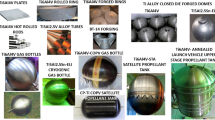

60NiTi is an alloy with 60 wt% of nickel (Ni) and 40 wt% of titanium (Ti). This alloy was developed in the 1950s at the Naval Ordnance Laboratory (NOL) along with 55NiTi (55 wt% of Ni and 45 wt% of Ti). Both of these alloys exhibit the shape memory effect to different extents. The unique properties of 60NiTi, which are suitable for surface engineering (tribological) applications, are enumerated here. With appropriate heat treatment, this alloy can achieve high hardness (between Rc 55 and Rc 63). It has very good corrosion resistance and is resilient. Machinable before its final heat treatment, this alloy can be ground to fine surface finish and to tight dimensions. At one time, due to the popularity and wider applications of 55NiTi, the study of 60NiTi suffered. Recently, 60NiTi alloy gained some technological advantages due to advanced materials synthesis processes and progress in surface engineering. A feasibility study of 60NiTi bearings for space application has shown promise for its further development and suitability for other tribological applications. This report focuses on an overview of the properties and potential tribological and biomedical applications of 60NiTi.

Similar content being viewed by others

References

R. Paluri and S. Ingole, JOM 63 (6), 77 (2011).

R. Harris and W. Roberts (Paper presented at the Surface Engineering Proceedings, 2006), pp. 201–209, 220

T.-H. Huang, J.-U. Guo, and C.-T. Kao, Surf. Coat. Technol. 205, 1917 (2010).

S. Kobayashi, Y. Ohgoe, K. Ozeki, K. Sato, T. Sumiya, K.K. Hirakuri, and H. Aoki, Diamond Rel. Mater. 14, 1094 (2005).

T. Muguruma, M. Iijima, W.A. Brantley, and I. Mizoguchi, Angle Orthodont. 81, 141 (2011).

M.J. Jackson, L.J. Hyde, W. Ahmed, H. Sein, and R.P. Flaxman, J. Mater. Eng. Perf. 13, 421 (2004).

C.J.D. Spitzer, Fishing Vessel Casualty Task Force Report (Washington, DC: U.S. Coast Guard, 1999).

C. William English, Pedestrian Slip Resistance: How to Measure It and How to Improve It, 2nd ed. (Alva, FL: William English, Inc., 2003).

W.J. Buehler, WOL oral history supplement—NITINOL re-examination, WOLAA LEAF VIII( I) (Olney, MD: White Oak Laboratory Alumni Association Inc, 2006).

G. Kauffman and I. Mayo, Chem. Educ. 2, 1 (1997).

A. Sickinger (Paper presented at SMST-2003: The International Conference on Shape Memory and Superelastic Technologies, 2004)

R.R. Adharapurapu and K.S. Vecchio, Experimen. Mech. 47, 365 (2007).

Industry Updates, J. Failure Anal. Prevent. 11, 645 (2011).

G.J. Julien, U.S. patent US6422010B1 (2002)

C. DellaCorte, Lubricat. Eng. 65, 26 (2009).

M.K. Stanford, F. Thomas, and C. DellaCorte, Processing Issues for Preliminary Melts of the Intermetallic Compound 60-NITINOL (Washington, DC: NASA, 2012).

K. Otsuka and X. Ren, Progr. Mater. Sci. 50, 511 (2005).

A.A. Khamei and K. Dehghani, Mater. Chem. Phys. 123, 269 (2010).

S. Civjan, E.F. Huget, and L.B. DeSimon, J. Dental Res. 54, 89 (1975).

S.A. Thompson, Int. Endodont. J. 33, 297 (2000).

K. Dehghani and A.A. Khamei, Mater. Sci. Eng., A 527, 684 (2010).

R.R. Adharapurapu, Phase Transformations in Nickel-Rich Nickel-Titanium Alloys: Influence of Strain-Rate, Temperature, Thermomechanical Treatment and Nickel Composition on the Shape Memory and Superelastic Characteristics (2007), Ph.D. Dissertation, University of California, San Diego.

A. Khamei and K. Dehghani, Metall. Mater. Trans. A 41, 2595 (2010).

G.J. Julien, U.S. patent US8047552B2 (2011)

W.J. Buehler, R.E. Jones, E.F. Heintzelman, and R.H. Lundsten, DTIC Document (White Oak, MD: Naval Ordinance Lab, 1973).

C. DellaCorte, S. Pepper, R. Noebe, D. Hull, and G. Glennon, Intermetallic Nickel-Titanium Alloys for Oil-Lubricated Bearing Applications (Cleveland, OH: NASA, 2009).

