Abstract

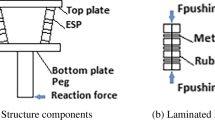

The task of the peg-in-hole assembly is a very common task in industry. Despite its intuitive comprehensibility and everyday experience, the industrial assembly faces specific problems. The naive approach of inserting with bare hands an industrial peg inside into an industrial hole can very certainly bring to the jamming and damaging because of a very small gap between them. Therefore, the initial alignment of the details before insertion, so-called peg-on-hole phase, or simply peg-on-hole, is of the special importance in industry to avoid jamming. This paper develops the description and analysis of this phase based on the methods of analytical mechanics. As a common approach, the details in this study are considered as cylindrical, and such that peg is supported at the edge of vertically fixed hole, and could freely move keeping a three-point contact with three degrees of freedom, namely (i) nutation angle or align describing planar motion of aligning parts, (ii) precession angle or slide describing rotational motion around hole axis, and (iii) self-rotation angle or slip describing rotational motion about its axis. The analytical approach implies the system of Lagrange Equations for this particular case of motion, which is called Dynamic Differential Equations (DDE). DDE describes interconnections between motion in three degrees of freedom on one side, reaction forces on another side, and the external forces and torques on the third side. DDE includes geometrical properties of the details, and full descriptions of velocities, normal reactions, and friction forces at the contact points. It is the most general description of the peg-on-hole case. As the example of application, the normal reactions were found for relative large alignment angles far from reduction into a two-point contact, and for a small alignment angles, when system transits to the two-point contact. It was shown that for both cases, reaction forces become larger during alignment because they have to balance the force of gravity. For the larger angles, slip reduces the reaction forces, whereas for small alignment angles, slip and slide increases them.

Similar content being viewed by others

References

Lefebvre T, Xiao J, Bruyninckx H, De Gersem G (2005) Active compliant motion: a survey. Adv Robot 19(5):479–499

Xu J, Hou Z, Liu Z and Qiao H (2019) Compare contact model-based control and contact model-free learning: a survey of robotic peg-in-hole assembly strategies arXiv, 1904.05240 https://arxiv.org/abs/1904.05240

Whitney DE (1982) Quasi-static assembly of compliantly supported rigid parts. J Dyn Syst Meas Control 104(1):65–77

Jasim IF, Plapper PW, Voos H (2017) Contact-state modelling in force-controlled robotic peg-in-hole assembly processes of flexible objects using optimised gaussian mixtures. Proc Inst Mech Eng B J Eng Manuf 231(8):1448–1463

Fei Y, Zhao X (2003) An assembly process modeling and analysis for robotic multiple peg-in-hole. J Intell Robot Syst 36(2):175–189

Xu J, Hou Z, Wang Q, Xu B, Zhang K, Chen K (2018) Feedback deep deterministic policy gradient with fuzzy reward for robotic multiple peg-in-hole assembly tasks. IEEE Trans Ind Inf:1–1

Tang T, Lin HC, Zhao Y, Chen W, Tomizuka M (2016) Autonomous alignment of peg and hole by force/torque measurement for robotic assembly. Automation Science and Engineering (CASE), 2016. IEEE International Conference, New Jersey, pp 162–167

Abu-Dakka F, Nemec B, Ude A (2012) Peg-in-hole using dynamic movement primitives. In: Proceedings of the RAAD, pp 143–149

Zhu Z, Hu H (2018) Robot learning from demonstration in robotic assembly: a survey. Robotics 7(2):17–17

Kyrarini M, Haseeb MA, Risti’c-Durrant D, Gräser A (2018) Robot learning of industrial faassembly task via human demonstrations. Auton Robot:1–19

Tang T, Lin HC, Zhao Y, Fan Y, Chen W, Tomizuka M (2016) Teach industrial robots peg-hole-insertion by human demonstration. In: Advanced Intelligent Mechatronics (AIM), 2016. IEEE International Conference, New Jersey, pp 488–494

Liljekrans D (2012) Investigating peg-in-hole strategies through teleoperation. Master’s Thesis. University of Southern Denmark. http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.727.7529&rep=rep1&type=pdf

Savarimuthu TR (2013) Analysis of human peg-in-hole executions in a robotic embodiment using uncertain grasps. In: Proceedings of the 9th International Workshop on Robot Motion and Control, pp 233–239. https://doi.org/10.1109/RoMoCo.2013.6614614

Sutton RS, Barto AG (2018) Reinforcement learning: an introduction MIT press

Inoue T, Magistris GD, Munawar A, Yokoya T, Tachibana R (2017) Deep reinforcement learning for high precision assembly tasks. 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Canada, pp 819–825

Xu J, Hou Z, Wang W, Xu B, Zhang K, Chen K (2018) Feedback deep deterministic policy gradient with fuzzy reward for robotic multiple peg-in-hole assembly tasks. IEEE Trans Ind Inf:1–1

Thomas G, Chien M, Tamar A, Ojea JA, Abbeel P (2018) Learning robotic assembly from CAD. arXiv 1803.07635http://arxiv.org/abs/1803.07635

Su J, Qiao H, Liu C, Ou Z (2012) A new insertion strategy for a peg in an unfixed hole of the piston rod assembly. Int J Adv Manuf Technol 59:1211–1225. https://doi.org/10.1007/s00170-011-3569-y

