R, Weaver ML, Thompson GB (2015) Hardening behavior and phase decomposition in very Ni-rich Nitinol alloys. Mater Sci Eng A 639:336–344

Della Corte C, Stanford MK, Jett TR (2015) Rolling contact fatigue of superelastic intermetallic materials (SIM) for use as resilient corrosion resistant bearings. Tribol Lett 57(3)

Stanford M (2018) Friction and wear of unlubricated NiTiHf with nitriding surface treatments. NASA/TM-2018-219740

Stanford MK (2017) Hardness and second phase percentage of Ni-Ti-Hf compounds after heat treatment at 700C

Zhang F, Zheng L, Wang Y, Hu Z (2019) Effect of Ni content and Hf addition on the unlubricated wear performance of Ni-rich NiTi alloys. Intermetallics 112:106548

Zeng L, Luo B, Bin LI, Bai Z, Ouyang S, Fan W (2015) Effects of solution-aging treatment on microstructures and properties of Ti–55.06% Ni–0.3% Cr alloy. Trans Nonferrous Metals Soc China 25(6):1865–1871

Stanford MK (2012) Charpy impact energy and microindentation hardness of 60-NITINOL, Report NASA/TM-2012-216029, NASA Glenn Research Center, Cleveland

Khanlari K, Ramezani M, Kelly P, Cao P, Neitzert T (2018) Reciprocating sliding wear behavior of 60NiTi as compared to 440C steel under lubricated and unlubricated conditions. Tribol Trans 61(6):991–1002

Khanlari K, Ramezani M, Kelly P, Cao P, Neitzert T (2018) Comparison of the reciprocating sliding wear of 58Ni39Ti-3Hf alloy and baseline 60NiTi. Wear 408:120–130

Nasehi J, Ghasemi HM, Abedini M (2016) Effects of aging treatments on the high-temperature wear behavior of 60Nitinol alloy. Tribol Trans 59(2):286–291

Yang JR, Yu TH, Wang CH (2006) Martensitic transformations in AISI 440C stainless steel. Mater Sci Eng A 438:276–280

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Waqar, S., Wadood, A., Mateen, A. et al. Effects of Ni and Cr addition on the wear performance of NiTi alloy. Int J Adv Manuf Technol 108, 625–634 (2020). https://doi.org/10.1007/s00170-020-05380-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05380-0