Abstract

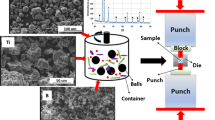

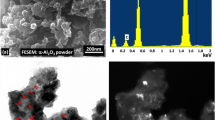

One of the identified shortcomings militating against the widespread application of Ti6Al4V alloy in the aerospace sector of the economy includes its unsatisfactory hardness and proneness to high-temperature oxidation which in turn adversely impact its abrasion resistance properties in certain service conditions. The work reported in this paper forms an important aspect of the effort put together in addressing these composite issues. Precisely, the effects of the nano-reinforcements of aluminum nitride (AlN) and hexagonal boron nitride (h-BN) on the microstructure, phase contents, hardness, and oxidation resistance of Ti6Al4V-based composites were considered. The prepared powders were sintered by spark plasma sintering (SPS), an innovative sintering method which enables the implementation of fast heating and cooling rates. Thereafter, scanning electron microscopy, optical microscopy, and X-ray diffractometry were employed to observe and study the microstructure and phase contents, Archimedes’ principle was applied to evaluate the densification, Vickers’ microhardness test was used to measure the hardness values, and thermogravimetric analysis technique was used to study the oxidation resistance of the sintered composites. A homogeneous blend of the nano-reinforcements of 1.5 wt% each of AlN and h-BN gave the highest relative densification value of 99.77% while the hardness value (656.01 HV) was less than that of Ti6Al4V-3h-BN (716.80 HV) which gave more credence to the phase contents in the microstructure as the most influencing factor determining the hardness property of the composites than ordinary relative densification. Meanwhile, Ti6Al4V-1.5AlN-1.5h-BN with the minimum positive weight change (0.36 mg/cm2) exhibited the greatest thermal oxidation resistance in air.

Similar content being viewed by others

References

Guleryuz H, Cimenoglu H (2009) Oxidation of Ti-6Al-4V alloy. J Alloys Compd 472:241–246

Biswas A, Majumdar JD (2009) Surface characterization and mechanical property evaluation of thermally oxidized Ti-6Al-4V. Mater Charact, 513-518

Abe JO, Popoola OM, Popoola API, Ajenifuja E, Adebiyi DI (2019) Application of Taguchi design method for optimization of spark plasma sintering process parameters for Ti-6Al-4V/h-BN binary composite. Eng Res Express 1(025043):1–20

Boyer RB (1996) An overview on the use of titanium in the aerospace industry. Mater Sci Eng A213:103–114

Brice DA, Samimi P, Ghamarian I, Liu Y, Brice RM, Reidy RF et al (2016) Oxidation behavior and microstructural decomposition of Ti-6Al-4V and Ti-6Al-4V-1B sheet. Corros Sci 112:338–346

Ramaswamy R, Marimuthu P, Selvam B (2016) An overview on mechanical properties of particulate reinforced Ti6Al4V metal matrix composites. ARPN J Eng Appl Sci 11(9):6066–6069

Callister WD, Rethwisch DG (2015) Materials science and engineering: an introduction. John Wiley & Sons, Inc., Hoboken

Kim IY, Choi BJ, Kim YJ, Lee YZ (2011) Friction and wear behaviour of titanium matrix (TiB+TiC) composites. Wear 271:1962–1965

Ray AK, Venkateswarlu K, Chaudhury SK, Das SK, Kumar BR (2002) Fabrication of TiN reinforced aluminium metal matrix composites through a powder metallurgical route. Mater Sci Eng A338:160–165

Wang H, Muralidharan G, Leonard DN, Haynes JA, Porter WD, England RD, Michael H, Dwivedi G, Sampath S (2018) Microstructural analysis and transport properties of thermally sprayed multiple-layer ceramic coatings. J Therm Spray Technol 27:371–378

Pierson HO (1996) Handbook of refractory carbides and nitrides: properties, characteristics, processing and applications. 1st ed. Noyes Publications, Norwich

Thankachan T, Prakash KS, Kamarthin M (2018) Optimizing the tribological behavior of hybrid copper surface composites using statistical and machine learning techniques. J Tribol 140(3):031610 1-8

de Cortázar MG (2007) Development of a new reinforced titanium alloy: basic research and technological transfer for the Ti-6Al-4V/TiB material. Barcelone: HAL archives-universes

Eichler J, Christoph L (2008) Boron nitride (BN) and BN composites for high-temperature applications. J Eur Ceram Soc 28:1105–1109

Jiang X, Weng Q, Wang X, Li X, Zhang J, Golberg D, Bando Y (2015) Recent progress on fabrications and applications of boron nitride nanomaterials: a review. J Mater Sci Technol 31:589–598

Abe JO, Popoola AP, Popoola OM (2020) Consolidation of Ti6Al4V alloy and refractory nitride nanoparticles by spark plasma sintering method: microstructure, mechanical, corrosion and oxidation characteristics. Mater Sci Eng A 774(138920):1–10