Xia Y, Yin Y. Zhaoneng Chen Z (2006) Dynamic analysis for peg-in-hole assembly with contact deformation. Int J Adv Manuf Technol 30: 118–128. https://doi.org/10.1007/s00170-005-0047-4

Zamyatin VG(1972) Geometric conditions of the assemblability during automatic assembly of the cylindrical junctions with gap. (Геометрические условия собираемости при автоматической сборке цилиндрический соединений с зазором). Proceedings of higher educational institutions. Маchine Building 12: 162–166

Kristal MG (2000) Estimation of the error of the relative positions of the conjugated surfaces during the automated assembly of cylindrical details. (Оценка погрешности относительного расположения сопрягаемых поверхностей при автоматической сборке цилиндрических деталей). Assem Mach Build Dev Build 6:20–23

Peeva II, Vipliemov VD (2009) Passive-active relative orientation in conditions of the automated assembly. (Пассивно-активное относительное ориентирование в условиях автоматической сборки). Assem Mach Build Dev Build 6:23–26

Simakov AL, Simakov AD (2009) Alignment of the stages of the orientation of the attaching detail during the motion on the searching trajectory. (Согласование этапов ориентации присоединяемой детали при движении по поисковой траектории). Assem Mach Build Dev Build 6:20–22

Kuznetsov SV, Simakov AL (2013) Phase portraits of the relative and angular alignment of the details during the automated alignment. (Фазовые портреты относительного и углового совмещения деталей при автоматической сборке). Assem Mach Build Dev Build 2:12–20

Holodkova AG (2004) Peculiarities of the automated executions of the cylindrical joints with small gap. (Особенности автоматического выполнения цилиндрических соединений с малым зазором). Assem Mach Build Dev Build 4:14–18

Ivanov AA (2009) Analytical conditions of the automated assembly. (Аналитические условия автоматической сборки). Assem Mach Build Dev Build 8:13–17

Chernyakhovskaya LB, Simakov DA (2012) Kinematics and dynamics of the process of the assembly of cylindrical details. (Кинематика и динамика процесса сборки цилиндрических деталей). Assem Mach Build Dev Build 1:27–42

Jarkov GE, Prilutskiy VA (2012) Selfadjustment of the positions of details during the assembly. (Саморегулирование положения детали при сборке). Assem Mach Build Dev Build 9:12–14

Jarkov GE (2014) Method of the assembly by the change of the position of mass center. (Метод сборки изменением положения центра тяжести). Assem Mach Build Dev Build 11:7–9

Bojkova LV, Vartanov MV, Zimina IN (2015) Mathematical model of the robotized assembly with use of adaptation and low-frequency oscilations. (Математическая модель роботизированной сборки с применением адаптации и низкочастотных колебаний). Assem Mach Build Dev Build 16:16–20

Ivanov AA (2013) Vibrational assembly systems. (Вибрационные сборочные системы). Assem Mach Building Dev Build 5:7–10

Bakšys B, Chadarovičius A, Pilkauskas K (2009) Experimental research of parts vibratory alignment with remote center compliance device. J Vibroeng 11(2):226–232

Bojkova LV, Vartanov MV, Martynovich NA (2013) Mathematical model of dynamics of the conjunction of the details with use of an industrial robot and a vibrational device (Математическая модель динамики сопряжения деталей с применением промышленного робота и вибрационного устройства). Assem Mach Build Dev Build 1:12–15

Kristal MG, Chuvilin IA (2008) Investigation of the dynamics of vibrational conjunction with the lower support of the edge of the enclosed detail. (Исследование динамики вибрационного сопряжения с нижней опорой торца охватываемой детали). Assem Mach Build Dev Build 4:13–17

Kristal MG, Chuvilin IA (2008) Model of the dynamics of rotational assembly of cylindrical details. (Модель динамики ротационной сборки цилиндрических деталей.). Assem Mach Build Dev Build 8:12–15

Kremleva NG, Bezrukova TB (2015) Investigation of the process of automated rotational assembly of cylindrical details. (Исследование процесса автоматической ротационной сборки цилиндрических деталей). Assem Mach Build Dev Build 6:29–32

Bruyninckx H, Demey S, Dutrе S, De Schutter J (1995) Kinematic models for model based compliant motion in the presence of uncertainty. Int J Robot Res 14(5):465–482. https://doi.org/10.1177/027836499501400505

Bruyninckx H, Dutrе S, De Schutter J (1995) Peg-on-hole: a model based solution to peg and hole alignment. In: Proceedings of the IEEE International Conferenceon Robotics and Automation, pp 1919–1924. https://doi.org/10.1109/ROBOT.1995.525545

Chernyakhovskaya LB, Simakov DA (2017) Peg-on-hole: fundamental principles of motion of a peg leaning on a horizontal hole edge. Adv Sci Technol Res J 11(4):49–59. https://doi.org/10.12913/22998624/77036

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chernyakhovskaya, L.B., Simakov, D.A. Peg-on-hole: mathematical investigation of motion of a peg and of forces of its interaction with a vertically fixed hole during their alignment with a three-point contact. Int J Adv Manuf Technol 107, 689–704 (2020). https://doi.org/10.1007/s00170-019-04806-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04806-8