Abstract

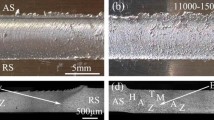

A friction stir processing-based method was used to repair cracks in the 2024 aluminum alloy plates. The temperature field and plastic material flow pattern were analyzed on the basis of experimental and finite element simulation results. Microstructure and tensile properties of the repaired specimens were studied. The results showed that the entire crack repairing was a solid-phase process and plastic materials tended to flow toward the shoulder center and then resulted in the repairing of cracks. Meanwhile, the coarse grain structures were refined in repaired zone (RZ), while the grains in thermal–mechanically affected zone and heat-affected zone were elongated and driven to grow up. Meanwhile, large phases are crushed into small particles and dispersed inside the RZ. Finally, the strength of the repaired specimens can be restored dramatically and their ductility can be partially restored. After heat treatment, the tensile properties of the repaired specimens can be further enhanced.

Similar content being viewed by others

References

S.P. Zhu, Q. Lei, H.Z. Huang, Y.J. Yang, W.W. Peng, Int. J. Damage Mech. (2016). doi:10.1177/1056789516651920

M.D. Sangid, Int. J. Fatigue 57, 58 (2013)

J.Y. Wang, H. Soens, W. Verstraete, N.D. Belie, Cement Concer. Res. 56, 139 (2014)

K.W. Nam, E.S. Kim, Mater. Sci. Eng. A 547, 125 (2012)

M.M. Escobar, S. Vago, A. Vázquez, Compos. Part B Eng. 55, 203 (2013)

S.R. White, N.R. Sottos, P.H. Geubelle, J.S. Moore, M.R. Kessler, S.R. Sriram, E.N. Brown, S. Viswanathan, Nature 409, 794 (2001)

X.X. Chen, A.D. Matheus, O. Kanji, M. Ajit, H.B. Shen, R.N. Steven, K. Sheran, F. Wudl, Science 295, 1698 (2002)

R.P. Wool, Soft Matter 4, 400 (2008)

R.N. Lumley, I.J. Polmear, in Proceedings of the First International Conference on Self-Healing Materials, Noordwijk aan Zee, The Netherlands, April 18–20, 2007

N. Shinya, J. Kyono, K. Laha, in Proceedings of the First International Conference on Self-Healing Materials, Noordwijk aan Zee, The Netherlands, April 18–20, 2007

S. Hautakangas, H. Schut, N.H.V. Dijk, P.E.J. Rivera, D. del Castillo, S.V.D. Zwaag, Scr. Mater. 58, 719 (2008)

A. Hosoi, T. Nagahama, Y. Ju, Mater. Sci. Eng. A 533, 38 (2012)

J.W. Murray, A.T. Clare, J. Mater. Process. Technol. 212, 2642 (2012)

X.G. Zheng, Y.N. Shi, K. Lu, Mater. Sci. Eng. A 561, 52 (2013)

L. Giraud, H. Robe, C. Claudin, C. Desrayaud, P. Bocher, E. Feulvarch, J. Mater, Process. Technol. 235, 220 (2016)

M. Narimani, B. Lotfi, Z. Sadeghian, Mater. Sci. Eng. A 673, 436 (2016)

O.O. Tinubu, S. Das, A. Dutt, J.E. Mogonye, V. Ageh, R. Xu, J. Forsdike, R.S. Mishra, T.W. Scharf, Wear 356–357, 94 (2016)

Z.W. Li, Y.M. Yue, S.D. Ji, P. Chai, L. Wang, Mater. Des. 94, 368 (2016)

Z. Zhang, B.L. Xiao, Z.Y. Ma, Mater. Charact. 106, 255 (2015)

Z.H. Zhang, W.Y. Li, Y. Feng, J.L. Li, Y.J. Chao, Acta Mater. 92, 117 (2015)

X.C. Liu, C.S. Wu, J. Mater. Process. Technol. 225, 32 (2015)

K.S. Arora, S. Pandey, M. Schaper, R. Kumar, J. Mater. Sci. Technol. 26, 747 (2010)

H. Aydın, A. Bayram, D. İsmail, Mater. Des. 31, 2568 (2010)

J. Wang, R. Fu, Y. Li, J. Zhang, Mater. Sci. Eng. A 609, 147 (2014)

A. Simar, Y. Bréchet, B.D. Meester, A. Denquin, C. Gallais, Prog. Mater. Sci. 57, 95 (2012)

H. Aydın, A. Bayram, A. Uğuz, K.S. Akay, Mater. Des. 30, 2211 (2009)

Z. Hu, S. Yuan, X. Wang, Y. Huang, Mater. Des. 32, 5055 (2011)

Z. Li, Y. Yue, S. Ji, P. Chai, Z. Zhou, Mater. Des. 90, 238 (2015)

Acknowledgments

This research was jointly supported by the National Natural Science Foundation of China (Grant No. 51405309) and the Natural Science Foundation of Liaoning Province (Grant No. 2015020183).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Ren, JG., Wang, L., Xu, DK. et al. Analysis and Modeling of Friction Stir Processing-Based Crack Repairing in 2024 Aluminum Alloy. Acta Metall. Sin. (Engl. Lett.) 30, 228–237 (2017). https://doi.org/10.1007/s40195-016-0489-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-016-0489-8