Yu Y, Zhang W, Dong W, Yang J, Feng Y (2015) Effects of pre-sintering on microstructure and properties of TiBw/Ti6Al4V composites fabricated by hot extrusion with steel cup. Mater Sci Eng A638:38–45

Matizamhuka WR (2016) Spark plasma sintering (SPS) – an advanced sintering technique for structural nanocomposite materials. J South Afr Inst Min Metall 16:1171–1180

Firestein KL, Steinman AE, Golovin IS, Cifre J, Obraztsova EA, Matveev AT, Kovalskii AM, Lebedev OI, Shtansky DV, Golberg D (2015) Fabrication, characterization, and mechanical properties of spark plasma sintered Al–BN nanoparticle composites. Mater Sci Eng A 642:104–112

Falodun OE et al. (2017) Synthesis of Ti-6Al-4V alloy with nano-TiN microstructure via spark plasma sintering technique. IOP Conf Series: Mater Sci Eng, 272(012029), pp. 1–6

Kgoete FM, Popoola AP, Fayomi OS (2019) Oxidation resistance of spark plasma sintered Ti6Al4V-TiN composites. J Alloys Compd 772:943–948

Ujah CO, Popoola AP, Popoola OM, Aigbodion VS (2018) Electrical conductivity, mechanical strength and corrosion characteristics of spark plasma sintered Al-Nb nanocomposite. Int J Adv Manuf Technol, 1-8

Machethe K, Popoola AP, Aigbodion VS, Popoola OM (2019) Electrochemical study of spark plasma-sintered copper reinforced with Ni/SiC micron-sized particles for electrical applications. Iran J Sci Technol Trans Sci 43:457–464

Kanyane R, Popoola AP, Malatji N (2019) Development of spark plasma sintered TiAlSiMoW multicomponent alloy: microstructural evolution, corrosion and oxidation resistance. Results Phys 12:1754–1761

Avwerosuoghene MO et al (2019) Evaluation of the sinterability, densification behaviour and microhardness of spark plasma sintered multiwall carbon nanotubes reinforced Ti6Al4V nanocomposites. Ceram Int 45:19864–19878 Singhal et al., 2008

Yadav V, Harimkar SP (2011) Microstructure and properties of spark plasma sintered carbon nanotube reinforced aluminum matrix composites. Adv Eng Mater 13(12):1128–1134

Krishnamohana S, Ramanathan S (2013) Synthesis and characterization of Ti6Al4V alloy by powder metallurgy. Int J Eng Res Technol 2(11):2725–2729

Asl MS (2017) Microstructure, hardness and fracture toughness of spark plasma sintered ZrB2–SiC–Cf composites. Ceram Int 43:15047–15052

Ocak BC, Yavas B, Akin I, Sahin F, Goller G (2018) Spark plasma sintered ZrC-TiC-GNP composites: solid solution formation and mechanical properties. Ceram Int 44:2336–2344

Cavaliere P (2019) Spark plasma sintering of materials: advances in processing and applications. 1st ed. Springer Nature, Basel, Gewerbestrasse 11, 6330 Cham, Switzerland

Samal S (2016) High-temperature oxidation of metals. In: Ahmad Z (ed) High temperature corrosion. IntechOpen, London, pp 102–121

Saunders SR, Monteiro M, Rizzo F (2008) The oxidation behaviour of metals and alloys at high temperatures in atmospheres containing water vapour: a review. Prog Mater Sci 53:775–837

Rizzo HF (1960) Oxidation of boron at temperatures between 400 and 1300°C in air. In: Kohn JA, Nye WF, Gaulé GK (eds) Boron synthesis, structure, and properties. Springer, Boston

Opila E, Jacobson NS (2016) Corrosion of ceramic materials. In: Opila E, Jacobson NS (eds) Oxidation and corrosion of non-oxide ceramics. NASA Glenn Research Center, Cleveland, pp 329–384

Talekar VR, Patra A, Sahoo SK (2020) Oxidation behavior of oxide dispersion-strengthened W–Ni alloys. Oxid Met 93:17–28

Raphel A, Kumaran S, Kumar KV, Varghese L (2017) Oxidation and corrosion resistance of AlCoCrFeTiHigh entropy alloy. In: Materials Today: Proceedings 4. Elsevier, San Francisco, pp 195–202

Leyens C, Peters M (2003) Titanium and titanium alloys: fundamentals and applications. 1st ed. WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

Acknowledgments

The authors would like to appreciate the Department of Chemical, Metallurgical and Materials Engineering and Centre for Energy and Electric Power (CEEP), Tshwane University of Technology (TUT), Pretoria, South Africa, for their support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abe, J.O., Popoola, A.P.I., Popoola, O.M. et al. Microstructural, phase, hardness, and oxidation resistance studies of AlN/h-BN-reinforced Ti6Al4V matrix composites synthesized by spark plasma sintering. Int J Adv Manuf Technol 107, 2985–2994 (2020). https://doi.org/10.1007/s00170-020-05207-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05207-y