M.D. McNeese, D.C. Lagoudas, and T.C. Pollock, Mater. Sci. Eng., A 280, 334 (2000).

C. DellaCorte and G.N. Glennon, U.S. patent 8182741 (2012)

G.J. Julien, EP patent 1,224,045 (2002)

G.J. Julien, U.S. patent US6293020B1 (2001)

G.J. Julien, U.S. patent US6571665B2 (2003)

G.J. Julien, U.S. patent US6267402B1 (2001)

G.J. Julien, U.S. patent US2002/0187020A1 (2002)

C. DellaCorte, E. Lewis III, and J.S. Clifton, Static Indentation Load Capacity of the Superelastic 60NiTi for Rolling Element Bearings (2012)

C. DellaCorte, R.D. Noebe, M. Stanford, and S.A. Padula (Paper presented at the 2011 Symposium on Rolling Element Bearings sponsored by the American Society of Testing and Materials, Anaheim, CA, 13–14 April 2011)

S.V. Pepper, C. DellaCorte, R.D. Noebe, D.R. Hull, and G. Glennon, ESMATS (Washington, DC: NASA, 2009).

C.M. Jackson, H. Wagner, and R.J. Wasilewski, NASA SP-5110 NASA Special Publication 5110 (Washington, DC: NASA, 1972).

C.M. Chan, S. Trigwell, and T. Duerig, Surf. Interf. Anal. 15, 349 (2004).

G. Firstov, R. Vitchev, H. Kumar, B. Blanpain, and J. Van Humbeeck, Biomaterials 23, 4863 (2002).

G.G. Guo, X. Zheng, Z. Liu, Q.L. An, and M. Chen, Key Eng. Mater. 487, 34 (2011).

J.V. Gould, Machinability of Nickel-Titanium Alloys (Cincinnati, OH: DTIC Document, Metcut Research Associates, Inc., 1963).

Nitinol 60 Machined to Tight Tolerances, http://asmcommunity.asminternational.org/portal/site/www/NewsItem/?vgnextoid=1a32455d023e7210VgnVCM100000621e010aRCRD

Abbott Ball Solves Nitinol 60 Machining Problems, 2013, http://news.thomasnet.com/companystory/Abbott-Ball-Solves-Nitinol-60-Machining-Problems-573917

S.V. Pepper, C. DellaCorte, and G. Glennon, Lubrication of Nitinol 60 (2010)

S. Ingole, H. Liang, and P. Mohanty (Paper presented at the 4th ASM International Surface Engineering Congress and 19th International Conference on Surface Modification Technologies, 1–3 August 2005)

C. DellaCorte and W.A. Wozniak (Paper presented at the 41st Aerospace Mechanisms Symposium, 2012)

Golden Star Surgical Industries homepage, 2013, http://goldenstarsurgical.com/enterwebsite/

M.P. Wells, Surgical Instruments: A Pocket Guide (St. Louis, MO: Saunders, 2010).

SM-100 Knives, Summit Materials, LLC, website, 2013, http://www.summitmaterials.com/sm-100/knives/

H. Kapczynski, Surgical Instruments 101-An Introduction to KMedic Certified Instruments, 1997, http://www.teleflex.com/en/usa/pdf/KMedic_Surgical_Instruments_101.pdf

Y.-T. Kim and D.-E. Kim, Advanced Tribology, ed. J. Luo, et al. (Berlin: Springer, 2010), p. 859–60

M.A. Baumann, Dental Clin. North Am. 48, 55 (2004).

S. Saito, T. Wachi, and S. Hanada, Mater. Sci. Eng., A 161, 91 (1993).

Y. Furuya, A. Sasaki, and M. Taya, JIM, Mater. Trans. 34, 224 (1993).

M. Taya, A. Shimamoto, Y. Furuya, and O.-g. Okabe-cho, Proceedings of the 10th International Conference on Composite Materials, ICCM-10, ed. A. Poursatip and K. Street (Cambridge, U.K.: Woodhead Publishing Limited, 1995)

Committee for a Review of Adaptive Structure Materials Research That Could Pose a Threat to US National Security, Adaptive Materials and Structures: A Workshop Report (Washington, DC: The National Academies Press, 2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ingole, S. 60NiTi Alloy for Tribological and Biomedical Surface Engineering Applications. JOM 65, 792–798 (2013). https://doi.org/10.1007/s11837-013-0610-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-013-0610-7