Abstract

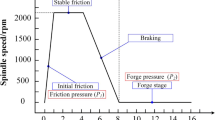

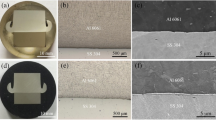

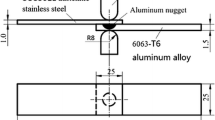

The continuous drive friction welding of aluminum alloy to stainless steel was investigated in this paper. Microstructural characterization, intermetallic compound (IMC), and mechanical properties of the friction welded Al/Fe joint were studied. Results showed that thermal mechanically affected zone (TMAZ) at the Al side was subjected to both thermal cycling and mechanical force, and grain size was 1–3 μm, and streamlines were more dramatically than at the steel side. In fully dynamic recrystallized 127 zone (FDRZ), microstructure became the fine equiaxed grains, and its width at the steel side was about 5 μm. The local Si enrichment IMC layer was formed at the interface area of Al/Fe joint, and its average thickness was about 300 nm. IMC layer was relatively flat at the steel side, while uneven at the Al side. The hardness reached to the maximum value (395.8 HV) at the steel side in FDRZ, and the average hardness was only 76 HV in heat-affected zone (HAZ) at the Al side. When forge pressure was below 220 MPa, the tensile strength of joint was approximately linearly related to the forge pressure.

Similar content being viewed by others

References

Wan L, Huang Y (2018) Friction welding of AA6061 to AISI 316L steel: characteristic analysis and novel design equipment. Int J Adv Manuf Technol 95(9):4117–4128

Wang T, Sidhar H, Mishra RS, Hovanski Y, Upadhyay P, Carlson B (2018) Friction stir scribe welding technique for dissimilar joining of aluminium and galvanised steel. Sci Technol Weld Join 23(3):249–255

Cheepu M, Che W-S (2019) Characterization of microstructure and interface reactions in friction welded bimetallic joints of titanium to 304 stainless steel using nickel interlayer. T Indian I Metals 72(6):1597–1601

Sun G-Q, Xu G-S, Shang D-G, Chen S-J (2019) Welding parameter selection and short fatigue crack growth of dissimilar aluminum alloy friction stir welded joint. Weld World 64:1–9

Z. Fan, H. Yu, F. Meng, C. Li (2016) Experimental investigation on fabrication of Al/Fe bi-metal tubes by the magnetic pulse cladding process. 83(5):1409–1418

Ogawa D, Kakiuchi T, Hashiba K, Uematsu Y (2019) Residual stress measurement of Al/steel dissimilar friction stir weld. Sci Technol Weld Join:1–10

Su H, Wu CS, Pittner A, Rethmeier M (2014) Thermal energy generation and distribution in friction stir welding of aluminum alloys. Energy 77:720–731

Huang Y, Wan L, Meng X, Xie Y, Lv Z, Zhou L (2018) Probe shape design for eliminating the defects of friction stir lap welded dissimilar materials. J Manuf Process 35:420–427

Du B, Yang X, Liu K, Sun Z, Wang D (2019) Effects of supporting plate hole and welding force on weld formation and mechanical property of friction plug joints for AA2219-T87 friction stir welds. Weld World 63(4):989–1000

Kang M, Yoon J, Kim C (2020) Hook formation and joint strength in friction stir spot welding of Al alloy and Al –Si-coated 314hot-press forming steel. Int J Adv Manuf Technol 106(5-6):1671–1681

Wan L, Huang Y (2018) Friction stir welding of dissimilar aluminum alloys and steels: a review. Int J Adv Manuf Technol 99(5):1781–1811

Huang Y, Wan L, Si X, Huang T, Meng X, Xie Y (2019) Achieving high-quality Al/steel joint with ultrastrong interface. Metall Mater Trans A 50(1):295–299

Kimura M, Kusaka M, Kaizu K, Nakata K, Nagatsuka K (2016) Friction welding technique and joint properties of thin-walled pipe friction-welded joint between type 6063 aluminum alloy and AISI 304 austenitic stainless steel. Int J Adv Manuf Technol 82(1):489–499

Hynes NRJ, Velu PS (2018) Effect of rotational speed on Ti-6Al-4V-AA 6061 friction welded joints. J Manuf Process 32:288–297

Reddy AC (2017) Evaluation of parametric significance in friction welding process of AA1100 and Zr705 alloy using finite element analysis. Mater Today Pro 4(2, Part A):2624–2631

Kimura M, Ishii H, Kusaka M, Kaizu K, Fuji A (2009) Joining phenomena and joint strength of friction welded joint between aluminium–magnesium alloy (AA5052) and low carbon steel. Sci Technol Weld Join 14(7):655–661

Sahin M (2010) Joining of aluminium and copper materials with friction welding. Int J Adv Manuf Technol 49(5):527–534

Yılmaz M, Çöl M, Acet M (2003) Interface properties of aluminum/steel friction-welded components. Mater Charact 49(5):421–429

Fukumoto S, Tsubakino H, Okita K, Aritoshi M, Tomita T (1999) Friction welding process of 5052 aluminium alloy to 304 stainless steel. Mater Sci Technol 15(9):1080–1086

Kimura M, Suzuki K, Kusaka M, Kaizu K (2017) Effect of friction welding condition on joining phenomena, tensile strength, and bend ductility of friction welded joint between pure aluminium and AISI 304 stainless steel. J Manuf Process 25:116–125

Meshram SD, Madhusudhan Reddy G (2015) Friction welding of AA6061 to AISI 4340 using silver interlayer. Defence Tech 11(3):292–298

Li P, Li J, Salman M, Liang L, Xiong J, Zhang F (2014) Effect of friction time on mechanical and metallurgical properties of continuous drive friction welded Ti6Al4V/SUS321 joints. Mater Des 56:649–656

Winiczenko R, Goroch O, Krzyńska A, Kaczorowski M (2017) Friction welding of tungsten heavy alloy with aluminium alloy. J Mater Process Technol 246:42–55

Atabaki MM, Nikodinovski M, Chenier P, Ma J, Harooni M, Kovacevic R (2014) Welding of aluminum alloys to steels: an overview. J Manuf Sci Prod 14(2):59

Zhang C, Wang W, Liu X, Jin X, Qin Z, Rong C (2019) Mechanical properties and morphology features of intermetallic compounds in aluminum/steel continuous drive friction welded joints. Mater Report 33(16):2740–2745

Fuji A, Kimura M, North TH, Ameyama K, Aki M (1997) Mechanical properties of titanium-5083 aluminium alloy friction joints. Mater Sci Technol 13(8):673–678

Pan C, Hu L, Li Z, North TH (1996) Microstructural features of dissimilar MMC/AISI 304 stainless steel friction joints. J Mater Process Technol 31(14):3667–3674

Kato K, Tokisue H (2004) Dissimilar friction welding of aluminium alloys to other materials. Weld Int 18(11):861–867

Dong H, Li Y, Li P, Hao X, Xia Y, Yang G (2019) Inhomogeneous microstructure and mechanical properties of rotary friction welded joints between 5052 aluminum alloy and 304 stainless steel. J Mater Process Technol 272:17–27

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Zhao, H. & Peng, Y. Metallurgical reaction and joining phenomena in friction welded Al/Fe joints. Int J Adv Manuf Technol 107, 1713–1723 (2020). https://doi.org/10.1007/s00170-020-05128-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05128-w